How to Choose the Right Automotive Plugs and Connectors for Your Vehicle

Choosing the right vehicle connectors is crucial. Poor or incorrect connectors can lead to loose wires or overheating, potentially causing electrical issues. These problems can disrupt essential systems, such as brakes or sensors. In electric vehicles, improper connectors can damage both the car and the charger. Quality connectors are durable and provide protection against weather-related damage, helping you avoid costly repairs. This guide will highlight the importance of selecting the right connectors for your vehicle.

Key Takeaways

Choosing the right connectors is essential to prevent electrical issues that can disrupt critical vehicle systems.

Understand the different types of connectors—wire-to-wire, wire-to-board, board-to-board, and specialty connectors—to select the best fit for your vehicle's needs.

Always check the electrical details, including current and voltage ratings, to ensure connectors can handle the power requirements safely.

Prioritize safety and durability by selecting connectors that are weatherproof and made from strong materials to withstand harsh conditions.

Refer to your vehicle manual for specific connector requirements and compatibility to avoid mismatches.

Regularly test and inspect connectors for damage to maintain reliable connections and prevent future problems.

Consult with experts when in doubt, especially for complex systems like electric vehicle chargers, to ensure proper selection and installation.

Types of Vehicle Connectors

Knowing the types of vehicle connectors helps you choose wisely. Each type has a job to ensure smooth power and signal flow.

Wire-to-Wire Connectors

Wire-to-wire connectors join two or more wires together. They make strong and safe connections between circuits. These connectors stop electrical shorts and avoid wire splicing. A common type is bullet connectors, which have male and female ends that snap tightly. This keeps them connected even in vibrating vehicles. You’ll see these in car lights and speakers. Their small size also saves space in your car’s wiring.

Wire-to-Board Connectors

Wire-to-board connectors link wires to a circuit board. They connect wiring harnesses to control units or boards. The male part, called the "PCB Header," attaches to the board. The female part connects to the wiring harness. These are used in sensors where stable links are important. Wire-to-board connectors are easy to install and fix, making them great for modern cars.

Board-to-Board Connectors

Board-to-board connectors connect two circuit boards directly. They work well in small designs like infotainment or driver-assist systems. These connectors allow smooth communication between electronic parts in your car. They often have many pins and strong locks, making them tough and reliable.

Trailer Connectors

Trailer connectors link your car to a trailer. They help transfer power and signals between both systems. These connectors are needed for trailer lights, brakes, and other systems. They come in 4-pin, 5-pin, 6-pin, and 7-pin types. Each type is made for different towing needs.

A 4-pin connector works for basic tasks like tail lights and signals. For trailers with brakes or reverse lights, use a 5-pin or 6-pin connector. The 7-pin connector is the most flexible. It can charge trailer batteries or power inside trailer lights. Pick the right connector based on your trailer's needs and systems.

Specialty Connectors

Specialty connectors are made for specific car tasks. They ensure great performance and dependability.

High-voltage connectors for EVs and hybrids

High-voltage connectors are key for electric cars and hybrids. They handle the high power needed for batteries and motors. These connectors have strong insulation and locks to stop disconnections. They stay safe and work well, even in tough conditions. You’ll find them in EV chargers and battery systems.

Waterproof and weather-resistant connectors

Waterproof connectors keep your car’s wires safe from water and dirt. They use sealed covers to block moisture and debris. These are great for outdoor uses like headlights or off-road vehicles. They last long and work well in harsh weather.

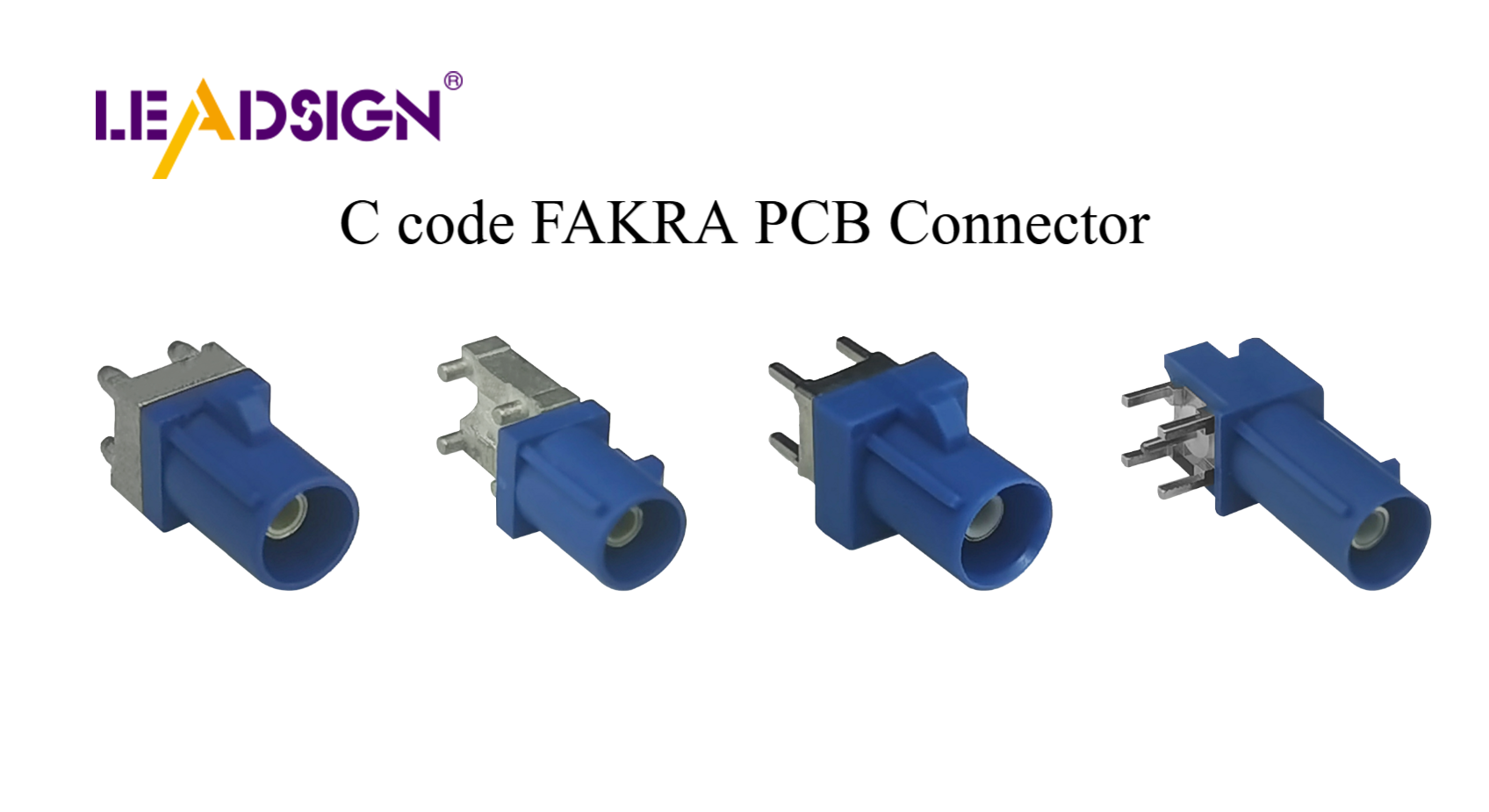

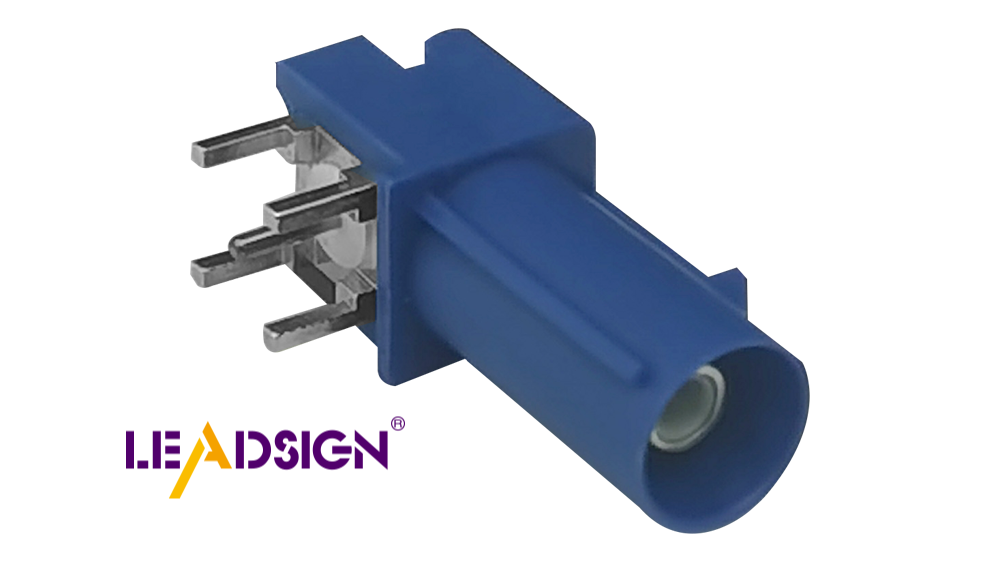

FAKRA connectors for automotive RF applications

FAKRA connectors are best for car radio frequency (RF) tasks. They handle high-frequency signals for GPS, satellite radios, and Bluetooth. Their coding system stops wrong connections, keeping signals steady. With strong locks, FAKRA connectors are secure and easy to use. Their small size saves space in modern cars.

Key Features of FAKRA Connectors:

Impedance: 50 Ω

Frequency range: DC up to 6 GHz

High data rates: Up to 8 Gbps

Temperature range: -40 °C to +105 °C

Mating cycles: ≥ 25

FAKRA connectors meet strict car industry standards. They are reliable and useful for advanced car systems.

Key Factors to Think About When Picking Electrical Connectors

When picking electrical connectors, think about important factors. These help ensure the connectors work well for your vehicle.

Electrical Details

Electrical details are key when choosing connectors. Check the current and voltage ratings. These show how much power the connector can handle safely. A low-rated connector might not work for strong systems like headlights.

The wire size must also match the connector. If sizes don’t match, wires may come loose or short out. For example, 4-way flat trailer connectors are great for small trailers. They handle basic lights without needing extra wiring. They are simple and affordable for light-duty trailers.

Also, impedance and frequency range matter for special connectors. High-frequency connectors, like FAKRA connectors, keep signals steady for GPS or infotainment systems.

Safety and Dependability

Safety is very important when choosing connectors. Good connectors lower the chance of failures or accidents. Pick ones with locks to stop them from coming apart. Waterproof connectors often have extra locks for a tight fit.

Weatherproofing is also key for safety. Water or dirt can harm connectors, causing rust or shorts. Waterproof connectors, like Weatherpak connectors, block water and stay strong in bad weather. They are great for off-road vehicles or outdoor lights.

Strength and Durability

Strong connectors last longer in tough conditions. Vibrations, hits, or temperature changes can break weak connectors. Durable ones handle these without failing.

The material of the connector matters for its strength. Good materials resist damage and last longer. Heavy-duty connectors are made for tough jobs and prove reliable over time.

Temperature range is also important. Connectors must work in your vehicle’s heat or cold. For example, FAKRA connectors work well from -40 °C to +105 °C. This makes them useful for many car systems.

Finally, check how many times you can plug and unplug the connector. Choose ones with high mating cycles for long-term use.

Environmental Conditions

The environment affects how well connectors work and last. Think about where the connector will be used in your vehicle. Things like heat, water, dirt, or chemicals can harm connectors.

If your car faces rain, snow, or rough roads, use waterproof connectors. These stop water and dirt from causing rust or failures. For example, Weatherpak connectors are great for outdoor lights or tough vehicles. Their sealed design keeps them strong and working well.

Hot or cold weather also impacts connectors. Some, like FAKRA connectors, handle temperatures from -40 °C to +105 °C. This makes them good for systems like sensors or infotainment. Always check if the connector can handle your car's temperature needs.

Vibrations in cars can loosen weak connectors. Strong ones, like wire harness connectors, stay secure even with constant shaking. These are perfect for areas like the engine, where vibrations are high.

Chemicals or oils can also damage connectors. Some are made with materials that resist corrosion and chemical harm. Picking connectors that meet industry rules helps avoid frequent fixes and saves money.

Termination Methods

Termination methods show how connectors attach to wires or circuits. Picking the right method ensures a strong and safe connection.

Crimping is a common way to connect wires. It uses pressure to join them, making a strong bond. This method is fast and doesn’t need soldering. Crimping works well for wire harness connectors because it resists wear and shaking.

Soldering is another way to connect wires. It melts solder to join wires and connectors. Soldered connections are strong and don’t loosen easily. But soldering takes more time and skill than crimping. It’s best for permanent and reliable connections.

Plug-and-play connectors are easy to use. They let you connect and disconnect parts without tools. For example, 4-way flat trailer connectors are simple to plug in. They’re great for small trailers and save time during setup.

Some connectors use insulation displacement. This method pierces the wire cover to make contact. It’s quick and avoids damaging the wire during installation.

Choose a termination method that fits your car’s needs. Make sure it matches the connector type and follows safety rules. A good method improves performance and helps connectors last longer.

Matching Connectors to Your Vehicle's Needs

Picking the right connector means knowing your car's systems. It also means understanding how the connector will be used. This helps the connector work well and fit your car's needs.

What Your Car Needs

Each car has its own electrical setup. You need connectors that match this setup. First, figure out what system the connector will support. For example, connectors for radios are different from engine ones.

Look at your car's wire harness connectors. They must fit the wiring and have the right number of pins. If they don’t match, the connection might fail. Also, think about the power the system needs. Systems like headlights or EV chargers need connectors that handle high power safely.

Temperature is important too. Some connectors break in extreme heat or cold. Engine connectors must handle heat, while outdoor ones need to resist freezing. Always check if the connector works in your car’s temperature range.

Rules and Standards

Connectors must follow safety rules based on where you live. These rules make sure the connectors are safe and reliable. For example, U.S. connectors often follow SAE rules, while Europe uses ISO standards.

Some rules control what materials connectors can use. Many places require RoHS-compliant connectors. These don’t have harmful stuff like lead. Using approved connectors keeps you safe and avoids legal trouble.

How Connectors Are Used

Knowing how a connector will be used helps you pick the right one. Here are some examples:

EV Charging Connectors

Electric cars need special connectors for charging. These handle high power safely. Type 1 and Type 2 connectors are common. Type 2 is popular in Europe. These connectors move power from the charger to the car.

EV connectors also have strong locks and insulation. This stops them from disconnecting by accident. Always use connectors made for EVs to stay safe.

Radios, Sensors, and Other Systems

Modern cars use connectors for radios, sensors, and more. Radios need connectors that handle high-frequency signals, like GPS or Bluetooth. FAKRA connectors are great for this because they keep signals clear.

Sensors, like parking or collision ones, need steady connections. Wire harness connectors help sensors send data correctly. Other systems, like lights or power outlets, use plug-and-play connectors. These are easy to set up and fix.

By knowing how each connector is used, you can choose the best one. This makes your car work better and last longer.

Step-by-Step Guide to Picking the Right Connectors

Understand Your Needs

First, figure out what your car's system needs. Think about what the connector will do. Is it for headlights, sensors, or radios? Different jobs need different connectors. For example, GPS or Bluetooth systems need FAKRA connectors. Simple lights might only need basic wire-to-wire connectors.

Check your system's power needs. Look at the current and voltage ratings. Make sure the connector can handle the power safely. If ratings don’t match, it could overheat or fail. Also, think about where the connector will be used. If it faces water, dirt, or heat, pick waterproof or weatherproof ones. For outdoor use, sealed connectors like Weatherpak work well.

Lastly, check your car's wiring setup. The connector must fit the wire size and pins. This ensures it works properly with your vehicle.

Use Your Vehicle Manual

Your car manual is a helpful guide for choosing connectors. It explains your car's electrical system and needed connectors. Look for sections about the wiring harness and compatible connectors.

Follow the manual's technical details. These include power ratings, wire size, and temperature range. For example, if it says the connector should handle -40 °C to +105 °C, pick FAKRA connectors. They meet this need.

If you're unsure, ask a mechanic or car electrician. They can explain the manual and suggest the right connectors.

Compare Connector Choices

Once you know your needs, look at connector options. Focus on strength, ease of use, and how long they last. Good connectors are reliable and prevent problems.

Check the connector's material. Strong materials last longer and handle tough conditions. Heavy-duty connectors are great for areas with vibrations, like engines.

Think about how the connector attaches to wires. Crimping is quick and strong. Soldering is more permanent but takes time. Plug-and-play connectors are easy to use and fix. Pick the method that suits your car and skills.

Finally, test the connector with your car. Make sure it fits well and works right. Check connectors often for damage. This keeps them working longer.

Pro Tip: Choose connectors with certifications like RoHS or SAE. These ensure safety and quality.

Test and Check

Testing your connector makes sure it works well in your car. This step helps avoid problems and ensures a strong connection.

Look at the Connector

Start by checking the connector for any damage. See if there are cracks, bent pins, or broken parts. A damaged connector can cause your car's system to fail. Regular checks help keep connectors working longer.Make Sure It Fits

Attach the connector to its matching part. It should fit tightly but not too hard to connect. A loose or tight fit might mean it doesn’t match. A good fit keeps it steady, even with shaking or heat changes.Test How It Works

Use a multimeter to check voltage and current flow. Compare the numbers to your car manual’s details. This step shows if the connector can handle the power safely.Try Real-Life Conditions

Test the connector in situations it will face in your car. For waterproof ones, put them in water. For engine connectors, test them in high heat. This ensures they work in tough conditions.Check Again After Testing

After testing, look for any damage like melted parts or rust. These problems mean the connector might not be right for your car.Keep Watching Over Time

Even after installing, check the connector regularly. This stops sudden failures and helps your car’s system last longer. Taking care of connectors keeps them working well.

Pro Tip: Follow a guide when testing connectors to stay safe. If unsure, ask an expert for help.

By testing and checking your connector, you can make sure it fits your car’s needs and works in all conditions.

Picking the right car connectors keeps your car safe and working. Look at things like power limits, strength, and weatherproofing. This helps avoid expensive fixes and keeps connections strong. Take steps to check what you need, read your car manual, and test connectors carefully. For tricky systems like EV chargers, ask experts or trusted guides. This makes sure your connectors follow rules and work well in real life.

What are the key things to think about when picking automotive connectors?

Focus on power needs, strength, and weather protection. Check if the connector can handle your car's current and voltage. Choose strong materials that resist shaking and extreme temperatures. For outdoor areas, pick waterproof connectors to block water and dirt.

How can I tell if a connector fits my car?

Look at your car manual for wiring and connector details. Match the connector's pins, wire size, and power limits to your car. If unsure, ask a mechanic or electrician to avoid mistakes.

Why does signal stability matter in car connectors?

Signal stability keeps systems like sensors working smoothly. Bad connectors can cause signal drops and problems. Good ones, like FAKRA connectors, keep signals steady even with heat or shaking. This helps your car work better and more reliably.

Do all cars need waterproof connectors?

Waterproof connectors are important for cars in wet or rough places. They stop water and dirt from harming wires. For off-road cars or outdoor lights, use waterproof ones like Weatherpak. For indoor areas, regular connectors might be fine.

How can I check if a connector works?

Here’s how to test a connector:

Look for cracks or bent pins.

Attach it and see if it fits well.

Use a multimeter to check power flow.

Test it in real conditions, like water or heat.

Check again for damage after testing.

Testing often helps avoid sudden problems.

What makes high-voltage connectors special?

High-voltage connectors handle the big power needs of electric cars. They have strong insulation and locks to stay safe. These connectors work well in EV chargers and battery systems.

Can one connector work for different car parts?

Some connectors, like wire-to-wire types, can do many jobs. But they must meet the needs of each part. For example, a headlight connector won’t work for GPS. Always check ratings before using one connector for different tasks.

How can I keep my car connectors in good shape?

To make connectors last longer:

Check them often for damage.

Clean off dirt and water.

Keep them tight to stop shaking from loosening them.

Replace broken ones quickly to avoid bigger problems.

Taking care of connectors keeps your car running well.

Why are FAKRA connectors good for cars?

FAKRA connectors are great for GPS, Bluetooth, and radios. They stop wrong connections and keep signals clear. They also handle heat and shaking, making them perfect for modern cars. Their small size saves space while working well.

Should I ask an expert when picking connectors?

Yes, especially for tricky systems like EV chargers. Experts help you pick connectors that fit your car’s needs. They make sure your car stays safe and works its best.

See Also

Why Fakra Connectors Are Essential For Today's Vehicles

Enhancing Data Flow With Advanced Automotive Connectors

Key Role of FAKRA Connectors in Vehicle Systems

Significance of Fakra Connectors in Automotive Sector

Boosting Data Transfer With High-Speed Automotive Connectors