Choosing the Right Auto Wire Connector Types for Your Vehicle

Selecting the appropriate automotive wiring connector types is crucial for your vehicle. These connectors play a vital role in ensuring optimal performance and safety. It is essential to consider how well the connectors match the electrical requirements and environmental factors. Using the wrong connectors can lead to poor connections, electrical issues, and potential safety hazards. Opting for the correct automotive wiring connector types enhances reliability and prevents potential problems.

Understanding Automotive Wiring Connector Types

When fixing your car's electrical parts, knowing about different automotive wiring connector types is important. These connectors help electric signals move smoothly between circuits, powering things like the engine control and car radio.

Types of Automotive Wiring Connector Types

Butt Connectors Butt connectors join two wires end-to-end. They are great for connecting wires securely in cars. You can get them in different sizes for various wire thicknesses.

Bullet Connectors Bullet connectors are easy to connect and disconnect. They have a male and female part that snap together. This type is handy when you need to often connect and disconnect wires, like in trailer wiring.

Spade Connectors Spade connectors look like forks and easily attach to screw terminals. They are used in cars where a strong connection to a terminal block is needed.

Ring Connectors Ring connectors have a round end that fits over bolts or screws. They make strong connections, perfect for grounding in vehicles.

Materials Used in Connectors

The materials of automotive wiring connector types affect how well they work and last.

Copper Copper connectors conduct electricity well and resist rusting. They are reliable for use in cars.

Aluminum Aluminum connectors are light and cheap but may not conduct as well as copper.

Brass Brass connectors balance good conductivity with durability, useful where rust resistance matters.

Connector Insulation Types

Insulation protects connectors from weather and keeps them safe.

Heat Shrink Heat shrink insulation tightly seals the connector against moisture and dust, ideal for outdoor car use.

Nylon Nylon insulation bends easily and resists wear, good for places with movement or vibration.

Vinyl Vinyl insulation is affordable and offers basic protection, used in less demanding car areas.

Knowing these automotive wiring connector types helps you choose wisely when working on your car's electrical system. Picking the right ones ensures your vehicle works well longer.

Things to Think About When Picking Connectors

Picking the right automotive wiring connector types is important. These connectors help your car's electrical parts work well and safely. Let's look at what you should consider.

Electrical Needs

Electrical needs are key when picking automotive wiring connector types. Make sure connectors can handle your car's electrical load.

Current Limit

A connector's current limit shows how much electricity it can carry safely. Pick connectors with a current limit that meets or is higher than your car's needs. Using connectors with low limits can cause overheating and failures.

Voltage Limit

Voltage limit is also important. It tells the highest voltage a connector can take without breaking. Ensure connectors match your car’s voltage needs. Wrong voltage limits can cause bad performance and safety risks.

Environmental Factors

Environmental factors affect how well automotive wiring connector types work and last. Think about where your car operates.

Temperature Changes

Temperature changes affect connectors' performance. Choose ones that handle hot and cold temperatures in your car’s area. Heat makes them expand; cold makes them brittle.

Water and Rust

Water and rust are big threats to connectors. Pick materials that resist water and rust for reliable connections, even in wet places, stopping electrical problems.

Physical Needs

Physical needs show how well connectors handle stress. You need strong connectors for your vehicle's demands.

Shake Resistance

Cars shake when moving. Choose shake-resistant connectors for secure connections that don’t loosen, keeping good electric flow.

Strength

Strength matters for long-lasting connectors. Choose tough materials to avoid frequent replacements, saving time and money.

Research Studies on Electrical and Environmental Impacts on Connectors show why choosing the right automotive wiring connector types is crucial. They help electric signals move across systems so parts work together smoothly.

By thinking about these things, you pick the best automotive wiring connector types for your car, ensuring it works safely and reliably.

Installation Tips and Best Practices

Installing Installing RF Connectors makes your car's electrical system work well. Follow these tips for safe and strong connections.

Proper Crimping Techniques

Crimping connects wires using automotive wiring connector types. It means squeezing the connector onto the wire tightly.

Tools Needed

To crimp well, you need certain tools:

Wire Stripper: Takes off wire covering.

Crimping Tool: Presses the connector on the wire.

Heat Gun: Shrinks insulation for extra safety.

These tools help make a strong connection.

Step-by-Step Crimping Guide

Strip the Wire: Remove 1/4 inch of cover from wire end.

Insert the Wire: Put stripped wire into connector until it touches metal.

Crimp the Connector: Use tool to press and secure wire in place.

Seal with Heat Shrink: Slide heat shrink over connection and heat it until tight.

These steps help make a good connection with automotive wiring connector types.

Ensuring Secure Connections

Secure connections are key for your car's electrical parts to work well.

Testing Connections

After setup, check if connections are secure:

Visual Check: Look for loose wires or bare metal.

Tug Test: Gently pull wires to see if they stay put.

Electrical Test: Use a multimeter to check flow and voltage levels.

Testing finds problems early, stopping future issues.

Fixing Common Problems

Sometimes problems happen even with care. Here’s how to fix them:

Loose Connections: Re-crimp if wires feel loose.

Corrosion: Clean connectors and use grease to stop rust.

Intermittent Signals: Look for broken wires or connectors; replace if needed.

Fixing these keeps your connectors working well.

By following these tips, your car's connectors will be safe and reliable.

Common Mistakes to Avoid

Picking Wrong Connector Types

Using the wrong connector can cause big problems in your car's electrical system. If connectors don't fit right, they might not work well and could fail.

Problems with Wrong Connectors

Overheating: If a connector can't handle enough electricity, it can get too hot. This might melt the cover and start a fire.

Signal Loss: Wrong connectors might not send signals well, making things like lights or sensors stop working.

Physical Damage: Bad connectors can break wires or bend pins if they don't fit right. This messes up the whole system.

*Check and clean often to stop dust and rust from messing up connectors.*

Ignoring Weather Conditions

Weather affects how well connectors work. Not thinking about this can cause problems later on.

Long-term Effects on Performance

Corrosion: Wetness makes connectors rust, which stops them from working well. Use materials that don't rust easily.

Temperature Changes: Very hot or cold weather can hurt connectors. Cold makes them crack; heat makes them loose.

Vibration Damage: Cars move a lot, so use strong connectors that won't shake loose and cause electric issues.

Tip: Regular checks and cleaning keep your car's electrical parts working well.

Choosing the right car wire connectors is important. Think about what your car needs for electricity and weather. Check what your car specifically requires to pick the best connectors. This keeps your car safe and reliable.

Using smart choices can stop problems like broken wires. For example, Boeing used Skylight technology to make wiring faster and with fewer mistakes. By doing similar things, you can keep your car's wires working well and dependably.

See Also

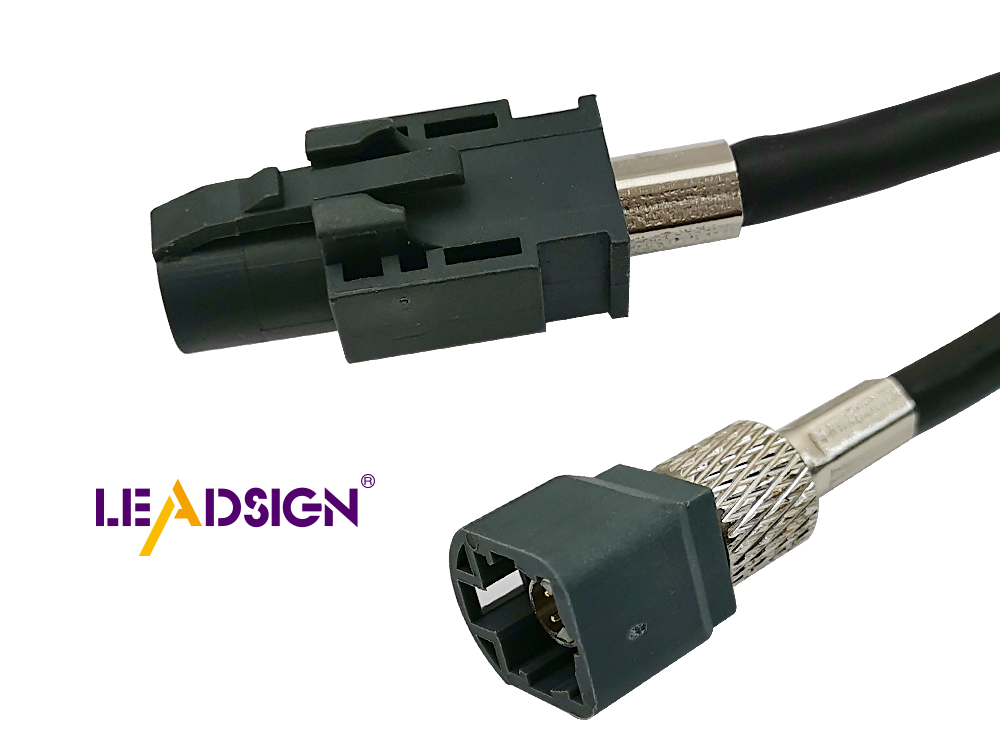

Significance of Fakra Auto Connectors in Contemporary Cars

Benefits of HFM Connectors in Auto Sector

Improving Data Transfer: Significance of High-Speed Auto Connectors