Choosing the Best Automotive Wire for High-Speed PCB Design

High-speed PCB design is important for cars. It helps data move quickly inside vehicles. Engineers have tough choices for materials and parts. They think about signal quality and heat control. Picking the right car wire is key here. The wire needs to handle fast data and stay safe. Good choices improve how cars work and prevent problems.

Learning About Fast PCB Design

Fast PCB design is very important in today's car electronics. It makes sure data moves quickly and well inside cars. This part talks about what makes fast PCB design special.

Special Features of Fast Design

Fast PCB design has special features that make it different from regular designs.

Hard Parts

Designers have many hard parts to think about with fast PCBs. They need to plan signal paths just right and handle electromagnetic noise. Smaller PCBs with more jobs need smart ideas to keep signals strong. Designers must think carefully about these things for the best results.

Fast vs. Frequent

People mix up fast and frequent designs, but they are not the same. Fast design is about quick data moving, while frequent design is about how often signals change. Both need careful work, but fast design focuses on data speed and keeping signals clear.

Important Things for Fast PCB Design

Many important things affect how good a fast PCB design works. Knowing these helps designers make good circuits.

Top Frequency Content

The top frequency content shows how fast data can move. Fast PCB design needs careful thinking about this so signals stay clear and not messy. Designers pick materials that work well at needed frequencies.

Quickest Rise Time and Data Speed

Quickest rise time and data speed are key for fast PCB design. These show how quickly a signal changes from low to high and how fast data travels in the circuit. Getting the best times needs picking the right parts and planning layouts well.

Science Study Results:

Almost all circuit designs aim to be smaller with more functions, faster speeds, and higher frequencies.

Fast PCB layout designers do lots of work early on to keep signals strong, power steady, and avoid electromagnetic problems.

By knowing these features and important things, designers can make fast PCB designs fit for modern cars. This knowledge helps cars run well, giving users a better ride.

Picking Materials for Fast PCBs

Choosing the right stuff is key in fast PCB design. The materials can change how well the circuit works. Engineers think about many things to make sure it works best.

Why Material Matters

Material properties are important in fast PCB design. They show how well the PCB handles high signals and keeps them clear.

Dielectric Constant and Energy Loss

The dielectric constant and energy loss are important. A low dielectric constant cuts signal delay, helping fast data move. Energy loss shows how much signal turns into heat. Lower numbers mean less energy lost, which helps fast PCB design work better.

"PCB materials differ in energy loss, heat control, and more."

Steady Performance

Steady material properties mean good performance all the time. Materials like FR-4 and PTFE are compared often. FR-4 is cheap and easy for big jobs but struggles with high signals. PTFE has a higher temperature limit, making it better for tough fast PCB tasks.

Tips for Choosing Materials

Picking the right materials means knowing their effects on design.

Low Dk Values for Speed

Materials with low dielectric constant (Dk) help fast PCB design by cutting signal delay. This matters when quick data moves are needed.

Keeping Signals Clear

Impedance control is also key. It makes sure signals move without getting messed up. Good impedance keeps signals clear, which is vital for fast PCBs. Engineers pick materials that match impedance to stop signal problems.

"FR-4 is strong and fireproof but PTFE is better for high signals."

By knowing these material facts, engineers can choose wisely in fast PCB design. This helps make circuits that work well in modern cars.

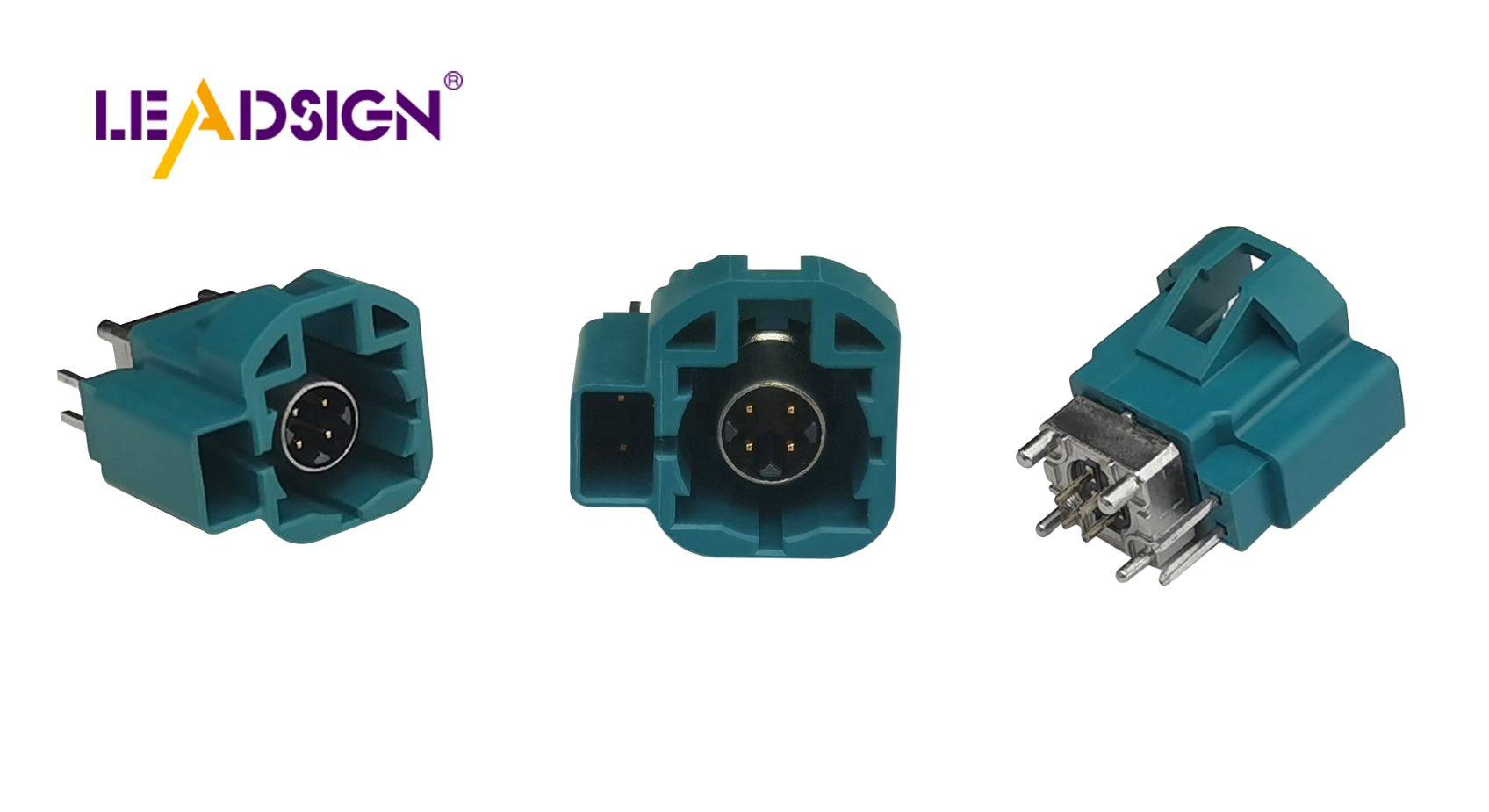

Connector Systems in Fast PCB Design

Connectors are very important in fast PCB design. They help data move well and keep signals clear. Engineers must pick the right connectors for today's car electronics.

HSD High-Speed Data Connectors

HSD Connectors are made for cars. They help data move fast, which is great for vehicles.

Features and Rules

HSD connectors have features that make them work well in fast PCB design:

Differential Signaling: This helps HSD connectors handle fast data without messing up. It keeps errors low by making sure both lines get the same signal changes.

Mechanical Keying and Latching: These keep connections safe, so they don't come apart by accident in cars.

Color Coding Options: This makes it easy to know where things go, stopping mistakes when putting them together.

HSD connectors follow global car rules, meeting tough needs of the industry.

Where They Are Used

HSD connectors are used in many car systems:

LVDS Cameras: They help cameras send video quickly and clearly.

USB and IEEE 1394 Uses: HSD connectors help share data fast in entertainment systems.

Ethernet and GVIF: These make sure car networks talk well, helping driver-assist systems.

Pluggable Connectors and Trends

Pluggable connectors are liked more now because they are easy to use.

Good Things About Pluggable Connectors

Pluggable connectors have many good points:

Easy to Install: Unlike fixed ones, pluggable ones can be taken out or put back easily. You don’t need to unscrew each one, making fixes simple.

Handles High Power Well: Some can take a lot of power, good for hard jobs.

These reasons make pluggable connectors popular in many fast PCB projects.

German Companies Lead

German companies are top in connector tech. They set trends and rules in fast PCB design with smart ideas that fit new car needs. Their lead comes from their focus on quality and careful engineering.

Planning and Layout Considerations

Component Placement and Signal Routing

In fast PCB design, where parts go is key. Engineers must place parts well for best work.

Avoiding Crosstalk and Heat Management

Crosstalk happens when signals mix up. To stop this, keep traces apart. Use shields to guard signals. Heat is also a problem. Hot parts can hurt performance. Place hot parts away from sensitive spots. Use heat sinks or vias to cool down.

Importance of Ground Planes

Ground planes help keep signals steady and cut interference. They make voltage stable and improve signal quality. Keep ground planes continuous to avoid signal issues. A good ground plane boosts fast PCB performance.

Use of CAD Software Tools

CAD tools are vital in PCB design today. They help control layout details precisely.

Predicting Layout Effects

CAD lets designers test different layouts easily. Change line lengths, widths, and board thicknesses to see effects. This helps pick the best setup for speed. Altium Designer Documentation shows CAD predicts many layout changes well.

Manufacturing Tolerances

Making PCBs can change their performance due to variations like hole placement affecting plating. Designers should plan for these changes early on. The Signal Integrity Journal says it's crucial to think about these differences so the final product works as expected.

In short, careful planning is key for fast PCB success. By focusing on part placement, routing, and using CAD tools, designers make strong circuits for cars.

Choosing the right materials is very important for fast car PCBs. Engineers pick materials that keep signals clear and working well. They need to know what car systems need and use them smartly.

"The industry is getting better at making PCBs eco-friendly by using green resources, saving energy in making them, and focusing on designs that can be recycled."

Following rules and good practices not only makes things work better but also supports being kind to the Earth, helping new ideas in PCB design.

See Also

Improving Automotive Data Transfer with FAKRA PCB Connectors

Benefits of FAKRA PCB Connectors for Automotive Uses

Boosting Data Transfer: The Significance of Fast Automotive Connectors

Advantages of Employing FAKRA PCB Connectors for Automotive Uses

The Significance of FAKRA PCB Connectors in Automotive Connectivity