Top Tips for Choosing Automotive Electrical Connectors Types

Choosing the right automotive electrical connectors types is crucial for ensuring your car operates efficiently and safely. These connectors play a vital role in the smooth functioning of electrical components, such as the engine and lighting systems. Selecting the appropriate types enhances your vehicle's reliability and reduces the risk of breakdowns. Consider factors like compatibility, strength, and weather resistance when making your choice. By doing so, you contribute to the longevity and safety of your car.

Electrical Needs

Voltage and Current Details

Knowing voltage limits

When picking car connectors, know the voltage limits. Voltage limits show the highest voltage a connector can safely handle. Picking the right one makes sure your car's electrical parts work well. If you choose one with too low a voltage limit, it might cause electrical problems or damage parts.

Thinking about current load

Current load is important too. It means the most current a connector can carry without getting too hot. Pick connectors that meet or go beyond your car's current needs. This stops overheating and fire risks. Always check how much current a connector can handle to keep your car safe and working well.

Maker's Instructions

Following rules matters

Makers give rules for using their connectors. These rules tell about voltage, current, how to install, and care tips. Following these keeps connectors working right and lasting long. Ignoring them can mean bad setups and shorter life for connectors.

Matching with car systems

Matching with your car's systems is key when picking connectors. Make sure they fit with your car's electric parts smoothly. This stops connection troubles and keeps everything running right. By choosing ones that match your car’s needs, you boost how well your car works overall.

Functional Needs

When picking car connectors, think about what your car needs. This makes sure your car's electric system works well.

Extra Functions

Sensors and data sharing

New cars use sensors and share data to work best. Pick connectors that help with these jobs. Connectors that share data let your car talk to systems like maps and music. This keeps your car smart with new tech.

Power sharing skills

Power sharing is key for car connectors. You need ones that send power to all parts of the car. This makes sure everything gets power to work right. Strong power-sharing connectors make your car run better.

Hybrid Connectors

Mixing many jobs

Hybrid connectors do many things in one piece. Think about these if you want a simple electric setup in your car. They handle tasks like power and data, so you need fewer connectors. This makes wiring easy and helps the car work well.

Good points and uses

Hybrid connectors are useful beyond just working well. They save space and cut weight, good for new cars. Use them in self-driving or driver help systems. Picking hybrid connectors keeps your car ahead in tech.

Termination and Sealing

Impact on Assembly

Easy to put in

Pick connectors that are simple to put in. Easy ones save time and stop mistakes. Find designs that need no special tools. This helps you set up your car's electric system fast.

Strong connections

Strong connections help your car work well. Choose connectors that stay tight even when stressed. They should fit snugly and not loosen over time. This stops electrical problems and keeps your car running fine.

Environmental Protection

Keep out water and dust

Keep water and dust away from connectors. These can cause rust and harm, leading to issues. Pick connectors with good seals like Amerline's military-style ones, which last long in tough spots.

Handle hot and cold

Temperature changes can hurt connectors. Get ones that handle heat and cold well. They work right in any weather. TE Connectivity makes strong ones for this, ensuring they stay reliable always.

Material Choices

Cover Materials

Plastic and Metal Choices

Think about the cover materials for car connectors. You can pick plastic or metal. Plastic ones are light and don't rust easily. They bend into different shapes. Metal ones are strong and last long. They handle tough weather better than plastic. Choose based on what your car needs.

Effects on Weight and Price

Material choice changes weight and price. Plastic makes cars lighter, saving fuel. It's usually cheaper too. Metal is heavier but lasts longer. It might cost more now but saves money later by needing less fixing. Think about your budget when picking.

Trustworthiness and Price

Balancing Quality with Money

Finding a good mix of quality and cost is key. Good connectors may cost more, but they work well in all weather. Check what your car needs and decide how much to spend on good parts. Spending more now can stop big fixes later.

Lasting Strength

Strength matters when choosing connectors. You want them to last long without breaking down. Pick materials that don't wear out fast. Think about where you drive your car most often. Tough places need stronger connectors to keep working well for years.

Reliability and Durability

Working in Different Conditions

Handling bumps and shakes

When picking car connectors, think about bumps and shakes. Cars move a lot, especially on bumpy roads. Connectors that handle these movements stay connected well. This keeps your car's electric parts working without stopping. Find connectors made for these conditions to stop loose connections.

Fighting rust

Rust can harm connectors, making them work badly or fail. Choose connectors that fight rust well. They last longer and work better in many places. Water, salt, and chemicals cause rust, so pick materials that block these things. This way, your car's electric parts stay safe and work right over time.

Checking and Rules

Following industry rules

Make sure the connectors you pick follow industry rules. These rules mean the connectors are safe and work well. Following them shows the connectors were tested hard and meet good standards. Picking such connectors makes sure your car's electric system is safe.

Why testing matters a lot

Testing is key for making sure connectors work well. Makers test them in different ways to see how they do. Testing finds weak spots so they can be fixed before use. When you choose tested connectors, you trust they will last long and work great. This lowers chances of electric problems in your car.

Miniaturization Benefits

Good Things About Smaller Connectors

Saving Space in Cars

Smaller connectors save space in cars. Using them helps fit more parts in tight spots. This is important because modern cars need to use every bit of space well. With tiny connectors, you can put more stuff in less room, making the car work better.

Less Weight Helps

Besides saving space, small connectors make cars lighter. Lighter cars use less fuel and go faster. Picking small connectors cuts weight but keeps connections strong. This makes driving smoother and saves gas, which is good for the planet.

Comparing with Big Connectors

How They Work Differently

Small connectors are great but might not be as strong. Bigger ones carry more power and last longer. When choosing, think about what your car needs most—small size or strength? Knowing this helps pick the right connector for your car.

What Your Car Needs

Different cars need different connectors. Fast cars may need stronger ones for more power. Small cars might like tiny ones to save space. Think about what your car's electric system needs before picking a connector type. This way, you get the best fit for how your car works.

Fitting with Wires

Making Sure They Fit Right

Matching sizes of connectors and wires

When picking car electrical connectors, make sure they fit the wires. This is important for keeping a strong connection. If they don't match, it might get loose or not work, causing problems. Always check both connector and wire sizes to ensure they fit well.

Stopping connection troubles

To stop connection troubles, look at how connectors are made. Good ones are designed carefully to avoid misalignment. Work with suppliers offering both regular and custom options, like those with Circular Connectors. Custom fits keep quality high and ensure everything fits right, reducing issues.

Ensuring They Work Well

Keeping signals clear

Keeping signals clear is key for your car's electric systems to work well. You need connectors that send signals without breaks. Bad signal strength can cause data loss or errors between parts of the car. Pick connectors made for your car's data needs so signals stay strong.

Delivering power well

Good power delivery is also very important when choosing connectors. Modern car features like sensors need steady power supply. Hybrid Connectors are great because they carry both power and signals, helping today's complex wiring systems. By ensuring good power delivery, you boost your car's electric system performance.

Service and Delivery

Lead Times

Planning for making things on time

When picking car connectors, think about how long they take to get. Planning well helps you finish work on time without waiting too long. Know how long each supplier takes to send stuff, so your work goes smoothly. This smart planning stops slowdowns in making things.

Trusting suppliers

Trustworthy suppliers are important for smooth work. Pick ones known for sending things on time. Good suppliers, like Amerline, help reduce wait times a lot. They make sure you get connectors quickly, keeping your work moving fast.

Design Changes

Making them fit your needs

You can change connectors to fit what you need. Work with suppliers who let you do this to make them work better with your car's electric parts. Changing them makes sure they fit well in your car's system.

How changes affect delivery times

Changing designs is good but can slow down getting them. Plan for extra time when changing designs. Talk closely with suppliers to manage these times well. By knowing delays, you can plan better and keep everything on track.

Engineering Help

Why Experts Matter

Getting Help to Choose

Picking car connectors can be hard. You need help from experts. They know which connectors are best for your car. Experts understand the details and suggest good products. By asking them, you pick connectors that work well and make your car better.

Fixing Problems

When your car's electric system has issues, experts help a lot. They find and fix problems fast, so your car doesn't stop working long. Experts have the tools and knowledge to solve tough problems. With their help, you keep your car's electric parts safe and avoid big repair costs.

Using Helpful Resources

Important Papers

Having detailed papers is key when using car connectors. These papers tell how to install and take care of them. They help you learn about different connector types. By reading these papers, you know how to make your car's electric system work best.

Learning Programs

Learning programs are important for using car connectors right. Many suppliers teach about new tech and smart ways to use it. These lessons build your skills so you can choose wisely. Support services also give expert advice when needed. By using these resources, you stay current with new ideas and keep getting better at what you do.

Picking the right automotive electrical connectors is important for your car. Here are some tips to help:

Know Electrical Needs: Understand voltage and current needs.

Think About Functions: Make sure connectors do needed jobs.

Look at Materials: Balance strength with price. Check How Reliable They Are: Ensure connectors handle different conditions. reliable connector solutions

By thinking about these things, you make your car work better. Always learn more or ask experts for best results. Your car's safety and efficiency rely on smart choices.

See Also

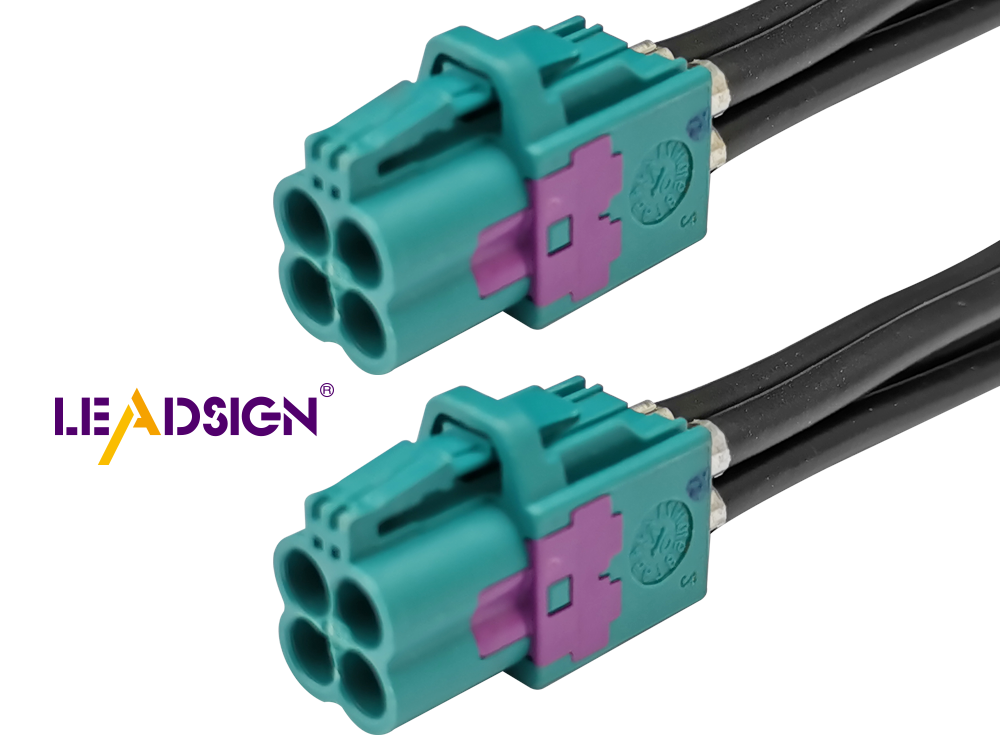

Why FAKRA Connectors Are Essential for Automotive Use

Significance of Fakra Connectors in Today's Vehicles

Benefits of FAKRA PCB Connectors for Cars