Top Tips for Choosing Automotive Electrical Connectors Types

Selecting the appropriate automotive electrical connectors types is crucial for ensuring optimal performance and safety in vehicles. These connectors play a vital role in facilitating the smooth flow of electricity between various components. With a variety of connector types available, each serving a specific purpose, it is essential to understand their characteristics to make informed choices that meet the specific requirements of your vehicle.

Understanding Car Electrical Connectors

What They Are and How They Work

Car electrical connectors are important parts in a car's electric system. They link two parts together, letting electricity flow smoothly without losing power. These connectors have a pin and a spring that keeps them connected. Good connections keep cars safe and working well. They make sure all electric parts work right, lowering the chance of problems.

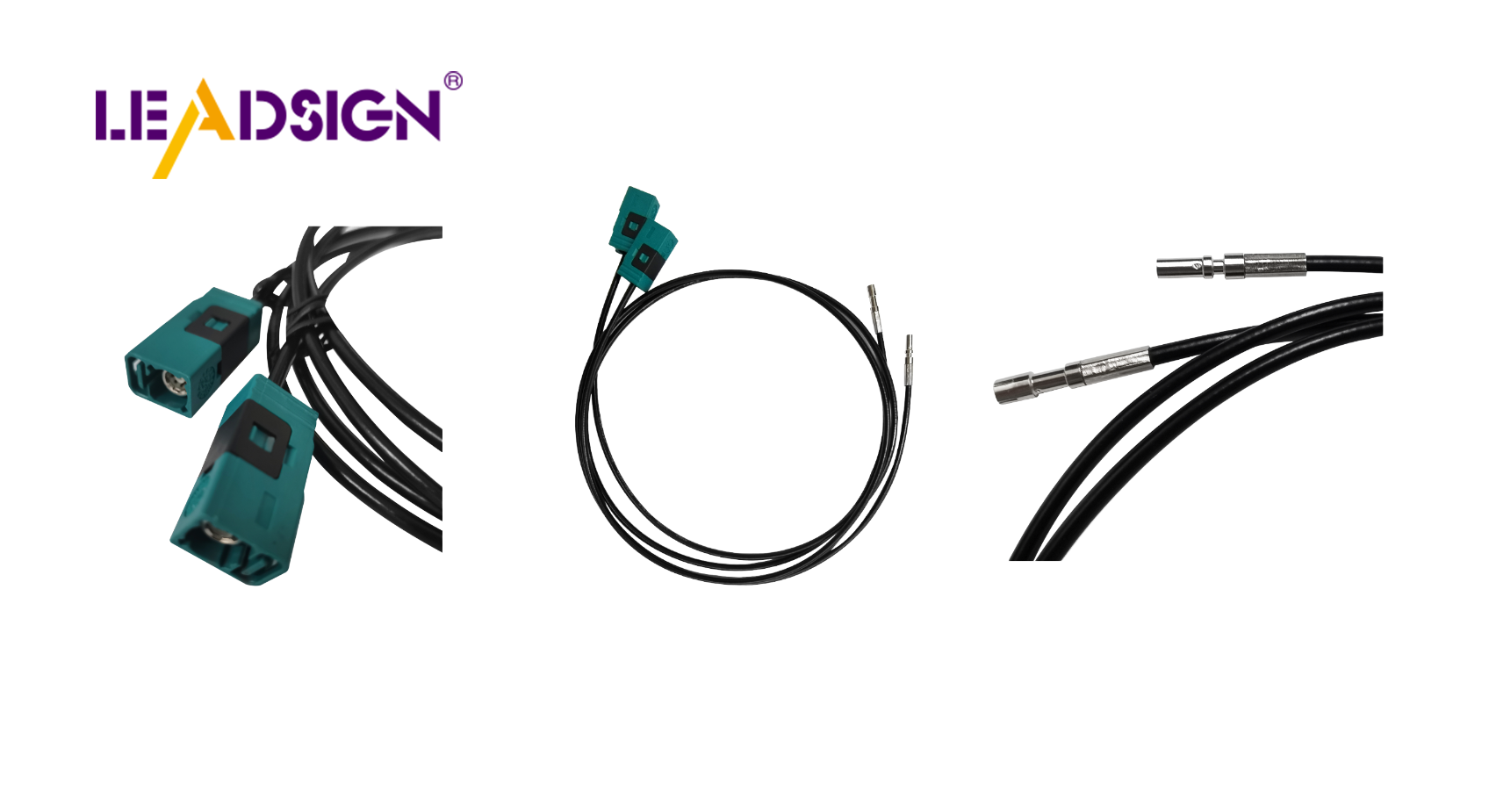

Common Types of Car Electrical Connectors

Knowing different car connectors helps pick the right one for each job. Here are some common ones:

Blade Connectors and Their Uses

Blade connectors are often used in cars. They have a flat piece that fits into a slot. These are good for quick connects and disconnects, perfect for parts needing regular checks or swaps.

Ring and Spade Connectors for Strong Links

Ring and spade connectors fit over bolts or screws to stay secure. The ring is round, while the spade looks like a fork with an open end. They're used where strong links are needed, like grounding wires or battery ends.

Butt Connectors for Joining Wires

Butt connectors join two wires together. They have a metal tube with a cover. You put wire ends in the tube and crimp it tight. They're key for making wires longer or fixing broken ones.

Special connectors meet unique needs in cars. They're made to handle tough conditions like heat, shaking, or rusting. For example, Special connectors manage high-voltage cables safely under hard conditions.

Special connectors meet unique needs in cars. They're made to handle tough conditions like heat, shaking, or rusting. For example, hybrid car connectors manage high-voltage cables safely under hard conditions.

Important Things to Think About When Picking Connectors

Choosing the right car electrical connectors needs careful thought. These things help make sure connectors work well and safely in cars.

Electrical Needs

Matching voltage and current for safety

Car connectors must fit the car's power levels. This stops overheating and keeps power flowing well. For example, don't use a low-voltage connector in a high-power spot. This mismatch can cause problems or even fires.

Connectors should fit with car systems exactly. Each part might need different wire sizes or ways to connect. Using the right connector makes everything work together smoothly. This lowers chances of issues and boosts how well the car runs.

Connectors should match the car's parts exactly. Each part might need different wire sizes or ways to connect. Using the right connector makes everything work together smoothly. This lowers chances of issues and boosts how well the car runs.

Weather Conditions

Handling heat and cold for all climates

Car connectors should handle hot and cold weather. Cars face different temperatures, from freezing to very hot. Strong connectors stay good in these conditions, stopping failures that could harm safety.

Fighting water and rust for lasting use

Water and rust can hurt connectors badly. Car connectors with special coatings stop these problems. This protection makes them last longer, working well over time. It also cuts down on fixing costs.

Physical Features

Being tough for long-lasting use

Connectors should take hits like bumps or shakes without breaking apart. Strong car connectors keep connections tight even on bumpy roads or when used a lot.

Easy to put in and fix for user ease

Simple-to-use connectors make setup easy and quick. Car connectors with easy designs save time during installation. Easy fixes keep them working great, helping the whole car stay reliable.

Tips for Best Performance

Installing Connectors Correctly

Installing automotive electrical connectors types right is key for safety. Using the best tools stops problems.

Tools You Need

Installers need certain tools to do a good job. These are:

Wire strippers: Take off wire cover without harm.

Crimping tools: Attach connectors tightly to wires.

Multimeter: Check electric links and voltage.

Heat gun: Helps shrink tubing for extra protection.

These tools help make strong connections.

Mistakes to Avoid for Good Results

Avoiding mistakes keeps connectors working well. Installers should:

Strip wires correctly: Don’t cut too much cover, or wires show.

Crimp properly: Bad crimps cause loose links and failures.

Align correctly: Wrong alignment causes bad contact and issues.

Avoid these errors to keep systems strong.

Regular Checks and Care

Checking connectors often helps them last longer. Finding problems early saves money on repairs.

Spotting Wear Signs

Regular checks find wear signs like:

Corrosion: Look for rust that blocks electricity.

Frayed wires: Check for exposed wires causing shorts.

Loose connections: Ensure connectors stay tight.

Finding these early helps fix them fast.

Steps for Routine Checks

Routine checks have steps to keep connectors working:

Look over visually: Check for damage or rust often.

Tighten connections: Make sure all are tight regularly.

Use multimeter test: Confirm voltage is correct.

Following these steps keeps systems safe and efficient.

Testimonial: "Rayco Electric did great work replacing my panel on time and cost as promised. The installer was neat, polite, and cleaned up after finishing the job." - Customer

This shows why professional setup and care matter, ensuring happy customers and good performance.

Choosing the right automotive electrical connectors is very important. It helps cars work well and stay safe. The blog talked about different connector types and what they are used for. It showed how important it is to match connectors with power needs and weather. Picking the right ones makes sure they work well when needed.

Remember: Think about power needs, weather, and how strong they are. This keeps your car's electric parts working longer and better.

See Also

Significance of FAKRA Connectors in Auto Industry Applications

Vital Role of Fakra Auto Connectors in Contemporary Cars

Benefits of FAKRA PCB Connectors in Auto Sector