How to Choose the Right Automotive Electrical Connectors Types

Selecting the appropriate automotive electrical connectors types is crucial. These connectors ensure your vehicle operates efficiently by linking various electrical components. They power essential systems like headlights and assist with driver-assistance technologies. As the demand for electric vehicles grows, the need for advanced connectors becomes more apparent, highlighting our desire for enhanced connectivity, convenience, and safety in modern cars. Opting for the right types of connectors not only enhances vehicle safety and performance but also contributes to a smoother driving experience.

Types of Automotive Electrical Connectors

Picking the right automotive electrical connectors is key for your car's systems to work well. Let's look at some common connector types and how they are used.

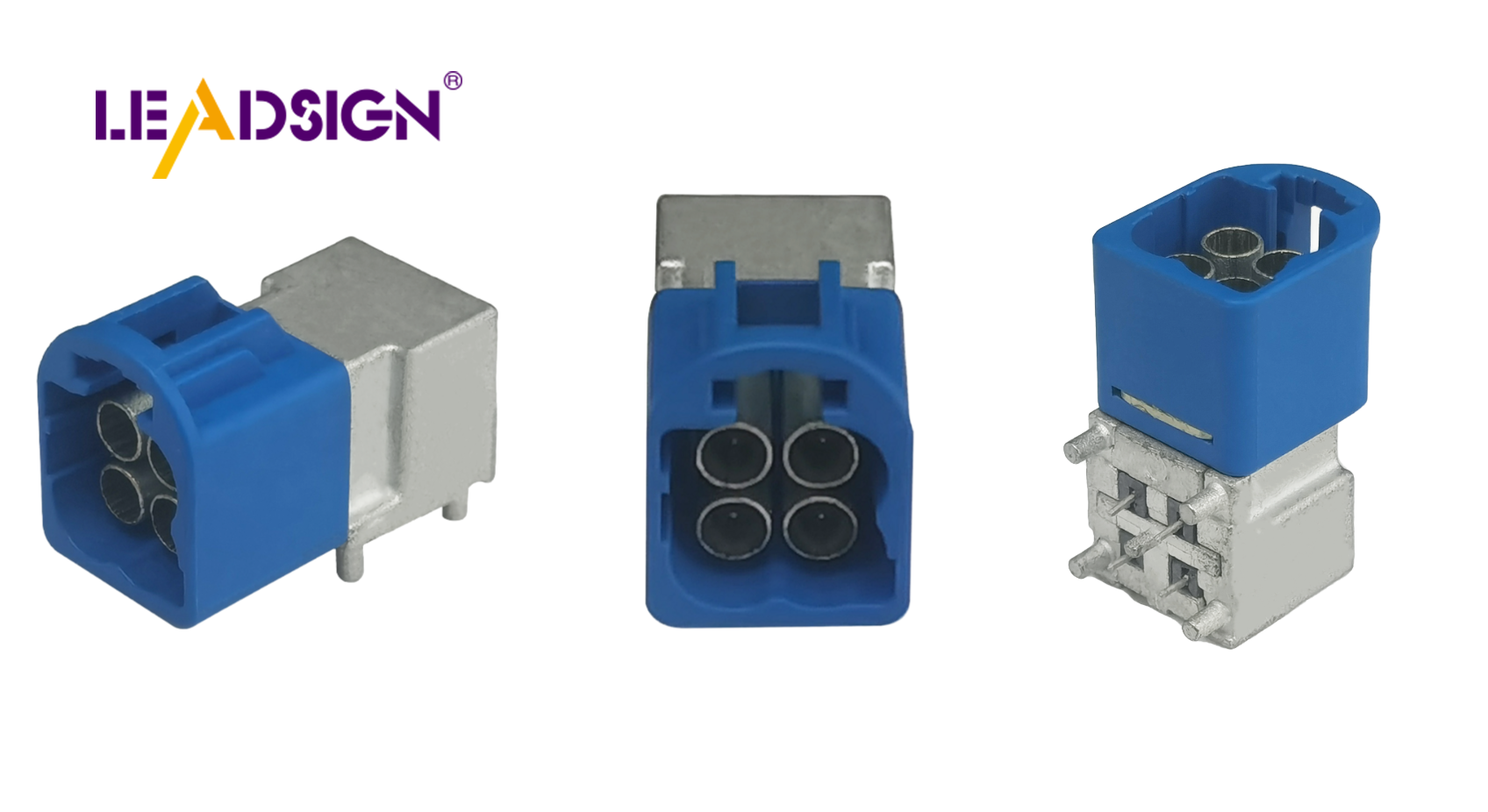

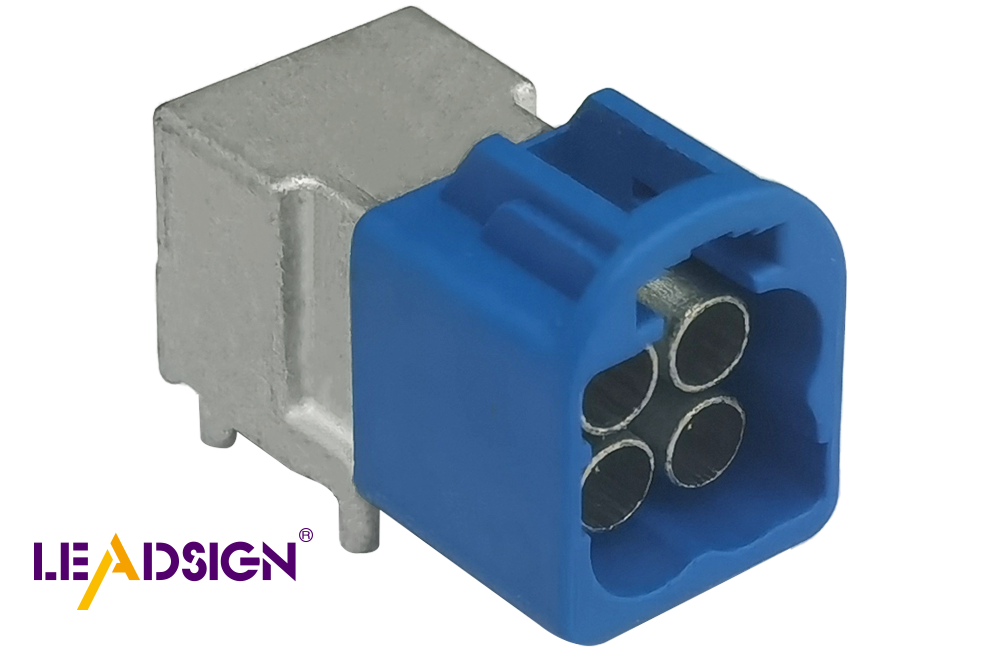

HSD Connectors

Uses in car electronics

HSD connectors (High-Speed Data) are important in today's cars. They are found in entertainment systems, cameras, and displays. These connectors send data quickly using low-voltage signals. They also work with USB 2.0/3.0 and Ethernet, so they can be used in many ways.

Pros and cons

HSD connectors have many good points. They stop crosstalk and outside noise, making sure data moves smoothly. Their shielded design gives a 100 Ω impedance, great for high-speed signals. But remember their limits; they might not fit all car connections.

Other Common Connector Types

USB connectors are everywhere in cars. You use them to charge gadgets or link infotainment systems. But using them often can wear them out if not cared for properly. To make them last longer, use lubricants to cut down on wear and stop corrosion.

Ethernet Connectors

Ethernet connectors are more needed now with smart car tech growing fast. They help with quick data sharing, crucial for driver-assist systems and other digital uses. When picking Ethernet connectors, check they fit your car’s needs.

OEM Connectors

Why OEM connectors matter

Using OEM connectors (Original Equipment Manufacturer) keeps your car's electric parts working right. These match your car's original specs perfectly for a snug fit and steady performance.

Perks of compatibility and trustworthiness

OEM connectors bring many perks like fitting well with current systems, lowering electric problems risk. By choosing OEMs, you keep your vehicle’s connections strong over time which boosts safety and performance overall.

Important Things to Think About When Picking Connectors

When picking automotive electrical connectors, think about some important things. These help your car's electric system work well.

Current Rating

Knowing power needs

Know what power your car parts need. Each part has its own power needs. Pick connectors that can handle this power. If you pick weak ones, they might break or not work right. This helps your car run smoothly without stopping suddenly.

Matching connectors to the car's system

Make sure the connectors fit your car's system. They should match the system rules. This stops electric problems and keeps parts connected well. Doing this keeps your car’s electric system working right and avoids problems.

Mechanical Properties

Strong and can handle tough conditions

Connectors need to be strong and handle tough stuff like water, shaking, and heat changes. Pick ones made for these things. Studies show: Water and shaking can mess up connections. Strong connectors make your car's electric system last longer.

Easy to put in and fix

It's good if connectors are easy to put in and fix. This saves time when fixing or changing them. It also keeps your car running well with less downtime.

Fit with Car's Electric System

Making sure they fit right

Make sure the connectors fit perfectly in the car’s system. A good fit makes all parts work together nicely. Right-fitting connectors stop electric issues and keep the car running well.

Stopping electric problems

Stopping electric problems is very important. Pick connectors that lower risk of issues happening. Studies show: Old age, heat, or past fixes can weaken them, causing breaks later on. Picking good ones lowers these risks, keeping your car safe.

Ways to Connect and Their Benefits

Picking the right way to connect automotive electrical connectors is very important. Crimping is a popular choice because it has many benefits.

Crimping as a Way to Connect

Crimping means squeezing a connector onto a wire. This makes a strong and safe connection. It's used a lot in cars because it works well and fast.

Why Crimping is Better

Strong Connections: Crimping makes the wire and connector hold tight together. This keeps them connected even when things shake or get hot.

Reliability: Crimped connections break less often than soldered or twisted ones. This is important for cars where everything needs to work right all the time.

Efficiency: Crimping is quick, so it's good for making lots of parts fast. It saves time and money for car makers.

Consistency: Crimping makes every connection the same, which helps avoid mistakes. This keeps car electrical systems working well.

Example: In one car project, a cable part got rejected because it cracked during crimping. This shows why using good crimping methods matters to keep customers happy.

Tips for Good Crimping

Use Good Tools: Buy good crimp tools made for your connectors. Right tools make sure crimps are tight and safe.

Pick Right Connector Size: Make sure the connector fits the wire size well so nothing gets loose or breaks.

Check Often: Look at crimps often for any damage or wear signs early on to stop problems before they happen.

Follow Maker's Rules: Do what the maker says about how to crimp right so you get good results and keep warranties valid.

By knowing why crimping is good and following these tips, your car's electrical connectors will stay strong and last long.

Taking care of car electrical connectors is very important. It keeps your car safe and working well. Check connectors often for wear, rust, or damage to stop problems before they happen. Automotive Professionals say pigtail connectors are small but very important. They link key parts like sensors and switches. These affect engine work and safety features.

"Pigtail connectors do a lot in the tricky world of car design and care."

Use this guide to make smart choices for a longer-lasting, better-performing car.

See Also

Significance of FAKRA Connectors in Auto Industry Usage

Vital Role of FAKRA Auto Connectors in Contemporary Cars

Essentiality of HSD Connectors in Auto Sector