Essential Tips for Choosing Automotive Electrical Connectors Types

Selecting the appropriate automotive electrical connectors types is crucial. These connectors facilitate communication between various components in your vehicle, such as fuel, engine timing, and emissions systems. Opting for the right types is essential to prevent issues and ensure the reliability of your car. Consider factors like weather resistance and frequency of connection to enhance the performance and longevity of your vehicle.

Understanding Car Electrical Connectors Types

Picking the right car electrical connectors needs some knowledge. This helps your car's electric parts work well and safely.

Technical Details

Current and Voltage Limits

When choosing connectors, check current and voltage limits. These show how much electricity the connector can handle. Using a weak connector can cause it to overheat or break. Always match the connector to your car's needs.

Signal Quality

Signal quality is key for good data transfer between parts. Bad signal quality can cause data loss or noise. Pick connectors that keep signals strong, especially for fast data like USB or Ethernet.

Practical Things to Think About

Weather Conditions

Car connectors must handle different weather conditions. Heat, wetness, and chemicals can harm them. Use sealed connectors if your car faces tough weather. They block dust and water, keeping them reliable.

Physical Stress

Physical stress includes shaking and pressure on connectors. Good connectors should be strong with locks to stop unplugging by accident. Look for ones that hold cables tight even when stressed.

Wire Connections

Wire connections mean how wires join to connectors. Crimping and soldering are common ways. Crimping is easy to set up and fix, so it's popular. Make sure the connection type fits your use and stays secure.

Knowing these things helps you pick the best car electrical connectors types. This makes your car safer and better performing.

Material and Market Considerations

When picking automotive electrical connectors types, think about material and market. These help connectors work well and last long.

Material Choice

Conductivity and Rust Resistance

Picking the right connector material is key. Materials with good conductivity help electricity flow better. For example, FeCo nanowires coated with Au cut resistance by 14% in rubber connectors. This shows why choosing conductive materials matters. Also, focus on rust resistance. Rust can ruin connectors over time, causing problems. Choose materials like gold or other rust-proof coatings to keep connectors strong in tough places.

Swapping and Matching

Why Standardization Matters

Standardized connectors make swapping easy across systems. They are simple to replace and fit well, cutting downtime and costs. Standard ones are easy to find for replacements or upgrades since they are common in stores. Following standards makes sure your automotive electrical connectors types fit well with old systems, boosting reliability and performance.

Choosing the right automotive electrical connectors types needs thought. Look at technical details, materials, and real-world use. These help them work best. Connector Experts say they are for special jobs like engine control. Knowing this makes your car safer and more reliable. Always learn more and ask experts for advice on specific uses. Connector Supplier says smart choices in connectors matter a lot. This way, you pick ones that fit your car's needs well.

See Also

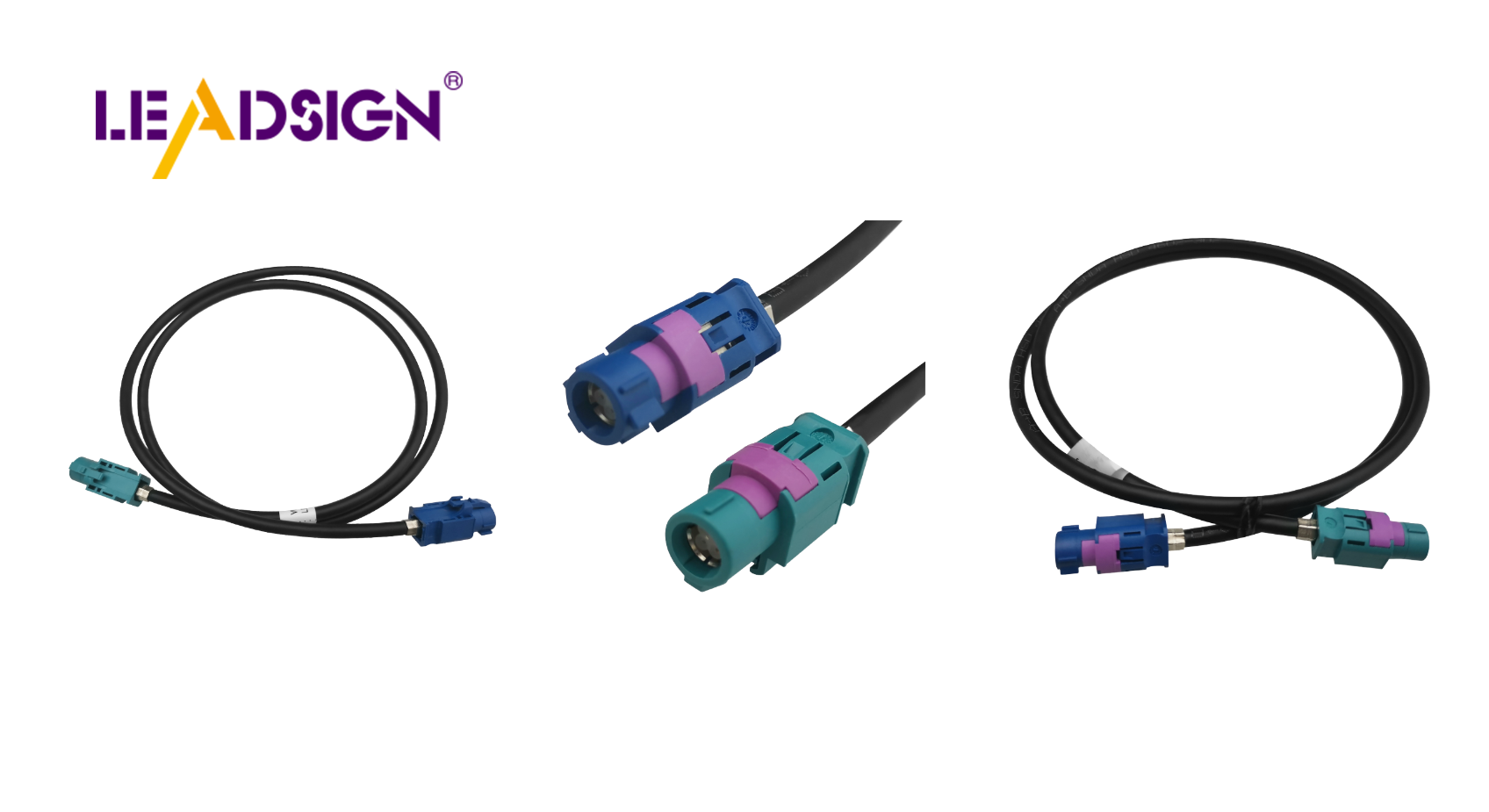

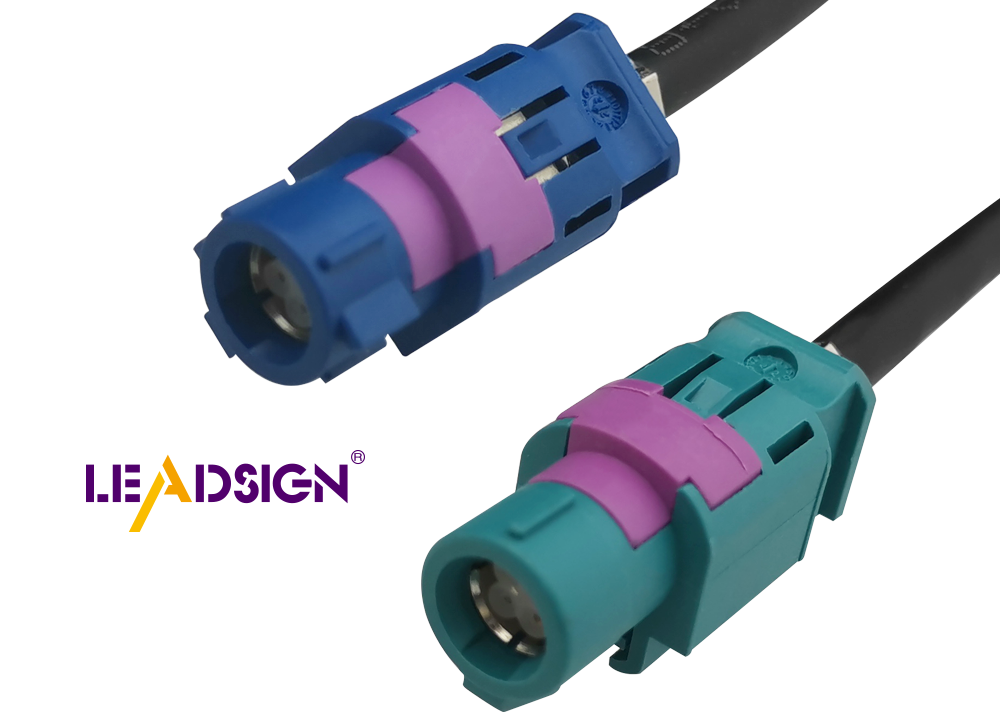

Significance of FAKRA Connectors in Automotive Usage

Essentiality of FAKRA Auto Connectors in Contemporary Cars

Foundations of HSD Connectors in Automotive Sector