Expert Advice on Choosing Automotive Harness Connectors for Modern Vehicles

Choosing the right auto harness connectors is very important. These connectors keep electrical systems like airbags and ABS working safely. Good connectors stop problems that might affect safety. Picking the right auto harness connectors improves your car's performance and makes it last longer.

Key Takeaways

Picking the right car harness connectors is very important. They help keep the car safe and working well.

Check your car's voltage, current limits, and environment first. This makes sure the connectors fit and don’t overheat or break.

Buying good connectors might cost more at first. But it saves money later by needing fewer repairs and lasting longer.

Understanding What Your Vehicle Needs for Auto Harness Connectors

Voltage and Current Details

Know your car's voltage and current limits. This helps you pick connectors that won't overheat or fail. Low-voltage connectors can't handle high-power systems like EV batteries. Check your car's specs to match the right connectors. This avoids damage and keeps your car working well for a long time.

Weather and Environment Challenges

Connectors must handle tough conditions cars face daily. Common problems include:

Very hot or cold temperatures

Water, humidity, and moisture

Fluids like brake oil or antifreeze

Salt and other corrosive materials

Water can cause rust, making connectors less effective. Heat can wear them out faster, especially near engines. Salt can damage metal parts, lowering performance. Use connectors that resist water, dust, and rust to keep them working in bad conditions.

Choosing Between OEM and Aftermarket Connectors

Decide if you need OEM or aftermarket connectors. Here's a simple comparison:

Feature | Aftermarket Connectors | |

|---|---|---|

Dependability | Very reliable with fewer risks. | May not be as dependable. |

Fit | Matches the car's original system perfectly. | Might not fit as well. |

Installation | Easy to install without changes. | May need extra work to fit. |

Durability | Made with strong materials for tough use. | Quality varies by brand. |

Price | Costs more but worth it for quality. | Cheaper but might lack durability. |

If you want reliability, go for OEM connectors. If saving money is key, check aftermarket options carefully to ensure they fit and work well.

Exploring Types of Automotive Connectors

Blade connectors

Blade connectors are very common in cars. They have a flat metal piece that fits into a matching slot. These connectors are often found in fuse boxes and wiring systems. Their design keeps them secure, so they work well for circuits you disconnect often. Blade connectors are simple to use and give a strong connection. This is why they are popular in modern vehicles.

Bullet connectors

Bullet connectors work best for simple to medium circuits. They are shaped like a cylinder, with one end fitting into the other. These connectors are great when you need to connect or disconnect wires quickly. For example, they are used in lights or audio systems. Their small size saves space, and they lock tightly for a stable connection. Bullet connectors are a smart choice for easy and quick setups.

Pin connectors

Pin connectors are flexible and used in many car systems. They have a pin and a socket that create a strong connection for signals or power. You’ll find them in sensors, control modules, and infotainment systems. Pin connectors come in different sizes to fit your car’s wiring. They are tough and precise, making them perfect for important systems.

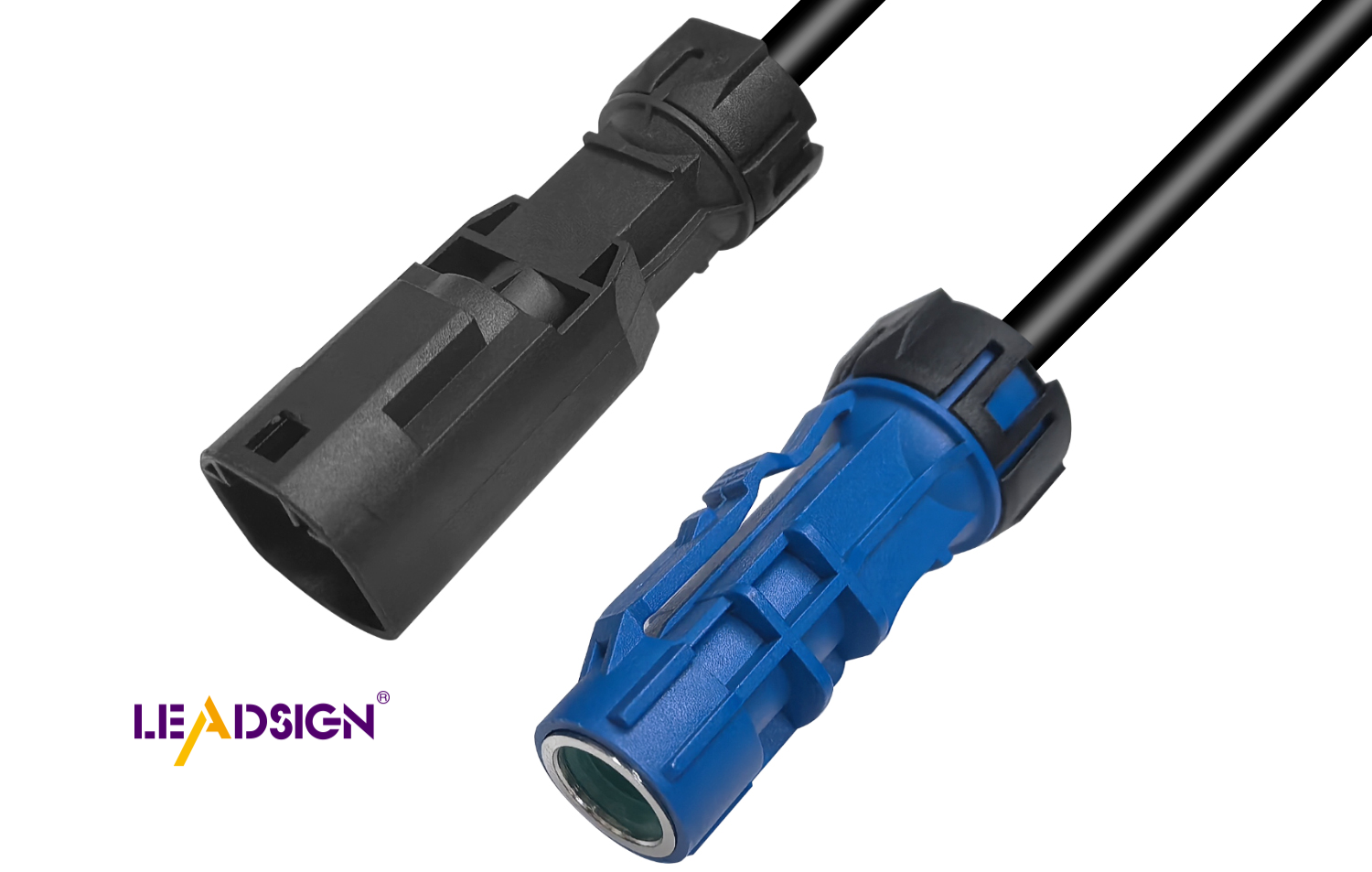

Specialty connectors for advanced systems

Specialty connectors are made for high-tech systems like ADAS and EVs. They are reliable for safety features like emergency braking and pedestrian alerts. High-power specialty connectors are key for EVs, helping with power transfer and efficiency. These connectors often have coatings to resist rust and are waterproof for tough conditions. They lower the chance of failure, saving money on repairs and keeping your car running well.

Tip: Always think about your car’s needs when picking connectors. Each type has a special job, so choosing the right one keeps your car safe and working properly.

Ensuring Compatibility and Durability

Matching wire thickness and power requirements

Make sure the connectors fit your car's wire size and power needs. If connectors can't handle the system's voltage or current, they may overheat or fail. Always check your car's electrical system details. This ensures the connectors work well with the wires and avoid damage. Using the wrong size can cause loose connections. Loose connections lower performance and increase accident risks.

Material selection (metal vs. plastic)

The material of connectors affects how strong and reliable they are. Plastic types like PBT, LCP, and PA66 are strong and handle heat well. These are great for tough conditions. Metals like copper alloys and stainless steel conduct electricity better and resist rust. Gold and silver coatings improve conductivity and stop corrosion. Gold is very stable, while silver reduces wear and friction. Picking the right material keeps connectors working for a long time.

Material Type | Common Materials | Key Characteristics |

|---|---|---|

Engineering Plastics | PBT, LCP, PA66 | Strong, stable, and heat-resistant |

Metal Materials | Copper alloys, stainless steel | Conducts electricity well, resists rust |

Precious Metal Plating | Gold, Silver | Great conductivity, resists rust, reduces wear |

Environmental resistance (waterproofing, dustproofing, corrosion protection)

Connectors must handle tough weather and conditions. Waterproof connectors stop water damage. Install them properly to seal them tightly. Clean them often and use coatings to prevent rust. Dustproofing is also important, especially for off-road cars. Gold and silver coatings help stop rust and keep connectors strong. Protecting connectors from the environment keeps your car's systems safe and lasting longer.

Tip: Check your connectors often for damage or wear. Regular care helps them last longer and avoids expensive fixes.

Installation and Maintenance Tips for Automotive Connectors

Tools and techniques for easy installation

Having the right tools makes installing connectors simple and secure. Keep these tools handy:

Wire strippers to safely remove wire coverings.

Crimping tools to tightly attach terminals.

Pliers to hold or bend wires during setup.

Heat guns to shrink tubing and seal connections.

Always follow the maker’s instructions when installing connectors. Use crimping tools to make strong, lasting connections. Heat guns seal connectors, keeping out water and dust. Using proper tools and methods makes installation easier and ensures connectors last longer.

Ensuring secure and reliable connections

Strong connections are key for your car to work well. Match the connector type to the wire size and power needs. For example, blade or pin connectors suit certain systems best. Make sure connectors lock tightly in place. Loose ones can cause problems or safety issues.

Check connectors after installing them. Look for misalignment or poor fits. A good connector stays firm even with vibrations. Following these steps keeps your connectors working properly.

Regular maintenance to prevent wear and tear

Taking care of connectors helps them last longer. Follow these steps to avoid damage:

Wipe connectors with a soft cloth and mild soap.

Use a wire brush to clean off rust if needed.

Add a rust-resistant coating for extra protection.

Inspect connectors often, especially after bad weather or salty roads. Check them before towing or after muddy or wet drives. Regular checks catch problems early and extend connector life. Cleaning and care keep them working well and safe from heat or moisture.

Tip: Taking care of connectors saves money on repairs. A little effort keeps them working like new.

Avoiding Common Mistakes When Choosing Auto Harness Connectors

Skipping compatibility checks with vehicle systems

A big mistake is not checking if connectors fit your car. If the connector doesn’t match the wire size or type, it won’t work well. This can cause problems or even make systems fail. For example, a wrong connector might loosen and stop working over time. Always check your car’s details to pick the right connectors. This ensures they stay secure and work properly.

Forgetting about environmental conditions

Another mistake is ignoring the weather and conditions your car faces. Heat, rain, and dust can damage connectors quickly. Water can rust them, and heat can make them weak. These problems can lead to failures and cost more to fix. Pick connectors that handle the tough conditions your car deals with. This keeps them working longer and saves money.

Picking connectors just because they are cheap

Choosing cheap connectors can cause more problems later. Low-cost ones often break or fail under heavy use. For instance, a weak connector might stop working with high power, leading to expensive repairs. Spending more on good-quality connectors saves money in the long run. They last longer and work better, making them worth the price.

Tip: Avoid these mistakes by checking your car’s needs, the environment it faces, and the quality of the connectors you buy.

Cost and Value Considerations for Automotive Connectors

Balancing upfront cost with long-term value

Think about more than just the price of connectors. Cheap ones might break often or need repairs. Good connectors work well over time and prevent failures. Strong materials like rust-proof metals or tough plastics last longer. These may cost more but handle tough conditions better. Spending more now can save money later.

Check how your car is used. If it faces heat or moisture, buy connectors with protection. This can save repair costs in the future. Always choose connectors that pass strict quality tests. Tested connectors are more reliable and last longer. By considering these points, you can find the best mix of cost and quality.

Evaluating total cost of ownership

Good connectors lower costs by lasting longer and needing less care. They keep your car running without problems. For example, rust-proof connectors survive wet or salty areas better. This means fewer replacements and repairs. Over time, the higher price pays off with fewer issues. Picking the right connectors saves money and keeps your car working well.

Investing in quality for reliability and safety

High-quality connectors make cars safer and more reliable. Battery connectors with insulation stop shocks and short circuits. Anti-looseness features keep them secure during vibrations. Rust-proof coatings and easy-to-use designs add to their durability. These are especially important for electric and self-driving cars. Bad connectors can cause safety risks and costly fixes. Choosing certified, high-quality connectors ensures they work well in all conditions.

Tip: Spending more on good connectors now avoids big repair costs later.

Picking the right car harness connectors keeps your vehicle safe. Knowing what your car needs helps you choose wisely. Strong, good-quality connectors last longer and save money. Talk to experts or trusted sellers to find the best match.

FAQ

What matters most when picking car connectors?

Make sure they fit your car's systems. Check that the connectors match the wire size, power needs, and weather conditions. This keeps them working safely and properly.

How can connectors stay strong and last long?

Pick connectors made from tough materials like stainless steel or strong plastics. Choose ones with tight locks and coatings to stop rust and wear.

Can all car systems use the same connectors?

No, each system needs specific connectors. For example, fast data systems need special connectors, while simple circuits can use blade or bullet connectors.

See Also

Why Fakra Connectors Are Essential For Today's Vehicles

Enhancing Data Transmission In Vehicles With Advanced Connectors

Understanding The Role Of HSD Connectors In Automotive