How to Choose the Right Wire Connector Types for Automotive Wire

Choosing the right wire connector types for automotive applications is crucial. Automotive wire connections require durability, as they tend to fail more often than those in aircraft. Exposed auto wires and rigid connector covers add to the challenge. There are various automotive wire connectors, each designed for specific tasks. Understanding these options ensures vehicles operate efficiently and safely.

Understanding Wire Connector Types for Automotive Wire

Common Types of Wire Connectors

Butt Connectors

Butt connectors link two wires in a line. Put each wire in the connector and press it tight. These connectors are easy to use for fixing or making wires longer. They come in different sizes for various wire thicknesses.

Ring Terminals

Ring terminals join a wire to a bolt or screw. The ring shape makes it hold well. Place the ring over the bolt and tighten it up. This type is used when you need a strong connection.

Spade Terminals

Spade terminals look like forks, which makes them simple to attach and remove. Slide the spade under a bolt head and tighten it down. This design is quick for places where you often unplug wires.

Bullet Connectors

Bullet connectors have male and female parts that click together. They make connecting and disconnecting wires easy. These are great when you change parts often.

Specialty Connectors for Auto Wire

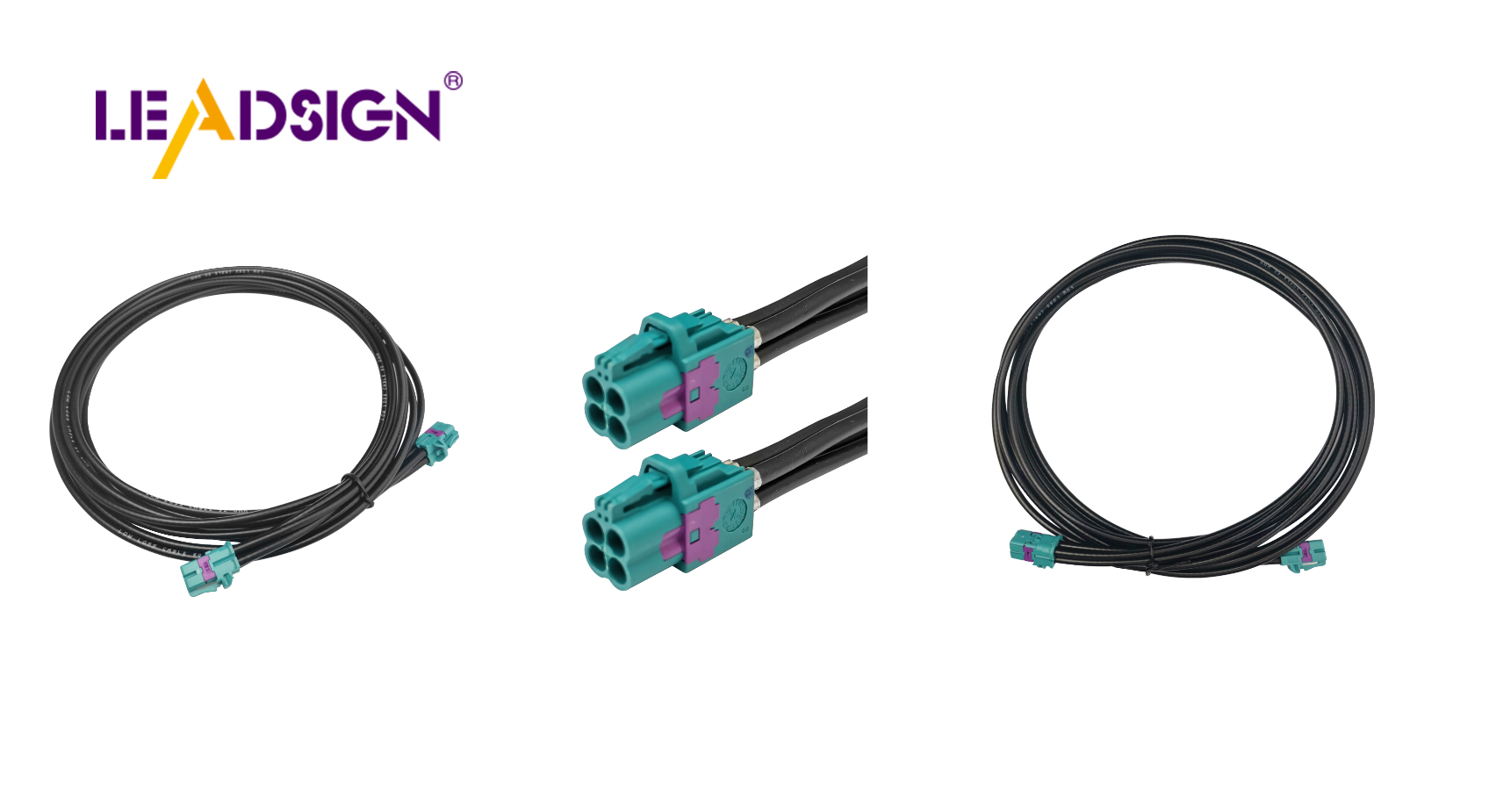

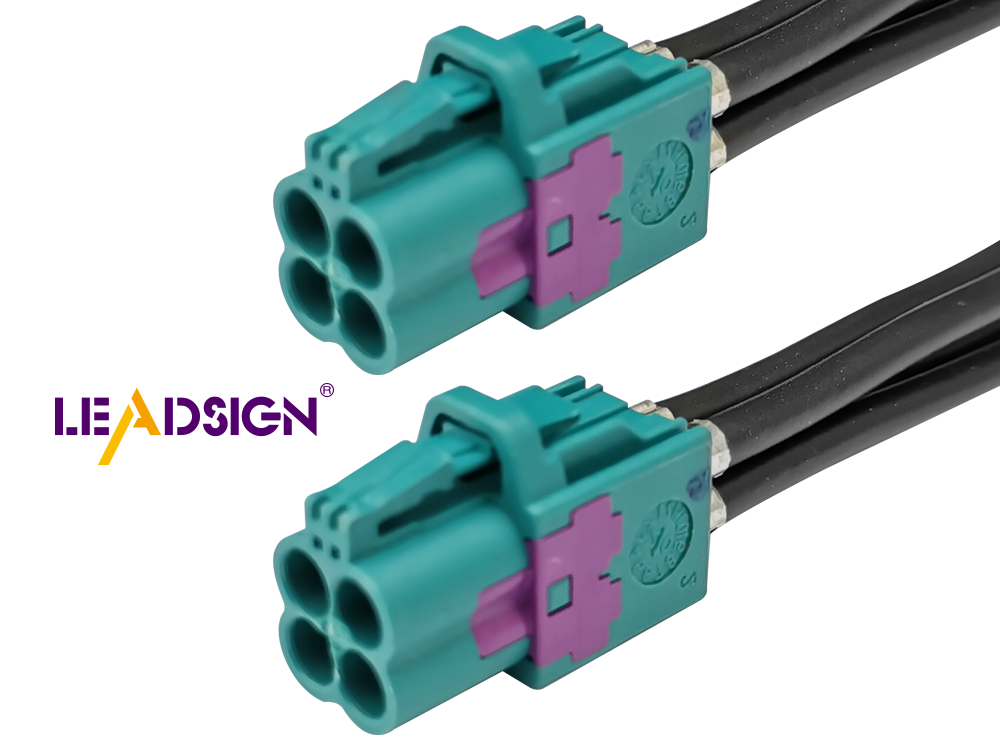

FAKRA Connectors

FAKRA connectors are special for high-speed data in cars. They handle speeds up to 20 GHz. Their small size fits new car tech like cameras. FAKRA connectors give fast, steady connections.

Weather Pack Connectors

Weather Pack connectors stand up to tough weather conditions. They have seals that keep out water, salt, and other bad stuff. Using special grease helps them last longer. They stay connected even in rough environments.

Deutsch Connectors

Deutsch connectors work well in hard situations. They're known for being reliable and easy to use. You see them where shaking and bumps happen a lot in cars. They make sure power flows smoothly between parts.

Things to Think About When Picking Wire Connectors

Picking the right wire connectors for cars is important. Each choice helps wires work well and stay safe.

Power Needs for Car Wires

Current and Voltage Levels

Car wire connectors need to handle certain power levels. Picking the right ones stops them from getting too hot. Too much heat can break them or start fires. Always check what each connector can handle.

Insulation and Material Choices

Insulation keeps car wires safe from damage. The stuff connectors are made of matters a lot. Pick strong materials that last long. Good insulation means connections won't fail quickly.

Weather Conditions

Temperature Handling

Cars face very hot or cold weather. Wire connectors must survive these changes. Heat makes things expand, cold makes them crack. Good connectors stay strong in all temperatures.

Water and Rust Protection

Water and rust can ruin car wire connectors. Wetness and rust make them stop working well. Sealed ones keep water out, lasting longer with rust-proof materials.

Physical Needs

Shake and Hit Resistance

Cars shake and bump a lot, which loosens wires. Pick connectors that don't come loose easily. Strong connections keep power flowing without breaks.

Easy Setup and Fixing

Easy setup saves time and mistakes when connecting wires. Simple designs make it fast to connect securely. Easy-to-use ones make fixing easier too, keeping car wires working well.

Industry Rules and Following Them

Important Rules for Car Connectors

ISO Rules

ISO rules are important in making cars. They make sure wire connectors are safe and good quality everywhere. The ISO/SAE 21434 rule is about keeping cars safe from cyber threats. This rule helps car makers make cars safer from hackers. Using these rules makes car wire connections safer.

SAE Rules

SAE rules help with car building. They talk about many parts of car wire connectors. Engineers use SAE rules to make sure connectors work well in different places. These rules keep connector design and function the same everywhere. Following SAE rules makes sure car wire connectors do what they should.

Why Following Rules Matters in Cars

Safety Checks

Following industry rules keeps cars safe. Good wire connectors stop electric problems. Safe connectors lower fire and accident risks. Makers must follow rules to keep people safe in cars. Safety checks make sure we use the right wire connector types.

Working Well and Lasting Long

Industry rules make sure auto wire connectors work well and last long. Good connectors keep power steady in cars. Rules help them handle tough weather conditions too. Performance checks ensure they work right over time. Following these rules gives us strong car wire connections.

Choosing the right wire connectors for cars keeps them safe. Think about electrical needs, weather, and how they will be used. OEM connections are better quality and last longer. This means less fixing and fewer problems. Ask experts for help with special uses. Focus on performance and following rules to keep things working well. Good connectors make car parts last longer and work better.

See Also

Significance of FAKRA Connectors in Auto Industry Usage

Essentials of HSD Connectors in Auto Sector

Significance of Fakra Connectors in Auto Sector