How to Choose the Right Custom Cable Assembly Manufacturer with LEADSIGN

Choosing the right custom cable assembly manufacturer is crucial for the success of your project. High-quality cables are essential, and LEADSIGN stands out as a leader in creating custom cable solutions. Many companies require specialized cables to address their unique challenges, and LEADSIGN crafts these with expertise and precision. Renowned in the automotive industry for exceptional service and quality, partnering with LEADSIGN ensures you receive superior custom cables that perform exceptionally well.

Knowing Your Customization Needs

What do you need exactly?

Finding the right cables

Picking the correct cable is important. Each project needs different cables. Some might need Custom Cables for special problems. These cables can make things better and stronger. Think about what each project needs. Check the details and pick the best one.

Figuring out length and connectors

Cable length is very important. Too long or short can be bad. Measure well to get it right. Connectors are also crucial. Different uses need different connectors. Ensure they fit the equipment perfectly.

How will you use the cables?

Thinking about where they'll be used

The place affects how cables work. Tough spots need strong cables. Consider where they will be used. Will it be very hot or wet? Pick cables made for those places. This makes sure they last long.

Checking performance needs

Performance matters a lot in picking cables. Good cables give better results. Look at what your project needs. Does it need fast data transfer? Or maybe strong power delivery? Custom Cable Assembly solutions can meet these needs well.

Checking the Environment

What affects cables in the environment?

Thinking about temperature and wetness

Heat and cold can hurt cables. Wet places can make them rust. Pick cables that handle heat and cold well. Choose ones that don't get ruined by water. This helps them work better.

Dealing with chemicals or sunlight

Chemicals and sun can harm cables. Some places have strong chemicals. Sunlight can break them down too. Get cables with special covers to protect them. These covers keep out chemicals. Sun-safe materials stop sun damage, making them last longer.

How to make sure they last and work well?

Picking strong stuff for tough spots

Tough places need strong cables. Strong stuff doesn't wear out fast. Find ones that resist scratches and cuts. Look for thick jackets on cables. These jackets guard against damage, keeping them working.

Testing if they are tough enough

Testing shows if cables are strong. Makers test in labs like real life conditions. They check if they last long and stay strong. Ask how they test the cables you want to use.

Making Sure Quality is Good

What quality rules should be followed?

Important certifications and rules

Quality rules are very important in making cables. Look for stamps like UL, ISO9001, and CSA. These show the maker follows industry rules. A certified maker gives safe, reliable products. Certifications mean they follow strict rules. This means you get high-quality cables.

Checking and testing steps

Checking and testing are key for good quality. Makers need strong steps to check things. Regular checks find problems early. Testing makes sure cables work in different places. Ask how the maker tests their cables. Good makers test for strength and performance. This shows the cables fit your needs.

How to check if a maker is trustworthy?

Looking at old projects and customer reviews

Old projects tell a lot about a maker. See what projects they finished before. Good projects show skill and know-how. Customer reviews give helpful info too. Happy customers mean good service and quality.

"We have had no issues with product quality and have been using the cables you’ve provided for both industrial and commercial lighting applications."

This review shows the maker is steady and reliable.

Checking for steady quality checks

Quality checks keep standards high always. Steady checks make sure every item is good enough. Ask if they have a team just for quality checks. This team watches every step of making stuff. Steady quality checks mean fewer mistakes, better products too! A maker with strong checks gives peace of mind, so you can trust them to give great cables each time.

What Makes a Good Cable Maker?

Why Some Makers Are Better

Knowing the Job Well

Experience is key for cable makers. Many years mean they understand needs well. They can handle tricky projects easily. Long-time makers have done many jobs before. This shows what they can do. For example, working with engineers helps special markets. Good prices show they care about quality and new ideas.

Making Special Products

Top makers offer custom solutions. They make cables fit special needs. Like setting up stock systems to help clients. A system like VMI helps manage supplies well. Makers must change to meet different needs. Modular solutions show this skill too. Checking first samples keeps service good. Being flexible in design and making is important.

How to Check Their Service?

Quick Replies and Talking

Good talk builds trust with customers. Makers should answer questions fast. Quick replies show they care about customers' happiness. Clear talk helps know project needs better. They should explain hard stuff simply too. Regular updates tell clients how things are going along.

Help After Buying and Warranties

Help after buying is important for staying friends long-term with clients! Makers should give full support after sending products out! Warranties make people feel safe using them! Strong warranties mean they believe in their product's worth! If problems happen, fix them fast! Keep helping so products work great always! Trustworthy makers stand by what they sell!

Picking the right cable makers needs thinking about key things. Knowing what you need helps pick the best cables. Checking where they will be used makes sure they last. Quality checks by cable makers are very important. Certifications like UL and ISO9001 show they follow rules. Looking at old projects and reviews shows if they are good. LEADSIGN gives great benefits as a partner. They know cars well and help customers a lot, making them a top choice for custom cables. Trust LEADSIGN for high-quality, special solutions.

See Also

Maximizing the Potential of HSD Cable Assemblies in Technology Today

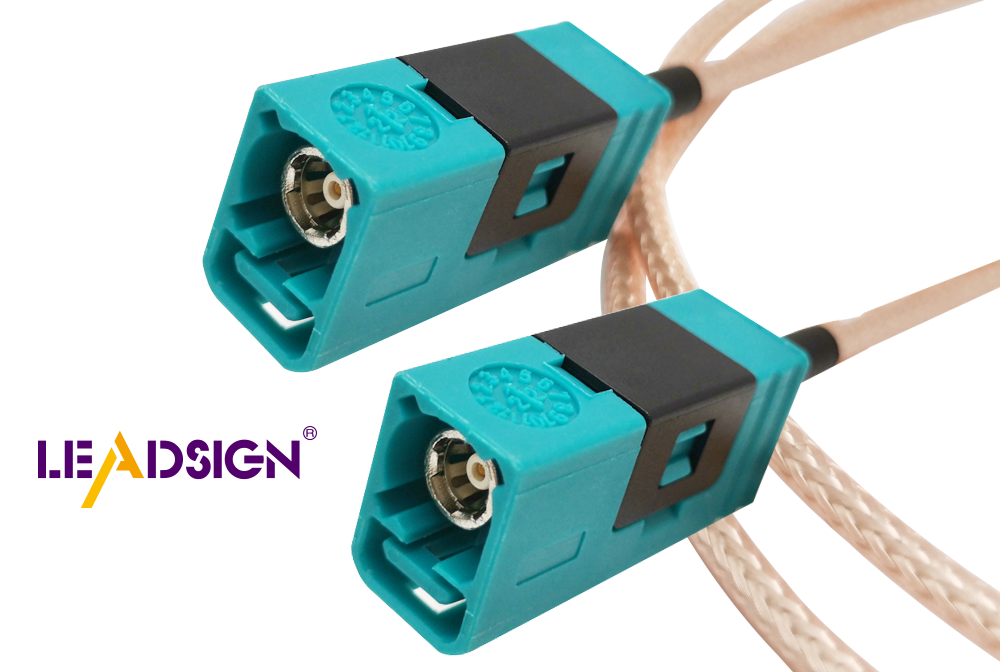

Harnessing the Strength of FAKRA Coaxial Cable Connections

Unlocking the Potential of FAKRA Coaxial Cables