How to Choose PCB Board to Wire Connectors for Automotive Applications

In cars, good connections are key for proper performance. PCB board to wire connectors help send power and data smoothly. These connectors deal with tough conditions like shaking, heat, and bad weather. A bad connector can cause problems in steering or brakes, risking safety. Choosing the right connector makes it strong and reliable. It also keeps your circuit board safe from damage. This choice affects how stable your system works, which is very important.

Key Takeaways

Choose connectors that fit your circuit board's size and shape to maximize space and functionality.

Opt for connectors with strong locking mechanisms to ensure secure connections that withstand vibrations and movement.

Select connectors that can handle the electrical requirements of your car, including current and voltage limits.

Prioritize durability by choosing connectors made from materials that resist extreme temperatures and environmental factors.

Look for connectors with high IP ratings to protect against water, dirt, and rust, ensuring long-lasting performance.

Always verify that connectors meet industry standards and certifications for safety and reliability.

Regularly check and maintain your connectors to prevent issues and ensure optimal performance over time.

Key Things to Think About When Picking PCB Board-to-Wire Connectors

When picking connectors for cars, think about important things. These help the connectors work well in tough conditions and keep your circuit boards safe.

Design Features

Connector size and shape

The connector's size and shape should match your circuit board. Small connectors save space, which is important in cars with limited room. Pick a design that fits well without losing any function.

Locks for secure connections

Cars move and shake a lot. Good locks stop wires from coming loose. Look for connectors with strong locks to keep them steady even when shaken or bumped.

Handling vibration and stress

Shaking can loosen parts or break them. Choose connectors built to handle lots of movement. Strong materials protect your circuit board from damage caused by shaking or pressure.

Electrical Needs

Current and voltage limits

Connectors have limits on how much power they can handle. Make sure the connector matches what your car needs. Too much power can make it overheat or fail.

Clear data signals

In cars, clear signals are needed for parts to talk to each other. Fast data connectors like USBs help send information smoothly without problems. This is key for safety features and entertainment systems.

Working with car power systems

Car power levels often change a lot. Your connectors need to handle these changes without breaking down. Pick ones that work well with your car’s power system.

Durability in Tough Conditions

Handling hot and cold temperatures

Car connectors face very hot or freezing weather. Use ones made from materials that don’t break in extreme heat or cold.

Protection from water, dirt, and rust

Water, dirt, or rust can ruin connections. Waterproof connectors block these things out and keep your board safe in harsh places.

Meeting car industry rules (like ISO or SAE)

Car connectors must follow strict rules to be safe and reliable. Look for ones approved by groups like ISO or SAE so they meet high standards.

By thinking about these points, you’ll pick strong, long-lasting connectors for your car systems. The right choice keeps your boards working safely for a long time.

Learning About PCB Connectors: Types for Car Systems

In cars, knowing about PCB connectors is very important. These connectors help wires and boards stay connected and work well together. Let’s explore the types of PCB connectors and how they fit car needs.

Wire-to-board connectors

Wire-to-board connectors join wires to circuit boards securely. They are great for linking sensors, motors, or other car parts.

Pin headers and receptacles

Pin headers are common PCB connectors. They connect two boards or a wire to a board. This allows power or signals to move easily. Single row pin headers save space in small designs. Dual row pin headers give more connection points without needing much extra room. These connectors are useful and dependable for many car uses.

IDC (Insulation Displacement Connectors)

IDC connectors make connecting wires simple by cutting through insulation to reach the conductor. This makes setup fast and easy without losing quality. In cars, IDC connectors send data clearly and steadily.

Terminal block connectors

Terminal block connectors are strong and flexible for joining wires to PCBs. They work well in systems needing regular changes or fixes.

Screw-type terminal blocks

Screw-type terminal blocks use screws to hold wires tightly in place. This keeps connections steady even with lots of shaking. You can adjust them easily by tightening or loosening the screws, making them handy for cars.

Spring-loaded terminal blocks

Spring-loaded terminal blocks don’t need tools like screw-types do. Springs hold the wires firmly, saving time during setup while keeping connections secure. These are perfect for tight spaces where tools might not fit.

Specialty automotive connectors

Specialty PCB connectors handle tough conditions in cars with special features for strength and safety.

Waterproof connectors

Waterproof connectors keep water, dirt, and grime out of your connections. They’re great for places like under the hood or near wheels where moisture is common. Seals stop water from getting inside and breaking the connection.

High-temperature connectors

High-temperature connectors can handle very hot areas in your car without melting or changing shape. They’re ideal near engines or exhausts where heat levels get high.

By learning about these PCB connector types, you can pick what fits your car best. Whether it’s wire-to-board ones for sensors, terminal blocks for flexibility, or specialty ones for harsh spots, there’s an option that works well.

Common Problems in Car Systems

Car connectors face many hard challenges. Vibrations, heat, cold, and tough weather can hurt how they work. Let’s look at these problems and ways to fix them.

Shaking and Pressure

How shaking affects connectors

Cars shake from engines, bumpy roads, or sudden stops. This shaking can loosen wires or break connections. It might even make signals stop working. Over time, this can cause your system to fail completely. Shaking also harms the circuit board base, causing more issues.

Fixes like strong locks and tough materials

To stop problems from shaking, use stable connectors. Pick ones with strong locks that hold wires tightly in place. Materials are important too. Strong plastics or metals handle pressure better. Good connectors keep your system steady and working well.

Hot and Cold Temperatures

What heat and cold do to connectors

Car connectors deal with very hot engines or freezing weather. Heat can melt them, while cold makes them crack easily. These changes can also harm the circuit board base by making it shrink or grow.

Picking materials for heat and cold

Choose materials that handle heat without melting, like special plastics or metals. For cold places, use flexible materials that won’t crack easily. Some designs let parts expand safely so connections stay strong no matter the temperature.

Weather Problems

Dangers from water, dirt, and chemicals

Cars go through rain, mud, and dirty roads often. Water or dirt can get into connectors and ruin metal parts inside them. This can mess up signals or cut off power completely.

Why IP-rated connectors help

Use waterproof connectors with high IP ratings to block water out. Dustproof ones keep dirt away too. These features protect your system even in bad conditions.

By solving these problems early on, car systems will work better for longer times.

Best Practices for Picking and Installing PCB Connectors

Choosing the right PCB connector is very important. It helps your printed circuit board work well in tough conditions. Let’s go through the steps simply.

Tips for Choosing

Checking what your system needs

First, know what your system requires. Think about where the circuit board will be used. Will it face heat, shaking, or water? For cars, strong connectors are a must. Also, think about power needs. Does it need to handle high electricity or fast data? For small spaces, pin header connectors are great. If you’re linking many boards, use board-to-board connectors.

"Picking the right PCB connector is key to making devices work better and last longer." – Expert in PCB Connectors

Match the connector to your needs to avoid problems later.

Picking certified connectors

Certifications are important too. Look for ones tested by groups like ISO or SAE. These tests show they are safe and strong enough for use. In cars, certified connectors protect your printed circuit boards and follow rules. This step is part of any good PCB design guide.

Installation Steps

Aligning and securing connections properly

When installing, align everything carefully. Bad alignment can cause weak signals or damage parts like the ground plane. Make sure pins fit into holes correctly on things like pin header connectors. Use locks or screws to keep them steady so they don’t move during vibrations.

Checking and maintaining regularly

After installing, check often for damage or loose parts. Look at the ground connections closely since they help keep systems stable. Clean dirty parts if needed and replace broken ones quickly. Following these simple steps keeps systems working longer.

By picking good connectors and installing them right, you make sure your system stays reliable and works efficiently over time.

New Ideas in Connector Technology for Cars

Car connectors are getting better and more advanced. They are now smaller, smarter, and stronger than before. These changes help make car systems work well even in tough places. Let’s look at the new ideas shaping the future of PCB connectors for cars.

Smaller and High-Density Connectors

Why they help modern car designs

New cars need smaller parts to save space. Tiny connectors do the same job as big ones but take up less room. This makes them great for tight spaces in cars. Engineers can also add more parts without losing any function.

High-density connectors go further by giving many connection points in a small size. For example, pin header connectors are popular for saving space. Single-row ones use little room, while dual-row ones give more connections without needing extra space. These features make them perfect for linking sensors or control units in today’s cars.

Small connectors are easy to install too. Their size makes setup faster and simpler. Even though they’re tiny, they stay strong and keep working well under hard conditions.

Smart Connectors with Extra Features

Examples of smart tools built into connectors

Smart connectors are changing how car systems work. These have special tools inside that make them better. Some even check their own health while working.

Imagine a connector that warns you if it becomes loose or unstable. This helps fix problems early before they get worse. Smart connectors also keep important systems like brakes safe by staying connected all the time.

Pin header connectors often work well with these smart tools because of their design. By using these advanced types, you can build systems that fix themselves and stay efficient longer.

Better Materials and Coatings

Stronger against damage from wear or weather

The materials used in making connectors matter a lot. New coatings now protect them from rust, dirt, or chemicals better than before.

For instance, modern coatings stop moisture from ruining connections near engines or under cars where conditions are harshest. They also improve how electricity flows through the connector to keep signals clear and steady.

Stronger materials mean these parts don’t break easily from shaking or heat changes either. Pin header connectors benefit greatly from these updates as they become tougher for both power delivery and data transfer tasks.

These improvements make connectors last longer too by reducing wear over time so replacements aren’t needed often anymore—saving money while keeping everything running smoothly!

By using these new ideas, you’ll create car systems that are small yet powerful! Whether choosing pin headers for flexibility or smart options packed with features—you’ll ensure your designs remain top-notch always!

Picking the right PCB connectors is very important for cars. Focus on things like design, power needs, and toughness. These connectors keep circuit boards safe from shaking, heat, and bad weather. Always check with makers to ensure they fit your board. Test them in real-life situations to make sure they work well. Learn about new designs and stronger materials too. By doing this, you’ll create systems that work better and last longer.

FAQ

What do PCB board-to-wire connectors do in cars?

These connectors join wires to circuit boards. They help send power and data smoothly. They also handle shaking, temperature changes, and dirt or moisture. This keeps the system strong and working well in hard conditions.

How can I pick the right connector size?

Choose a connector that fits your circuit board properly. Small ones are good for tight spaces. Bigger ones give more connection points if needed. Match the size to what your system needs.

Why is it important for car connectors to resist shaking?

Cars move a lot, which can loosen connections or break parts. Connectors that resist shaking stay secure and protect your board from damage. This helps the system work even on rough roads.

What materials should connectors have for hot or cold weather?

Use connectors made of materials that won’t melt in heat or crack in cold. Special plastics and metals work best for handling extreme temperatures. These also keep ground connections safe from harm.

Why are waterproof connectors useful in cars?

Waterproof connectors stop water, dirt, and chemicals from getting inside. They’re great for places exposed to rain, mud, or engine fluids. These keep your circuit board safe and last longer.

What does an IP rating mean for connectors?

IP ratings show how well a connector blocks dust and water. Higher numbers mean better protection against tough conditions. In cars, these protect ground connections from failing due to bad weather.

How can I install PCB connectors correctly?

Line up the connector with the circuit board carefully when installing it. Use locks or screws to hold it steady so it doesn’t move around later. Check them often to fix problems early and keep things stable.

What’s the difference between pin headers and terminal blocks?

Pin headers connect wires directly to boards and save space in small designs. Terminal blocks let you adjust easily, making them good for systems needing frequent changes or fixes.

Are there special connectors for fast data transfer?

Yes! Connectors like USBs are made for quick data movement without errors. These are perfect for car entertainment systems or safety features needing clear signals.

How do I take care of my car’s PCB connectors over time?

Check your connectors often for dirt, damage, or loose parts. Clean them if dirty and replace broken ones quickly. Pay close attention to ground connections since they keep everything running smoothly.

See Also

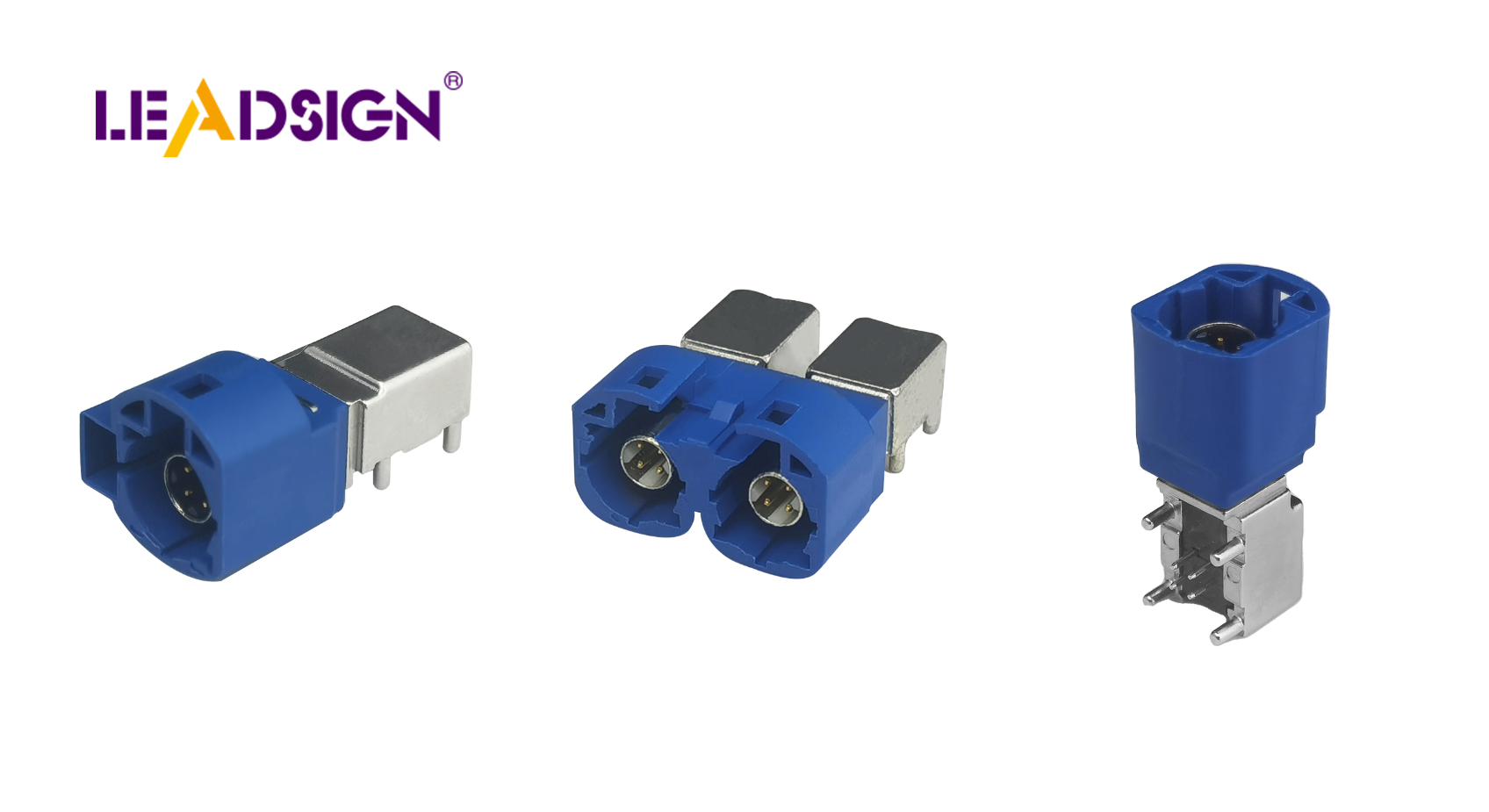

Exploring FAKRA PCB Connectors' Benefits for Automotive Use

Why FAKRA PCB Connectors Are Essential for Vehicles

FAKRA PCB Connectors: Key to Automotive Communication

Improving Vehicle Communication Through FAKRA PCB Connectors