How to Choose and Install Automotive Electrical Connectors Types

Choosing the right automotive electrical connectors types is crucial for your vehicle's performance and safety. These connectors facilitate the transmission of electric signals to various components, ensuring that lights, brakes, and steering systems function properly. High-quality connectors prevent electrical issues and reduce repair costs, contributing to overall vehicle safety. Proper installation is essential to maintain strong connections, which in turn extends the lifespan of your car's electrical components. By selecting the appropriate connectors, you can keep your vehicle in optimal condition, minimizing breakdowns and ensuring a smooth driving experience.

Understanding Automotive Electrical Connectors Types

Automotive electrical connectors types are important for your car's electrical system. They help electric signals and power move smoothly through circuits. Knowing about different connectors helps you pick the right one.

Common Types of Connectors

Blade Connectors Blade connectors are flat metal pieces that fit into slots to connect. They are common in cars because they are simple and dependable. These work well for low to medium power needs.

Bullet Connectors Bullet connectors look like cylinders and fit into matching sockets. They give a strong connection and are easy to unplug if needed. These are good when you need to disconnect often.

Pin Connectors Pin connectors can be used in many ways. They handle high power, like for headlights or starters. Their design sends both power and data well.

Uses and Applications

Power Distribution Connectors send power to different car parts. They make sure things like lights and ignition get the power they need.

Signal Transmission Connectors also carry data between electronic parts, which is key for GPS, music, and safety systems.

Pros and Cons of Each Type

Durability

Blade Connectors: Strong against shaking, great for cars.

Bullet Connectors: Durable but might wear with lots of use.

Pin Connectors: Very strong, especially with high power.

Ease of Installation

Blade Connectors: Simple slide-in installation.

Bullet Connectors: Need careful alignment but easy to use.

Pin Connectors: Harder to install; needs proper fit.

Knowing these automotive electrical connectors types helps you choose wisely. Picking the right connector keeps your car's electrical system working well.

Picking the Right Connector

Choosing good car connectors is important for your car's safety. Think about a few things to make sure they work well with your car. Choosing good car connectors is important for your car's safety. Think about a few things to make sure they work well with your car.

Things to Think About

Car Details

Your car's details help you pick the right connectors. Check how much power your car parts need. Big power needs, like headlights, use pin connectors because they handle more power. Knowing this stops problems. right connectors

Connector Shape and Size

Connector shape and size matter for fitting right. Pick ones that fit in your car's space. Blade connectors are small and fit well in tight spots. Measure space and compare it to connector size.

Pin Number and Setup

Pin number and setup are key when picking connectors. Make sure the connector has enough pins for all wires. This keeps signals and power lines connected right. Wrong pins can cause problems.

Fitting with Current Systems

Matching Wire Thickness

Match the connector to wire thickness for a strong link. The connector should fit the wire size in your car. Wrong size can lead to bad links or electric troubles.

Handling Weather Conditions

Weather handling matters when picking connectors too. Think about what your car faces, like rain or heat. Strong weatherproof connectors stop damage and last longer.

By thinking about these things, you pick good connectors that boost your car's safety and performance. Smart choices keep your car's electric system working well for smooth driving.

Installation Process

Putting in automotive electrical connectors types right is key. It makes sure the connection works well. Follow these steps to get your wires ready and connect them properly.

Getting Wires Ready

Before you connect, get the wires ready. This helps make a strong connection that lasts.

Stripping and Cleaning

Take Off Wire Cover: Use a wire stripper to peel off about a quarter-inch of cover from each wire end. This shows the metal inside, which is needed for a good link.

Clean the Ends: After stripping, clean the bare wire ends with a cloth or brush to remove dirt or rust. Clean wires help electricity flow better and stop connection problems.

Crimping Steps

Crimping is how you attach connectors to wires strongly.

Pick Right Crimp Tool: Choose a crimp tool that fits your connector type snugly so it doesn't break.

Crimp Connector On: Put the stripped wire into the connector and use the crimp tool to squeeze it tight onto the wire so it stays put.

Hooking Up Connectors

After prepping wires, hook up connectors carefully for good alignment and security.

Aligning Correctly

Line Up Connectors: Make sure male and female parts match up right to avoid bad connections.

Check Fit: Before locking, see if they fit smoothly together for a stable connection.

Securing Connection

Lock Connectors In Place: Many have locks; use them to keep connections tight against shakes or moves.

Look Over Connection: Check visually for gaps or misalignments that might weaken it.

Making Sure It's Secure

A secure fit keeps connections working long and well.

Testing Connection Strength

Do Continuity Test: Use a multimeter to check if electricity flows without breaks.

Test Stability: Gently pull on wires; they shouldn't come loose easily if secure.

Adding Protection

Use Heat Shrink Tubing: Slide tubing over connection, heat it for insulation against wetness or rust.

Wrap with Tape: Add electrical tape around it for extra protection from dust or debris.

By following these steps, you can install automotive electrical connectors types well, boosting your vehicle's electric system performance for safe driving.

Picking the right car connectors is key for safety and performance. Connectors help your car's electric parts talk to each other. Check and clean them often to avoid expensive fixes. Use heat shrink tubing to protect them from weather damage. Following good steps makes your car work better and safer. Good connectors are needed for smooth electric signals, keeping your car running well and safely.

See Also

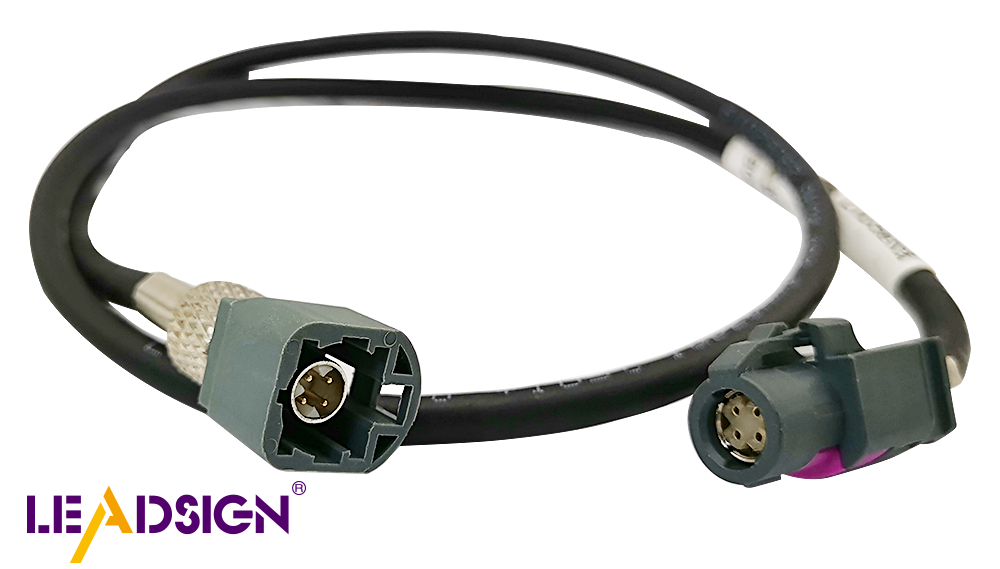

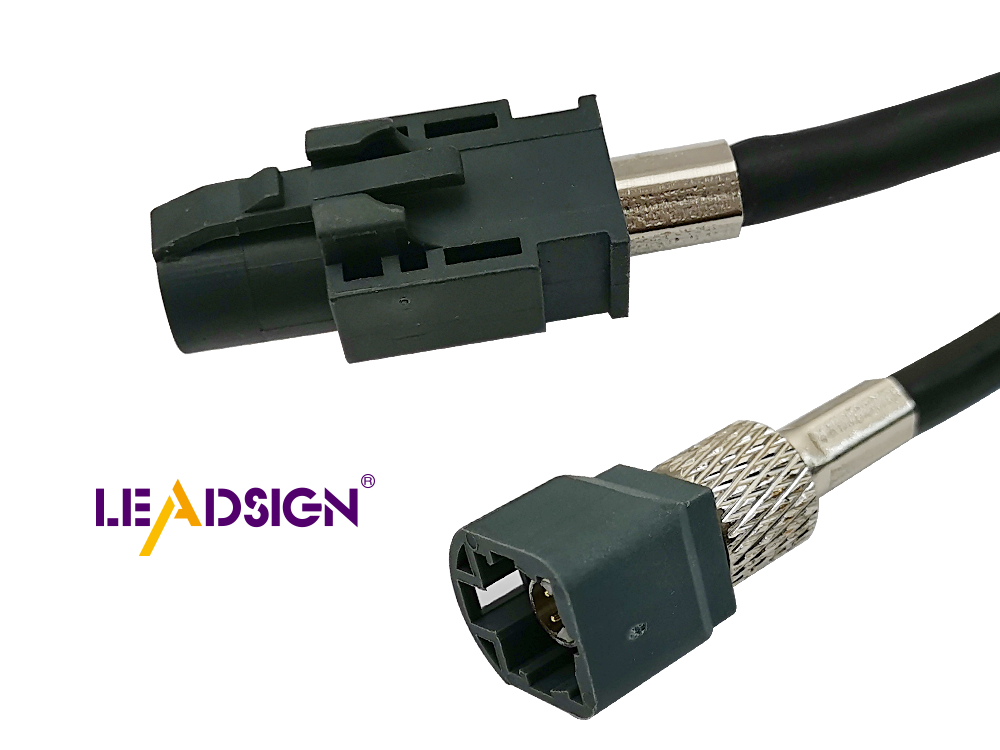

Understanding HSD Connectors Essential for Automotive Applications

Why FAKRA Connectors Matter in Automotive Technology

Benefits of HFM Connectors for Automotive Performance