Simple Steps to Care for Automotive Plugs and Connectors

Taking care of automotive plugs and connectors is important. They help keep the electrical system working well and safely. Ignoring them can cause problems like overheating or failures. Regular care of automotive plugs and connectors stops these issues and makes the system last longer. Simple steps can save money and keep your car running well.

Key Takeaways

Regularly inspect automotive connectors for damage and corrosion to prevent costly repairs and ensure reliable performance.

Use the right tools, such as connector removal tools and dielectric grease, to maintain and install connectors effectively.

Choose the appropriate type of connector based on its application to enhance durability and functionality in your vehicle.

Clean connectors properly by disconnecting the battery and using contact cleaner to remove dirt and grime, ensuring they work efficiently.

Protect connectors from corrosion by using dielectric grease and storing them in a dry, cool place to extend their lifespan.

Follow proper installation techniques, including crimping and soldering, to create strong and secure connections that prevent electrical issues.

Address loose or broken connections promptly to avoid bigger electrical problems and maintain your car's overall performance.

Getting Ready to Work on Automotive Plugs and Connectors

Good preparation is key to taking care of connectors. Learn about the types and gather the right tools. This makes the job easier and more effective.

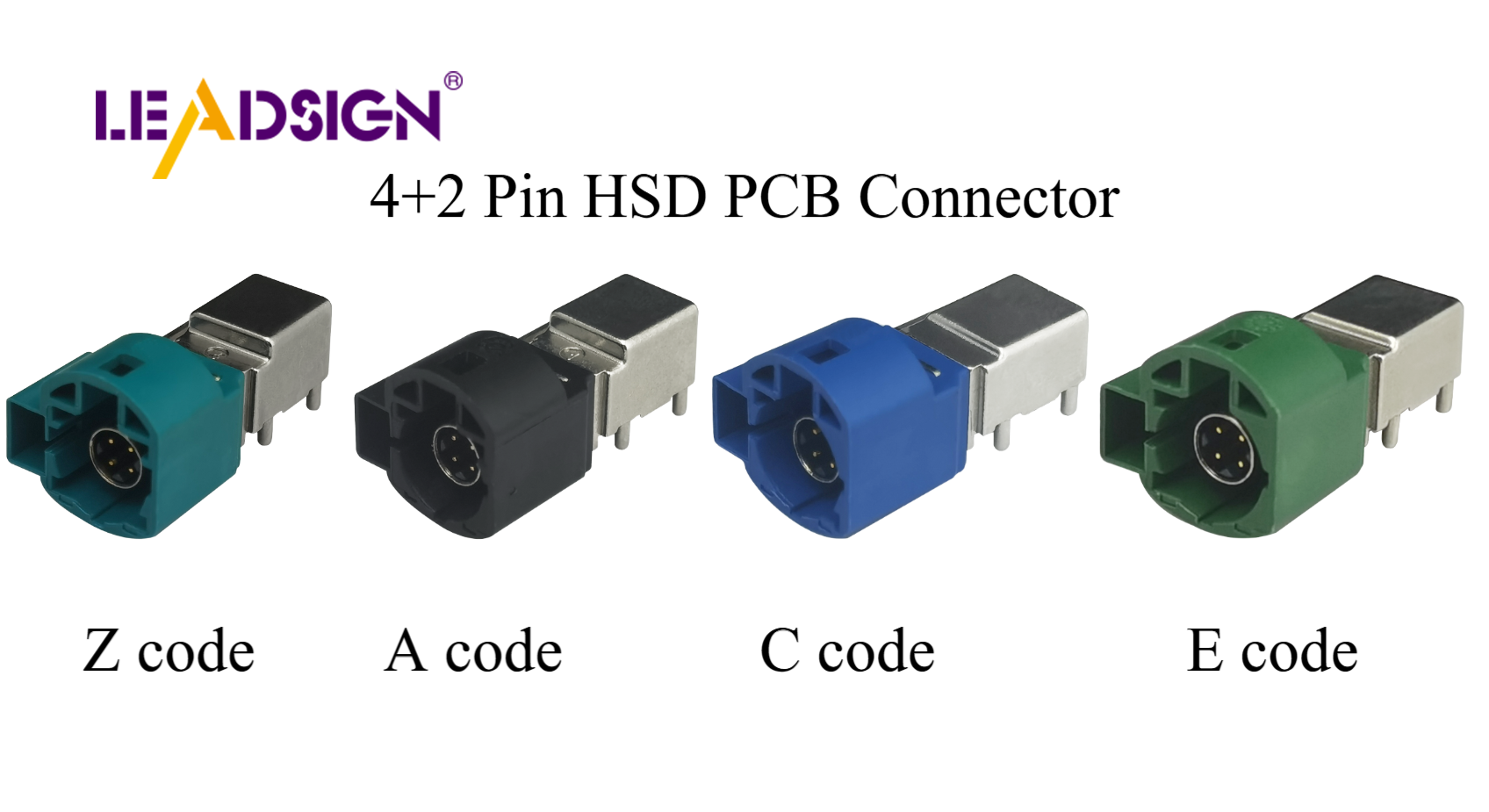

Knowing Different Types of Connectors

There are many kinds of connectors, each with a purpose. Knowing them helps you pick the right one for your car. For example:

Pin/Pigtail Connectors: These send signals between car parts like the engine and radio. They help parts work together smoothly.

Wire Connectors: These carry signals to make car electronics work. Without them, parts won’t connect, causing problems.

Weather Pack Connectors: These are tough and resist heat, chemicals, and water. They are great for engines and outdoor areas.

Learning about these types helps you choose the best connectors for your car. This keeps it working well and lasting longer.

Tools You Need for the Job

Having the right tools makes working on connectors easier. Here are some tools you’ll need:

Connector Removal Tools: These help take out pins without breaking them.

Crimping Tools: These make sure wires stay tightly connected.

Soldering Kit: Use this to make strong, lasting connections.

Cleaning Supplies: Clean dirt and rust off connectors to keep them working.

Dielectric Grease: This grease protects connectors from water and rust.

With these tools, you can fix and install connectors easily and correctly.

Tips for Maintaining Connectors

Caring for automotive connectors helps them last longer and work well. Use these tips to avoid expensive repairs and keep your car running smoothly.

Check for Damage and Corrosion Often

Check connectors regularly to find problems early. Look for broken wires or loose pins. Corrosion looks like green or white buildup on metal parts. Fixing corrosion quickly stops more damage and keeps connections strong.

Experts in Automotive Maintenance say, "Caring for connectors is important for your car's electronics."

Inspect connectors every few months or during regular car check-ups. This helps you fix small issues before they become big problems.

How to Clean Electrical Connectors

Cleaning keeps connectors working well. Dirt and grease can cause problems. Follow these steps to clean them:

Disconnect the Battery: Always unplug the battery to stay safe.

Use Cleaning Tools: Special tools clean connectors without breaking them.

Spray Contact Cleaner: Use this to remove dirt and grime.

Dry Completely: Make sure everything is dry before reconnecting.

Don’t use rough materials that might scratch the connectors. Clean connectors last longer and work better.

Protecting Connectors from Corrosion

Corrosion is bad for connectors. Protect them with these tips:

Use Dielectric Grease: This grease blocks moisture and stops rust. Keep it off metal parts.

Store Safely: Keep connectors in a dry, cool place. Use sealed boxes to block dust and water.

Pick Weatherproof Connectors: In tough conditions, use weatherproof types like Weather Pack Connectors. They resist water, heat, and chemicals.

Experts in Automotive Maintenance advise, "Follow expert tips to store connectors safely."

These steps protect connectors from rust and keep them working for years.

Best Ways to Install Automotive Plugs and Connectors

Installing connectors the right way keeps your car safe and working well. Following proper steps reduces mistakes and makes connectors last longer. Here’s how to get ready and install them correctly.

Getting Wires and Connectors Ready

Good preparation is key for a successful installation. First, check wires and connectors for damage. Look for broken wires, bent pins, or rust. Damaged parts can cause bad connections or failures.

Follow these steps to prepare:

Remove Wire Insulation: Use a wire stripper to carefully take off the covering.

Clean Connectors: Make sure connectors are clean. Use a contact cleaner to remove dirt.

Match Sizes: Check that the wire size fits the connector. Wrong sizes can cause loose connections.

Taking time to prepare helps make strong and reliable connections.

Picking the Right Connector for Your Car

Choosing the right connector is very important. Using the wrong one causes many electrical problems. To avoid this, think about these things:

Where It’s Used: For wet or hot areas, use weatherproof connectors. These protect against water and rust.

Wire Size: Make sure the connector fits the wire snugly.

Purpose: Know what the connector is for. Pin connectors send signals, while weatherproof ones work in tough conditions.

Picking the right connector helps it work better and last longer.

Crimping and Soldering Tips

Crimping and soldering attach wires to connectors securely. Each method has its own benefits. Doing them right makes connections stronger.

Crimping:

Use the Right Tool: Pick a crimping tool made for your connector.

Place the Wire: Put the stripped wire into the connector.

Press Firmly: Squeeze the tool tightly to secure the wire.

Crimping is fast and creates a strong hold.

Soldering:

Heat the Area: Use a soldering iron to warm the wire and connector.

Add Solder: Melt solder onto the joint for a solid connection.

Let It Cool: Wait for the solder to cool before touching it.

Soldering makes a strong bond, great for areas with lots of movement.

For extra protection, cover the joint with heat shrink tubing. This keeps out water and protects from wear.

Pro Tip: Always ground properly during installation. Good grounding stops electrical problems and keeps things safe.

By learning these steps, you can install connectors easily and keep your car’s electrical system working well.

Troubleshooting Common Problems with Automotive Plugs and Connectors

Knowing how to fix issues with automotive plugs and connectors keeps your car's electrical system working well. Finding and solving problems early saves money and keeps everything running smoothly. Here are simple steps to handle common problems.

Fixing Loose Connections

Loose connections can cause flickering lights or parts not working. This happens when pins or terminals don’t connect properly. To fix it:

Check the Connector: Look for bent or loose pins. Use pliers to straighten them gently.

Tighten the Connection: Push the connector in firmly until it locks in place.

Test It: Turn on the car’s electrical system to see if it works.

Pro Tip: Check your car’s connectors during regular maintenance to catch loose ones early.

Fixing loose connections quickly stops bigger problems and keeps your car running smoothly.

Repairing or Replacing Broken Connectors

Broken connectors, like cracked covers or damaged pins, can stop electricity from flowing. If you find these problems, decide to fix or replace the connector. Follow these steps:

Look at the Damage: See if it’s a small issue, like a loose pin, or a big one, like a cracked cover.

Fix Small Problems: Use tools like crimpers or soldering kits to repair it. Replace broken pins or wires if needed.

Replace Badly Broken Connectors: If it’s too damaged, get a new connector that matches your car.

Expert Insight: "Flickering lights or bad sensor readings often mean a pin problem. Fixing it early avoids bigger issues."

Fixing or replacing broken connectors keeps your car’s electrical system strong and reliable.

Finding Electrical Problems

Electrical problems, like signals cutting out or not working, can be tricky to find. These issues often come from bad connections or faulty connectors. Use these steps to figure it out:

Look for Visible Problems: Check for rust, dirt, or damage on connectors. Clean or replace them if needed.

Test the Circuit: Use a multimeter to check voltage and connections. This helps find the problem spot.

Adjust Connections: If the problem continues, fix the connector ends or improve cable protection.

Pro Tip: Label wires during repairs to make putting them back easier.

Finding electrical problems takes time and focus. Fixing the main issue gets your car’s electrical system working again.

Looking after plugs and connectors helps your car work well. Check them often, clean them, and install them correctly. These steps keep them in good shape. Doing this improves your car’s performance and makes the electrical system last longer. It also saves money and keeps driving safe and reliable. Start caring for your connectors now for a strong and problem-free system.

FAQ

Why is fixing car electrical connectors important?

Fixing damaged connectors keeps your car’s electrical system working well. Bad connectors can cause problems like flickering lights or parts not working. Ignoring these issues might leave you stuck. Fixing connectors is simple and saves money compared to replacing wires.

What do electrical connectors do in a car?

Connectors help car parts talk to each other and work together. They make sure systems like lights, sensors, and radios run smoothly. Knowing their job helps you pick the right ones for your car.

Why is picking the right connector important?

The right connector keeps your car running well. It handles dirt, water, and shaking without breaking. Using the wrong one can cause bad connections, failures, and expensive repairs.

How can I stop connectors from rusting?

Rust weakens connectors and stops electricity from flowing. To stop rust, use dielectric grease to block water, but keep it off metal. Store connectors in dry boxes to keep out dust and water. Use weatherproof connectors for tough conditions.

How should I store car electrical connectors?

Good storage keeps connectors working longer. Pick a safe spot and check them often. Use sealed boxes to keep out dust and water. Always buy real parts to make sure they fit and work well.

How often should I check my car’s connectors?

Check connectors every few months or during regular car check-ups. Look for rust, wear, or loose parts. Regular checks catch small problems before they become big ones.

What tools do I need to fix connectors?

You’ll need tools like connector removers, crimpers, and a soldering kit. Cleaning supplies like contact cleaner and dielectric grease are also helpful. These tools make fixing and installing connectors easier.

Can I clean connectors myself?

Yes, you can clean connectors with the right tools. First, unplug the battery to stay safe. Use contact cleaner to remove dirt, and let them dry before reconnecting. Don’t use rough materials that might scratch them.

What are signs of a bad connector?

Signs include flickering lights, parts not working, or random electrical problems. You might also see rust, bent pins, or loose parts. Fixing these problems early stops bigger damage.

How does caring for connectors save money?

Taking care of connectors stops expensive repairs by catching problems early. Clean connectors last longer and prevent electrical failures. This saves money and keeps your car running well.

See Also

Why Fakra Connectors Matter in Today's Vehicles

Significance of FAKRA Connectors in Car Technology

Enhancing Vehicle Data Flow with Advanced Connectors