Car Wire Connector Types: Essential Knowledge for Vehicle Maintenance

Knowing different car wire connector types is crucial for fixing cars. These connectors play a vital role in ensuring the smooth operation of your car's electrical components. The automotive industry, valued at $17 billion in 2021, is projected to grow by 5.8% annually until 2026. With the advancement of automotive technology, the demand for more reliable car wire connectors is increasing. These connectors facilitate the connection of electrical ends and enable the proper functioning of new safety features. By familiarizing yourself with various car wire connector types, you can enhance your car repair skills and easily identify any issues.

Basics of Car Wire Connectors

What are Car Wire Connectors?

Definition and Purpose

Car wire connectors are key parts in a car's electrical system. They join different electrical pieces, helping power and signals move well in the car. Without them, the car's electrical system wouldn't work right. Automotive Electrical Connectors are made to fit car needs, giving strong connections that last through daily use.

Common Materials Used

The stuff used in these connectors affects how they work and last. Usually, they're made from plastic, metal, and ceramic. Each has its job:

Plastic: Used often because it's light and cheap.

Metal: Picked for high-power uses due to good conductivity.

Ceramic: Best for hot places as it handles heat well.

These materials help connectors deal with changes like temperature shifts and wetness.

Importance in Vehicle Maintenance

Role in Electrical Systems

Car wire connectors keep your car's electrical systems working. They link everything like the battery, lights, sensors, and music systems. Keeping these connectors clean ensures all parts get needed power to work well. This is crucial for modern cars that depend on electronics.

Impact on Vehicle Performance

Your car's performance can suffer if wire connectors are bad or rusty. This can cause problems like dim lights or sensor issues. Checking these connectors often can stop such problems, making sure your car runs smoothly. Knowing their importance helps you keep your vehicle safe and performing well.

How Car Wire Connectors Changed Over Time

First Designs

Early Uses and Ideas

Long ago, car wire connectors were very simple. They used cloth-covered wires to join parts. These early connectors worked but weren't fancy like today's. They mainly linked the battery to important parts like lights and the engine starter.

New Technology Changes

As technology got better, so did car wire connectors. New materials and ways of making them improved their use. Cloth wires changed to stronger stuff like special plastics. These new materials made connectors last longer and work better in different situations. This helped cars have more complex electrical systems.

Today's Smart Connectors

Modern Trends

Now, car wire connectors are very advanced. They fit electric and hybrid cars well. These connectors handle cool features like music systems, GPS, and safety gadgets. Strong materials help them stand heat and rust, keeping cars working well.

What’s Next?

In the future, car wire connectors will keep getting better. As cars change, new connector ideas will come up too. We’ll need connectors for self-driving cars and better connections. Future ones might be smart with real-time checks and save energy better. Knowing these changes helps you fix modern cars easily.

Types of Car Wire Connectors

Knowing car wire connector types helps in fixing cars. Each type has a special job and benefits. Let's look at some common connectors you might see.

Pig Tail Connectors

Features and Benefits

Pig Tail Connectors are often used in cars. They join wires to parts well. These connectors are easy to use and connect strongly. You can add them to old wires fast, great for quick fixes. Their design stops electrical problems, keeping connections stable.

Common Applications

Pig Tail Connectors are in lights and low-power uses. They connect headlights, taillights, and inside lights easily. DIY fans like them for car projects because they’re simple.

Bullet Connectors

Features and Benefits

Bullet Connectors make connecting and disconnecting wires easy. Their round shape fits tightly, stopping loose connections from shaking. These connectors last long and handle medium power, good for many car uses.

Common Applications

Bullet Connectors are used where wires need frequent changes. They’re found in speakers, power windows, and other electronics. Their design keeps connections safe but easy to fix or swap out.

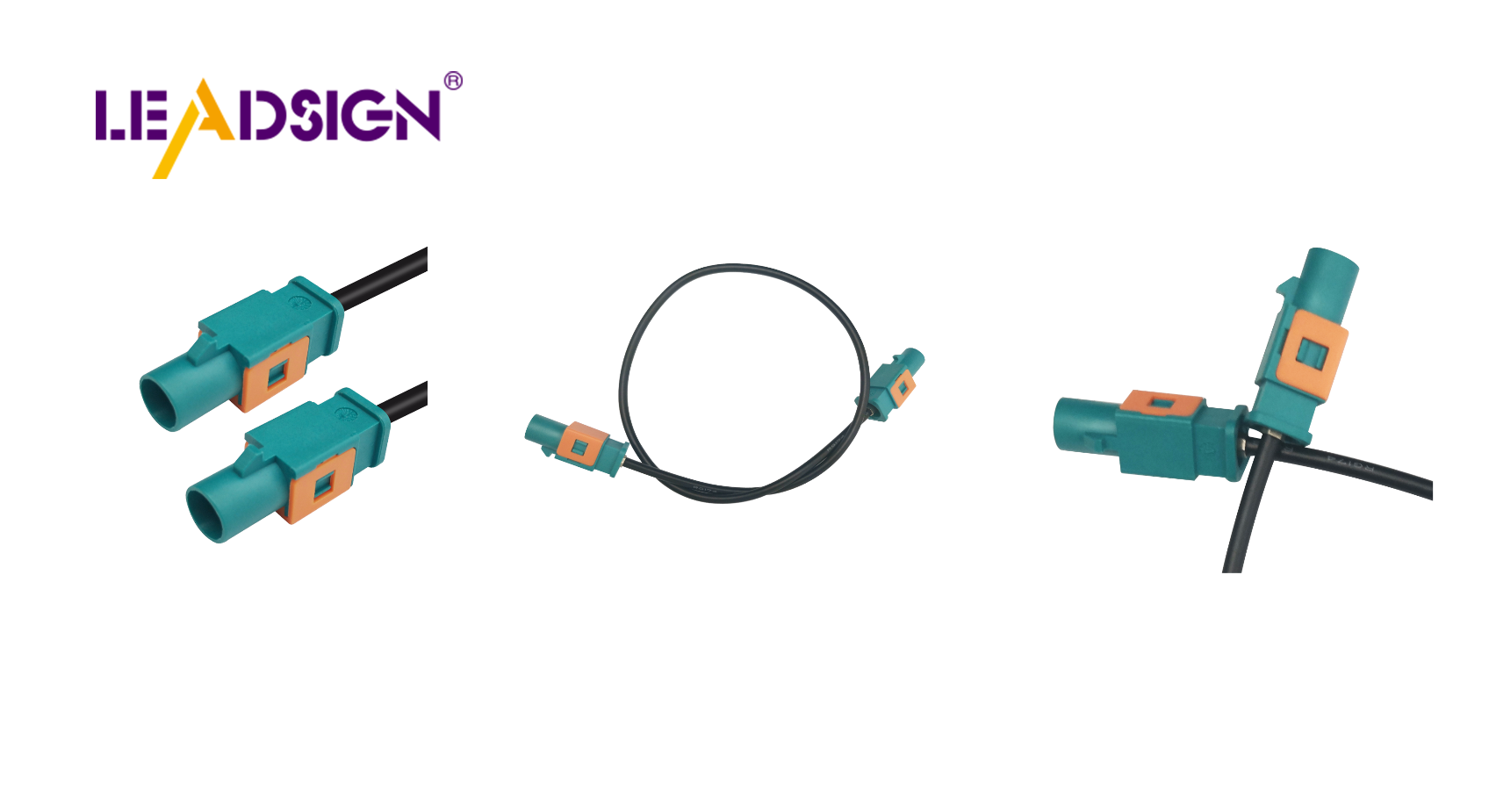

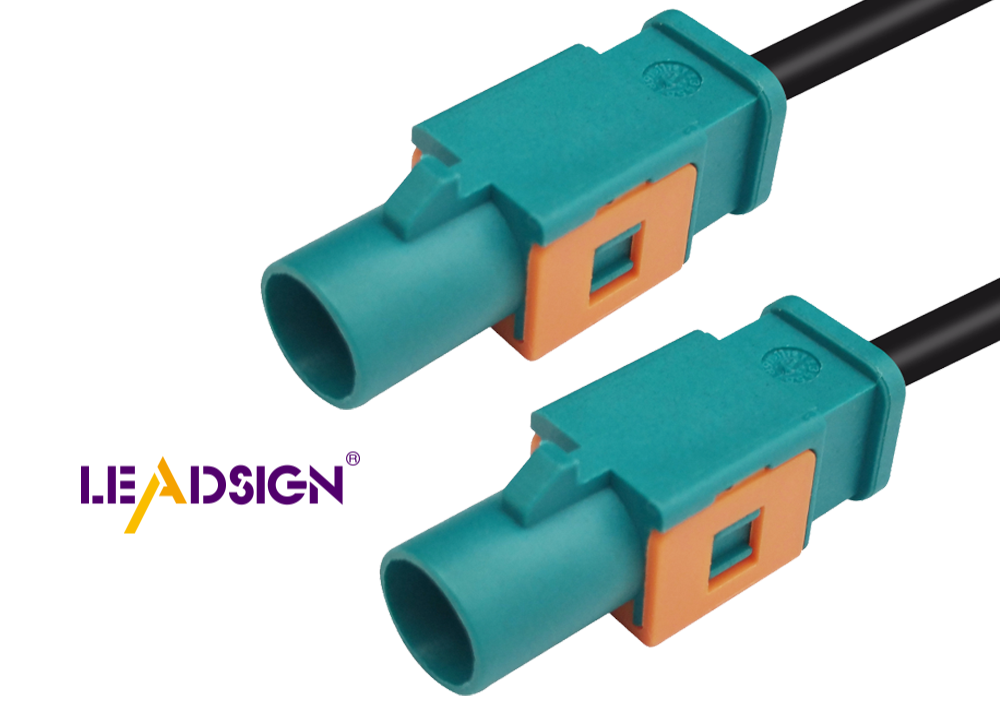

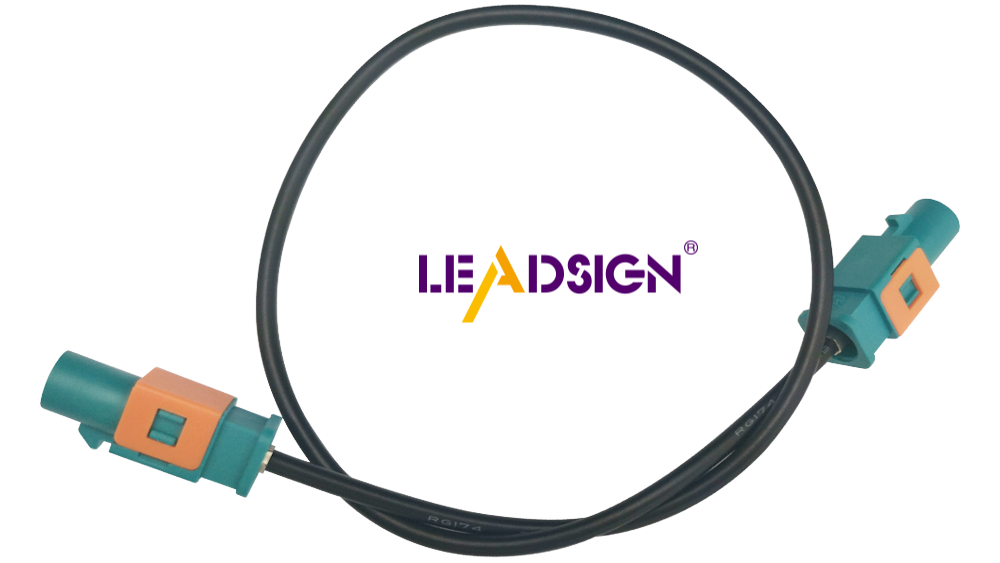

FAKRA Connectors

Features and Benefits

FAKRA Connectors work with high-frequency car systems. They meet strict car rules for safe connections. These have double locks for extra safety when put together. They're strong against tough weather conditions.

Common Applications

FAKRA Connectors are in advanced car systems like radios, GPS, and infotainment setups. They handle lots of data well, perfect for new cars with fancy electronics.

By learning about these connectors, you improve your car-fixing skills. Each type has its own perks to keep your car's electric parts working right.

Installation Techniques and Best Practices

Getting Ready to Install

Needed Tools

Before starting, gather all tools you need. The right tools make things easier:

Wire Strippers: Take off wire covers.

Crimping Tool: Attach the connector to the wire.

Screwdriver: Pick the right one for your connectors.

Multimeter: Check if wires are connected well.

Heat Gun: Use for shrinking tubes.

Staying Safe

Safety is very important with electrical work. Follow these steps to stay safe:

Disconnect the Battery: Always unhook the car battery first.

Wear Safety Gear: Put on gloves and glasses for protection.

Work in a Fresh Air Place: Make sure air moves around well.

Avoid Wet Areas: Stay dry to avoid shocks.

Check Connections Twice: Look over connections before reattaching the battery.

Easy Installation Steps

Joining Wires

Joining wires right is key for good electricity flow. Do these steps:

Strip the Wire: Remove about half an inch of cover from wire ends.

Put Wire in Connector: Push wire into connector till it hits metal part.

Crimp Connector: Squeeze connector onto wire tightly with crimping tool.

Test Connection: Use multimeter to see if connection works.

Keeping Connectors Secure

After joining wires, keep connectors steady:

Use Heat-Shrink Tubing: Slide tubing over joint and shrink it with heat gun for safety.

Tidy Up Wires: Keep wires neat to stop tangles or mix-ups.

Hold with Cable Ties: Tie wires down so they don’t move around much.

Look Over Work Again: Check everything before hooking up battery again.

By using these tips, your car's electrical parts will be safe and strong. Good prep and careful work lead to lasting results!

Q&A: Common Issues and Maintenance Tips

Fixing Usual Problems

Finding Bad Connectors

Car wire connectors can cause car problems. It's important to find bad ones. Watch for blinking lights, broken sensors, or power cuts. These show connector issues. Look for damage, rust, or loose parts. Waterproof connectors stop water in the engine area. But if there are problems after washing the car, check waterproofing.

Fixes and Repairs

After finding a bad connector, fix it right away. First, unhook the battery for safety. Clean with contact cleaner to remove dirt and rust. If broken, get a new connector. Use waterproof ones where it's wet often. They protect better from water trouble. Make sure all parts fit tight before connecting the battery again.

Care Tips

Regular Checks

Regular checks keep your car's electric system healthy. Look at connectors every few months for wear. Focus on wet spots like the engine area. Spotting rust or damage early stops bigger issues later on. Check connectors when doing Regular checks car care.

Cleaning and Upkeep

Clean connectors work best when they are clean too! Use a soft brush or cloth to clear dust off them easily enough! Contact cleaner helps remove any rust that might be there as well! Don't use water or harsh stuff that could hurt them though! For extra help against moisture buildup try adding some dielectric grease too! Good cleaning makes connectors last longer so cars run smoothly!

Knowing car wire connectors is key to keeping your car's electrical parts working. You now know about different connector types, their jobs in how cars work, and how to put them in right. This helps you fix common problems and improve your car-fixing skills.

How car wires have changed shows the constant new ideas in cars. By using this knowledge, you understand more about what makes your car work and the smart designs that make driving safer and more fun.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive: A Beginner's Guide

Significance of Fakra Connectors in Today's Automobiles

The Role of Fakra Connectors in Honda Cars

In-Depth Look at Fakra Connectors: Understanding Types and Uses