What You Need to Know About Car Wire Connector Types

Wire connectors are important for your car's electrical system. They connect different electronic parts smoothly. Knowing car wire connector types helps you fix your car better. Bad connectors can break and cause noise or damage cables. By knowing the right types, you make your car safer and work better. Good connectors handle heat well and seal tightly, lasting longer. Learn this to keep your car working well.

Basic Info on Wire Connectors

What Wire Connectors Do

Wire connectors are key parts of a car's electric system. They link wires, making sure connections stay strong. This lets electricity move easily through the car. Using good connectors stops electric problems and keeps your car running well.

Main Parts

Wire connectors have important parts that help them work:

Connector Termination Type: Shows how wires attach to connectors. Keeps them secure.

Sealing Materials: Protects from water and dust, making them last longer.

Rated Voltage: Tells the highest voltage they can safely handle.

Signal Integrity: Keeps signals clear without messing up.

Interchangeability: Makes it easy to swap or upgrade without issues.

Why They're Important in Cars

Keeping Cars Safe

Wire connectors are vital for safety in cars. They make sure lights and sensors work right. Good connections stop short circuits and fires, keeping everyone safe. Picking quality connectors boosts your car's safety.

Affecting How Cars Work

A car's performance depends on its wire connectors. Good ones keep contact steady, helping systems run smoothly. Right connectors lower malfunctions and boost how well your car works.

Historical Perspective

How Wire Connectors Changed

Early Days

Long ago, car wire connectors were simple. They just linked wires together. These connectors didn't last long. They weren't sealed well, so water and dust got in. This meant they needed fixing or changing often.

New Ideas

Now, wire connectors are much better. Makers focus on making them strong and efficient. Today's connectors have special seals to keep out bad weather. They can handle more electricity and keep signals clear. These changes help your car's electric parts work well.

Connector Technology Trends

New Tech Features

New connector tech has cool features now. Some can move data really fast, like HSD connectors. These are good for cameras and music systems in cars. The goal is to make sure wires stay connected without mistakes.

Future Changes

In the future, wire connectors will get even smarter. They'll work with digital systems for better checks and fixes. Connectors might use wireless tech and be more flexible too. As tech grows, these connectors will make cars safer and more fun to drive.

Understanding Car Wire Connector Types

When fixing your car's wires, knowing the different car wire connector types is important. Each type has special features and benefits for certain uses. Let's look at some common types.

Crimp Connectors

Crimp connectors are popular because they work well and are easy to use.

Features and Benefits

Reliability: Crimp connectors make a strong connection. A tool squeezes them onto the wire tightly.

Durability: They resist shaking and damage, perfect for cars.

Ease of Use: No need to solder. Just use a crimping tool.

Common Applications

Automotive Wiring: Use crimp connectors to join wires in your car.

Home Repairs: They're good for quick home fixes too.

Industrial Settings: Great for tough jobs where trust is needed.

Solder Connectors

Solder connectors give a lasting connection in a different way.

Features and Benefits

Strength: Soldering makes a strong bond that handles stress well.

Conductivity: It offers great power flow through wires.

Precision: Allows exact connections, stopping loose wires.

Common Applications

Circuit Boards: Attach parts on boards with solder connectors.

Audio Equipment: Perfect for clear sound connections.

Delicate Electronics: Best for gadgets needing steady links.

Push-On Connectors

Push-on connectors let you connect wires fast and easily.

Features and Benefits

Quick Connection: Connect or disconnect without tools quickly.

Versatility: Fits many wire sizes and kinds.

User-Friendly: Even beginners can use push-on connectors easily.

Common Applications

Automotive Repairs: Use them for quick car fixes.

Home Electronics: Ideal for hooking up speakers or devices at home.

Prototyping: Handy in setups that change often.

Knowing these connector types helps you pick the right one. Whether you want strength, ease, or reliability, there's a connector that suits your task.

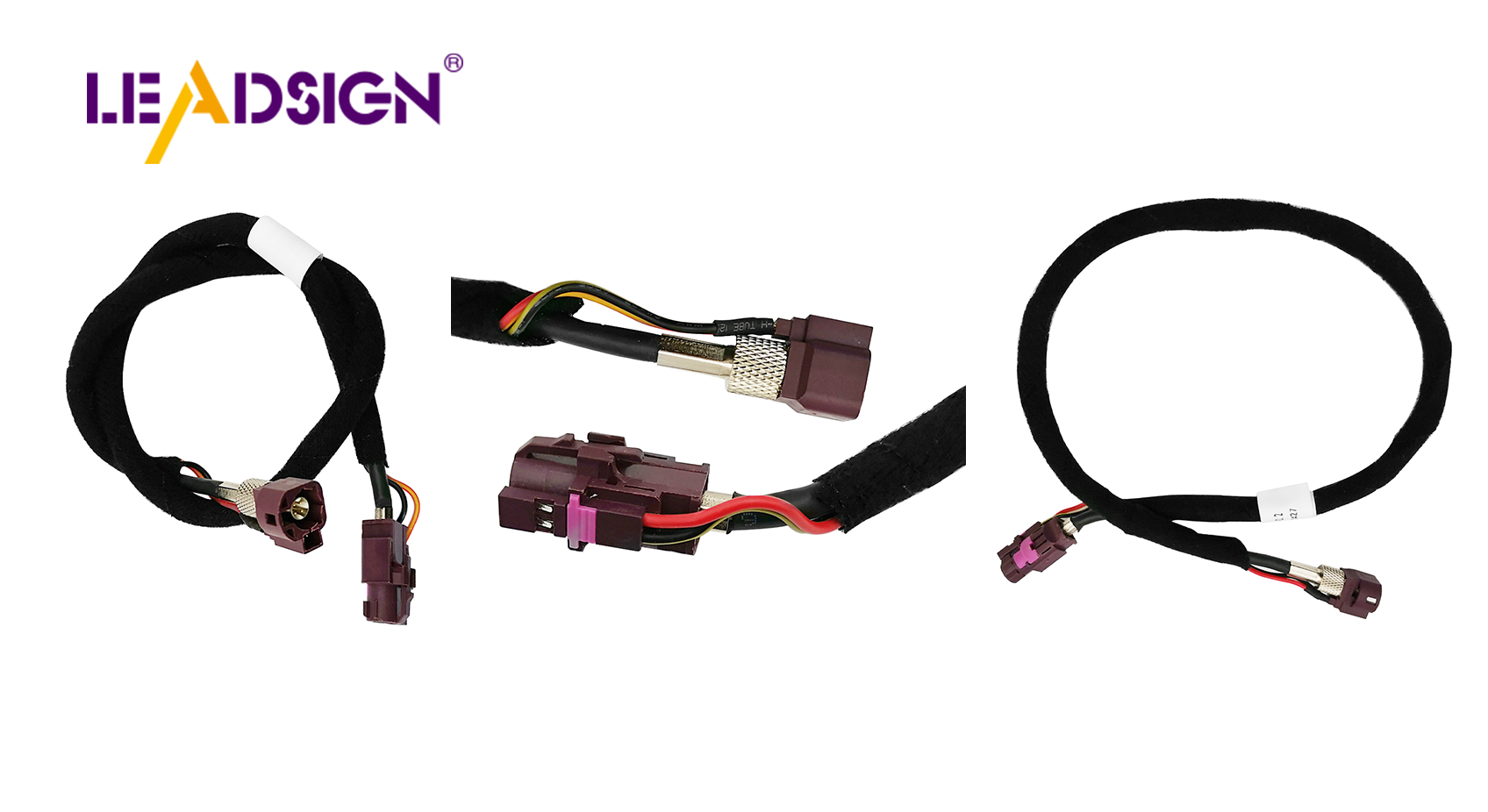

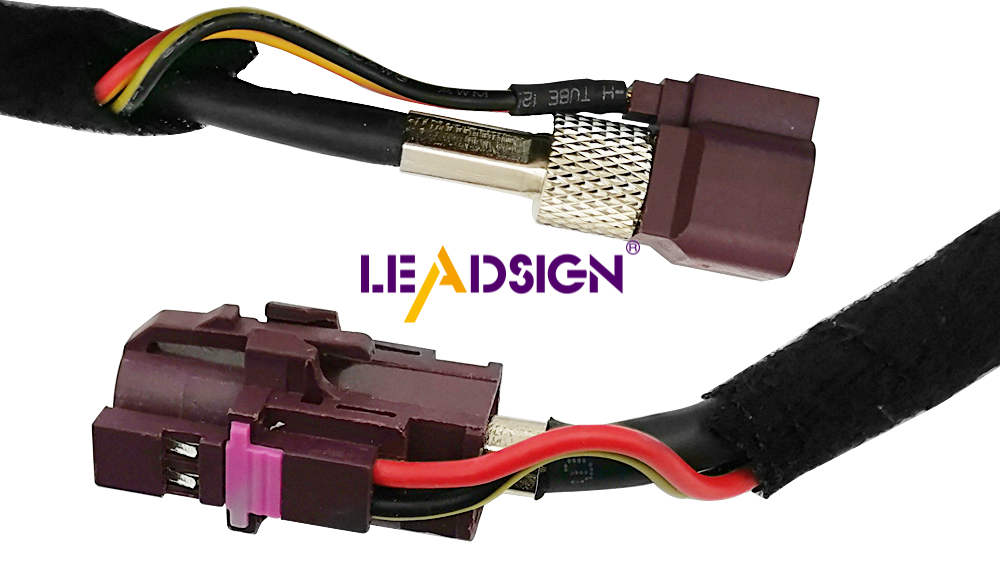

Specialty Connectors

Specialty connectors have special features for car wiring needs. Knowing them helps you pick the right one.

Features and Benefits

High-Speed Data Transfer: HSD connectors send data fast. They're great for cameras and music systems needing quick data.

Robust Construction: They have strong locks to keep connections safe. This stops accidental unplugs, making them reliable.

Versatility: These connectors work with USB, Ethernet, and LVDS. They fit many car electronics.

Ease of Use: Easy to connect and disconnect like plugging in. Good for setups that change often.

Common Applications

Automotive Electronics: Used in cars for sensors and cameras. They keep systems working smoothly.

Telecom Industries: Used in radio stations for fast data and strong links.

Digital Infotainment Systems: Improve car entertainment by keeping connections steady.

By knowing these connector types, you can boost your car's performance and reliability.

How to Install Connectors

Putting in car wire connectors right helps your car's electric system work well. This part will show you the tools and steps needed for a good installation.

Tools You Need

Must-Have Tools

First, get these important tools:

Wire Strippers: These take off the plastic cover from wires without breaking them.

Crimping Tool: Use this to fasten crimp connectors onto wires.

Soldering Iron: Needed for solder connectors, making a strong join.

Heat Gun: Helps shrink heat shrink tubing over joins, keeping them safe.

Extra Tools

These aren't required but can help:

Multimeter: Check if electricity flows right and connections are good.

Cable Ties: Keep wires neat and stop them from tangling.

Label Maker: Mark wires so you know what they are later.

Installation Steps

Getting Ready

Know the Connector Type: Find out which connector type you need. It might be crimp, solder, or push-on connectors.

Collect Supplies: Gather all tools and connectors. Make sure they fit your needs.

Be Safe: Unplug the car battery to avoid shocks.

Doing the Job

Strip the Wire: Use wire strippers to take off about half an inch of plastic from wire ends.

Connect Wires:

For crimp connectors, put the wire in and use a crimper to lock it tight.

For solder connectors, twist wires together, add solder, and heat with a soldering iron until it melts into place.

For push-on connectors, just push the wire in until it clicks.

Cover the Join: Slide heat shrink tubing over it and use a heat gun to make it snug for protection.

Final Steps

Check Connections: Use a multimeter to see if everything is connected well with no resistance.

Tidy Up Wires: Use cable ties to bundle wires neatly so they don't get damaged or mixed up.

Reconnect Battery: After checking everything works, plug back in the car battery and test if all systems run fine.

By doing these steps, you make sure connections last long and work well. Products like Amphenol Sine Systems Connectors and others are reliable choices for different connector types because they're tough against bad weather, keeping your car's electric system safe and working well.

Common Problems

Fixing Tips

If your car's wire connectors have problems, try these easy tips to find and fix them:

Check Loose Connections: Look at all connectors to see if they are tight. A loose one can cause electrical trouble.

Look for Rust: Check connectors for rust or corrosion. Clean with a brush or replace them if needed.

Use a Multimeter: Test with a multimeter to see if the connector works right.

Check Wires for Damage: See if wires near connectors are broken or frayed. Fix or change damaged wires to make them work again.

Confirm Connector Type: Ensure you use the correct car wire connector types for your job. The wrong type can cause bad performance.

Care Tips

Taking care of your car's wire connectors stops future problems. Here are ways to keep them good:

Clean Often: Clean connectors regularly to remove dirt and keep connections strong.

Use Grease: Put dielectric grease on connectors to stop moisture and rust.

Check During Maintenance: Inspect connectors during regular car checks. Finding issues early saves time and money.

Change Old Connectors: Replace worn-out ones quickly to avoid electric failures.

Common Questions

Connector Fit

How do I know if a connector fits my car?

Look in your car's manual or ask an expert to check fitment. Different car wire connector types do different jobs, so pick the right one.

Can I use different brand connectors?

Yes, but make sure they match original specs and standards for safety and performance.

Safety Issues

Are there risks with wire connectors?

Wrong or broken connectors can be risky, causing short circuits or fires. Always use the right ones and check them often.

What should I do when working with connectors?

Unplug the battery before touching electric parts. Wear gloves and glasses for safety from injuries.

By knowing these common problems and questions, you keep your car's wire connectors in top shape, making it safer and better.

Knowing car wire connector types is key for keeping your car's electric system working. You now know about different connectors, their features, and how to install them. Using this knowledge makes your car safer and work better.

"Picking the right connector is not hard. Industry rules give good choices."

Always pick connectors that match what you need and keep them stored safely. If you have questions or need help, just ask. Your car's safety and performance rely on smart decisions.

See Also

Exploring Fakra Connectors: Basics, Varieties, and Practical Uses

Understanding HSD Connectors in Automotive Sector

Significance of Fakra Auto Connectors in Contemporary Cars