Car Wire Connector Types: What You Need to Know

Automotive electrical connectors types are crucial in cars. They facilitate communication between various electronic components. As automotive technology advances, these connectors evolve to handle intricate systems within vehicles. They ensure efficient signal transmission, enabling seamless operation of lights and radios. Understanding different car wire connector types is essential for effective car repairs, enhancing vehicle performance and safety.

Car Wire Connectors

Knowing about different automotive electrical connectors types is important for fixing cars. These connectors help car systems work well. Let's look at some common connector types used in cars.

Blade Connectors

Features and Uses

Blade connectors are often used in car wiring because they are simple and dependable. They have a flat metal piece that fits into a matching slot. This makes connecting and disconnecting easy, which is good for parts that need regular checking or changing.

Common Applications

Blade connectors are used in car lights like headlights and taillights. They also connect sensors and switches in the car's electric system.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end easily. They hold wires tight by squeezing them into each side of the connector. This keeps the connection strong, which is important for keeping the car's wiring safe.

Common Applications

In cars, butt connectors fix or extend wires. They are handy for replacing broken wires or adding new parts to the car's electric system.

Ring Connectors

Features and Uses

Ring connectors connect wires to bolts securely. The ring shape fits over a bolt, then you tighten it with a nut. This keeps things stable, especially where there’s shaking or movement.

Common Applications

Ring connectors are used for battery connections and grounding tasks. They can also join several wires to one spot, making them useful in many car electric systems.

Spade Connectors

Features and Uses

Spade connectors are important in car electrical systems. They look like a flat fork. This shape helps connect and disconnect wires easily. You can remove them often without special tools. Their simple design makes them reliable, reducing electrical problems.

Common Applications

In cars, spade connectors are used a lot. They join wires to things like switches and fuse blocks. Their design makes fixing or changing parts easy. Mechanics like spade connectors because they are simple to use. These connectors help keep car wiring neat and working well. Knowing about different automotive electrical connectors types, like spade connectors, can improve your car's performance and safety.

Picking the Right Connector

Choosing the right connector for cars needs careful thought. Knowing what to look for helps pick a connector that fits the car's electric system.

Things to Think About

Power Needs

First, check what power the connector needs. This means knowing how much current and voltage it will handle. For example, spade terminals are used in car stereos because they connect wires well. They come in different sizes to fit various wire thicknesses and bolt sizes, making sure they work with the system's power needs.

Weather Conditions

The place where the connector is used matters a lot too. Connectors should handle changes in temperature, wetness, and chemicals. Sealed connectors stop water and dirt from getting inside, making them last longer even in tough places.

Matching with Car Systems

Maker's Rules

Following maker's rules is key when picking connectors. Makers give advice on which connectors work best for their cars to keep them safe and running well. These rules include details about size, shape, and material of connectors that must match the car’s design.

Connector Stuff

What a connector is made of affects how it works and lasts. Connectors can be made of vinyl, nylon, or heat shrink materials. Each gives different protection levels. Insulated spade terminals stop short circuits for safety while non-insulated ones save money if extra safety isn't needed.

Installation and Maintenance Tips

Installing and taking care of car wire connectors is important. Doing it right helps them last longer and work well.

How to Install Connectors

Tools You Need

To put in car connectors, you need some tools:

Wire cutters

Crimping pliers

Heat gun (for heat shrink)

Multimeter (to test connections)

These tools help make sure the wires stay connected safely.

Easy Steps to Follow

Get Wires Ready: Cut off the plastic cover from wire ends with cutters. Make sure the bare wire fits the connector size.

Pick a Connector: Choose one that matches the wire size and where it will be used. Use sealed ones if they might get wet.

Crimp It: Put the bare wire into the connector. Squeeze it tight with crimping pliers so it stays put.

Use Heat Shrink: If using heat shrink, slide it over the connection. Warm it with a heat gun to make it fit snugly for extra protection.

Check Connection: Test with a multimeter to see if it's working right.

Expert Tip: "Research on connectors and cables should start early in design for best results."

Keeping Connectors in Good Shape

Check Often

Look at connectors often to catch problems early. Check for wear or damage and fix them quickly.

Look Closely: See if there are cracks or loose parts.

Test Functionality: Use a multimeter to check if electricity flows well.

Fix Common Problems

When things go wrong, find out why:

Loose Parts: Tighten or change connectors if they're loose.

Rusty Parts: Clean rusty connectors or replace them.

Broken Wires: Fix or swap broken wires to keep things working.

Expert Tip: "Connectors are key in car wiring, helping devices talk, making repairs easy, and keeping cars safe."

By following these tips, car wire connectors will work better and keep your vehicle safe and efficient.

Car wire connectors are important in car systems. They help parts talk to each other, making cars safer and work better. Picking the right connector is key for keeping things strong and easy to fix. Experts say connectors help find and change bad parts fast, saving time. For tricky setups, ask a pro for help. They know how to pick and put in connectors right, keeping your car working well. By knowing these tips, people can choose wisely to keep their car's wires good and safe.

See Also

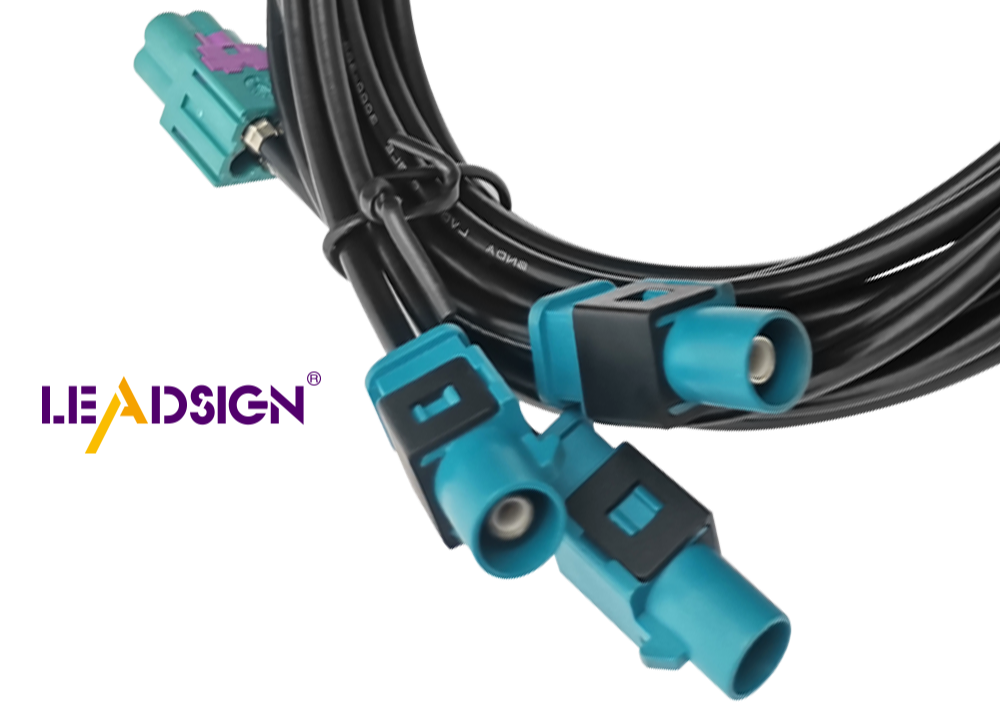

Exploring FAKRA Connectors: An Extensive Overview

Decoding FAKRA Connectors: An In-Depth Analysis

The Benefits of FAKRA Connectors: Uses and Setup Advice