Car Wire Connector Types Explained

Automotive wiring connector types are crucial for your vehicle's electrical system. They play a vital role in transmitting electricity and signals efficiently to various components. By using these connectors, you can prevent wire shrinkage and reduce the risk of short circuits, ultimately enhancing the safety of automobiles. In 2021, the market value of automotive wiring connectors reached $17.047 billion. Understanding the different types of automotive wiring connectors is essential for ensuring the optimal performance and safety of your vehicle in today's advanced automotive technology landscape.

Basics of Car Wire Connectors

Definition and Purpose

What are car wire connectors?

Car wire connectors are important in a car's electrical system. They help electricity move smoothly between different parts. These connectors join wires together so that power flows easily through the car.

Why are they essential in vehicles?

Car wire connectors keep your car's electrical system safe and working well. They stop problems like shrinking wires or short circuits. This helps your car work better and be more reliable.

Components of a Wire Connector

Knowing the parts of a wire connector shows why it's useful.

Connector housing

The connector housing is like a protective cover. It keeps out dust, water, and damage. This makes sure connections stay strong even in tough conditions.

Terminal pins

Terminal pins carry electricity inside the connector. They connect wires to make sure power moves well. Good materials for these pins help electricity flow efficiently.

Insulation materials

Insulation materials add extra protection to the connector. They stop unwanted electric paths and guide current correctly. Strong insulation makes your car's electrical system last longer.

By learning these basics, you see how car wire connectors help keep your vehicle safe and working well.

Historical Evolution of Car Wire Connectors

Early Developments

Initial designs and materials

Long ago, car wire connectors were simple. They used copper and rubber. These helped electricity move and kept it safe. But they didn't last long or work well. As cars got more complicated, better connectors were needed.

Evolution in automotive technology

Cars changed a lot over time. This meant wire connectors had to change too. Stronger materials and new designs came about. These changes helped with modern car systems. A report talks about big tech changes in cars today. New tech makes connectors more important for car design now.

Modern Innovations

Advanced materials and designs

Today’s car connectors are much better. They use strong plastics and metals now. These can handle tough conditions well. The way they lock is also improved with three parts to stay secure.

Integration with electronic systems

Modern cars use lots of electronics now. Connectors fit well with these systems today. This helps different parts talk to each other better in the car. As tech grows, expect even cooler connector ideas soon! They will keep making your car safer and work better.

Automotive Wiring Connector Types

Knowing about different automotive wiring connector types helps your car's electrical system work well. Each type has special features and uses, making them good for different jobs in your car.

Blade Connectors

Blade connectors are very common in car wiring.

Features and applications

Blade connectors have a flat metal piece that fits into a slot. You see them in fuse boxes where quick connections are needed. They work well for low-voltage things like car lights.

Advantages and disadvantages

Advantages:

Easy to connect and disconnect without tools.

Stay connected even if the car shakes.

Disadvantages:

Only for low-voltage uses.

Can rust if they get wet.

Ring Connectors

Ring connectors connect wires differently in cars.

Features and applications

These have a ring end that goes over bolts or screws. Use them when you need a strong connection, like with battery wires.

Advantages and disadvantages

Advantages:

Strong and stable connection.

Good for high-power uses.

Disadvantages:

Need tools to put on or take off.

Slower to connect than other types.

Butt Connectors

Butt connectors join two wires together easily.

Features and applications

They are tube-shaped so you can put wires in both ends. Use them to fix or extend wires in cars.

Advantages and disadvantages

Advantages:

Simple with crimping tools.

Give a safe, covered connection.

Disadvantages:

Not for high-power uses.

Need careful crimping to work well.

Knowing these automotive wiring connector types helps you choose right when fixing your car's electrical parts. Each type has its own job, keeping your car safe and working right.

Other Automotive Wiring Connector Types

Knowing different automotive wiring connector types helps fix your car's electrical system. Each type has a special job to keep your car running well and safe.

Pig Tail Connectors

Pig Tail Connectors join wires to devices. They make strong, reliable links. These are used when you need a direct connection to something. Their design fits easily into current wiring systems for smooth electricity flow.

Features:

Strong link to devices

Fits easily into systems

Applications:

Connecting sensors

Attaching electronics

Bullet Connectors

Bullet Connectors let you quickly connect or disconnect wires. Their round shape makes them fit snugly for good connections. They're handy where you often unplug, like in car lights. They handle medium electric loads, so they're good for many uses.

Features:

Fast connect and disconnect

Round shape for tight fit

Applications:

Car lighting

Temporary links

Scotch Locks

Scotch Locks help join a new wire without cutting the old one. You can add wires fast without soldering. They're great when adding extras or quick fixes are needed.

Features:

No need for soldering

Quick wire joining

Applications:

Adding extras

Quick repairs

By learning these connector types, your car’s electrical system stays strong and works well. Each type has its own benefits, helping you pick the right one for your needs. Whether connecting gadgets or making quick fixes, knowing these connectors keeps your car safe and working fine.

Practical Uses and Tips

Knowing how to install and care for car connectors keeps your car's electrical system working well. Let's look at the tools you need, how to set them up, and fix common problems.

How to Install

Tools You Need

To put in car connectors, you need certain tools. These help make sure connections are strong:

Wire Strippers: Take off wire covers without harm.

Crimping Tool: Attach connectors tightly to wires.

Screwdriver Set: Turn screws on connectors.

Multimeter: Check if electricity flows right.

Having these tools ready makes setting up easier.

Steps to Follow

Do these steps to put in car connectors right:

Get Wires Ready: Use strippers to take off a bit of cover from wires.

Pick the Right Connector: Match connector with wire size.

Put Wire In: Place bare wire into connector end.

Crimp It Tight: Use tool to hold wire firm in place.

Check Connection: Use multimeter to see if it works well.

Doing this makes sure your car runs better.

Fixing Problems

Solving Connection Issues

Sometimes connections don't work right. Here’s what can go wrong and fixes:

Loose Connections: See if it's crimped tight enough; redo if needed.

Rusty Parts: Look for rust; clean with cleaner stuff.

Broken Wires: Find breaks; swap out bad wires.

Fixing fast stops more trouble later.

Keeping Connectors Good

Regular checks keep connectors working great:

Look Often: Check for wear or damage often.

Clean Sometimes: Use cleaner spray on them now and then.

Keep Tight Connections: Make sure they stay snug and firm.

Taking care of them helps your car's electric parts last long and work well.

Knowing different car wire connectors is important for your car's electrical system. These connectors keep things safe and working well, which is very important today. Experts say the car market is full of new ideas, using electronics to make cars better. With this knowledge, you can choose wisely when fixing your car. Whether it's a small fix or an upgrade, picking the right connector helps a lot. Stay updated and keep your car running nicely.

See Also

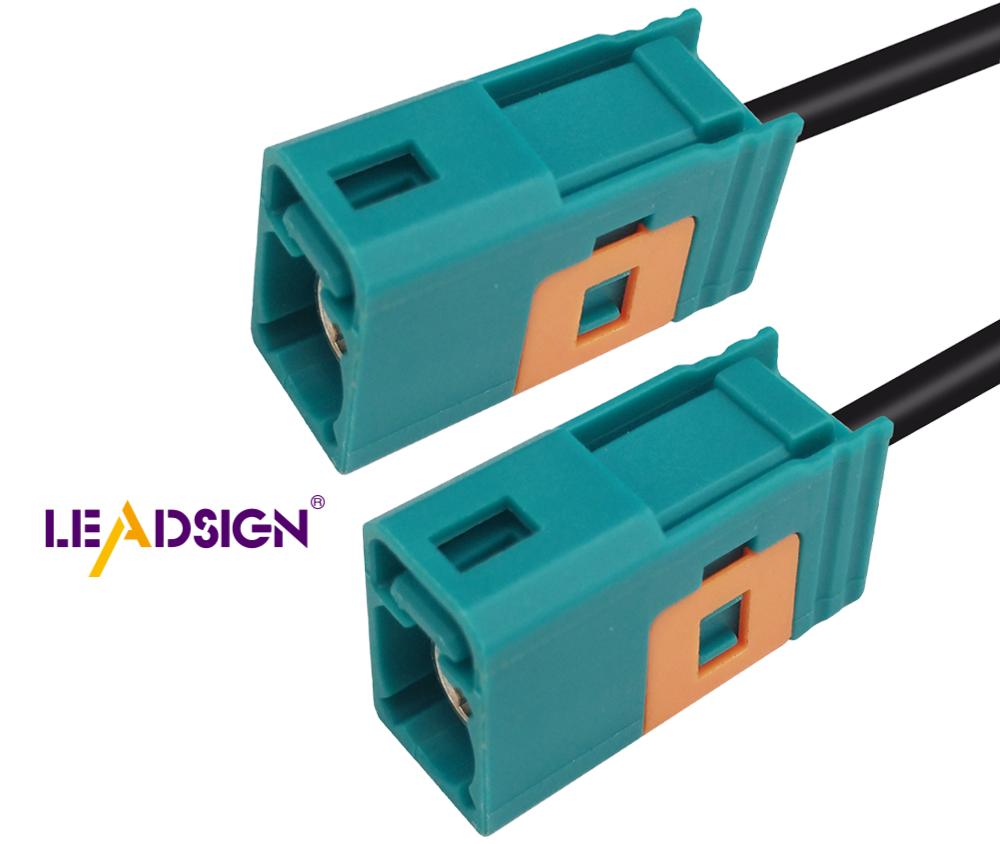

Exploring HSD Connectors in Automotive Applications

Navigating Ford Fakra Connector Options

In-Depth Look at Fakra Connectors: Fundamentals, Varieties, and Uses