Car Wire Connector Types Explained

Automotive wiring connector types are crucial in car systems. They play a vital role in maintaining strong and reliable electrical connections. Without the right connectors, vehicles may experience electrical issues, potentially compromising safety. Various automotive wiring connector types are designed for specific purposes, ensuring that electrical circuits function correctly and all components operate seamlessly. Understanding the significance of these connectors highlights their contribution to enhancing car performance and safety.

Automotive wire connectors are key parts of car systems. They keep circuits working well and safely. Each connector type has a job to do, helping the car stay reliable.

Blade connectors are very common in cars. They connect easily and securely, making them useful for many tasks.

Standard blade connectors have a flat metal piece that fits into a slot. They are easy to use and trusted in cars. These connectors make it simple to connect or disconnect wires during fixes.

Mini blade connectors work like standard ones but are smaller. They fit in tight spaces and still hold strong connections for signals to pass through smoothly.

Bullet connectors have a round shape for easy connecting and disconnecting. They're popular because they’re versatile and simple to use.

Male bullet connectors have a pin that fits into female ones. They hold tight even when things shake, perfect for frequent unplugging needs.

Female bullet connectors have a socket for male pins. Together, they make strong connections, often used in car lights where quick setup is needed.

Butt connectors link two wires end-to-end, keeping electricity flowing smoothly. They're great for adding wire length or fixing broken wires.

Insulated butt connectors have covers that stop shorts and rusting. They're good in wet places, keeping connections safe over time.

Non-insulated butt connectors don't have covers but work where extra insulation will be added later or isn't needed. They offer an affordable way to join wires securely.

Classification Systems

Knowing how car wire connectors are classified helps keep cars safe. These systems give rules for making and using connectors right.

ISO Standards

What ISO Standards Mean

ISO makes rules for many things, including car wire connectors. These rules make sure connectors work well and are safe to use. They check the materials, design, and tests used. By following these rules, makers create connectors that work in all cars and places.

Why Following Rules Matters

Following ISO rules is important for good car wire connectors. When makers follow them, their parts work well in different situations. This lowers the chance of electrical problems that can break cars or cause danger. Fixers use these good parts to make sure repairs are safe and correct.

Other Classification Systems

SAE Standards

SAE also has rules for car wire connectors. They focus on how well they handle electricity and last long. These help make sure connectors can take heat, shaking, and wetness in cars. By using these rules, makers ensure their parts work well even when it's tough.

Special Maker Rules

Some companies have their own special rules for making car wire connectors. These might include new ideas not in other standards. For example, a company could design a connector that's easier to put in or works better. Even with special rules, they must still fit with normal ones to be safe.

Common Problems and Fixes

Car wire connectors are important for keeping cars working well. But they can have problems that affect how they work. Knowing these issues and fixes helps keep cars safe.

Bad Connections

Bad connections in car wire connectors cause many electrical troubles. Finding the reasons and fixing them keeps things running smoothly.

Why Connections Go Bad

Wrong Setup: Workers might not set up connectors right, causing loose links.

Worn Out: Connectors wear out from use and weather over time.

Wrong Parts: Using mismatched connectors can make bad connections.

How to Fix Connections

Right Setup Ways: Make sure workers use correct setup steps with proper tools.

Check Often: Look at connectors often to find worn ones and change them fast.

Pick Right Parts: Choose connectors that fit wires well for a good link.

Rusting

Rust is a big problem for car wire connectors. It can ruin connections and cause failures.

Why Rust Happens

Wetness Exposure: Water makes metal parts rust over time.

Chemical Contact: Road salt or engine fluids speed up rusting.

Bad Sealing: Poor seals let water reach the connectors.

How to Stop Rust

Use Sealed Connectors: Pick sealed ones to block water and dirt.

Protective Coatings: Spray anti-rust stuff on connectors for extra safety.

Clean Regularly: Clean them often to remove dirt that causes rust.

Fixing these common problems helps car wire connectors work well again. Checking often and setting up right keeps cars safe and working fine.

Picking the right connector is key for a car's wires. Each type has a job to keep circuits working well and safe. Choosing the right one helps the car last longer and work better.

To keep car wires reliable, check them often and install them right. Mechanics should use good connectors that follow rules. This stops problems like bad links and rust, making sure the car runs smoothly and safely.

See Also

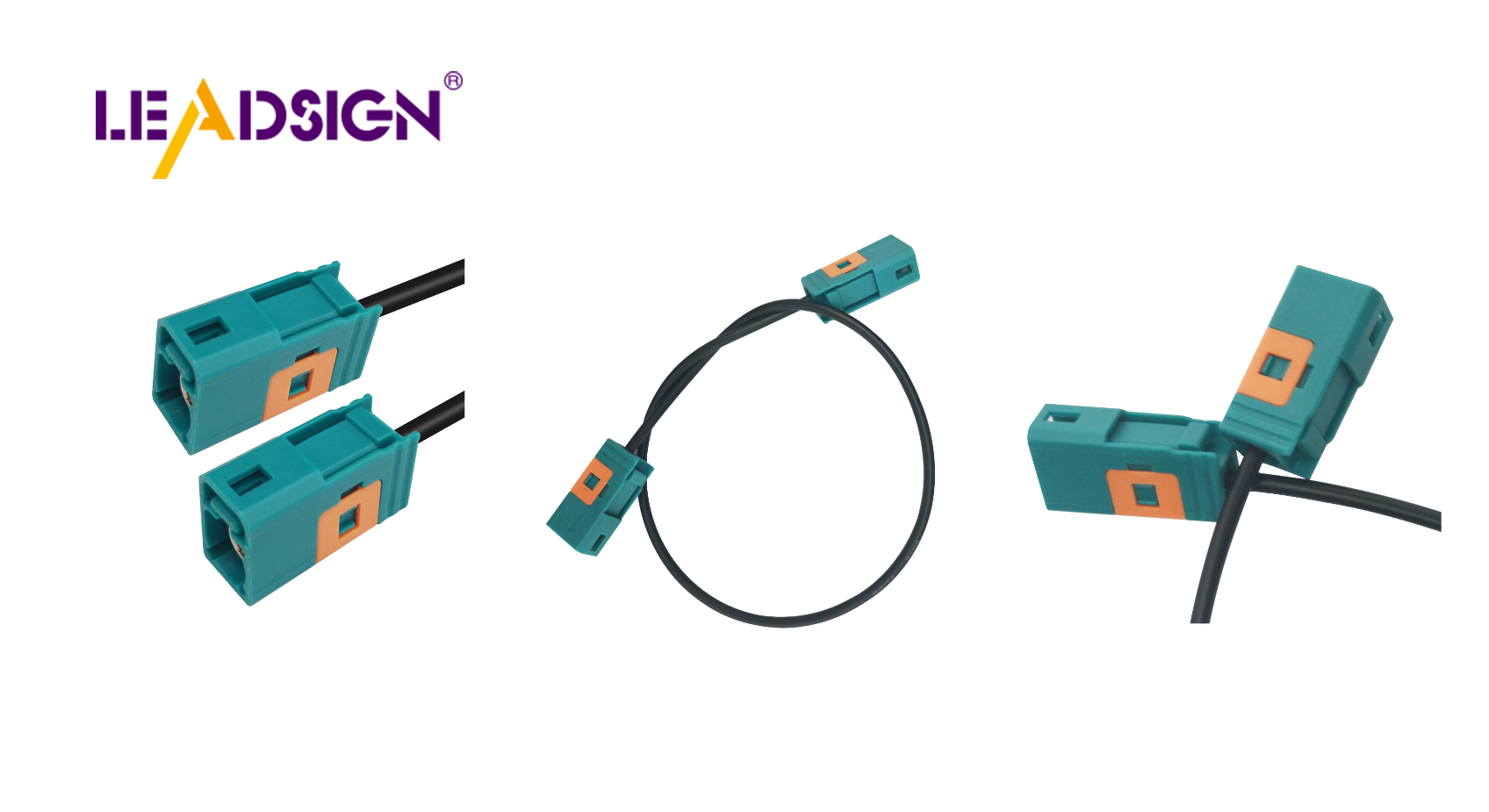

Exploring HSD Connectors in Automotive Technology

Navigating Ford Fakra Connectors

In-depth Look at Fakra Connectors: Fundamentals, Varieties, and Uses