What Is a Custom Automotive Wiring Harness and Why It Matters

A custom car wiring harness, which includes car harness connectors, is like your car's nerves. It links electrical parts so they work together smoothly. Newer cars need these systems for cool features like smart driving and entertainment. Bad harness designs can lead to problems like worn wires or water leaks. Good connectors stop these issues, making cars safer and better.

Key Takeaways

Custom car wiring harnesses link electrical parts for better safety.

With good materials and smart design, they prevent electrical problems.

Spending on a custom harness saves money by cutting repairs.

Understanding Custom Automotive Wiring Harnesses

What Is a Wiring Harness?

A wiring harness is a group of wires bundled together. It connects different parts of your car to make them work. It sends power and signals, keeping everything running smoothly. Unlike single parts like fuses, it combines all electrical systems. This design affects how well your car works and stays safe. Without a good wiring harness, things like brakes or steering might stop working.

Key Components of Car Harness Connectors

Car harness connectors link the wiring harness to circuits and power. They include parts like connectors, fuses, and fuse blocks. Connectors join wires to circuits for smooth power flow. Fuses stop damage by breaking if too much power flows. Fuse blocks hold many fuses, making repairs easier. These parts work together to keep your car safe and reliable.

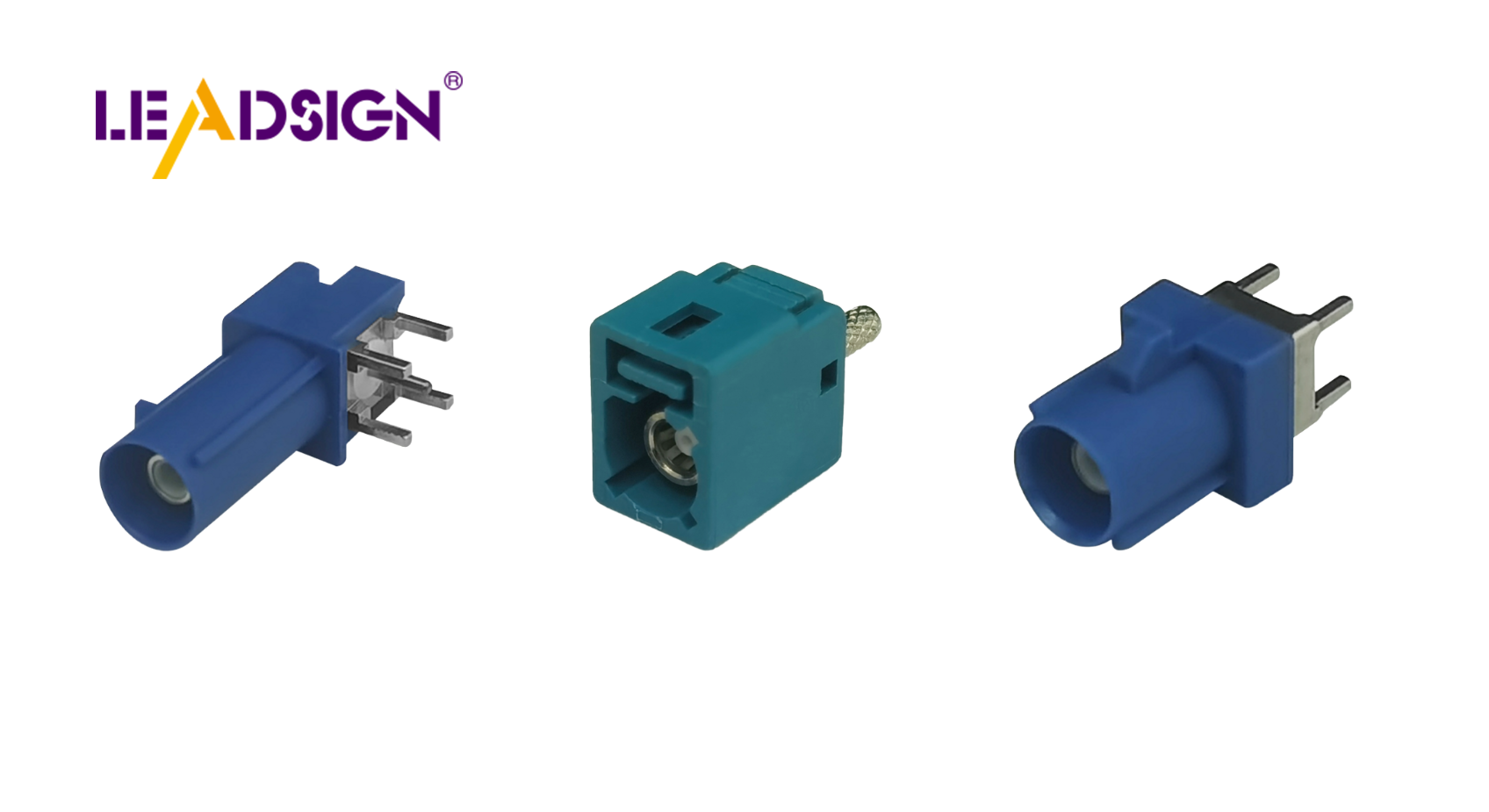

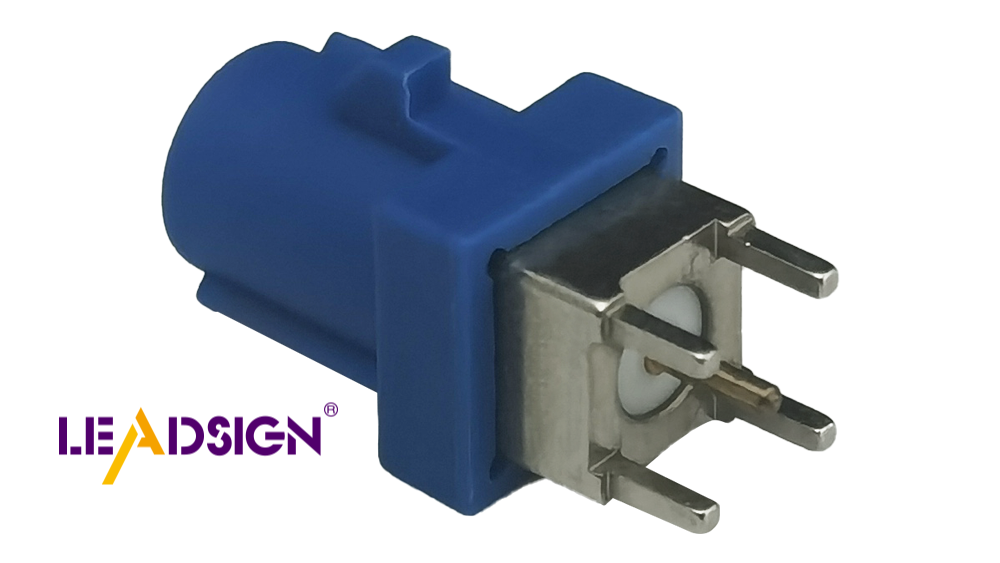

Features of Automotive Electrical Connectors

Automotive connectors are made for tough car conditions. They use strong materials like copper for power, brass to stop rust, and nylon to handle heat. They last long even in bad weather. They have locks for tight fits, waterproofing for safety, and small designs to save space. These features help connect systems like GPS, radios, and sensors reliably.

Designing and Making Custom Wiring Harnesses

How Wiring Harnesses Are Designed for Cars

Making a custom wiring harness starts with planning. First, gather parts like wires, connectors, and heat shrink tubing. These parts make sure the harness is safe and works well. Then, measure and draw a layout to plan wire paths and sizes. This helps decide where to place connectors and terminals. After planning, use a crimping tool to attach terminals securely. Finally, test the harness to make sure it works before using it.

Special software makes designing easier. For example, RapidHarness helps create car wiring harnesses quickly. SaberES Designer improves layouts and works with CAD systems. Figma lets teams share ideas and work together during design. These tools make the process faster and more accurate.

Customizing Wiring Harnesses

Custom wiring harnesses are made for specific car needs. You can pick wire sizes, layouts, and coverings that fit the car's environment. Special connectors, like waterproof ones, add extra protection. Manufacturers work with customers to create designs that match their needs. This makes the harness strong and reliable, improving how the car works.

Making and Checking Wiring Harnesses

Manufacturers follow strict rules to make good wiring harnesses. They check materials to ensure they meet quality standards. During production, they look for problems early. Tests, like checking if wires connect properly, make sure the harness works. They also follow rules like ISO 9001:2015 to keep quality high. These steps make sure the harness is safe and dependable for cars.

Benefits of Custom Automotive Wiring Harnesses

Better Performance and Dependability

Custom wiring harnesses help cars work better by managing power. They are important for modern cars with many electronic parts. For example, in electric cars, a good harness helps power flow well. This improves how far the car can go and how reliable it is. Unlike regular harnesses, custom ones use strong materials that handle tough conditions. They work well even with strong vibrations or big temperature changes.

Custom harnesses are also stronger. Experts use top-quality wires and connectors to improve signals. This lowers the chance of electrical problems. These features make cars more dependable and less likely to break down.

Greater Safety and Efficiency

Custom harnesses are made to fit your car's needs. This makes them safer and more efficient than regular ones. Trusted makers follow strict rules and test harnesses carefully. This ensures they work well in different situations. Special steps, like using heat shrink tubing, add extra safety and prevent failures.

They also offer better safety features. Custom harnesses protect against things like water or dust. Waterproof connectors and good packaging keep them working in bad weather. These features make your car safer for you and others.

Saves Money and Lasts Longer

Custom harnesses save money over time. Makers use smart tools to design and build them faster. This lowers labor costs and speeds up production. Testing during making finds problems early, avoiding costly repairs later.

Custom harnesses last longer than regular ones. They are made with strong materials and advanced methods. They handle tough conditions like heat and shaking without breaking. Their long life means fewer replacements, saving you money in the long run.

Custom car wiring harnesses are very important for today's cars. They make cars better by being lighter, safer, and more efficient. If your car has many electronic parts, think about custom options. Check your wires, choose good materials, and ask experts to help your car work its best.

FAQ

What does a custom car wiring harness do?

It links your car's electrical parts together. This helps power flow smoothly and systems work better. It also makes your car safer and more reliable.

How can you tell if your car needs one?

If your car has special electrical needs, you might need it. Adding things like GPS, radios, or sensors often requires custom wiring.

Can it make your car use energy better?

Yes, it can help. Custom harnesses remove extra wires and improve layouts. They use strong materials to make your car run efficiently.

See Also

Why HSD Connectors Matter in Today's Automotive Sector

Fakra Connectors: Essential Components for Modern Vehicles

Fakra Automotive Connectors: Key to Vehicle Performance

Boosting Data Transfer with High-Speed Automotive Connectors