Everything You Need to Know About Car Harness Connectors Installation

Car harness connectors are key to your car's electrical system. They help parts like sensors, lights, and radios work together. Installing them right is important for safety and function. Bad installation can cause loose wires, short circuits, or even fires. For instance, in 2021, Mercedes-Benz recalled cars due to fire risks. This happened because a power harness was not installed properly. Follow this guide to avoid problems and install connectors safely.

Key Takeaways

Pick connectors that match your car's electrical needs. This keeps connections safe and working well.

Test your connectors once installed. Testing finds problems early and keeps your car's system working.

Use safety rules when installing. Safety steps stop accidents and keep you and your car safe.

Understanding Car Harness Connectors

What Are Automotive Wire Harness Connectors?

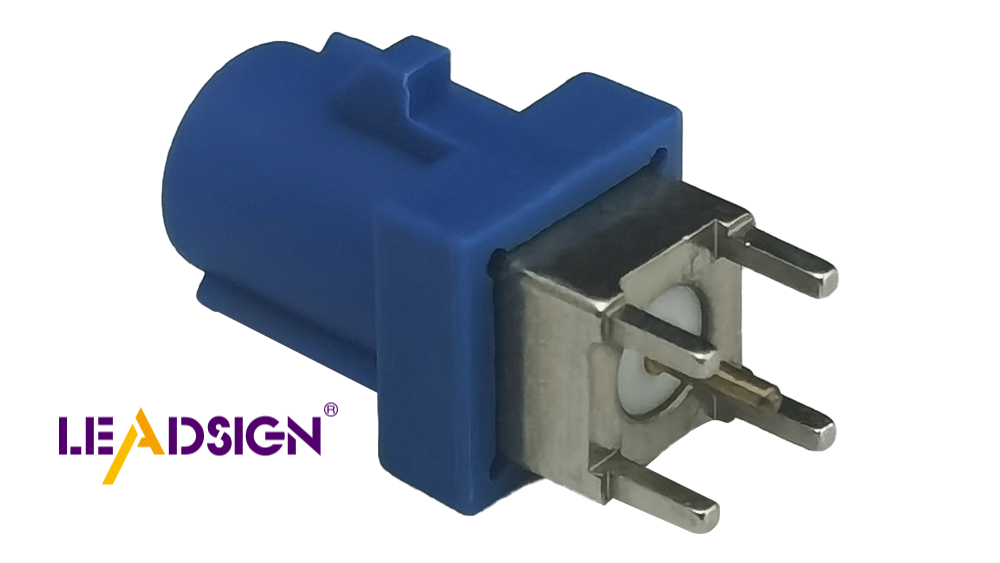

Automotive wire harness connectors are vital for your car's electricity. They connect parts like sensors, lights, and radios to work together. These connectors have two main pieces: the male plug and female socket. The plug moves, but the socket stays still. Together, they hold wires and cables securely.

Each connector has important parts to keep it working well:

Connector Housing protects terminals from dust and water.

Terminal Position Assurance locks in place to show it's secure.

Single Wire Seal and Block Seals stop dirt and moisture from entering.

Cavity Plugs cover unused spaces to keep things clean.

These features make connectors safe and reliable for your car.

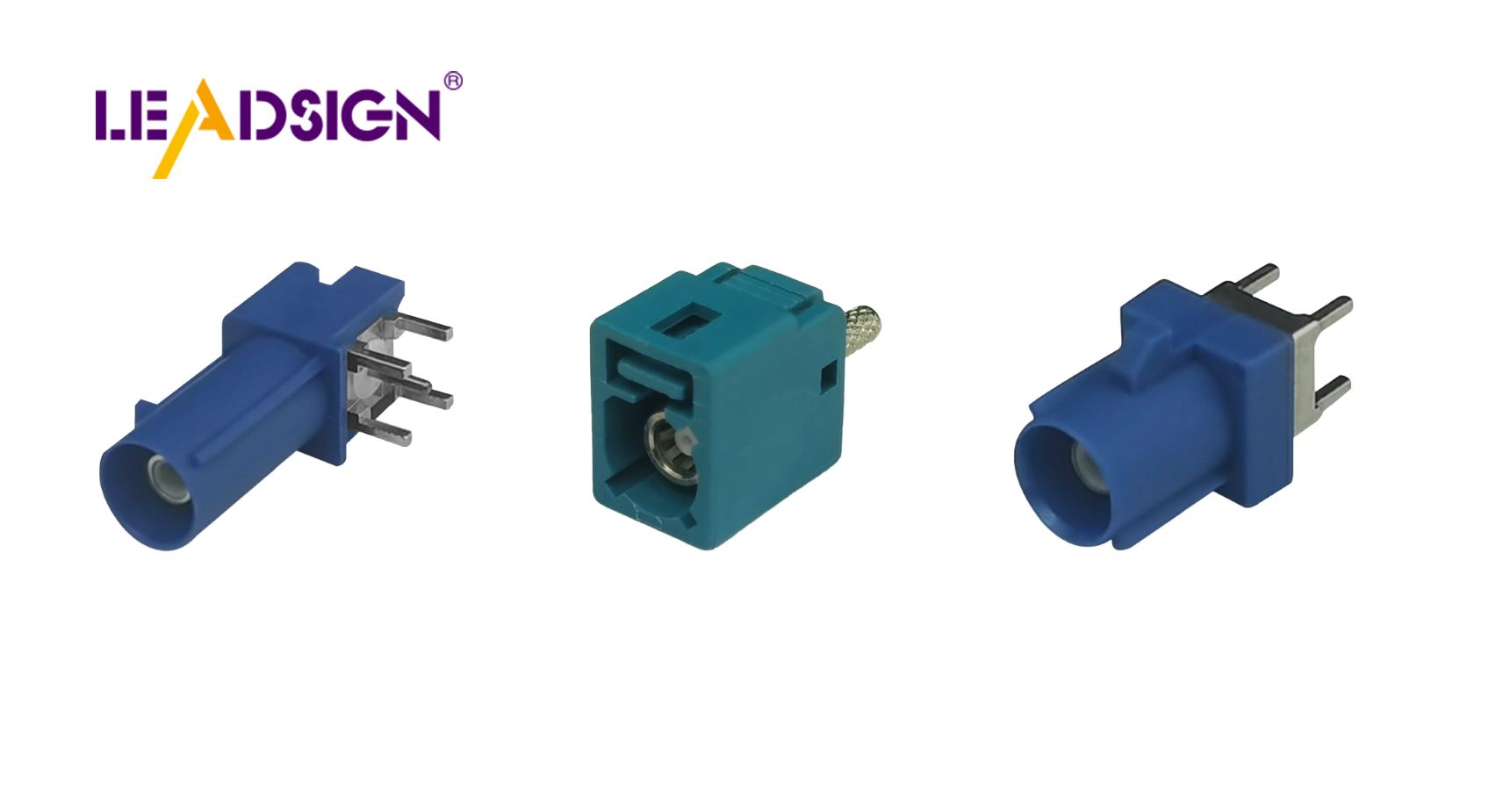

Types of Automotive Connectors

Different connectors do different jobs. Here are some common ones:

Pin Connectors carry strong currents for lights or engine controls.

Pigtail Connectors are round for low currents or rectangular for high voltage.

Socket Connectors match with pin connectors for stable links.

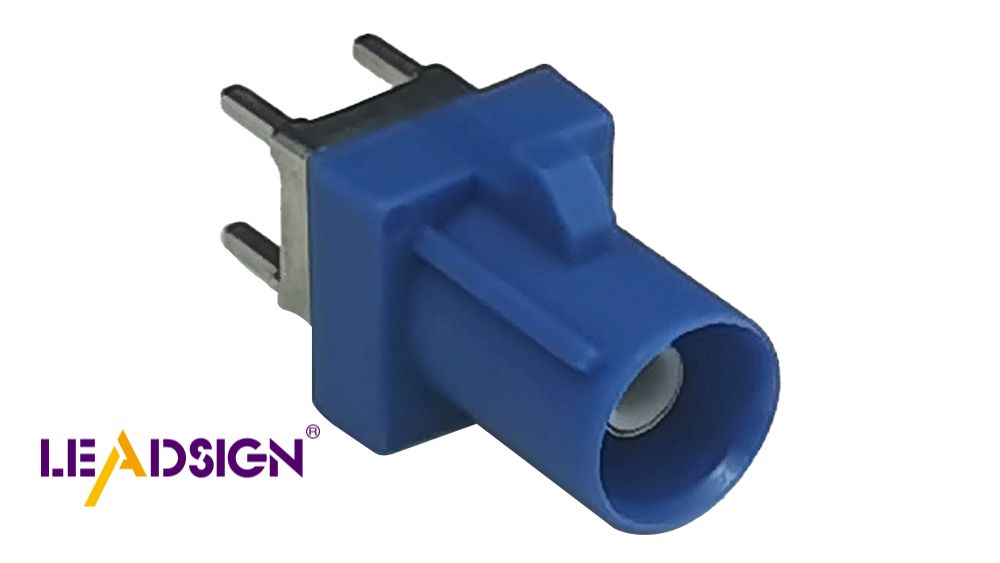

Barrel Connectors send signals for GPS or audio systems.

Sealed Connectors block moisture, while unsealed ones allow quick fixes.

Pick the right connector based on your car's wiring needs.

Functions of Automotive Wire Harness in Vehicles

Wire harnesses do more than just link wires. They organize and protect power and signals in your car. This helps everything, like headlights and radios, work properly.

Here’s why they matter:

They connect all electrical parts inside and outside the car.

They keep your car's electrical system safe and steady.

They guide power and signals, lowering risks of damage or problems.

Without a good wire harness, your car's safety and performance may drop. Whether you're making or installing one, details are very important.

Pre-Installation Preparation

Tools You Need for Wire Harness Connector Installation

Before starting, gather the right tools for the job. The correct tools make work easier and connections stronger. Here’s what you’ll need:

Wire strippers to peel off the wire covering.

Crimping tools to attach terminals tightly to wires.

Pliers to hold and bend wires as needed.

Heat guns to shrink tubing and seal connections.

Pick crimping tools that match your wire size and terminal. This ensures the connection stays strong over time. Heat shrink tubing protects wires from water and rust. Also, choose connector housings that fit your needs. They keep everything secure and safe.

Staying Safe While Installing Automotive Connectors

Safety is very important when working with car connectors. Follow these steps to stay safe and do the job well:

Remove wire insulation carefully without cutting the wire.

Use crimping tools to make tight connections.

Solder wires if you need a stronger bond.

Cover connections with heat shrink tubing for protection.

Work in a clean, dry place to avoid accidents. Check your tools and wires before starting. Being careful helps prevent mistakes and keeps your car’s system safe.

Planning Your Car Harness Connector Installation

Good planning makes installation easier and faster. First, gather tools like wire harnesses, connectors, and sleeves. Keep your workspace clean and bright. This helps you focus and avoid errors.

Understand how your wire harness is laid out. Plan where each wire and connector will go. This saves time and ensures everything fits well. Following these steps improves your work quality. With good preparation, you’ll do the job right.

Step-by-Step Wire Harness Connector Installation

Picking the Right Car Wire Connectors

Choosing the right connectors is the first step. Think about your car's electrical needs and type. The size, material, and strength of the connector are important too.

Here’s a simple checklist to help:

Match the connector to your car’s power and voltage needs.

Pick moisture-resistant connectors if they’ll face water.

Make sure the connector fits your cables and has enough contacts.

Choose materials that handle heat and shaking well.

Use good-quality connectors to avoid future problems.

The right connectors make your wiring job easier and safer.

Getting Wires and Connectors Ready

Before connecting, prepare wires and connectors carefully. This helps the installation go smoothly.

Follow these tips:

Cut wires to the right length, leaving a little extra.

Strip just enough insulation off the wire ends.

Pick terminals that match your wire size and use.

Keep wires neat to avoid tangling and ensure they work well.

Tip | Why It’s Important |

|---|---|

Arrange Wires Neatly | Keeps everything organized and working better. |

Use Proper Pleating | Stops wires from tangling and controls their length. |

Prevents damage during use. | |

Secure Connector Housing | Makes sure connectors stay in place. |

Preparing well now saves you trouble later.

Connecting and Securing Wires

Now connect the wires to the connectors. Use tools like crimpers or soldering irons for strong links. Crimping is quick and secure, while soldering lasts longer.

Cover connections with heat-shrink tubing for protection. This keeps out water and dirt. For outdoor areas, use weatherproof connectors. They last longer in tough conditions.

Organizing the Wire Harness

After connecting, organize the wire harness. Use zip ties or clips to hold wires in place. Avoid sharp edges that might cut the wires. Use grommets if wires go through metal parts.

For complex setups, multi-pin connectors can group wires neatly. A tidy harness looks good and works better. It also prevents future problems.

By following these steps, your wire harness will be safe, strong, and ready to use.

Testing and Quality Assurance

How to Test Automotive Wire Harness Connectors

Testing makes sure your car's connectors work well and safely. There are different ways to test them. First, do a visual inspection. Check for loose wires, broken insulation, or bad crimps. Then, try a continuity test. This checks if electricity flows through the harness correctly. Continuity testing has been used since the 1930s. It started with manual tools and now uses fast electronic testers.

Other useful tests include:

Short circuit tests to find unwanted wire connections.

High voltage tests to check if wires handle strong currents.

Resistance measurement to ensure electricity flows properly.

Pull tests to see if wires are firmly attached.

Bend/Flex tests to confirm wires can move without breaking.

These tests help find problems early and keep your harness working well.

Ensuring Proper Installation of Car Harness Connectors

After testing, make sure the connectors are installed right. Check that all wires are tight and covered. Use heat-shrink tubing to protect wires from water and dirt. Ensure connectors are locked so they don’t come loose. Keep the harness neat to avoid tangles or stress. A good installation prevents future problems and makes repairs easier.

Troubleshooting Issues in Wire Harness Connector Installation

Sometimes, problems happen during installation. Common issues include bad wire cutting, messy layouts, or missing parts. To fix these:

Use proper tools to cut and strip wires neatly.

Arrange wires carefully to avoid mix-ups.

Label wires clearly for easier repairs later.

Bad crimping or soldering can also cause issues. Always use the right methods for strong connections. Don’t tie wires too tightly, as this can harm them. Add strain relief and pick the right connectors to avoid mistakes. Fixing these problems ensures your harness is safe and lasts longer.

Common Mistakes to Avoid

Picking the Wrong Connectors or Tools

Using the wrong connectors or tools can cause problems. It may lead to loose wires, bad performance, or damage to your car. To avoid this, remember these tips:

Count the pins. Make sure the connector matches the original.

Check your car’s needs. Use connectors that fit its requirements.

Avoid cheap connectors. They might break and cost more later.

Ask for help. If unsure, talk to a professional.

The connector size should match the wire size for a good fit. Don’t strip too much or too little wire covering. Avoid squeezing wires too hard, as it weakens the connection.

Skipping Safety Rules During Installation

Ignoring safety rules can be dangerous. For example, a wiring mistake could cause a short circuit. This might harm your car or even start a fire.

Terrance Murray ignored safety rules and faced legal trouble. His actions could have caused serious injuries. He was jailed for 26 weeks and fined.

Always follow safety steps. Wear safety gear, work in a clean area, and check your tools. These steps protect you and your car.

Not Testing After Installation

Testing after installation is very important. It helps find hidden problems before they get worse.

Testing checks if your wiring and connectors work well. A simple test can show if electricity flows correctly. Other tests, like pull or bend tests, check if connections are strong and flexible.

Don’t skip testing. It saves time and money by fixing issues early. Testing also ensures your car’s electrical system is safe and reliable.

Knowing about car harness connectors is important for safety. Installing them properly keeps your car working well and prevents damage. It also makes the electrical system more efficient. Prepare carefully, stay safe, and test your work to ensure success.

These steps help avoid mistakes and keep things running smoothly. A good installation lowers the chance of problems and improves performance. With this guide, you can do the job confidently. Follow these tips to keep your car’s electrical system reliable for a long time!

FAQ

What happens if I pick the wrong connector?

Wrong connectors can cause loose wires or system problems. Always choose connectors that fit your car's needs.

How can I check if my connectors are installed right?

Test them with a continuity tester to see if electricity flows. Look for tight wires, no exposed parts, and locked connectors.

Is it okay to use old connectors again?

It’s better not to reuse old connectors. They might be worn out or damaged. New ones work better and keep your car safe.

See Also

Exploring Ford Fakra Connectors: A Comprehensive Overview

Understanding HSD Connectors: Key Insights for Automotive Use

Why FAKRA Z Connectors Matter in Automotive Systems