A Beginner's Guide to Auto Harness Connectors for Modern Vehicles

Car harness connectors are important parts of modern cars. They connect electrical systems, helping parts work together smoothly. Good connectors make cars safer by supporting airbags and brakes. Electric cars need advanced connectors to handle complex systems. These connectors meet the need for safety and performance in today’s cars.

Key Takeaways

Car harness connectors link electrical parts in modern cars. They keep the car safe and working well.

Pick connectors based on power, voltage, weather, and your car type.

Clean and check connectors often to avoid damage. This makes them last longer and work better.

Understanding Car Harness Connectors

Types of car harness connectors

Car harness connectors have different types for specific uses in cars. Here are some common ones you might see:

Engine Wire Harness: Links engine parts and sends performance signals.

Chassis Wire Harness: Connects electrical parts on the car's frame.

Body Wire Harness: Powers lights, locks, and safety features.

Door Wire Harness: Controls power windows and locks easily.

Dashboard Wire Harness: Powers dashboard buttons and screens.

Powertrain Wire Harness: Helps the engine and transmission work together.

HVAC Wire Harness: Runs heating, cooling, and air systems.

Autonomous Driving Harness: Manages power for self-driving features.

Antenna Harness: Links the antenna to get clear signals.

Electric Vehicle (EV) Harness: Handles high-voltage power in electric cars.

You’ll also see different connector shapes, like bullet ones for audio, flat ones for tight spots, and rectangular ones for complex systems.

Functions and applications in modern vehicles

Car connectors are key to running a car’s electronics. They connect parts so systems work smoothly. For example, inline connectors join cables, and PCB mount connectors link circuits on boards. These connectors power airbags, GPS, and music systems.

In electric cars, these connectors safely handle high-voltage power. They also support features like self-driving and keyless entry. Strong materials and secure locks keep them working in tough conditions. This makes sure your car stays safe and works well.

Key Factors to Consider When Choosing Automotive Wiring Harness Connectors

Power and voltage needs

When picking car wiring connectors, check power and voltage needs. Connectors must handle current without overheating or losing power. Too much voltage can cause sparks or damage. The number of connector pins is also important. More pins allow better signals and multiple connections. Think about the environment too. Heat, cold, or water can affect how connectors work. Strong locks and vibration resistance keep them reliable. Below is a summary table:

Factor | Description |

|---|---|

Handles system current without overheating or losing power. | |

Voltage rating | Prevents sparks or damage by staying within safe limits. |

Number of contacts | More pins improve signals and allow multiple connections. |

Environmental conditions | Works well in heat, cold, or wet areas. |

Mechanical factors | Strong locks and vibration resistance ensure reliability. |

Type of termination | Good wire ends keep signals clear and make setup easier. |

Material | Choose plastic for lightness or metal for strength. |

Signal integrity | Use materials that lose less signal for better performance. |

Interchangeability | Pick connectors that are easy to find and replace. |

Protection from water and dust

Car connectors should block water and dust to stay safe. Look for ones with high IP ratings for better protection. Waterproof connectors are great for areas exposed to rain or splashes. Materials like nylon or PBT resist car fluids and chemicals. These features help connectors last longer in tough conditions.

Fit for your car's model

Not all connectors work with every car. Check if the connector fits your car’s model. Some connectors are made for specific wiring systems. Using the wrong one can cause problems or failures. Always check the details before buying.

Strength and material quality

Strong connectors last longer in your car. Plastic ones like PA6 or PA66 are light and tough. Metal ones are stronger for heavy-duty use. Gold or tin-plated brass or copper pins conduct electricity well and resist rust. Good materials protect against wear and damage.

Space and easy setup

Modern cars have limited space. Small connectors save room and are easier to install. Multi-pin connectors make plugging in faster and reduce mess. Always check your car’s space before choosing a connector.

Installation and Maintenance of Car Wiring Connectors

Getting ready to install

Before starting, gather all tools and materials needed. This makes the process easier and safer. Important tools include:

Wire Strippers to cut wires neatly.

Crimping Tool for attaching pins tightly.

Soldering Iron to make strong connections.

Weatherproof Connectors to keep out water.

Heat Shrink Tubing to protect wires from harm.

Electrical Tape for extra safety.

Safety is very important when working on car connectors. Always disconnect the car battery to avoid electric shocks. Wear gloves and goggles to stay safe. Work in a bright area and never work on a hot or running car. These steps help prevent accidents and ensure safe installation.

Easy steps to install

Here’s how to install car wire connectors:

Remove wire insulation using a wire stripper.

Attach male pins to wires with a crimping tool.

Add a seal to keep out dust and water.

Securely connect terminals to the right connectors.

Avoid common mistakes during setup. Don’t use household wire nuts; instead, use butt connectors and crimping tools. Make sure the positive lead connects well to the car body for proper power flow. Using the right tools and methods ensures a good connection.

Tips to keep connectors working

Taking care of connectors makes them last longer. Check them often for loose wires or damage. Clean them with de-ionized water to remove dirt. Use harness covers to protect wires from damage. Add lubricant to connectors that move a lot to reduce wear.

Store wires in a dry, cool place to avoid harm. Choose high-quality connectors made from rust-proof materials for better durability. Re-terminate cables sometimes to keep connections strong and clean. These tips help your car connectors stay in great shape.

Popular Brands and Models of Automotive Wiring Harness Connectors

Overview of trusted brands

When picking car connectors, some brands are well-known for quality. Here are a few trusted names:

TE Connectivity: Makes tough connectors that work in harsh conditions.

Aptiv: Creates durable connectors that fit many car systems.

Molex: Focuses on strong, sealed connectors for tough car setups.

Yazaki: A top company in wiring since 1941, known for quality.

Delphi: Famous for waterproof connectors that last a long time.

These brands are trusted because they meet modern car needs.

Features of popular models

Good car connectors have special features for today’s vehicles. For example, TE Connectivity connectors lock tightly and resist weather. Molex uses materials that keep signals clear, even in fast systems. Yazaki connectors are strong and work well in electric and self-driving cars.

Some models have many pins to connect several systems at once. Waterproof designs stop water damage, and small sizes fit tight spaces. These features help connectors work well in all conditions.

Comparing and choosing the best car wiring connector

To find the right car connector, think about these points:

Criteria | Description |

|---|---|

Current rating | Handles your car’s power without overheating or failing. |

Voltage rating | Works safely with your car’s voltage to avoid damage. |

Number of contacts | More pins mean better signals and more connection options. |

Environmental Conditions | Stays strong in heat, cold, or wet areas. |

Mechanical factors | Locks tightly and handles bumps or vibrations. |

Type of termination | Choose soldering, crimping, or screw-on ends for easy setup. |

Material | Pick plastic for light use or metal for heavy-duty needs. |

Signal integrity | Uses materials that keep signals clear and strong. |

Interchangeability | Fits standard systems, so replacements are easy to find. |

By checking these factors, you can pick a connector that works well and lasts long.

Picking the right car connectors is very important. Follow these steps:

Make sure connectors fit your car’s power needs.

Choose connectors with more pins for stronger signals.

Check if they can handle tough weather and shaking.

Good quality, proper fit, and strength keep your car safe and lasting longer.

FAQ

What does a car wiring harness connector do?

It links electrical parts to share power and signals. This makes systems like lights and GPS work properly in your car.

How can you pick the right connector for your car?

Make sure it matches your car model and power needs. Check if it handles tough conditions and stays strong over time.

Is it possible to install car connectors yourself?

Yes, you can do it. Use tools like wire cutters and crimpers. Always disconnect the battery first to stay safe while working.

See Also

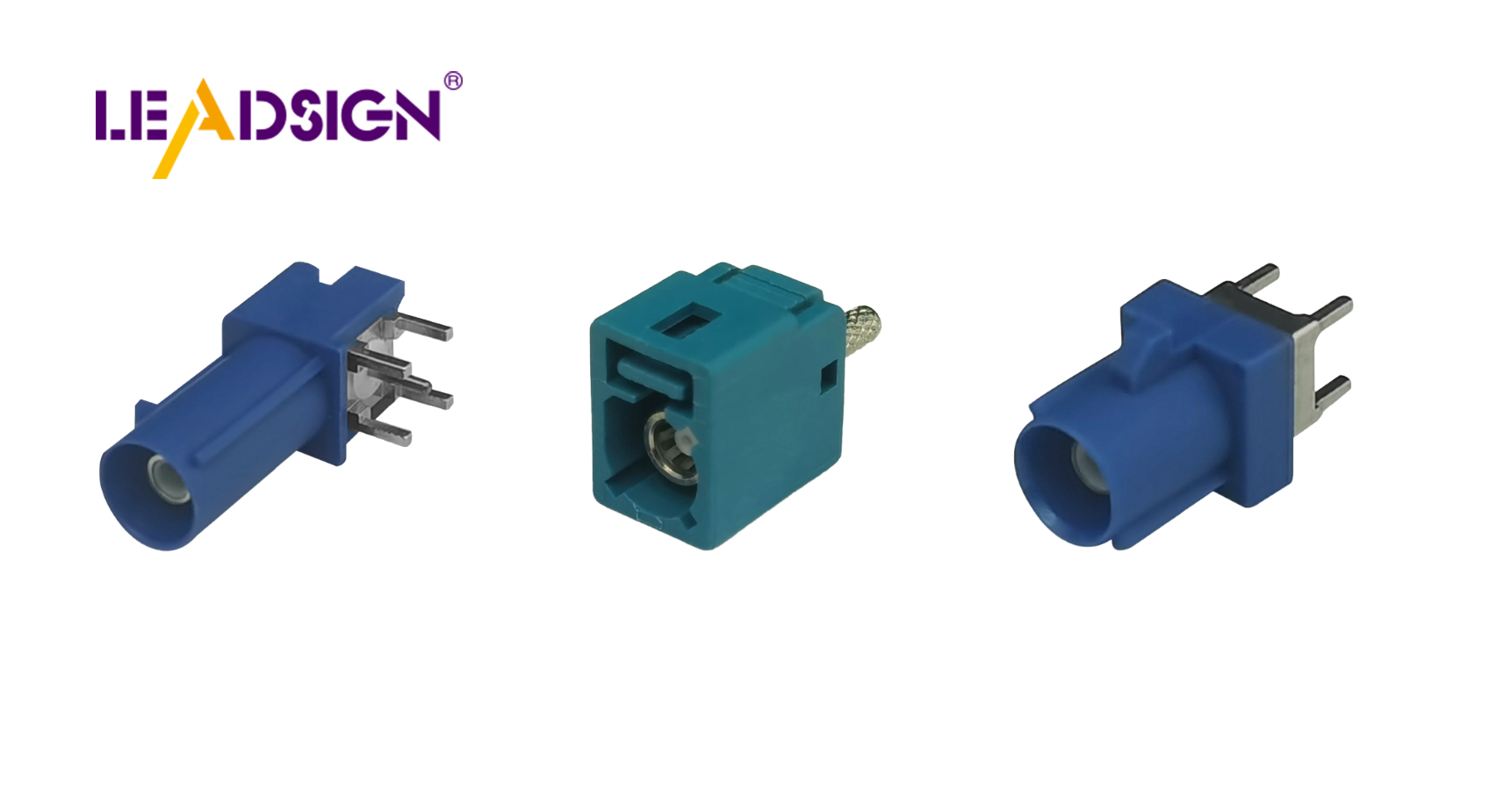

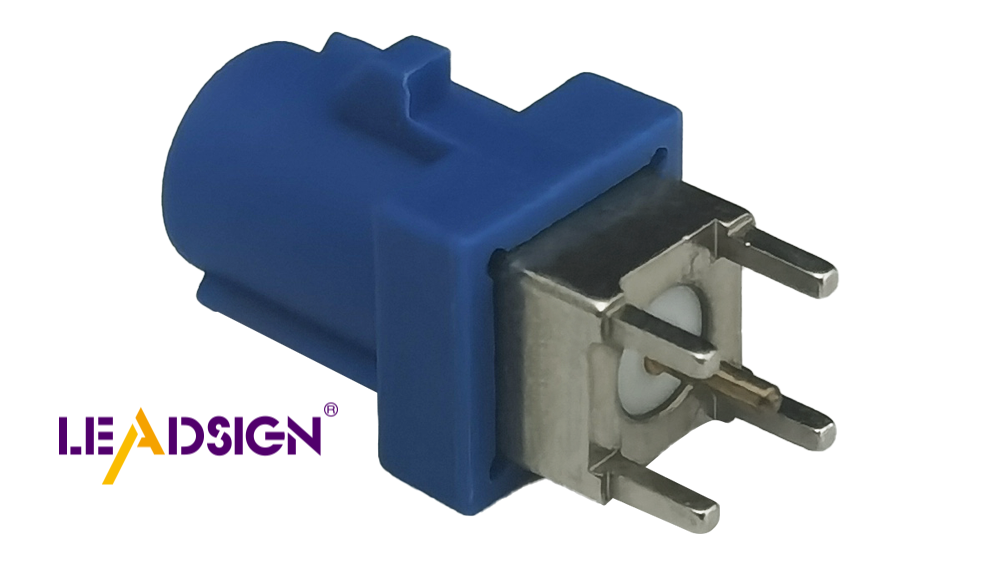

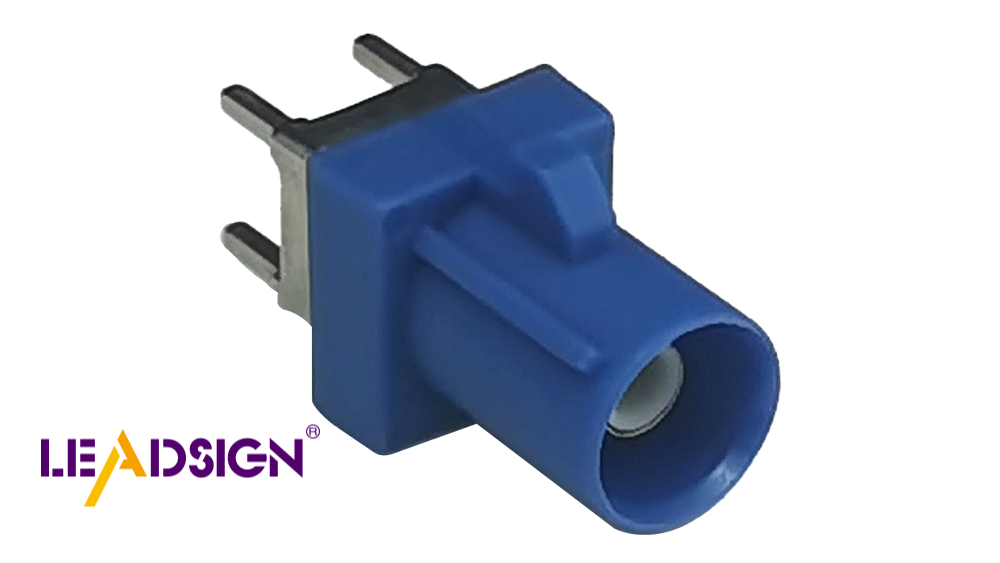

Understanding HSD Connectors Essential for Automotive Applications

Why Fakra Connectors Are Crucial for Today's Vehicles

An Overview of Ford's Fakra Connector System