What Causes Car Harness Connectors to Fail?

Car harness connectors are important for your car’s electrical systems. If they break, you may see flickering lights or engine problems. Sensors might stop working too. This can affect safety features like anti-lock brakes. It could make controlling your car harder in emergencies. Ignoring these issues can cause bigger problems later.

Key Takeaways

Rust and water can harm car harness connectors. Use special grease to keep out water and dirt.

Check and clean connectors often to stop bigger issues. Watch for damage and clean them regularly.

Installing connectors the right way is very important. Make sure they fit well and use good-quality parts to prevent problems.

Common Reasons Car Harness Connectors Fail

Rust and Water Damage

Rust is a big problem for car connectors. Water can sneak inside and cause rust or other damage. This weakens the connection and stops electricity from flowing well. Over time, the damage gets worse and might break the connector completely. You may see flickering lights or sensors not working.

To stop rust, use special greases made for connectors. These greases block water, dirt, and salt from getting in. They also protect the surface and stop rust from forming. Pick greases that resist water and salt spray. These work best in tough weather conditions.

Damage from Daily Use

Everyday use can harm your car’s connectors. Driving vibrations, plugging and unplugging, or pulling too hard can cause cracks or loosen them. Over time, this damage makes the connector stop working.

If you see cracks or loose plugs, fix them quickly. Waiting can lead to bigger problems, like broken wiring. Check your connectors often to catch damage early.

Too Much Electricity or Short Circuits

Too much electricity happens when a device uses more power than it should. For example, wipers might overwork when clearing heavy snow. This can heat wires and harm the connector. Short circuits happen when wires touch where they shouldn’t. Both can melt connectors or even start fires.

To prevent this, keep your car’s electrical parts in good shape. If something seems wrong, test the wires to check for problems.

Bad Installation or Factory Mistakes

Sometimes, connectors fail because they weren’t installed right. A loose fit can make the connection weak. Poor materials from the factory can also cause early failure.

When replacing a connector, make sure it fits tightly. A good fit helps the wiring work well. Always pick high-quality connectors to avoid replacing them often.

How to Troubleshoot Problems with Car Harness Connectors

Check for Damage or Rust

Look closely at the car connectors. A quick check can show problems. Look for:

Wires that look burned or discolored.

Broken or torn wires.

Dirt or grime on the connector pins.

Cables that are too short or not aligned.

If you find these issues, clean or replace the parts. Keeping connectors clean and fixed helps them work well and avoids bigger problems.

Test the Wiring Harness

Testing checks if the wiring works properly. You’ll need tools like a multimeter or tester. Follow these steps:

Set the tester to low voltage and resistance.

Attach the connectors to a testing device.

Test each wire for problems.

Listen for a beep or check the screen for results.

A good result means the wiring is fine. A bad result shows where the issue is. This keeps your wiring in good condition.

Clean and Fix Rusty Connectors

Rust can ruin connectors, but cleaning can help. Use sprays or baking soda paste to clean them. For tough rust, use a wire brush. After cleaning, add grease to stop future rust. If the damage is bad, replace the wires and cover them with heat shrink tubing.

Replace Broken Connectors or Wires

Sometimes, fixing isn’t enough. Replace broken connectors or wires when needed. Use a connector kit and crimper for a tight fit. Solder wires if required and cover them properly. If unsure, ask a professional for help. Replacing bad parts keeps your car’s wiring safe and reliable.

Preventative Maintenance for Wiring Harnesses

Regular Inspections and Cleaning

To keep your wiring harness working well, check it often. Look for dirt, rust, or any damage on the connectors. Clean connectors help electricity flow and prevent problems.

Here’s how to clean your wire harness:

Method | Description |

|---|---|

Pine Sol Soak | Soak the harness in Pine Sol and hot water for hours. |

Rinse | Wash the harness with a hose after soaking. |

Sun Drying | Let the harness dry in the sun for one or two days. |

Soapy Water | Clean the harness using hot soapy water. |

Brake Cleaner | Wipe the harness with brake cleaner and rags. |

WD40 | Use WD40 on a rag, but don’t soak the harness. |

Purple Power | Spray Purple Power, scrub with a brush, rinse, and dry. |

Dielectric Grease | Add dielectric grease when putting connectors back together. |

Cleaning your harness often keeps it working and avoids expensive fixes.

Using Protective Coatings or Sealants

Protective coatings can help your connectors last longer. These coatings stop wear and tear on connector surfaces. They also block water, dirt, and rust from causing damage.

Coatings keep the system safe from the environment. This stops rust and signal problems. They also seal the connectors, keeping them clean and working well. Adding these coatings is easy and saves money on repairs.

Installing Wire Harness Plug Connectors Correctly

Installing connectors the right way helps them last longer. Follow these steps:

Strip just enough insulation off the wire ends.

Use a crimper to attach terminals tightly to the wires.

Place the terminals into the connector housing correctly.

Test the wires and check the connections carefully.

After installing, test everything to make sure it works. Check that connectors fit tightly and are easy to plug and unplug. Don’t reuse single-use connectors or use the wrong size. Proper installation keeps your harness working well for a long time.

Car harness connectors can break due to rust, damage, or bad setup. Fixing these problems fast keeps your car working well. Cleaning and sealing connectors often can stop issues later.

Use strong covers and good-quality parts.

Stay away from harsh weather.

Switch to rust-proof wires.

Tight connections help safety features work when needed most.

FAQ

What should you do if a car accessory stops working?

Start by checking the wires for damage or loose plugs. A broken accessory might also be caused by a bad connector or a blown fuse.

How can you identify a grounding issue in your car?

Watch for flickering lights or devices not working right. Use a multimeter to test voltage at the ground spot. Fix any loose or rusty connections you find.

When should you replace a car harness connector?

Change it if you notice melted parts, bent pins, or heavy rust. Testing the connector can also show hidden problems that need fixing.

See Also

Why HSD Connectors Matter in Today's Automotive Sector

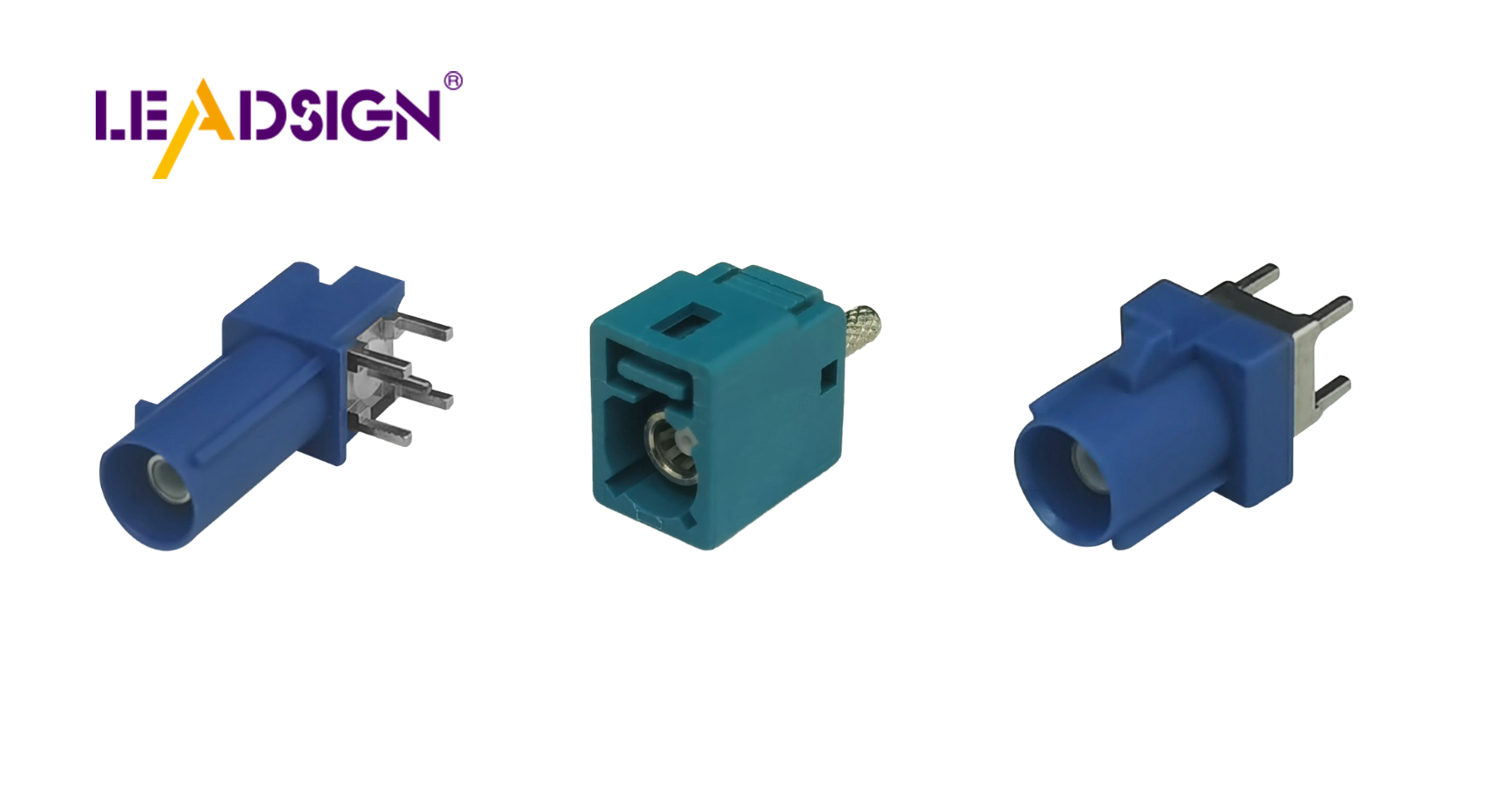

Fakra Connectors: Essential Components for Modern Vehicles

FAKRA Connectors: Key to Efficient Automotive Solutions