Master the Basics of Automotive Plugs and Connectors Installation

Putting in a car connector plug might seem hard at first. But it doesn’t have to be if you know what to do. Many beginners face problems like loose wires, rust, or burnt plugs. These problems happen because of bad setup, water, or too much heat. Knowing this helps you avoid mistakes and makes the job easier.

Problem | What Happens |

|---|---|

Loose wires | Happen if not installed right or shaken, causing power loss. |

Rust | Happens when plugs get wet, making connections weak and lowering voltage. |

Burnt plugs | Caused by too much heat from high resistance or overload, breaking the plugs. |

By learning about these common problems, you’re closer to installing your car plug the right way.

Key Takeaways

Get tools like wire cutters and crimpers before starting. Being ready helps make strong connections and easier installation.

Pick the correct plug for your car's requirements. Think about the type, size, and material to avoid problems later.

Test your connections using a multimeter after you're done. This checks if everything works and stops power issues.

Tools and Materials for Installing a Car Connector Plug

Before starting, gather the right tools and materials. This makes the job easier and ensures strong connections.

Important Tools You’ll Need

Here are the tools you should have:

Use a wire stripper to safely remove wire coverings.

A crimping tool helps attach pins tightly to wires.

Seals keep water and dust away from your connections.

Connectors hold terminals in place for steady connections.

These tools are necessary for a good installation. Without them, wires might come loose or connections may fail.

Beginner-Friendly Materials to Use

If you’re just starting, try beginner kits. These kits often include a 4-way waterproof connector and instructions. They make the process simple and help you avoid errors.

Extra Tools for Better Results

Want to improve your work? Add a multimeter to check if connections work. Heat shrink tubing adds extra protection and lasts longer. These tools aren’t required but make your setup look better.

Having these tools and materials ready helps you succeed. Whether using waterproof connectors or others, being prepared is important.

Getting Ready for Installation

Picking the Best Car Connector Plug

Choosing the right plug is very important. Not all plugs fit every car, so think about these:

Where will the plug go? Is it for the radio or sensors?

What type of car do you have? Some need special plugs.

Does the plug size fit the space? It shouldn’t be too tight.

Pick strong materials. Good plugs resist rust and last longer.

High-quality plugs work better and are more reliable.

Follow these steps to choose easily:

Know what the plug is for, like voltage or current.

Match the plug type to your car’s needs.

Use materials that handle heat, water, or dirt.

Find customizable plugs if your setup is unique.

Check if the plug meets safety standards.

Pick a design that’s simple to use and maintain.

If unsure, try a 4-way waterproof connector. It’s easy to use and keeps wires safe.

Checking and Getting Wires Ready

Look at your wires before starting. Broken wires won’t work well. Replace any damaged ones.

After checking, strip the wire covering carefully. Use a wire stripper for clean cuts. Only expose enough wire to fit the plug. Too much bare wire can cause problems.

For waterproof plugs, make sure seals are in place. Seals keep water and dirt out, making connections last longer.

Staying Safe Before You Begin

Safety is very important. Disconnect the car battery to avoid shocks. Wear gloves to protect hands and glasses for your eyes.

Work in a clean, dry, and bright area. Stay away from flammable things. Be careful with tools like crimpers or heat shrink tubing.

Check everything twice before starting. Being ready makes the job safer and easier.

Step-by-Step Guide to Installing a Car Connector Plug

Stripping and Preparing the Wires

First, check the wires for any damage. Replace frayed or broken wires before starting. Cut all wires to the same length for neatness. Use a wire stripper to remove a small part of the insulation. If you don’t have one, use a knife carefully.

After stripping, twist the bare wires together to keep them neat. Slide a shrink tube onto the wire for later protection. This will shield the wires from dirt and heat in the engine. Once the wires are ready, move on to crimping the pins.

Crimping the Connector Pins

Crimping is an important step. Make sure the bare wire is about 0.10 inches long. Push the wire into the connector pin until it fits snugly. Use a crimping tool to tightly secure the pin. One crimp on each side is usually enough. Gently pull the wire to check if it’s tight. If it doesn’t move, it’s done correctly.

Assembling the Connector Housing

Next, put the crimped pins into the connector housing. Follow the instructions from the manufacturer for proper placement. For waterproof connectors, make sure the seals are in the right spots. This keeps water and dirt out. Once all pins are in, connect the plugs to ensure they fit well.

Testing the Connection for Functionality

Finally, test the connection to make sure it works. Use a multimeter to check for proper voltage and continuity. If everything is fine, slide the shrink tube over the crimped area. Heat it to seal the connection. This step makes the connection stronger and waterproof.

By following these steps, your installation will be secure and look professional.

Common Mistakes to Avoid During Installation

Mistakes can happen even if you’re prepared. Knowing what to avoid helps save time and effort. Let’s explore common errors and how to prevent them.

Using the Wrong Tools or Materials

Wrong tools or materials can cause weak or broken connections. For example, using pliers instead of a crimping tool won’t secure wires well. Loose wires can fail over time. Always use proper tools like wire strippers and crimpers.

Materials are important too. Cheap connectors may rust or break easily. Choose strong, high-quality connectors, especially waterproof ones. These handle dirt and water better, lasting longer in tough conditions.

Skipping Steps for Wire Preparation

Skipping wire prep can lead to big problems. If wires aren’t stripped properly, they won’t connect securely. Frayed wires can overheat and damage plugs.

Take time to check and prepare wires. Strip just enough insulation to show the wire. Twist the strands neatly for a clean connection. For waterproof plugs, slide seals on before crimping. Small steps like these make a big difference.

Not Testing the Connection

Testing might seem extra, but it’s very important. Without testing, you won’t know if the connection works. Loose wires or rust can cause power loss or failure.

Use a multimeter to check voltage and continuity. Fix any issues right away. Adding dielectric grease can stop rust and keep connections strong.

Avoiding these mistakes makes installation easier and better. Take your time, follow steps, and double-check your work for great results.

Troubleshooting and Tips for Success

Fixing a Faulty Connection

Sometimes connections don’t work even after careful setup. Don’t panic—it’s often simple to fix. First, check the wires. Look for loose ends or frayed parts. If you find any, strip the wire again and reattach the pin. Ensure the pin is tight and doesn’t move when pulled.

Then, check the connector housing. Pins in the wrong spots can cause problems. Remove and place them correctly. For waterproof connectors, confirm the seals are intact. Broken or missing seals let water in, causing trouble.

Lastly, use a multimeter to test the connection. If the voltage or continuity is wrong, review your steps. Small fixes usually solve the issue.

Tip: Use dielectric grease on pins before reassembling. It stops rust and keeps connections smooth.

Ensuring a Durable and Reliable Installation

A strong setup works better and lasts longer. Follow these steps for a reliable connection:

Use a crimping tool to secure male pins tightly.

Insert pins into the housing until they click in place.

Add seals to block moisture and dirt from entering.

Test the connection with a multimeter to ensure it works.

Check connectors often. Clean them and apply anti-rust coating to keep them in good condition.

These steps help your installation handle tough conditions and stay reliable.

Knowing When to Seek Professional Help

Sometimes, calling an expert is the best choice. Complex wiring or special connectors can be tricky. Professionals save time and prevent mistakes. If troubleshooting doesn’t fix the problem, they can find the issue fast.

Don’t hesitate to ask for help if unsure. It’s better to be safe than risk damaging your car’s electrical system.

Note: Safety comes first. If disconnecting the battery or handling wires feels unsafe, call a professional.

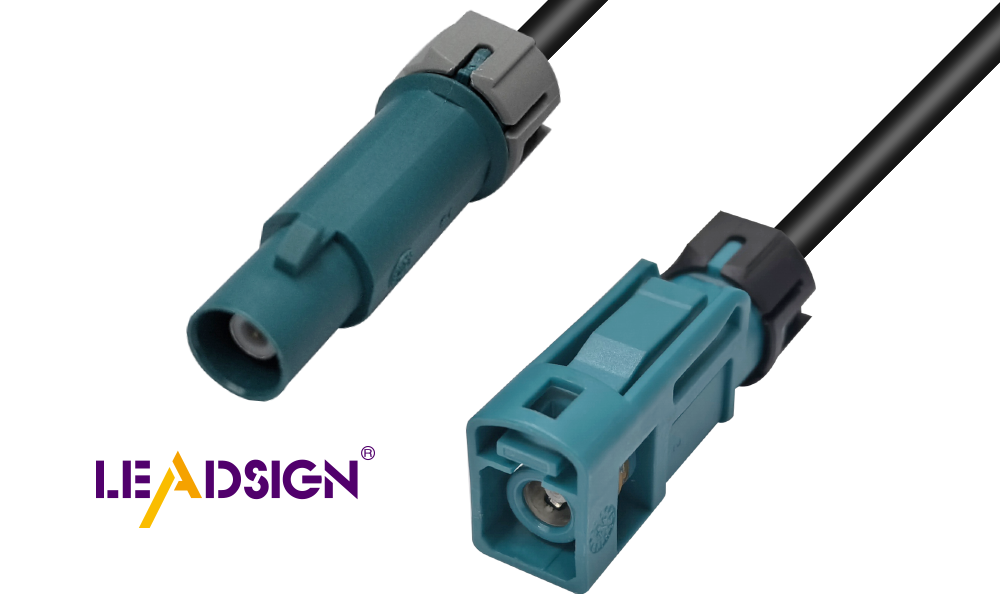

Putting in a car plug is easy with steps. First, learn about connector types, such as pin and socket ones. Make sure the pins match your car’s needs. Use strong materials to stop loose wires or rust. Keep it working well by using dielectric grease often. Work slowly, check everything twice, and feel proud of your new skill. You can do it!

FAQ

What is the best way to prevent rust on connectors?

Apply dielectric grease to the pins before assembly. It blocks moisture and keeps the connection smooth and rust-free. Regular maintenance also helps.

Can I use pliers instead of a crimping tool?

No, pliers don’t secure wires tightly enough. A crimping tool ensures a strong, reliable connection that won’t loosen over time.

How do I know if my connection is waterproof?

Check for intact seals and proper housing assembly. Test the connection by lightly spraying water. If no issues arise, it’s waterproof.

Tip: Always double-check seals for durability in harsh conditions.

See Also

Understanding HSD Connectors Essential for Automotive Applications

A Comprehensive Overview of Ford Fakra Connectors

Why Fakra Connectors Matter for Today's Vehicles