A Beginner’s Guide to Car Connector Plug Installation and Use

Car connector plugs are important for car wiring. They help make strong electrical connections. Installing them correctly makes cars safer and work better. Bad installation can cause loose wires, rust, or burnt plugs. This guide makes it easy to connect plugs safely and well.

Key Takeaways

Installing car connector plugs correctly is important for safety. Follow steps closely to avoid loose wires or damaged plugs.

Use proper tools and materials for the job. Tools like wire cutters and crimpers help make strong, lasting connections.

Regular care stops rust and damage. Clean plugs often and check for problems to keep your car working well.

Understanding Automotive Connectors

What is a car connector plug?

A car connector plug is a small but important part of your car's wiring. It helps connect different parts of the car securely. These plugs let power and data move smoothly, so systems like lights, music, and sensors work well. Without them, your car's electrical parts would not work together properly.

Car connector plugs also make fixing and upgrading easier. For example, you can unplug and plug in devices like stereos or tools without breaking the wires. This makes it easier to keep your car working well.

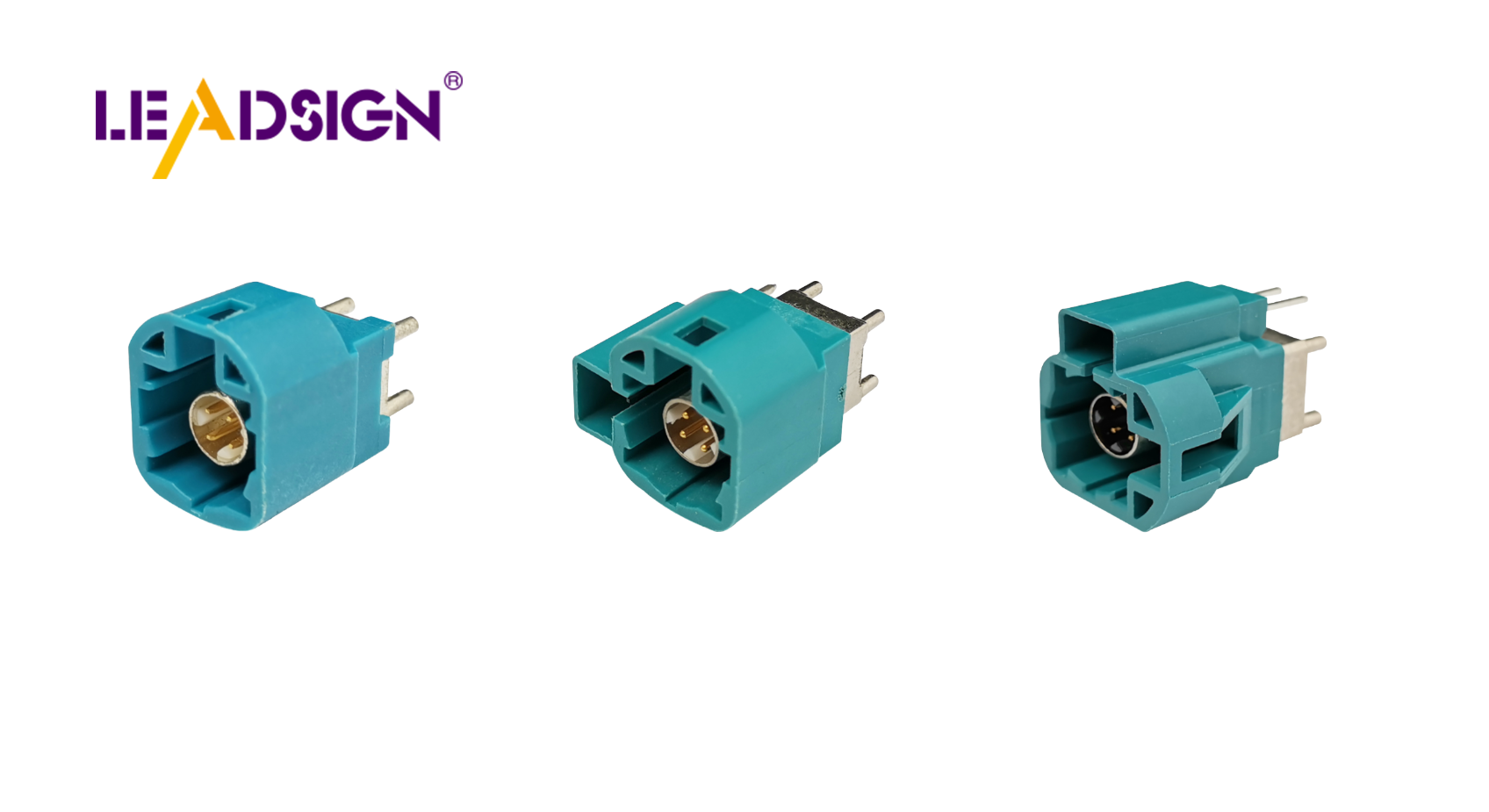

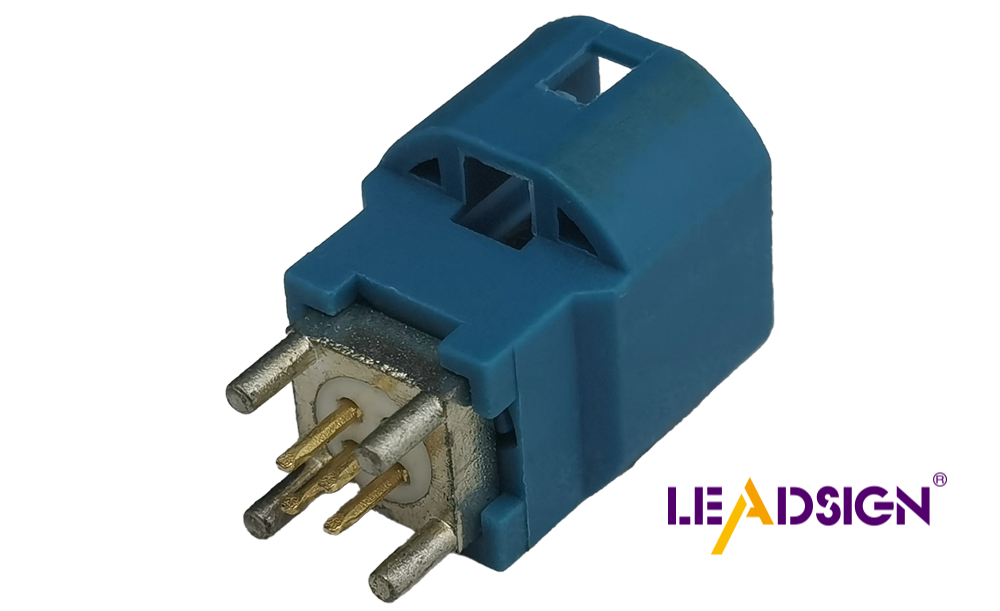

Automotive electrical connectors types

Car connectors come in many shapes and sizes for different jobs. Here are some common types of car connectors:

Connector Type | What It Does | Where It’s Used |

|---|---|---|

Easy to plug and unplug | Car music systems | |

Scotch Locks | Join wires without cutting or soldering | Quick fixes in hard-to-reach spots |

Square Connectors | Carry signals or power | Engine sensors |

Rectangular Connectors | Handle many wires for complex systems | Engine control systems |

Round and Flat Connectors | Power lights like headlights and taillights | Car lighting systems |

Specialized Connectors | Keep sound clear in music systems | In-car entertainment |

Each type of connector has a special job. For example, bullet connectors are great for music systems, while rectangular ones are used for engine controls. Picking the right connector helps your car work better.

Why proper installation is essential

Installing car connectors the right way is very important. If done wrong, it can cause problems like:

Loose wires that stop power from reaching parts of the car.

Rust from water that weakens connections and lowers performance.

Burnt plugs from too much heat, which can harm wires and devices.

By installing connectors correctly, you avoid these issues and keep your car running well. Always follow the steps and use the right tools to make a strong connection.

Tools and Materials for Installation

Tools you need for installing car connector plugs

To install car connector plugs, you need the right tools. These tools help make strong and safe connections. Here’s a list of what you’ll need:

Tool/Material | What It Does |

|---|---|

Wire Strippers | Take off wire covers without harming the metal inside. |

Crimping Tools | Securely attach connectors to wires, keeping them steady. |

Electrical Tape | Wraps connections to keep them dry and safe. |

Heat Shrink Tubing | Covers connections tightly when heated, blocking out moisture. |

These tools make the job easier and help your connectors last longer.

Best materials for strong wire harness connectors

Picking good materials is as important as using the right tools. For strong wire harness connectors, try these:

Light covers work in mild areas; heavy ones are for tough spots.

Braided sleeves stop wires from coming apart and add safety.

Common choices include heat-shrink tubing, split looms, and nylon braids. These materials keep your connectors safe and working well.

Safety gear for working with connectors

Safety is very important when working on wire harness connectors. Use these items:

Gloves to stop electric shocks.

Goggles to protect your eyes from sparks or flying bits.

A heat gun to safely shrink heat-shrink tubing.

These tools keep you safe while you work on your installation.

Tip: Check your tools and materials before starting. This helps you avoid problems and stay safe.

Step-by-Step Installation Process

Getting the wires ready

Start by getting the wires ready to connect. Follow these steps:

Use a wire stripper to remove about half an inch of insulation. This shows the metal wire without breaking it.

Pick the right connector for the job. For example, use butt connectors to join wires or ring terminals for grounding.

Put the stripped wire into the connector. Make sure the metal wire touches the inside of the connector fully.

Getting the wires ready well helps make a strong connection.

Picking the right car connectors

Choosing the right car connector is very important. First, check your car type to match the connector. Look at the pin layout since similar connectors can be different. Many brands use colors to make it easier to pick. Learn about common connectors like blade, bullet, and spade types. Wiring diagrams can also help you find the right connector.

Connecting the wire to the connector

Connect the wire to the connector tightly to avoid loose ends. Crimping works best for this. Use a crimping tool to press the connector onto the wire. Make sure all wire strands are inside the connector to stop short circuits. A ferrule can keep the wire neat during crimping. Gently pull the wire to check if it’s attached well.

Making the connection secure

Securing the connection needs more than just attaching it. Use strain relief tools like plastic clamps or molded jackets to stop fraying. Check that the connector’s lock clicks into place. This stops it from coming loose. Always double-check the lock for a strong and lasting connection.

Checking the connection works

Check the connection to make sure it’s safe and working. First, look closely for loose wires or bad alignment. Use a multimeter to test if electricity flows through. High-voltage tests can check insulation strength. Turn on the connected device to see if it works. These checks help avoid problems later.

Tip: If you need to unplug the connector, unlock it first to avoid breaking it.

Troubleshooting Automotive Connectors

Finding loose or bad connections

Loose or bad connections can cause car problems. Look for these signs:

Some parts lose power completely.

Lights, radios, or systems flicker or stop working.

A burnt smell or damage on the connector is visible.

To check, do a wiggle test. Move the connector and wires gently while the car is on. If things flicker or act strange, the connection might be loose. Look for rust, burn marks, or broken pins on the connector. Spotting these issues early can save money on repairs.

Fixing mistakes in wire harness connectors

Fixing wire harness problems needs careful work. First, press the release button to open the connector. Use a small tool to lift the lid and take out the pins. Check the wires for any damage. Replace damaged wires if needed. Attach wires using heat shrink butt connectors or solder with heat shrink tubing. For small insulation problems, use liquid electrical tape. Always make sure the connection is tight and test it before putting it back together. Cleaning and checking connectors often can stop future problems.

Stopping rust and damage

Rust and damage make connectors weaker over time. To stop this, clean connectors often to remove dirt. Look for rust or wear signs. Use dielectric grease to protect connectors from water and heat. Don’t tighten too much during maintenance to avoid breaking them. Use the right tools to handle connectors safely. These steps help connectors last longer and work better.

Tip: Taking care of connectors regularly means fewer repairs later.

Maintaining Automotive Wire Harness Connectors

Tips for regular checks and cleaning

Keep your car connectors in good shape with regular care. Clean the engine area to stop dirt from building up. Check plugs and wires often to ensure they stay tight. Follow your car’s maintenance guide for regular inspections.

Use a soft brush or air to clean dirt off. Don’t use water directly, as it can cause rust. If you see rust or grime, use a special cleaner for car connectors. Cleaning often stops dirt from harming connectors and keeps them working well.

Steps to replace broken car plugs

Fixing a broken connector needs careful steps. First, count the pins and check the size and shape. Make sure the new plug fits your car’s model and year.

Press the release button to separate the plug.

Lift the lock and gently pull out the pins with a tool.

Look for damaged wires. Replace bad wires and crimp them to the new plug.

After replacing, test the connection to ensure it works. This keeps your car’s systems running smoothly.

How to make connectors last longer

To make connectors last, clean them often to remove dirt. Check for damage regularly. Use the right tools to avoid breaking them during repairs. Protect them from water and heat with dielectric grease. Don’t tighten too much, as it can crack them.

Choose connectors with features like strain relief and water protection (IP67). These tips help connectors handle tough conditions and last a long time.

Knowing how to install a car connector plug properly helps your car work well. Learn about different connector types, wiring diagrams, and tools to avoid problems. Clean and check connectors often to stop damage and rust. Follow this guide to make safe connections and keep your car lasting longer.

FAQ

What does a car connector plug do?

It helps parts of the car connect safely. Power and data move smoothly, so systems work well.

How can you stop wire harness connectors from breaking?

Clean them often and use grease to block water. Check for damage and use the right tools to avoid cracks.

Can old connectors be used again?

Yes, if they are still in good shape. Look for rust, cracks, or loose parts. Replace bad ones to keep things safe and working.

See Also

Exploring Ford Fakra Connectors: A Complete Overview

Fakra Connectors Explained: Benefits, Uses, and Setup Advice

In-Depth Look at HSD Connectors: A Complete Guide

HSD Connectors 101: Essential Knowledge for Automotive Applications

Fakra Plug Insights: An All-Inclusive Guide to Understanding