Best Wire Connectors Types to Use Now

Selecting the appropriate wire connectors types is crucial for maintaining the safety and efficiency of electrical systems. Making informed choices can significantly reduce cable issues, with typical failure rates ranging from 0.7 to 2 per 100 miles annually. Industrial wire connectors types streamline both the manufacturing and installation processes, saving time and labor. Wire connectors types are utilized in residential, automotive, and industrial settings, each requiring specific types to meet unique demands. Understanding these requirements is essential for choosing the best wire connectors types to ensure optimal performance and reliability.

Overview of Wire Connectors

General Introduction to Wire Connectors

Definition and Purpose

Wire connectors link wires together. They make sure connections are safe and strong. Cable-to-Cable/Wire-to-Wire connectors join two wires or cables. One side sticks to the wire for good. This lets you plug and unplug the wire when needed. Wire-to-Board connectors join a wire to a circuit board (PCB). The PCB links can be pressed in or soldered.

Common Applications

Wire connectors have many uses. Panel Feed-through connectors let a wire pass through a panel. These often have seals for protection. Many have an IP rating, so they work in closed cabinets. Wire connectors are used at home, in cars, and factories. Each place needs special types for different jobs.

Importance of Choosing the Right Connector

Impact on Performance

Picking the right connector affects how things work. A good connector keeps electricity flowing well. This lowers power loss chances. A strong connection stops breaks from happening. Good connectors boost system performance overall.

Safety Considerations

Safety matters when picking connectors. A strong link stops electrical dangers. Right connectors cut short circuit risks down. Safe links guard against fires from electricity. Always pick connectors that follow safety rules.

Types of Wire Connectors

WAGO Connectors

Unique Features

WAGO connectors don't need tools to connect. You open and close them with a lever. This makes sure the connection is safe and strong. The clear cover lets you see if wires are connected right. They fit different wire sizes, so they work in many places.

Benefits

WAGO connectors make wiring easy. The lever saves time and effort when installing. The clear cover helps check for safety. They hold wires tight for a stable link. You can use them again, saving money on projects.

Ideal Use Cases

Use WAGO connectors at home or in businesses. They're good for lights and fixing wires. They work with solid or stranded wires. They're great when you need to change connections often.

Winged Connectors

Unique Features

Winged connectors have wings for better grip. These wings help twist and secure the connector easily. They hold wires tightly so they don't slip out. Different colors show which wire sizes they fit.

Benefits

Winged connectors are quick to install. Wings make it easier on your hands during use. Colors help pick the right size fast. They keep wires tight, stopping them from coming loose.

Ideal Use Cases

Use winged connectors in big electrical jobs. They're good in factories or offices where many connections are needed. They stay steady even where there's a lot of shaking.

T-tap Connectors

Unique Features

T-tap connectors let you join wires without cutting them first. You don't need to strip the wire because of their design. They're quick for adding new connections easily.

Benefits

T-tap connectors save time in wiring tasks by being simple to use without stripping wires first, reducing damage risk while ensuring good performance.

Ideal Use Cases

They're perfect for DIY projects at home or cars, adding circuits or devices temporarily.

Splice Connectors

Unique Features

Splice connectors join two wires without soldering. They connect quickly and securely. Use them inside or outside. They are strong and last long in different places. Industrial Connector Expert says splice connectors help power and signals work well. This keeps machines running smoothly.

Benefits

Splice connectors have many benefits. They are easy to install, saving time and money. You don't need special tools for a good connection. They fit with different wire types easily. The strong link stops wires from coming apart or failing. This makes systems safer and better.

Ideal Use Cases

Splice connectors work well in many jobs. Use them at home for lights or outlets. Car lovers use them for fixing car wires. Factories use them for machine care too. Their flexibility makes them great for many projects.

Things to Think About When Picking Wire Connectors

Picking the right wire connectors means knowing some important things. These things make sure the connectors work well where you use them.

Power Needs

Voltage and Current Needs

Every electrical system needs certain volts and amps. Choose connectors that fit these needs. A connector must handle all the current without getting too hot. If it gets too much power, it might break or be unsafe. Always check what both the connector and system need. This makes sure they work well together.

Working Conditions

Environmental Factors

The place where you use connectors matters a lot. Some places have water, dust, or chemicals. In these cases, pick connectors with seals to protect them. Seals keep bad stuff out. For example, panel feed-through connectors often have seals to stop damage. But splice connectors are simpler and might not work in tough spots. Always think about where you'll use the connectors.

Temperature Around

Heat Tolerance

Handling heat is also very important. High heat can ruin connector materials. Pick wire connectors that can take the heat of where they will be used. Connectors that handle high heat last longer and work better. Cold places need special care too because some materials get weak when cold. Make sure the connector material fits the temperature it will face.

Recommendations for Specific Applications

Car Electronics

Top Connectors for Cars

Car electronics need strong and reliable connectors. The best ones keep signals safe in cars. Pick connectors that handle tough conditions. These include shaking, temperature changes, and wetness. Industrial connectors are important in car gadgets. They help send signals safely for top performance.

Important Features to Look For:

Strength: Get connectors made from tough stuff. They last longer.

Sealing: Choose ones with seals to block water and dust.

Heat Resistance: Find connectors that work in hot and cold places. This stops damage.

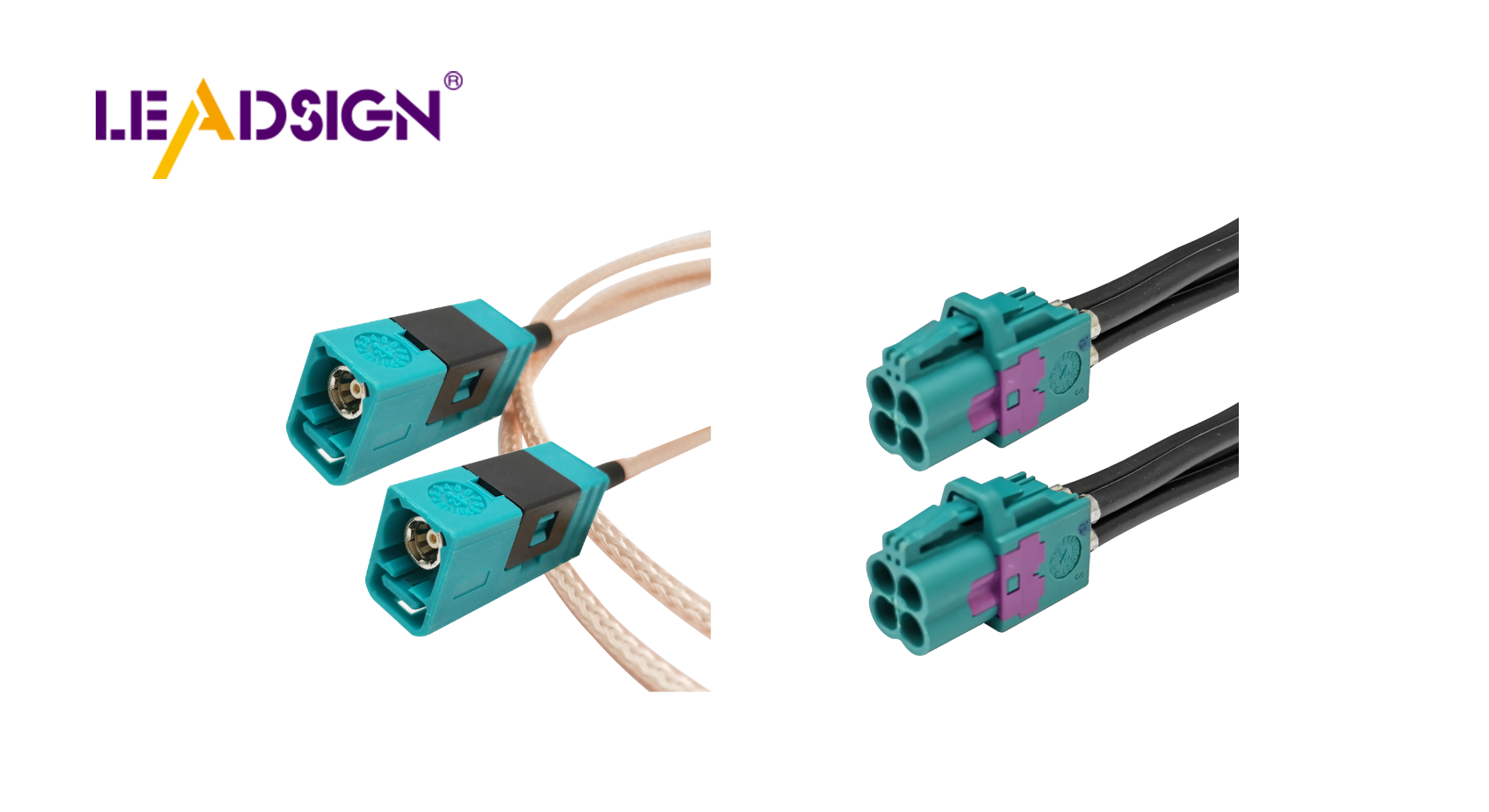

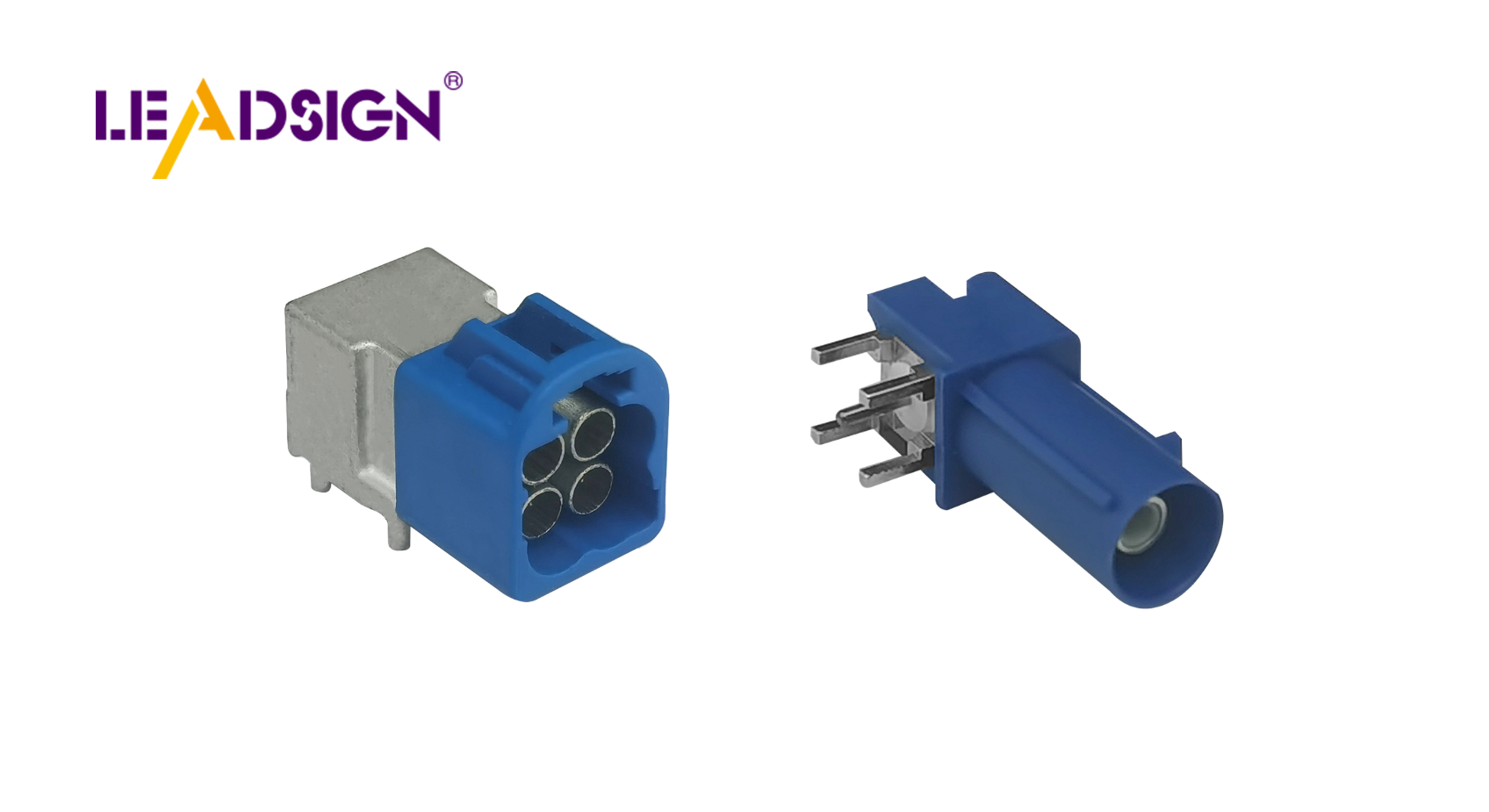

The LEADSIGN HSD product is a great car connector example. It works well in car systems. LEADSIGN HSD keeps connections safe and steady. These make sure signals move well in cars.

The LEADSIGN HSD product is a great car connector example. It works well in car systems. LEADSIGN HSD keeps connections safe and steady. These make sure signals move well in cars.

Benefits of LEADSIGN HSD Connectors:

Fast Data Transfer: LEADSIGN HSD moves data quickly, which is key for new car tech.

Strong Build: These connectors survive rough car conditions, lasting long.

Flexibility: They fit many car uses and adjust to different systems.

Picking the right wire connectors types for car electronics boosts safety and works better. Think about strength, sealing, and heat resistance. Products like LEADSIGN HSD give good solutions for cars' needs.

Choosing the right wire connectors keeps things safe and working well. Know about types like WAGO, Winged, T-tap, and Splice connectors. Each has special features for different uses. Think about power needs, where they will be used, and how hot or cold it gets when picking connectors. For car electronics, LEADSIGN HSD is a good choice. Always pick connectors that fit your needs. Right choices make things work better and last longer in many places.

See Also

The Significance and Flexibility of FAKRA Connectors

An In-depth Manual on FAKRA Connectors: Benefits, Uses, and Setup Advice

The Significance of HSD Connectors in Contemporary Technology