How to Select the Best Automotive Wire Connectors Types for Your Vehicle

Choosing the right wire connectors automotive type is crucial for your vehicle's safety, performance, and longevity. These small components ensure that wires connect properly and function reliably, reducing the risk of failure. High-quality connectors can enhance your car's overall operation while minimizing the chances of overheating or short circuits. Durable connectors tend to last longer and require less maintenance over time. When selecting the appropriate connectors, consider the power requirements, environmental conditions, and compatibility with your vehicle.

Key Takeaways

Choosing the right automotive wire connectors is essential for your vehicle's safety and performance, preventing issues like overheating and electrical failures.

Understand the different types of connectors—crimp, solder, push-in, blade, bullet, and FAKRA—each suited for specific applications and environments.

Always consider your vehicle's electrical needs, including voltage and current ratings, to select connectors that can handle the required power safely.

Environmental factors such as heat, moisture, and vibration should influence your connector choice; opt for weatherproof and durable options for tough conditions.

Testing connections after installation is crucial to ensure reliability; perform visual inspections, pull tests, and continuity checks to avoid future issues.

Investing in high-quality connectors made from materials like copper or brass enhances performance and longevity, ultimately saving you money on repairs.

Consult your vehicle's manual or seek expert advice if unsure about connector types or installation to ensure a proper fit and function.

Overview of Automotive Wire Connectors

What Are Automotive Wire Connectors?

Automotive wire connectors are important parts of your car's electrical system. They join circuits, allowing power and signals to move smoothly in your vehicle. These connectors come in many shapes and sizes for different wiring needs. They connect single wires or more complex systems with multiple wires. Proper connections keep your car's electrical system working well and reliably.

These connectors help your car run without problems. They stop loose or bad connections that might cause electrical issues. From headlights to sensors and infotainment systems, automotive wire connectors are key for smooth operation.

Purpose and Importance of Wire Connectors in Vehicles

Wire connectors have many uses in your car. They make strong, secure links between wires so power and signals flow properly. This is very important for systems like the engine, lights, and safety features.

These connectors do more than just work well. They keep your car safe by stopping electrical shorts, overheating, or failures. Good-quality connectors handle tough conditions like heat, water, and shaking. Using the right connectors protects your car's electrical system and saves you from expensive repairs.

Basic Components of a Wire Connector

Each wire connector has parts that work together to make a strong connection:

Housing: The outer cover keeps dust, water, and heat away. It also stops electrical shorts by providing insulation.

Contacts: These are the metal pieces that let electricity pass between wires. They are often made of copper or brass for better performance.

Locking Mechanism: This part keeps the connector in place, even if there’s movement or shaking.

Seals: Found in weatherproof connectors, seals block water and dirt from getting inside.

Knowing these parts helps you pick the right connector. For example, if your car faces tough weather, choose connectors with strong housings and good seals.

Types of Automotive Wire Connectors

Picking the right auto wire connector types is very important. It helps your car's electrical system work well. Below are three common types of wire connectors: crimp connectors, solder connectors, and push-in connectors. Each has unique features and uses.

Crimp Connectors

Crimp connectors are popular in cars. They join wires by squeezing them together with a crimping tool.

Advantages of Crimp Connectors

Reliable: Crimp connectors stay secure, even in vibrating vehicles.

Waterproof: Properly crimped wires resist water and dirt, lasting longer.

Easy to Use: Crimping is quicker and simpler than soldering.

Flexible: These connectors work with many different types of automotive wires, like battery wires.

Disadvantages of Crimp Connectors

Needs Tools: A crimping tool is required, which not everyone has.

Skill Needed: Bad crimping can cause weak connections that might fail.

Common Uses for Crimp Connectors

Battery wires

Headlights

Engine sensors

Areas with lots of shaking

Solder Connectors

Solder connectors use melted solder to join wires. They are good for small or low-power jobs.

Advantages of Solder Connectors

Strong Connection: Soldering makes stable links that last a long time.

Small Size: These connectors fit in tight spaces easily.

Precise: Great for detailed wiring where accuracy matters.

Disadvantages of Solder Connectors

Takes Time: Soldering is slower and needs more effort than crimping.

Heat Risk: Too much heat can harm wires or connectors.

Fragile: Soldered wires can break under stress or high heat.

Common Uses for Solder Connectors

Circuit boards

Low-power sensors

Fixed electrical systems

Infotainment wiring

Push-In Connectors

Push-in connectors are fast and don’t need tools. They use springs to hold wires tightly.

Advantages of Push-In Connectors

Fast Setup: No tools are needed, saving time.

Simple: Easy to use, even for beginners.

Reusable: You can remove and reuse them, saving money.

Disadvantages of Push-In Connectors

Not Strong: They aren’t as tough as crimp or solder connectors.

Limited Use: Not ideal for shaky areas or heavy-duty wiring.

Common Uses for Push-In Connectors

Interior lights

Speakers

Temporary wiring

Low-power circuits

By knowing these automotive connectors, you can choose wisely. Think about what matters most, like strength, ease, or precision. Each type fits specific jobs in your car's electrical system.

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They make a strong connection and are common in cars because they are simple and dependable.

Advantages of Blade Connectors

Easy to Use: These connectors are quick to attach or remove. They are great for fast fixes or changes.

Strong Fit: They stay in place, even with shaking or movement.

Useful: Blade connectors work with many wires and systems in cars.

Long-Lasting: They hold up well over time and in tough conditions.

Disadvantages of Blade Connectors

Low Power Limit: They might not work well for high-power needs.

Rust Risk: Without protection, they can rust from water or chemicals.

Common Uses for Blade Connectors

Fuse boxes

Headlight wires

Dashboard systems

Power setups

Bullet Connectors

Bullet connectors are round and snap together easily. Their shape makes them simple to spot and use in car wiring.

Advantages of Bullet Connectors

Fast Setup: They snap in quickly, saving time during installation.

Small Size: Their compact design fits tight spaces in cars.

Reusable: You can take them apart and use them again without damage.

Disadvantages of Bullet Connectors

Not Very Strong: They may not last in areas with lots of shaking.

Can Loosen: Over time, they might not stay as tight in stressful spots.

Common Uses for Bullet Connectors

Speaker wires

Inside lights

Extra power setups

Low-power circuits

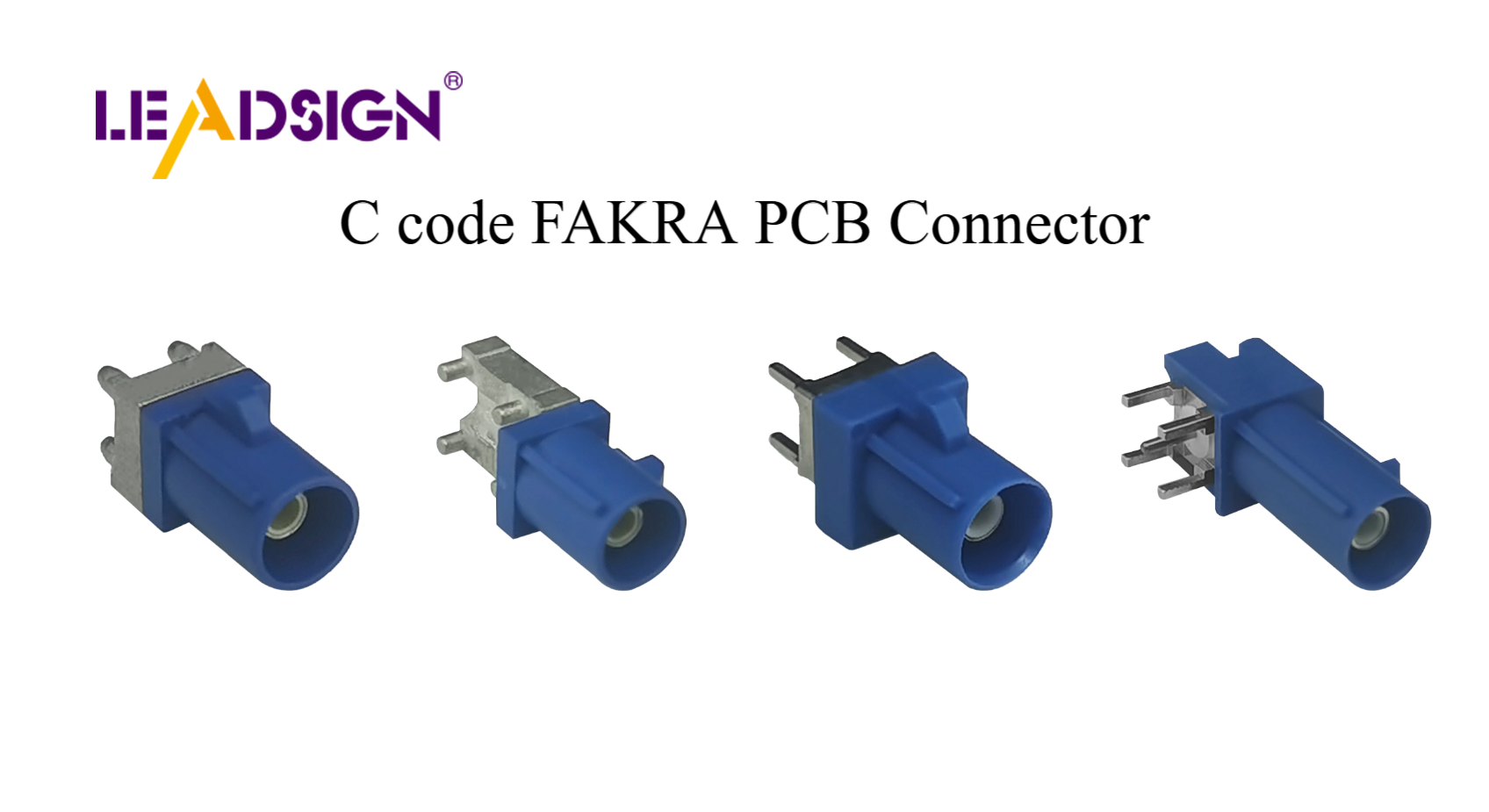

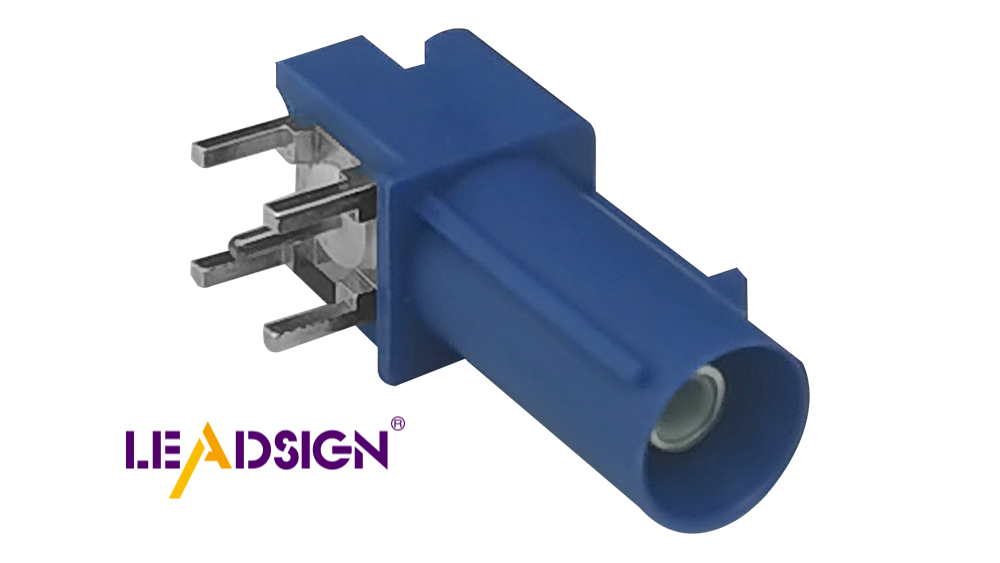

FAKRA Connectors

FAKRA connectors are special connectors for high-tech car systems. They are used in modern vehicles for communication and entertainment features.

Advantages of FAKRA Connectors

High Performance: These connectors handle fast data and signals well.

Color-Coded: The colors help avoid mistakes when connecting them.

Tough: They work in extreme heat, cold, and shaking.

Space-Saving: Their design saves room and makes plugging easier.

Common Uses for FAKRA Connectors

GPS systems

Radio antennas

Bluetooth and Wi-Fi

Keyless entry

Car sensors

Key Factors to Think About When Picking a Wire Connector

Choosing the right electrical connectors for your car needs careful thought. These factors help keep your car's electrical system safe and working well. Below are the main things to check when picking automotive wiring connector types.

Electrical Needs

Voltage and Current Limits

Knowing the current and voltage ratings of a connector is important. Each connector handles a certain amount of electricity. Using one that's too weak can cause overheating or system failure. For example, blade connectors work for medium power, while FAKRA connectors handle high-frequency tasks. Always match the connector's rating to your car's needs for safety.

Resistance and Conductivity

Good electrical connectors should have low resistance and high conductivity. Materials like copper or brass are great because they carry electricity well. Bad connectors with high resistance waste energy and hurt your car's performance. Pick connectors with low resistance for better results.

Environmental Challenges

Heat Resistance

Cars face extreme conditions, so temperature and moisture resistance are key. Some connectors, like FAKRA, can handle temperatures from -40°C to +105°C. This keeps them working in very hot or cold weather. Choose connectors that can handle your car's temperature changes.

Water and Rust Protection

Moisture and rust can damage connectors over time. Weatherproof connectors, like bullet or blade types, block water and dirt. This is vital for outdoor or engine use. Moisture-resistant connectors last longer and stay strong.

Vibration and Movement

Cars move a lot, so vibration and impact resistance is a must. Crimp connectors stay tight even in shaky areas. FAKRA connectors also work well in tough conditions. Pick connectors that can handle your car's bumps and shakes.

Wiring Compatibility

Matching Size and Type

Your connector must fit your car's wiring size and type. For example, blade connectors fit slots, and bullet connectors snap into place. Wrong-sized connectors can cause bad connections. Make sure the connector fits the wire gauge and stays secure.

Proper Fit and Use

A good fit ensures the connector works without problems. Loose connectors can cause electrical issues. For complex systems like automotive wiring harness wire, FAKRA connectors give secure and accurate links. Test the fit before deciding to avoid future troubles.

By thinking about these points, you can pick the best vehicle wires and connectors. The right choice will make your car's electrical system safer and more efficient.

Easy to Install

Tools You Need

The tools depend on the connector type. For blade connectors, no special tools are needed. Their flat shape lets you slide them into slots easily. This makes them great for quick and simple fixes. Bullet connectors are round and may need pliers. Pliers help make sure they fit tightly and stay secure.

For advanced connectors like FAKRA connectors, extra tools are often required. You might need crimping tools or special equipment to attach them. These tools ensure FAKRA connectors work well in systems like GPS or Bluetooth. Using the right tools makes the job easier and ensures a strong connection.

Time and Work Needed

The time and effort depend on the connector type and your skill. Blade connectors are the simplest to install. Their easy design lets even beginners finish in minutes. Bullet connectors are also quick but may take extra time to fit tightly.

Installing FAKRA connectors takes more time and care. These connectors are for modern systems, so they need precise work. You must align parts carefully and use the right tools to secure them. Though it takes longer, the result is a strong connection for advanced features.

If you want fast and easy, choose blade or bullet connectors. For complex systems, spend more time on FAKRA connectors for better results. Knowing how easy each type is to install helps you plan and get the best outcome.

Common Mistakes to Avoid

Skipping Electrical Needs

Not checking your car's electrical needs can cause big issues. Each connector has limits for voltage and current it can handle. Using a weak connector for a strong power job can cause overheating or failure. For example, a small connector might melt if used for high power. Always check the connector's ratings to match your car's needs. This keeps your car safe and prevents damage.

The material of the connector also matters. Good materials like copper or brass carry electricity better. Bad materials can waste energy and cause weak connections. Pick connectors with low resistance and good conductivity for better performance.

Ignoring Environmental Conditions

Weather and movement affect how well connectors work. Heat or cold can make connectors crack or stop working. Water can cause rust, which weakens the connection. Use weatherproof connectors with seals for wet or dirty areas.

Cars shake a lot, so vibration is a big problem. Loose connectors can cause trouble. Crimp and FAKRA connectors stay tight in shaky spots. Ignoring these issues can lead to more repairs and poor system performance.

Picking the Wrong Connector

Using the wrong connector type can mess up your car's wiring. Each connector is made for a specific job. Crimp connectors are great for shaky areas, while solder connectors are better for small, precise jobs. Push-in connectors are easy but not strong enough for heavy work.

Choosing the wrong connector can cause bad connections or even safety risks. Think about your car's needs before deciding. Check the wire size, job type, and conditions. Picking the right connector ensures safety and good performance.

Skipping Connection Testing After Installation

Always test the connection after installing it. Skipping this step can leave loose or bad connections. These issues might cause electrical problems or even safety risks. A quick test ensures your automotive wire connectors work properly and handle your car's electrical needs.

Why Testing is Important

A connector may look fine when installed. But hidden problems like weak crimps or misaligned wires can cause trouble. These issues might lead to overheating, short circuits, or failures. Studies show bad connectors lower vehicle safety and reliability. Testing helps find these problems early, saving money and avoiding dangers.

"Using high-quality automotive electrical connectors is vital for vehicle reliability and safety. Inferior connectors can lead to poor connections and potential hazards." – LEADSIGN-AUTO Journal

Steps to Test Your Connection

Here are simple steps to check your connection:

Look Closely

Inspect the connector for loose wires or damage. Make sure it fits tightly and securely.Pull Test

Gently tug the wires to ensure they stay in place. Wires should not slip out if installed correctly.Check Continuity

Use a multimeter to confirm smooth current flow. This ensures no interruptions in the connection.Simulate Load

Test the connector with the actual electrical load it will handle. This checks if it can manage voltage and current without failing.Test in Real Conditions

If possible, expose the connection to vibrations or temperature changes. This is crucial for connectors in tough environments.

Problems Found During Testing

Testing often uncovers hidden issues, such as:

Loose Wires: Caused by poor crimping or soldering.

Energy Loss: High resistance from bad materials or methods.

Rust: Moisture or corrosion can weaken connections. Use copper or aluminum connectors to resist this.

Why Testing Helps

Testing ensures your car's electrical system stays safe and reliable. It prevents sudden failures, lowers repair costs, and improves performance. Spending a few minutes testing protects your car and avoids risks.

Understand Your Vehicle's Wiring System

Start by learning about your car's wiring system. Check the type of wires, their size, and how complex the system is. For example, some cars use wiring harnesses to manage many circuits. Knowing if your car has these helps you pick connectors that fit well and work reliably.

Think about how much electricity the system needs. Each connector is made to handle certain voltage and current levels. Using the wrong one can cause overheating or damage. Also, consider the conditions your car faces, like heat, water, or shaking. Choose connectors that can handle these challenges and keep working properly.

Use the Manual or Ask an Expert

Your car's manual is a helpful guide for picking connectors. It lists the right types for your car's wiring system. Following these instructions avoids problems and ensures everything works as it should.

If the manual isn’t clear, ask a professional for help. A skilled technician can check your car and suggest the best connectors. They can also show you how to install them correctly. Getting expert advice saves time and prevents mistakes, especially for tricky systems like wiring harnesses.

Choose Good-Quality Connectors

Good connectors are important for your car's safety and performance. High-quality ones are made from strong materials like copper or brass. These materials carry electricity well and waste less energy, improving your car's efficiency.

Strong connectors often have features like waterproof seals and secure locks. These protect against water, rust, and shaking, making them great for tough conditions. For example, FAKRA connectors are perfect for modern systems like GPS and Bluetooth.

Some connectors are easy to install, like blade or bullet types. Others, like FAKRA connectors, need special tools but are very reliable. Pick connectors that are both easy to use and long-lasting for the best results.

Spending more on good connectors is worth it. Cheap ones might not last or work well. Investing in quality connectors keeps your car safe and reduces repair costs over time.

Test the Connector Before Installing It

Testing your connector first ensures it works safely and properly. This step helps find problems early, saving time and avoiding expensive fixes. Follow these simple steps to test your connector:

Check the Connector

Look closely at the connector for cracks, rust, or loose parts. Make sure it fits tightly with the wire and lines up with the terminal.Do a Pull Test

Gently tug the wires attached to the connector. This checks if they are secure and won’t come loose. A strong connection keeps your car’s electrical system running smoothly.Test with a Multimeter

Use a multimeter to check if electricity flows through. Place the probes on both ends of the connector to confirm it works correctly.Try Real-Life Conditions

Test the connector in conditions like shaking or heat changes. This is important for connectors used in tough spots, like near the engine.Check with Actual Power

Connect the system to its real power load. This ensures the connector can handle the voltage and current without problems.

Testing your connector before installing it makes your car safer and more reliable. Skipping this step can cause weak connections, overheating, or system failures. Spending a few minutes testing ensures a strong and lasting connection.

Choosing the right car wire connector is very important. It keeps your car safe and working well. Good connectors help power flow smoothly and prevent problems like overheating. Think about your car's power needs, weather conditions, and wire fit. If you skip this, you might face issues like broken lights or bad radios.

Check what your car needs for long-term care. Look at the manual or ask an expert if unsure. Picking the right connector now avoids future problems and keeps your car running reliably.

What are the most common mistakes when installing automotive wire connectors?

Mistakes during installation can cause problems later. A common error is using the wrong connector size or type for the wire. This can lead to loose connections or poor performance. Another mistake is skipping the testing step after installation. For example, you might install a stereo system but find it doesn’t work because of a loose wire or bad connection. Always test your connections before finishing the setup. Also, not using the right tools, like crimping pliers for crimp connectors, can weaken the connection and make it fail over time.

How do I know which connector type is best for my vehicle?

To pick the right connector, first check your car’s wiring system. Look at the wire size and how much electricity it needs, like voltage and current. Think about the environment too, such as moisture or shaking. For instance, FAKRA connectors are great for GPS or Bluetooth, while crimp connectors are better for areas with lots of movement. If you’re unsure, check your car’s manual or ask an expert.

Why is testing the connection after installation important?

Testing makes sure your connection is safe and works well. Without testing, problems like loose wires or bad contact might go unnoticed. For example, a connection might seem fine but fail later due to shaking or heat. Testing helps you find these issues early, saving time and avoiding damage to your car’s electrical system.

Can I reuse connectors after removing them?

Some connectors, like push-in or bullet types, can be reused if they’re not damaged. But crimp connectors usually can’t be reused. Once crimped, they lose their strength if removed. Reusing or re-crimping a bad connector isn’t a good idea because it makes the connection less reliable. Always check the connector before deciding to reuse it.

What tools do I need to install automotive wire connectors?

The tools depend on the type of connector. Crimp connectors need a crimping tool for a tight fit. Solder connectors require a soldering iron and solder wire. Push-in connectors don’t need special tools, so they’re easy for beginners. Advanced connectors like FAKRA may need special tools for proper alignment and secure installation.

How can I prevent corrosion in wire connectors?

To stop corrosion, use weatherproof connectors with seals, especially in wet or dirty areas. Make sure the ground wire is clean and free of rust before connecting. Adding dielectric grease can protect against moisture and rust. Check your connectors often for signs of corrosion and replace them if needed.

What should I do if a connection fails after installation?

If a connection fails, check the connector and wire for damage. Look for loose wires, bad crimping, or rust. For example, a loose ground wire might cause problems. Replace the connector if it’s damaged. Don’t reuse or re-crimp faulty connectors, as this can cause more failures.

Are high-quality connectors worth the investment?

Yes, good connectors make your car’s electrical system safer and more reliable. They’re made from strong materials like copper or brass, which carry electricity better and last longer. Features like waterproof seals and secure locks help them work well in tough conditions. Spending more on quality connectors reduces the chance of problems and costly repairs.

How do I ensure a secure connection during installation?

To make a secure connection, carefully strip the wire without damaging it. Use the right connector for the wire size and job. For crimp connectors, use a crimping tool to make a tight fit. After installing, do a pull test to check if the wires stay in place. You can also use a multimeter to make sure the connection works.

Can I install connectors without professional help?

Yes, you can install connectors yourself if you follow the steps and use the right tools. Simple connectors like blade or push-in types are easy to install and don’t need much experience. But for complex systems or advanced connectors like FAKRA, it’s better to ask a professional. Always check your car’s manual for instructions.

See Also

Why Fakra Connectors Are Essential for Today's Vehicles

Fakra Connectors: A Key Component in Automotive Technology

Enhancing Data Transfer in Cars with Advanced Connectors