Best Vehicle Connectors for Automotive Applications Compared

Vehicle connectors are important for keeping your car running well. They help maintain steady electrical connections, even in tough conditions. However, very hot or wet weather can cause rust and damage. Frequent use can also lead to wear and tear. Choosing high-quality vehicle connectors helps your car last longer and perform better.

Key Takeaways

Choosing high-quality vehicle connectors enhances your car's performance and longevity, ensuring reliable electrical connections even in harsh conditions.

Understanding the specific applications of different connector types—like wire-to-wire, wire-to-board, and board-to-board—can help you select the right one for your automotive needs.

Investing in trusted brands like TE Connectivity and Amphenol guarantees quality and reliability, ultimately saving you money on repairs and replacements.

Overview of Automotive Connector Types

Wire-to-Wire Connectors

Wire-to-wire connectors join two wires directly together. You can connect or disconnect them by plugging or unplugging. These are great for permanent links between single wires or cables. Butt connectors join wires end-to-end, while bullet connectors allow quick disconnections. Spade terminals are often used in car stereos. These connectors work well even in tough conditions, ensuring reliable performance.

Wire-to-Board Connectors

Wire-to-board connectors attach wires to a circuit board. They transfer power or signals between wires and electronics. These are found in engine controls and infotainment systems. Crimp connectors are attached by squeezing them onto wires. Heat shrink connectors seal tightly to resist weather damage. These connectors are popular in modern cars for their flexibility and usefulness.

Board-to-Board Connectors

Board-to-board connectors link two circuit boards together. They help electronic systems communicate easily. These are used in electric cars, in-cabin tech, and driver assistance systems. Their small size supports compact car designs. Board-to-board connectors are important for transferring data and power efficiently in modern vehicles.

Applications of Each Connector Type

Connector Type | Uses |

|---|---|

Pin Connectors | Engine controls, lights |

Socket Connectors | Sensors, switches |

Barrel Connectors | GPS, antennas, audio systems |

Each connector type has specific uses. Pin connectors are good for engine controls. Socket connectors work with sensors and switches. Barrel connectors are used in GPS and audio systems. Picking the right connector helps your car’s electrical systems work well.

Top Brands in Car Electrical Connectors

TE Connectivity

TE Connectivity is a top brand for car connectors. They make many products for different uses. Their AMP Electrical Components and DEUTSCH Connectors are very reliable. RAYCHEM makes strong heat-shrink products, and INTERCONTEC connectors are flexible. Below are some of their main products:

Product Family | Description |

|---|---|

AMP Electrical Components | Well-known for electrical parts. |

DEUTSCH Connectors | Famous for high-quality connectors. |

RAYCHEM | Makes dependable heat-shrink items. |

Laird External Antennas | Focuses on antenna solutions. |

INTERCONTEC connectors | Provides many connector options. |

KISSLING Relays and Switches | Makes strong relays and switches. |

Amphenol

Amphenol is another great brand for car connectors. Their products are tough and protect against weather. These connectors handle many pins for power and data. They work well in both easy and rough conditions. Amphenol connectors always perform reliably.

Molex

Molex creates new ideas for car connectors. Their MX150 and DuraClik connectors are strong and support sensors and cameras. Flexi-Latch+ connectors are small and light, great for EV batteries. Other features include:

Micro Board-to-Board Connections for ADAS and EVs.

Solutions that work well in extreme weather.

Yazaki

Yazaki connectors are small and very strong. They fit in tight spaces and work in many car systems. These connectors send power and data reliably. Their design lowers repair costs and improves car performance.

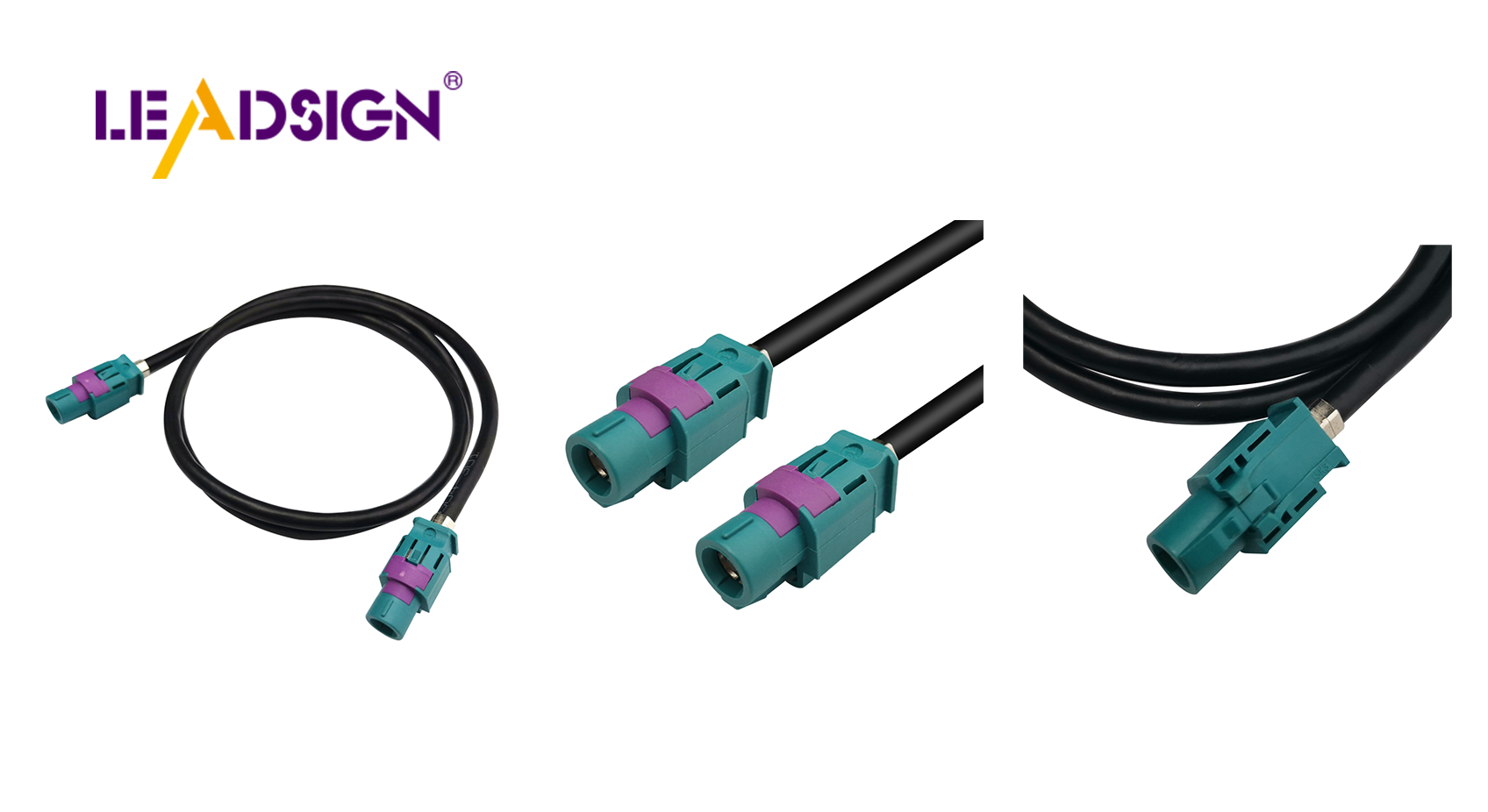

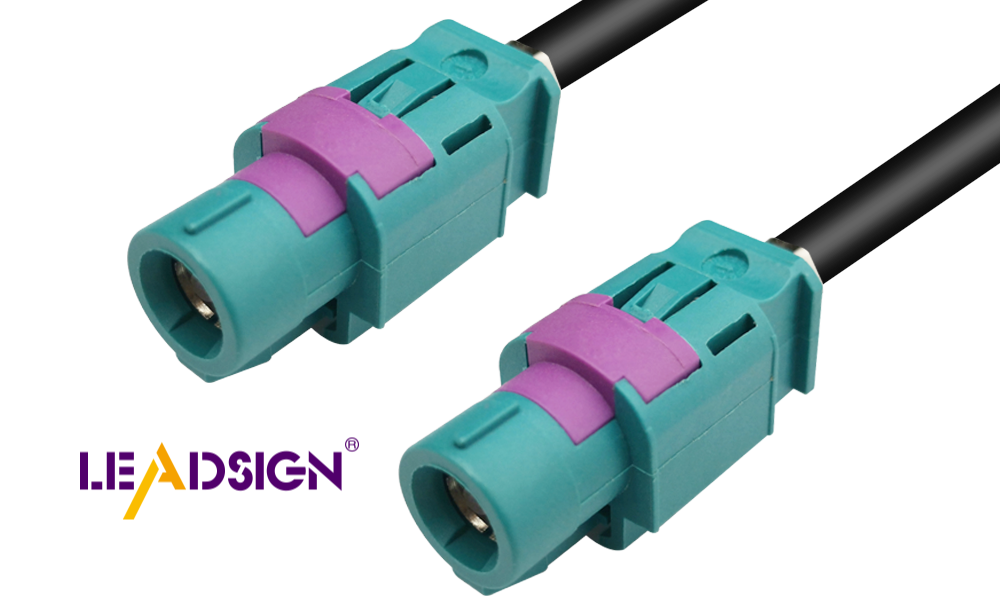

LEADSIGN and HSD Connectors

LEADSIGN’s HSD connectors are fast and efficient. They are great for infotainment and self-driving cars. These connectors are simple to use and last a long time. LEADSIGN is known for its quality and smart designs in car connectors.

Key Features and Benefits of Vehicle Connectors

Strong and Long-Lasting

Vehicle connectors need to be strong and last long. Good materials make them work well in tough conditions. Brass, bronze, and copper are used for electrical parts. These metals stop rust and damage, making connectors last longer. Plastic covers like PA66 and PBT protect against electricity and weather.

Plastic connectors are light and great for modern cars. Metal ones are stronger and handle rough conditions better. These materials keep connections steady, even in bad weather or when cars shake a lot.

Saves Money

Saving money is another benefit of good connectors. Strong materials mean fewer replacements are needed. This helps you spend less over time. Plastic connectors are cheap and easy to make. They also lower production costs. Reliable connectors stop problems, so repair costs are less.

New Technology

Modern connectors are made for advanced car systems. They send data fast for smart features like self-driving. Electric car connectors handle high power safely. Small and light designs save space and improve car performance.

Standard designs make fixing and building easier. Better materials make them safer and more reliable. Recyclable materials help the environment. These updates make connectors important for all types of cars.

Many Uses

Connectors are used in many ways. Wire-to-wire ones join wires together. Wire-to-board ones link wires to circuit boards. Board-to-board ones connect boards for power and data. High-power connectors are key for electric car batteries and engines.

Sealed connectors work in tough places and stay safe. They help with smart tech like sensors and entertainment systems. They are also important for electric cars, helping them run better.

Comparing Connectors Based on Important Factors

Material Strength and Weather Resistance

Picking good car connectors depends on strong materials. Metals like copper and brass last longer and work better. They don’t rust easily, so they’re great for long use. For electric cars, connectors must handle heat and shaking near motors. Waterproofing and sealing are needed for tough weather.

Weather resistance makes connectors last longer. Special oils protect them from water, rust, and dirt. This stops damage and keeps them working well in hard conditions. It also prevents wear and keeps them reliable over time.

Easy to Install and Fix

Putting in and fixing connectors can be hard without knowing how. Using wrong tools or not checking wire sides can cause problems. Always follow the right steps to avoid breaking them. Strain relief is important too. It stops wires from pulling and keeps systems safe.

Fixing connectors is simpler when they meet standard rules. Some connectors are made for certain places or weather, making repairs easier. Good sealing means fewer fixes are needed, saving time and work.

Works with New Car Systems

New cars need connectors for advanced systems. Size, circuits, and design decide if they fit. Electric cars need connectors for high power and fast data. Different regions have their own rules for designs. For example, the U.S. uses USCAR rules, while Europe and Asia have others.

Good teamwork between makers and suppliers ensures connectors fit these needs. This helps them work well in systems like sensors, screens, and driving aids.

Cost vs. Quality

Looking at features like strength and ease of use helps compare costs. Strong connectors may cost more but save money later. They lower repair costs and make systems work better. Plastic ones are cheap and light, while metal ones are stronger. Pick connectors that match your budget and needs.

Guide to Picking the Best Vehicle Connector

Understanding What You Need

Start by knowing what your system needs. Follow these steps:

Figure out if it needs power or data transfer.

Pick the right wire type for the job.

Match the wire size to the power it carries.

Choose insulation that works in your environment.

Select a connector type that fits your system.

Check if the connector housing is strong enough.

Pick contact materials that resist rust and conduct well.

Make sure it’s sealed to block water or dust.

Test if it locks securely and fits properly.

Confirm it meets industry rules.

Test it in real-world conditions.

Fix any design issues you find.

Finalize and write down the design details.

Thinking About Environment and Use

Where and how you use the connector matters. Ask yourself:

Will it face very hot or wet conditions?

Does it need to block water, oil, or gas?

Should it handle shaking or bumps?

For example, engine connectors must handle heat and shaking. Sealed ones are best for wet or dirty areas. Always match the connector to its environment for good performance.

Balancing Price and Quality

You need to balance cost and quality. Strong connectors may cost more but save money later. Plastic ones are cheap and light. Metal ones are stronger. Pick one that fits your budget and needs.

Why Brand Matters

Good brands like TE Connectivity, Amphenol, and Yazaki make reliable connectors. Their products are tested and follow rules. Trusted brands give you quality and help when needed.

Picking the right connectors helps your car work well. Brands like LEADSIGN, TE Connectivity, Amphenol, and Yazaki make great options. LEADSIGN is good for fast data, while Yazaki makes small, strong designs.

Think about what your car needs before choosing a connector. Make sure it follows car rules and fits your vehicle. Strong materials and good sealing make it last longer. Choosing the right connector saves money and keeps your car reliable.

FAQ

What materials make vehicle connectors last long?

Copper and brass are strong and don’t rust easily. Plastic covers like PA66 protect from weather and electricity, making them last longer.

How can you pick the best connector for your car?

Think about what your system needs. Check for power, data, and weather issues. Choose the right type, material, and sealing for your use.

Why do sealed connectors matter?

Sealed connectors keep out water, dust, and dirt. They work well in tough places like engines or outdoors, stopping damage and keeping connections strong.

See Also

HFM Connectors: Key Benefits for Automotive Connectivity

Transforming Vehicle Connectivity with HFM Connector Benefits

Fakra Connectors: Essential for Today's Automotive Technology