Best Practices for Using Auto Wire Connector Types

Using the right automotive electrical connectors types in cars is important. It helps keep things safe and working well. You should know about different types of car electrical connectors. This helps you pick the right ones. Connectors like bullet, butt, and spade are key for a car's electrical system. Following best practices when installing them is smart. It makes your connections last longer and work better. This improves how the car runs and lowers chances of problems. Quick disconnect harnesses make wiring easier and improve the whole electrical system.

Knowing About Car Electrical Connectors

Picking the right automotive electrical connectors types is key for your car's safety and power. Let's look at some common connectors and how to choose the best one.

Common Connector Types

Bullet Connectors

Bullet connectors are easy to use. They let you connect or disconnect wires fast. Use them when you often change parts. They fit snugly, so they don't come apart by accident.

Butt Connectors

Butt connectors join two wires end-to-end. They're great for making a lasting link. Use them to make a wire longer or fix a broken one. These ensure strong connections, keeping your car's system safe.

Spade Connectors

Spade connectors, also called fork connectors, help connect wires to blocks or screws. They're easy to put on and take off. Use them where wires need frequent changes, like in fuse boxes.

Picking the Right Connector

Matching Wire Size

Choose the right connector for your wire size. Wrong matches can cause bad links or harm. Always check wire size first for a good fit and top performance.

Thinking About Conditions

Weather affects connector choice too. If it’s wet or harsh, pick weatherproof ones to stop rust and last long. Good quality keeps systems working well.

"Wires are needed in all harnesses because they carry power and signals between car parts."

Using Car Wire Quick Disconnect Harnesses makes setup easier and cheaper. They’re color-coded for simple DIY jobs and upgrades.

Gathering Necessary Tools and Materials

To install car wire connectors well, you need the right tools. This section shows what you need.

Essential Tools

Wire Strippers

Wire strippers help get wires ready. They take off the cover without hurting the wire. This makes a good connection. Pick one that fits your wire size.

Crimping Tools

Crimping tools join connectors to wires tightly. They press them together for a strong hold. A good tool keeps connections firm over time. Use one that fits your connector type.

Soldering Iron (optional)

A soldering iron can make connections stronger with solder. It adds strength and helps in shaky places. It's not always needed but use it for extra safety.

Required Materials

Auto Wire Connectors

Auto wire connectors are key parts of wiring systems. They come in different shapes and sizes for easy linking. Choose ones that fit your wire size and conditions.

Heat Shrink Tubing

Heat shrink tubing covers and protects connections. It shrinks with heat to seal tight around wires and connectors, keeping out water and dirt.

Electrical Tape (optional)

Electrical tape gives more protection to connections. It stops them from coming apart by accident, useful when extra cover is needed.

By getting these tools and materials, you're ready for a good installation job.

Getting Ready and Doing the Job

In this part, you'll learn how to set up and put in car wire connectors. Getting ready right makes sure the connection is safe and works well for your car.

Getting Wires Ready

Taking Off the Cover

First, take off the cover from wires. Use a wire stripper tool. Put the wire in the right spot on the tool that matches its size. Squeeze and pull to remove the cover. This shows the bare wire for connecting. Be careful not to cut or hurt the wire strands.

Twisting Wire Strands

After taking off the cover, twist wire strands together. Hold tight and twist them clockwise. Twisting keeps them together so they fit into connectors easily. This step is key for a strong link.

Making Connections

Crimping Right

Crimping is important with car wire connectors. Put twisted wires into connectors. Use a crimp tool to press it onto wires hard. Press firmly so it holds tight. A good crimp stops wires from slipping out and keeps a solid link. Look at it closely to make sure it's secure.

Adding Solder (if needed)

Sometimes soldering is needed for extra strength. Heat up solder iron and add some solder to join parts together well. Let solder spread over all of it smoothly for more safety, especially where there's shaking around often. Let it cool before moving wires.

By doing these steps, you make sure car wire connectors are put in right, making your car's system safer and better.

Checking and Testing

Checking and testing make sure your car wire connectors work well. This step makes sure everything is safe and working right. You will look at the connections and do some tests to see if they are strong.

Looking at the Connection

Checking by Sight

Look closely at each connection. See if wires are all the way in connectors. Make sure no wire pieces stick out. Sticking out wires can cause problems or shorts. Check that connectors are not broken or cracked. A good look helps find problems early.

Pull Test

Gently pull on wires to check how strong the connection is. Wires should stay put and not come loose. If a wire slips out, it’s not secure. You need to fix it again. The pull test checks that car wire connectors hold tight in normal use.

Testing with Tools

Continuity Check

Use a multimeter for a continuity check. Set it to continuity mode. Touch probes to both ends of the connection. It should beep if the connection is good. This test shows if electricity flows well through wires. A good beep means your car wire connectors work right.

Voltage Drop Check

Do a voltage drop check for efficiency. Put multimeter probes on both ends of the wire when power is on. Measure voltage at both ends. A small drop means a good link, but a big drop shows too much resistance, which can be bad. This test checks that car wire connectors keep voltage steady.

By doing these steps, you make sure your car wire connectors are set up right and work well always.

Choosing the right car wire connectors is important for safety and performance. Always use good methods to make sure connections are strong. Doing it right stops problems and makes your car's wires last longer. Good wire links help your car work better and avoid breakdowns. By knowing about different types of car connectors, you can pick the best ones for your vehicle. Learning about these connectors is worth it because it keeps driving smooth and safe over time.

See Also

Enhancing Automotive Efficiency with HFM Connectors

Benefits of HFM Connectors for Automotive Sector

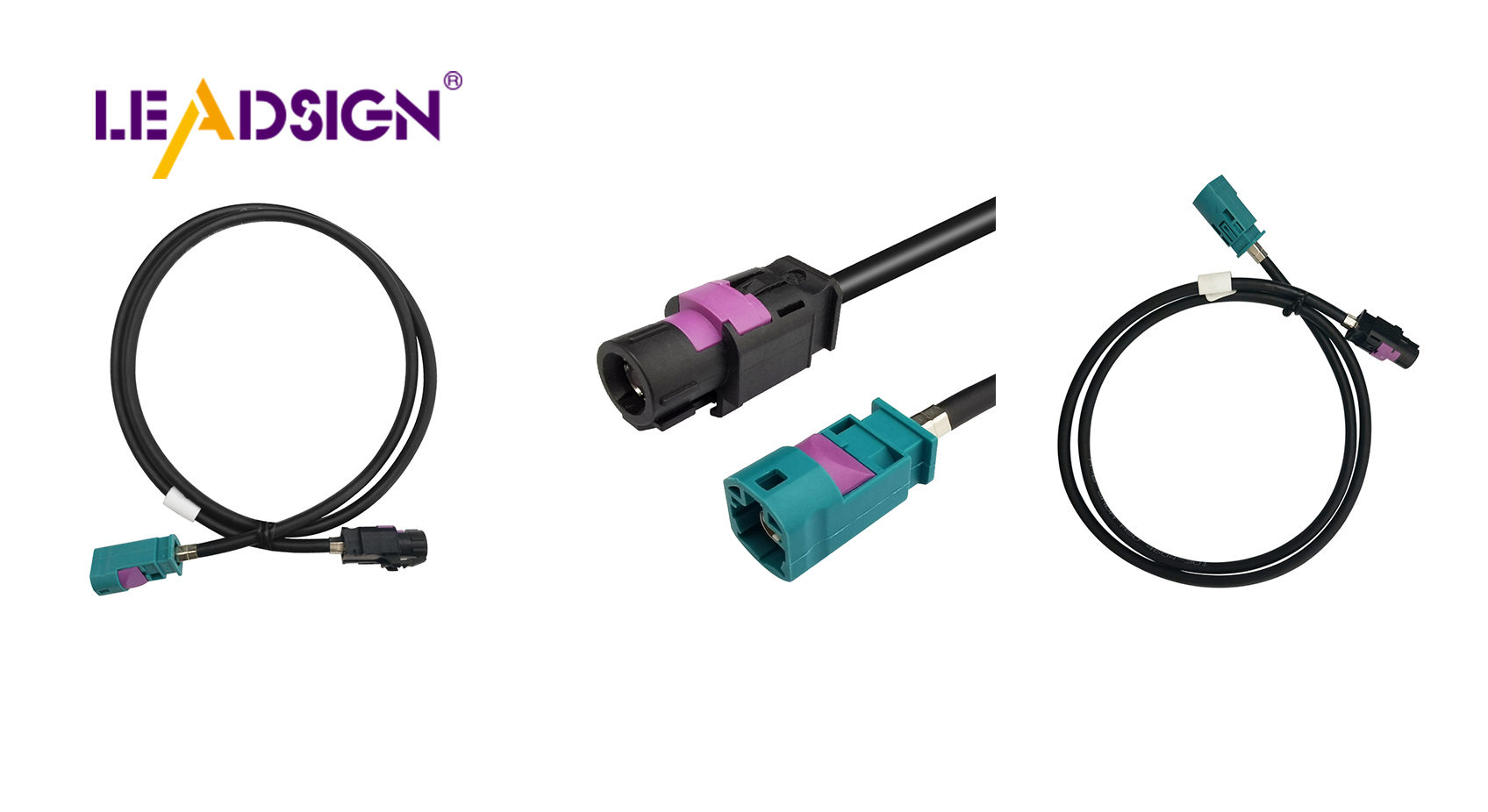

Significance of FAKRA Connectors in Automotive Uses