How to Identify the Best PCB Board Wire Connectors for Your Needs

Choosing the right PCB board to wire connectors is crucial. These connectors link components, allowing signals to flow easily and reliably. Quality connectors enhance performance and maintain strong signals. They also reduce the risk of failures. Consider factors like strength, fit, and project requirements to prevent issues down the line. The right connectors enable you to build robust systems that function effectively over time.

Key Takeaways

Understand your project's specific needs before selecting connectors to ensure compatibility and performance.

Consider the environmental challenges your PCB will face, such as heat or moisture, to choose durable connectors.

Evaluate the size and layout of your PCB to select connectors that fit well without crowding or wasting space.

Invest in high-quality connectors from trusted brands to reduce long-term costs associated with repairs and replacements.

Stay informed about market trends like miniaturization and faster data speeds to future-proof your designs.

Test your chosen connectors in real-world conditions to ensure reliability and performance before finalizing your project.

Opt for modular connectors if you anticipate future upgrades, allowing for easy adjustments and expansions.

Knowing What Your Project Needs

To pick the best PCB connectors, know your project needs first. Every project is different, so understanding these needs helps you make smart choices for strong and efficient designs.

Figuring Out Connection Needs

Think about what connections your project requires. Ask yourself:

How many wires or signals need to connect?

What current or voltage will the connectors handle?

Are the connections temporary or permanent?

For instance, if your project transfers data quickly, you’ll need special connectors like LVDS or USB 3.0. These keep data fast and stable. Simpler projects may only need basic headers or terminal blocks. By knowing this early, you can avoid problems later.

Challenges for Your Project

Each project has unique challenges to consider. Think about where your PCB will be used. Will it face heat, vibrations, or moisture? If yes, choose tough connectors that handle harsh conditions well. For example, car electronics need strong connectors with secure locks to stay reliable during movement.

Also, check your PCB’s size and layout. Small designs may need tiny connectors, while bigger boards offer more space options. Balancing these factors ensures good performance without design issues.

Cost and Future Growth

Your budget matters when picking parts. Good-quality connectors might cost more now but save money later by lasting longer and needing less fixing. Plan your budget wisely to get the best value.

Think about future upgrades too. If you plan to expand later, use modular connectors that allow easy changes or additions. These are great for growing projects.

By focusing on connection needs, challenges, and costs, you can pick the right connectors for better PCB performance.

Types of PCB Board Wire Connectors

Picking the right connector is important for your PCB's performance. Different connectors have unique uses, so knowing their features helps you choose wisely.

Header Connectors

Header connectors are very common in PCBs. They have rows of pins to link wires or parts to the board. These connectors work well for simple and dependable connections.

They come in single-row or double-row designs. Their small size fits tiny PCBs, saving space. They are easy to attach and remove, perfect for projects needing frequent changes.

Terminal Blocks

Terminal blocks are strong and flexible for connecting wires to PCBs. They use screws to hold wires securely without soldering. This makes them great for industrial projects needing regular adjustments.

They handle high currents and last a long time. Terminal blocks come in different sizes and styles to match your needs. Screw-type ones hold wires tightly and fit various wire sizes, making them ideal for tough jobs.

Wire-to-Board Connectors

Wire-to-board connectors join wires or cables directly to a PCB. They’re used in power supplies, data transfer, and sensors. Options like crimp connectors suit specific tasks.

These connectors ensure safe and steady links for all kinds of projects. In power systems, they manage high currents safely. For data transfer, they keep signals clear between parts. Their flexibility makes them essential in electronics today.

By learning about header connectors, terminal blocks, and wire-to-board types, you can pick the best one for your project’s needs.

Specialty Connectors

Specialty connectors are made for specific and unique tasks. They are useful when regular connectors don’t meet your project’s needs. These connectors are important in fields like cars, phones, and advanced gadgets.

For instance, screw-type connectors tightly secure wires using screws. This keeps wires stable even in tough conditions. Their strong build is perfect for industries needing long-lasting parts. They also fit different wire sizes, making them versatile.

Another example is modular connectors. These allow easy upgrades or changes to systems. They help maintain systems quickly and reduce downtime, keeping projects running smoothly.

When picking specialty connectors, think about your project’s needs. Check if they can handle the environment, space limits, or future updates. The right connector improves how well your PCB works.

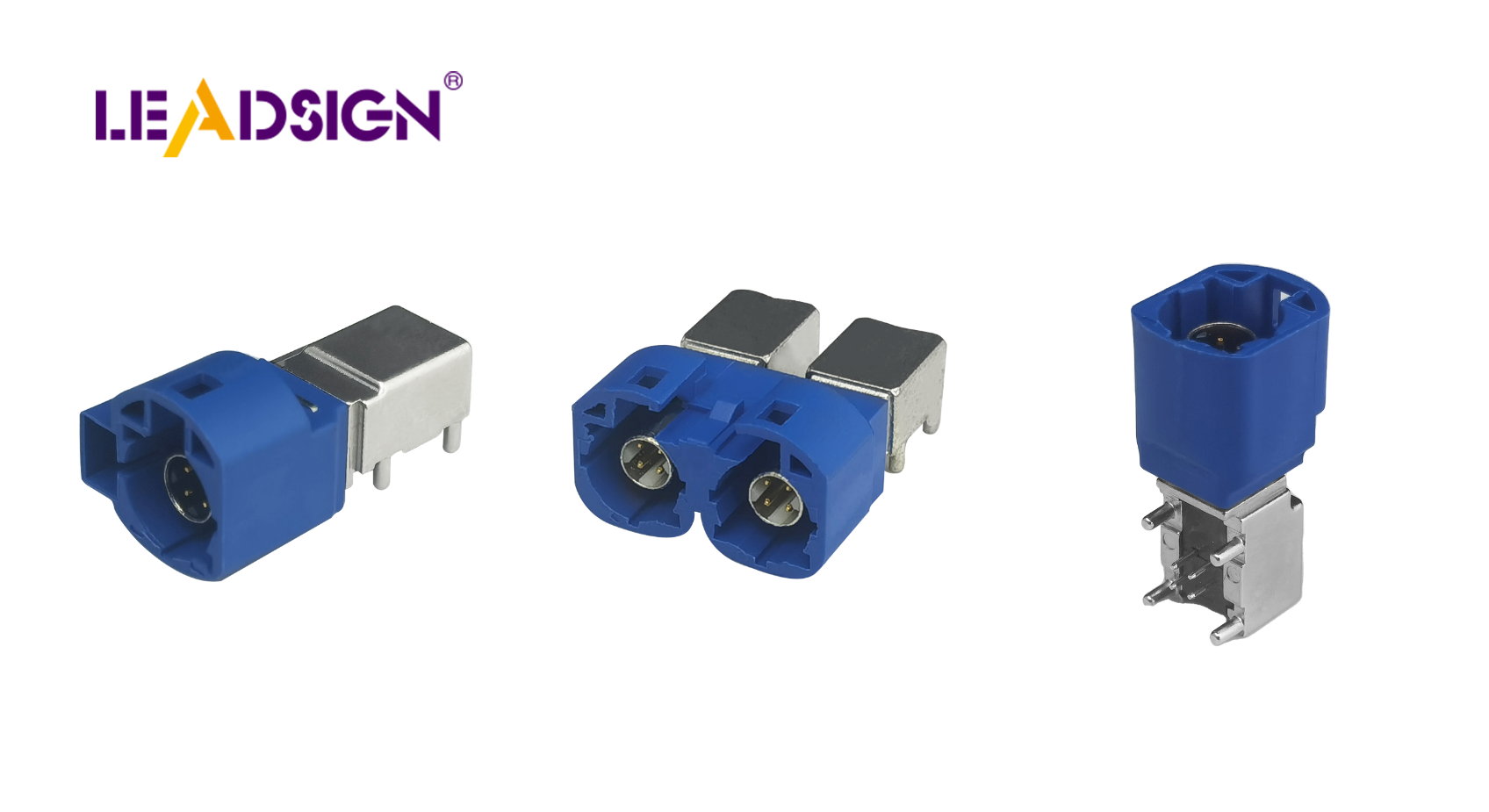

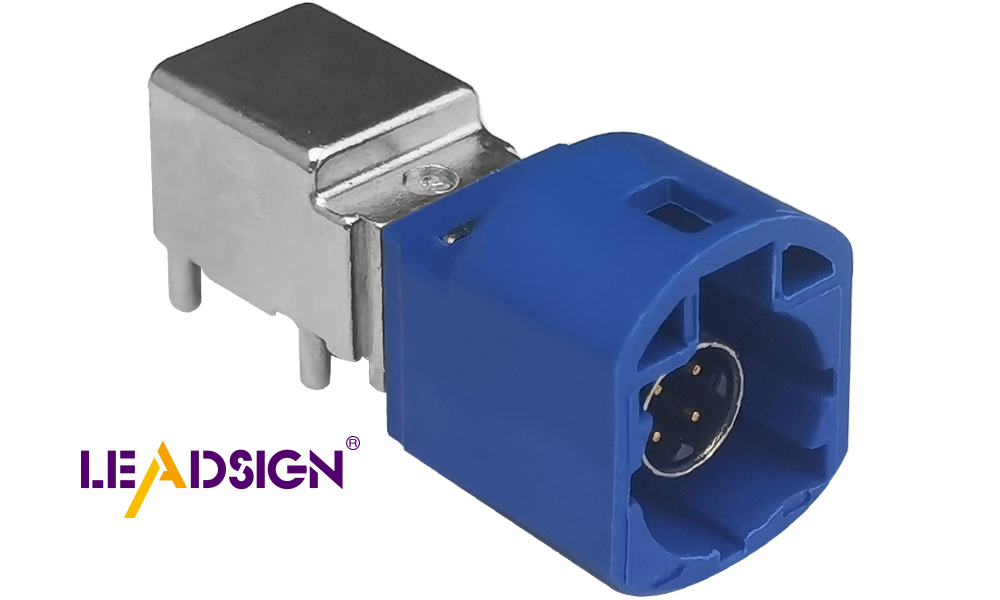

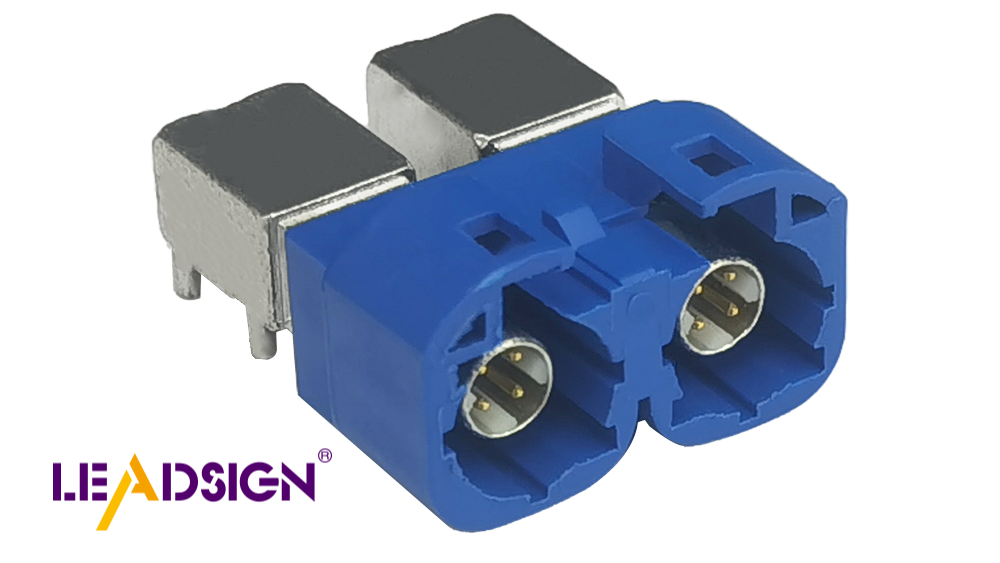

High-Speed Data (HSD) Connectors

High-Speed Data (HSD) connectors send data fast without losing quality. They are great for modern electronics needing quick and steady signals. You’ll see them in cars, entertainment systems, and communication devices.

HSD connectors work with signals like USB 3.0 and Ethernet. Their design reduces signal loss so data stays clear at high speeds. For example, in cars, HSD connectors help cameras show clear images reliably.

Important features of HSD connectors include:

Primary and secondary locks for extra safety.

Crimp connections to hold wires securely.

High cable retention force for strength under pressure.

Efficient coding systems to avoid wrong connections.

These connectors also handle harsh conditions well. They resist vibrations, temperature changes, and moisture effectively. Whether used in networks or telecom setups, HSD connectors ensure fast and reliable performance.

When choosing HSD connectors, think about your data needs first. Look at signal type, speed requirements, and environmental factors carefully. Picking the right one ensures smooth communication between parts for better PCB results.

Important Things to Consider

Choosing the right connectors helps your PCB work well. Each factor affects how your PCB performs in different situations.

Size and Space

Connector size affects how your PCB is designed. Small PCBs need tiny connectors to save space and still work. High-density connectors are good for tight spaces, allowing many connections in one spot. For example, plug-in connectors fit small areas while staying secure.

Big PCBs give you more options. You can use larger connectors like terminal blocks or power ones. These are bigger but work better for strong connections. Always pick connector sizes that match your board to avoid crowding or wasted space.

Strength and Dependability

Strong and dependable connectors keep things working smoothly. They should handle challenges like shaking, water, or heat changes. For example, car and airplane projects need tough connectors with extra protection against damage. Some PCB-mounted connectors have shields or waterproof designs for added strength.

Dependable connectors stay connected over time without failing. Wire-to-wire types often have locks to stop them from coming loose by accident. Power connectors safely manage high currents and voltages, lowering failure risks. Choose reliable ones to reduce fixing problems later.

Matching and Standards

Connectors must fit with your PCB and other parts easily. Check if they meet rules for your project’s needs. For instance, power ones should match the voltage and current levels of your board. High-speed data types like USB 3.0 or Ethernet must support fast data speeds too.

Standardized connectors make upgrades simple later on. Modular ones let you change systems without big redesigns. Picking standard options ensures everything works together now and in the future.

Easy to Use

Picking PCB connectors that are easy to use is important. They make assembly and repairs faster and simpler, especially for tricky projects.

Simple Plug-and-Play

Some connectors, like plug-in connectors, are very easy to use. You just plug or unplug them to connect parts. This is great for testing or projects needing frequent changes. Their simple design helps avoid mistakes, making them good for everyone.

Locks for Secure Connections

Connectors with locks keep connections safe and steady. For instance, wire-to-wire connectors often have locks to stop accidental disconnections. These are helpful in cars or factories where things move a lot.

Quick Changes with Terminal Blocks

If you need regular changes, terminal blocks are a smart choice. They use screws so you can connect wires without soldering. This makes replacing or adjusting parts quick and easy.

Protection Features

Some connectors, like PCB-mounted connectors, have shields for protection. These shields block interference and protect from damage, reducing the need for fixes later on.

Picking What Works Best

Choose connectors that fit your skills and project needs well. Beginners might like simple ones, while experts may want advanced features. Think about how easy it will be to install or adjust them during your work.

By focusing on ease of use, you save time, lower errors, and make your PCB system better overall.

Top Brands and Market Trends

Trusted Brands for PCB Connectors

Picking good pcb connectors means choosing trusted brands. Reliable brands make strong and efficient products. Popular ones include JST, Molex, and TE Connectivity. They offer many types of connectors for different projects.

JST Connectors: These are small and easy to use. They connect several wires to a pcb safely. Their design stops wrong connections, making them simple to handle.

Molex KK Systems: Molex connectors work well for power or signal tasks. They can be customized for precise needs, offering flexibility.

TE Connectivity: This brand makes tough connectors for harsh places like cars or factories. Their products last long and perform well in hard conditions.

Using a known brand lowers failure chances and keeps your pcb working smoothly.

New Connector Technology

Connectors are improving with better features like speed and strength. Recent updates help make systems faster and more reliable.

High-Speed Data (HSD) Connectors: These transfer data quickly without losing quality. You’ll find them in car electronics, communication tools, and entertainment devices.

Flexible Printed Circuit (FPC) Connectors: FPC connectors bend easily but stay strong. They’re great for small gadgets like phones or smartwatches.

RF PCB Connectors: These work well in high-frequency systems like wireless networks or radar setups. They keep signals clear and efficient.

These new designs help you create better systems that last longer.

Key Market Trends

Knowing trends helps you pick the right pcb connectors for your needs. The demand for flexible and reliable options is growing with technology changes.

Miniaturization: Smaller devices need tiny connectors that save space but still work well.

Sustainability: Eco-friendly materials are becoming important as companies aim to reduce waste.

Faster Data Speeds: With 5G growing, fast data transfer is key. USB 3.0 is an example of this trend.

Versatility: Modular connectors let you upgrade or adjust easily, perfect for changing projects.

By following these trends, you can choose the best connector now and later on!

Tips for Choosing the Right Connectors

Understanding Your Project Needs

First, figure out what your project requires. Think about where your PCB will be used. Will it face heat, shaking, or water? For example, car projects need strong connectors with locks to handle movement and tough conditions.

Next, check the electrical needs. What current, voltage, or signals will the connectors manage? Fast data tasks like USB 3.0 need connectors that keep signals clear at high speeds. Simpler projects might only need basic headers or terminal blocks.

Finally, look at your PCB’s size limits. Small boards may need tiny connectors to save space. Bigger boards allow more choices in connector size. Picking the right size ensures everything fits and works well together.

Testing Your Choices

Testing is important to see if your connectors work well. Start by building a sample PCB with the chosen connectors. This helps you test how they perform in real situations.

During testing, focus on strength and signal quality. Check if the connectors stay secure during shaking or repeated use. For fast data tasks, test if signals stay clear without loss.

Prototyping also shows design problems early on. You can fix these issues before making the final product. This saves time and money while ensuring good performance later.

Buying Good Connectors

Buying from trusted brands ensures reliable parts for your project. Brands like JST, Molex, and TE Connectivity make strong and useful connectors for many uses. For instance, JST is great for small designs, while Molex offers flexible options for power and signals.

When shopping for connectors, compare different suppliers carefully. Look for features that match your needs like locks or material quality. One engineer switched from Weidmuller to Phoenix Contact after finding better details in their design—showing why exploring options matters.

Think about cost too. High-quality connectors might cost more but last longer with fewer repairs needed over time. Buying in bulk can also save money on big projects.

By understanding needs, testing prototypes, and choosing trusted brands wisely, you can pick the best connectors for your PCB project.

Choosing the right PCB connectors is very important. They help create strong and efficient systems. First, know what your project needs. Then, look at different connector types. Check key things like size, strength, and how easy they are to use. Brands like Molex and Amphenol make good connectors for many uses. Learn about trends like smaller designs and faster data transfer to plan ahead. Always test your connectors well before using them. This avoids problems later and keeps your PCB working reliably for a long time.

FAQ

What are PCB connectors, and why do they matter?

PCB connectors join parts on a circuit board. They let power or signals move between components smoothly. Picking the right connectors keeps your system working well and prevents problems like weak signals or broken connections.

How can I choose the best connector for my project?

First, figure out what your project needs. Think about how many connections you need, the voltage or current levels, and where it will be used. For example, high-speed data projects may need USB 3.0 or Ethernet connectors. Testing them in real situations helps find the best fit.

Studies show testing connectors in their actual environment improves reliability.

What are some common types of PCB connectors?

Here are a few examples:

Header connectors: Good for simple setups.

Terminal blocks: Perfect for tough industrial jobs.

Wire-to-board connectors: Used for power systems and data sharing.

High-Speed Data (HSD) connectors: Made for fast data movement.

Each type has special uses, so knowing their features helps you pick wisely.

How can I make sure my connectors last in tough conditions?

Pick durable ones with features like waterproofing or vibration resistance. For example, car connectors often have extra locks to handle movement and extreme weather. Testing under harsh conditions like HALT (Highly Accelerated Life Testing) shows weak points early.

Strong design is key to making reliable connectors for hard environments.

Are smaller connectors better for small PCBs?

Not always. Small ones save space but might not handle high currents well. High-density types work in tight areas but must meet your electrical needs too. Balance size with what your project requires.

How do I test my chosen connectors?

Make a sample product using the selected ones. Check if they stay strong during shaking or temperature changes while keeping signals clear. Testing all at once reveals which one might fail first.

Research highlights testing all connector types together ensures better performance.

What are modular connectors, and when should I use them?

Modular ones let you easily upgrade or change systems later on. They’re great for projects that might grow over time, like industrial setups needing quick fixes without long delays.

How do I balance cost with quality when picking connectors?

Buy good-quality ones from brands like JST, Molex, or TE Connectivity. Though pricier upfront, they last longer and need fewer repairs later on. Buying in bulk also saves money on bigger projects.

What trends are shaping PCB connector designs today?

Some key trends include:

Miniaturization: Tiny designs for small devices.

Sustainability: Using eco-friendly materials.

Faster speeds: Supporting 5G and USB 3.0 tech.

Flexibility: Modular options for easy upgrades.

Keeping up with these trends helps future-proof your designs.

Can one connector work across different uses?

Not really. Each job has its own needs. For instance, car electronics need strong locks to handle shaking while gadgets focus more on being small and fast. Always match the connector to what your project demands most closely.

See Also

Exploring FAKRA Connectors for Enhanced Automotive PCB Performance

Why FAKRA PCB Connectors Are Essential for Automotive Use

Key Advantages of FAKRA Connectors in Automotive Systems

Significance of FAKRA Connectors for Automotive Communication