Best PCB Board to Wire Connectors for Automotive Applications

In cars, electronic systems need strong PCB board to wire connectors. These connectors link parts like engine controls and driver assistance tools. They are designed to handle tough conditions such as heat, vibration, and moisture. The circuit board helps keep wires secure, making repairs easier and systems operate more efficiently. Choosing the right connectors ensures they endure and perform well in challenging automotive environments.

Key Takeaways

Choose connectors that can withstand extreme heat, vibrations, and moisture to ensure long-lasting performance in automotive environments.

Opt for wire-to-board connectors like pin headers and crimp-style connectors for reliable and strong electrical connections.

Select waterproof and rust-resistant connectors to protect against environmental damage, especially in areas exposed to water and chemicals.

Consider the size of connectors to fit into tight spaces within modern vehicles without compromising on strength and reliability.

Always match connectors to the specific power and signal requirements of your car systems to prevent overheating and failures.

Utilize locking mechanisms in connectors to secure wires and prevent accidental disconnections during vehicle operation.

Regularly check product specifications and compatibility to ensure optimal performance and safety in automotive applications.

Special Needs of PCB Connectors in Cars

Challenges from the Environment

Heat Resistance

Car parts near engines face a lot of heat. Connectors must handle this heat without breaking down. Strong materials that manage heat well keep them working. For instance, tough designs and good cooling stop overheating and make them last longer.

Handling Vibrations and Shocks

Cars shake from bumpy roads or engine movement. This can loosen or harm connectors. To prevent this, pick connectors built to stay strong. Tight locks and secure designs keep connections steady during heavy shaking.

Protection from Water and Rust

Water or chemicals like road salt can damage connectors. Waterproof connectors with special materials block these problems. This keeps them working for a long time, even in wet places.

Electrical and Physical Performance

Managing Electricity

Car systems need connectors that handle different power levels safely. Choose ones with the right power limits to avoid overheating or breaking. Always check their specs before using them.

Strong Connections

Good connections are key for car electronics to work well. Loose wires can cause problems or failures. Use connectors with features like locking clips to hold wires tightly, even in tough conditions.

Small Size for Tight Spaces

Modern cars have many gadgets but little room inside. Small connectors save space while still working great. Pick ones that fit small areas but stay strong and reliable.

Overview of PCB Board to Wire Connector Types

Choosing the right connector is important for car electronics. Each type has its own uses and benefits. Knowing these options helps you pick the best one.

Wire-to-Board Connectors

Wire-to-board connectors link wires directly to circuit boards. They are common in cars because they work well and are flexible.

Pin Headers and Receptacles

Pin headers and receptacles are popular wire-to-board connectors. They have metal pins that fit into matching slots, making strong connections. These connectors are simple to use and can be removed easily. This makes them great for systems needing regular fixes or updates. Their small size also saves space, which is helpful in tight car areas.

Crimp-Style Connectors

Crimp-style connectors use tools to tightly attach wires to connectors. This creates strong electrical and mechanical links. They last long and resist shaking, perfect for tough car conditions. These connectors can handle high power levels, making them useful for demanding tasks.

Terminal Blocks

Terminal blocks connect multiple wires to a single spot on a board. They are easy to use and organize connections well.

Screw-Type Terminal Blocks

Screw-type terminal blocks hold wires with screws for a firm grip. This stops wires from coming loose due to movement or vibrations. They are simple to adjust or replace when needed. Their strong design makes them reliable for car systems.

Spring-Loaded Terminal Blocks

Spring-loaded terminal blocks use springs to secure wires without tools. This makes installation quick and easy. The spring keeps steady pressure on the wire, ensuring stable connections even during shaking or movement. Their small size is ideal for modern cars with limited space.

IDC (Insulation Displacement Connectors)

IDC connectors connect wires without removing their insulation first. They save time and work well in large projects.

Features and Benefits

IDC connectors cut through wire insulation to touch the inside conductor directly. No soldering or crimping is needed, so they install quickly. These connectors stay reliable even under tough conditions, reducing loose connection risks over time.

Common Use Cases in Automotive Applications

IDC connectors are used where fast wiring is needed, like lights or sensors in cars. They also support high-speed data transfer, fitting advanced car technology needs.

Best PCB Board to Wire Connectors for Cars

TE Connectivity AMP Superseal Series

Main Features and Details

The TE Connectivity AMP Superseal Series is strong and works well in cars. These connectors handle both power and signal tasks, making them useful for many needs. They can be mounted on boards, cables, or panels, giving design flexibility. Their seals protect against water, dust, and dirt, keeping connections safe in tough conditions.

Key details include:

Resists moisture and rust very well.

Works with high-current and low-voltage systems.

Locks tightly to avoid accidental disconnections.

Why It’s Great for Cars

The AMP Superseal Series is tough and flexible. It handles extreme heat and shaking easily. Its seals keep it working even in wet or dirty places. If you need reliable connectors for hard jobs, this series is a smart pick.

Molex Mini-Fit Jr. Connectors

Main Features and Details

The Molex Mini-Fit Jr. Connectors are small but powerful for car systems needing compact solutions. They have a 3mm pitch and carry up to 5A current, perfect for medium-power tasks. Options like terminal position assurance (TPA) improve connection safety. The included pins make them easy to assemble.

Key features include:

Small size fits tight spaces.

Handles high currents well.

TPA feature adds extra safety.

Why It’s Great for Cars

These connectors are perfect for modern cars with little space but big needs. Their small size fits tight spots without losing strength or reliability. Use them in infotainment systems or power modules where secure connections matter most.

JST VH Series Connectors

Main Features and Details

The JST VH Series Connectors are simple yet dependable wire-to-board options that handle high currents easily. They are built strong to last long while being quick to install due to their straightforward design. Different configurations meet various car system needs.

Key details include:

Handles high electrical loads.

Made from durable materials.

Easy design saves time during assembly.

Why It’s Great for Cars

The VH Series is ideal when you need strong connectors for heavy-duty tasks like battery systems or electric motors. They manage large electrical loads without failing over time, even in rough car environments.

Delphi/Packard Weather Pack Connectors

Main Features and Details

The Delphi/Packard Weather Pack Connectors are built for tough car conditions. They seal tightly, working well even in extreme weather. Their strong build makes them great for jobs needing precision and durability.

Key features include:

Weatherproof Build: Silicone seals block water, dirt, and debris from damaging connections.

Strong Materials: Tough thermoplastic resists damage from shaking and vibrations.

Multiple Uses: Works with both small and large power systems for flexibility.

Secure Locking System: Locks keep wires firmly connected to avoid accidental disconnections.

These connectors fit different wire sizes, making them useful for many setups. Their design is easy to install or fix, saving time and effort.

Why It’s Great for Cars

You can trust Delphi/Packard Weather Pack Connectors in harsh car environments. The seals protect connections from water and rust, ensuring they last long. Strong materials handle heat and constant movement, perfect for engines or tough areas.

These connectors hold wires steady under stress without failing. Use them for lights, sensors, or power systems where strength matters most. Their reliability makes them a smart choice for your car projects.

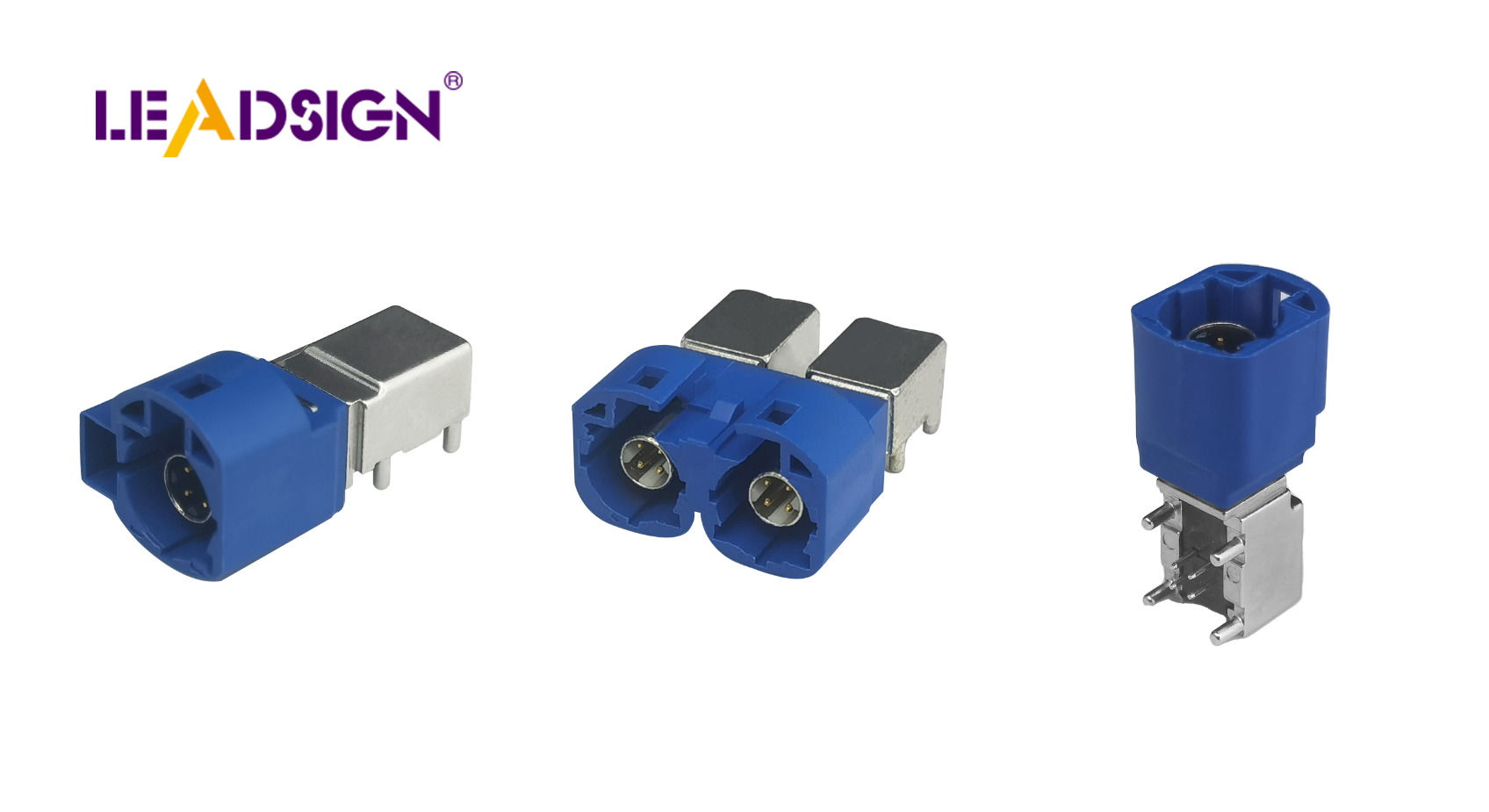

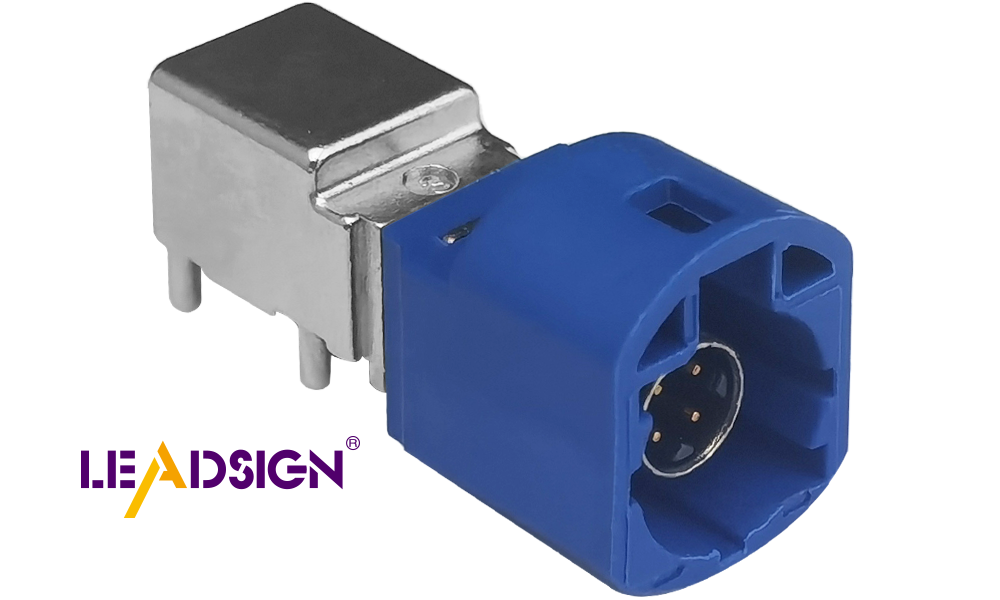

LEADSIGN HSD Connector

Main Features and Details

The LEADSIGN HSD Connector is made for fast data transfer in cars. It works well with modern systems like cameras or infotainment devices. Its clever design ensures smooth communication between parts.

Key features include:

Fast Data Transfer: Handles USB 3.0, Ethernet, and LVDS without delays.

Double Locking System: Extra locks stop wires from disconnecting by accident.

Crimp Connection: Creates strong bonds that stay stable over time.

High Wire Grip Strength: Keeps cables secure during heavy shaking or movement.

Smart Coding Options: Prevents wrong connections with coded plastic housings.

This connector works in many car electronics setups, making it very versatile.

Why It’s Great for Cars

The LEADSIGN HSD Connector meets the growing need for fast data in cars today. Use it in driver-assist tools (ADAS), entertainment systems, or digital networks. Its sturdy design performs well under heat and vibration.

Its speed makes it perfect for sending lots of data quickly without issues. Strong locks and durable materials ensure lasting performance even in hard conditions. For advanced car tech projects, this connector is an excellent pick.

Key Things to Think About When Picking Connectors for Cars

When choosing connectors for cars, think about important factors. These help make sure the connectors work well in tough conditions and fit your project needs.

Strength and Long Life

Strong Materials That Last

Car parts face a lot of stress every day. Good materials are needed to stop damage over time. Pick connectors made from strong plastics or metals that won’t crack or bend easily. For example, many automotive connectors use tough materials that stay solid even near hot engines.

Protection Against Weather Problems

In cars, connectors deal with water, dirt, and shaking often. To handle this, choose ones with waterproof covers and rust-proof coatings. Some products like the Automotive Sealed Connection System protect well against these issues. This is very useful for systems like engine controls where failure isn’t an option.

How Well They Handle Electricity

Matching Power Needs

Each car system has its own power needs. You need connectors that can handle the right amount of electricity without problems. For example, powertrain systems need ones that manage high currents safely. Always check their details to match your system’s needs.

Keeping Signals Clear

Modern cars depend on data moving smoothly for cameras or sensors. Bad signals can cause problems in these systems. Use connectors made to keep signals clear and avoid noise issues. Products like TE Connectivity’s automotive PCB headers send data fast while cutting down interference, perfect for advanced car tech.

Easy to Use and Fix

Simple Design for Quick Setup

Easy-to-use designs save time during setup and reduce mistakes. Look for crimp-style or spring-loaded types that make assembly simple but secure. For instance, the MXP120 Automotive Sealed Connection System is small enough for tight spaces but still easy to use.

Easy-to-Find Replacement Parts

Fixing car systems happens sometimes, so pick parts you can replace easily when needed. This saves time and makes repairs simpler later on. Companies like Molex or TE Connectivity offer many options with parts you can swap out quickly if required.

By thinking about these points carefully, you’ll find durable and easy-to-use connectors that work great in tough car conditions!

Common Problems and Fixes for PCB Board to Wire Connectors

Keeping Connections Strong

Crimping and Soldering the Right Way

To make strong connections, crimp wires tightly but carefully. Use enough pressure so the wire stays secure without harm. Weak crimping can cause loose wires and failures later. Soldering also needs care. Heat the solder just right to create a solid link between the wire and connector. These steps help connectors work well in tough car conditions.

Using Locks to Stop Wires from Disconnecting

Locks are important for keeping wires in place. Cars shake a lot, which can loosen wires if locks are missing. Pick connectors with clips or latches that hold wires firmly. These locks stop accidental disconnections, ensuring everything works smoothly even on bumpy roads.

Protecting Against Environmental Damage

Sealed Connectors Keep Water Out

Water can ruin connectors by causing rust or damage. Sealed connectors solve this problem with covers that block water and dirt. By using these, you protect your connections from moisture, making them last longer.

Choosing Vibration-Resistant Connectors

Cars vibrate constantly, especially near engines or wheels. This shaking can weaken connections over time. Use connectors made to handle vibrations, like those with strong housings or flexible parts that absorb shocks. These stay steady and reliable even in shaky spots.

Avoiding Compatibility Problems

Matching Connectors to Wires and Boards

Connectors must fit both the wire size and board design properly. If they don’t match, it could cause bad connections or damage parts. Always check sizes before choosing connectors to avoid such problems during setup.

Meeting Car Standards for Safety

Car systems need connectors built for extreme conditions like heat or high power loads. Make sure your connectors meet industry rules for safety and performance in vehicles. This ensures they work well without failing when needed most.

Choosing the best PCB connectors for cars ensures they last long. Connectors like TE AMP Superseal and LEADSIGN HSD work well. They handle heat, shaking, and wet conditions easily. Think about what your project needs before choosing. Match connectors to power, size, and environment needs. Always check product details to pick the right one. Share your thoughts or ask questions below. Your ideas might help others choose better connectors for their car projects.

FAQ

What are PCB board-to-wire connectors used for in cars?

PCB board-to-wire connectors join electronic parts inside a car. They help systems like engines, sensors, and screens work together smoothly. These connectors stay strong and reliable even in tough conditions.

Why is picking the right connector important for cars?

Choosing the right connector keeps systems working well and lasting long. It stops problems caused by heat, shaking, or water. The correct connector also ensures signals stay clear and connections remain stable.

How do I pick the best connector for my car project?

To find the best connector, think about these things:

Environment: Will it face heat, water, or vibrations?

Electric Needs: Match it to your system's power levels.

Space Limits: Use small ones if space is tight.

Strength: Pick materials that handle wear and stress.

Why are sealed connectors needed for cars?

Sealed connectors block water, dirt, and rust from causing damage. They are important for wet areas like near engines or outside lights. These keep systems working well in hard conditions.

Can regular connectors be used in cars?

Regular connectors might not handle tough car conditions well. Car-grade ones are made to resist heat, shaking, and moisture better. Using them lowers failure risks and keeps systems reliable.

What types of PCB board-to-wire connectors are common in cars?

The main types include:

Wire-to-Board Connectors: For direct wire-to-PCB links.

Terminal Blocks: To organize many wires neatly.

IDC Connectors: For quick setups without removing wire covers.

Each type works best depending on the job’s needs.

How can I make sure connections stay strong?

To keep connections secure:

Crimp or solder wires properly with care.

Use locks to stop wires from coming loose accidentally.

Match the connector size to wires and boards correctly.

What should I look for in high-speed data connectors?

For fast data transfer, choose connectors made for speed and stability. Look for features like LVDS support or Ethernet compatibility with strong locks to ensure smooth performance in advanced car tech.

Are small connectors good for tight spaces in cars?

Yes! Small connectors work great if built for car use. They save room but still perform well when made with durable materials and locking designs that hold steady even in cramped spots.

How can I avoid problems with connector compatibility?

To prevent issues:

Make sure the connector fits your wire size and PCB design perfectly.

Check it meets safety rules for cars.

Confirm its specs match your system’s needs before using it.

Planning ahead helps you pick the perfect connector every time!

See Also

Exploring FAKRA PCB Connectors' Benefits for Automotive Use

Why FAKRA PCB Connectors Are Essential for Automotive Systems

Key Advantages of FAKRA Connectors in PCB for Automotive

FAKRA PCB Mount Connectors: Enhancing Automotive and RF Performance

Improving Vehicle Communication Through FAKRA PCB Connectors