Choosing the Best Automotive Wire for High-Speed PCB Design

High-speed PCB design is important for cars. More people want hybrid and electric cars, so the PCB market is growing. It might reach $72.3 billion by 2026. Picking the right car wire is hard because it must be strong and work well. Good signal and connectors make sure data moves correctly, which is key for today's cars. Knowing these things helps choose the best high-speed PCB design for cars.

Understanding Fast PCB Design

What Makes Fast Designs Special

Fast PCB Design is important for new car tech. It makes boards that send data quickly without losing quality. This part talks about what makes fast designs special.

Why It's Complicated

Fast PCB Design can be tricky. Designers think about layout, materials, and parts to make it work well. It's hard because many signals move fast and can mess each other up. So, designers plan carefully to avoid problems.

Different Connections and Board Tech

Different connections are key in Fast PCB Design. Things like USB and Ethernet are used in cars a lot. Each has needs for speed and signal quality. The board tech must support these by giving enough space and stopping interference. New materials and layers help with this.

Keeping Signals Strong

Keeping signals strong is super important in Fast PCB Design. It makes sure signals get where they need to go without getting messed up.

Controlling Impedance

Controlling impedance helps keep signals strong. It means matching the line's resistance with the parts it's connected to. This stops echoes that can mess up data. Designers use tricks like changing line width to do this.

Using Two Signals

Using two signals helps keep things clear in Fast PCB Design. It sends two opposite signals on different lines, cutting down noise so the signal stays good. This is helpful where there's lots of interference, like in car systems.

Picking the Right Car Wire

Material Choices

Picking good materials for car wires is very important. They affect how well the wire works and lasts.

Insulation Properties

The insulation around a wire has two main features. A low number means signals move fast, which is needed for quick data. The other feature shows how much energy turns into heat. Lower numbers mean less heat, so things don't overheat in cars.

Wire Type and How It Works

The type of wire affects how it carries electricity and lasts. Automotive Connectors made from copper or brass are best. They carry electricity well and last long, which is great for cars where wires need to be tough.

Placing Parts on PCB

Putting parts in the right spot on a PCB helps them work better.

How Parts Work Together

How parts are placed affects their strength and function. Designers plan layouts to keep parts safe and connected well. Good placement stops breaks and keeps signals clear.

Heat Control with Ground Planes

Ground planes help control heat and keep signals clear. They let extra heat escape, stopping overheating. This keeps parts working safely longer. Ground planes also cut down signal noise, keeping data clear in fast PCBs.

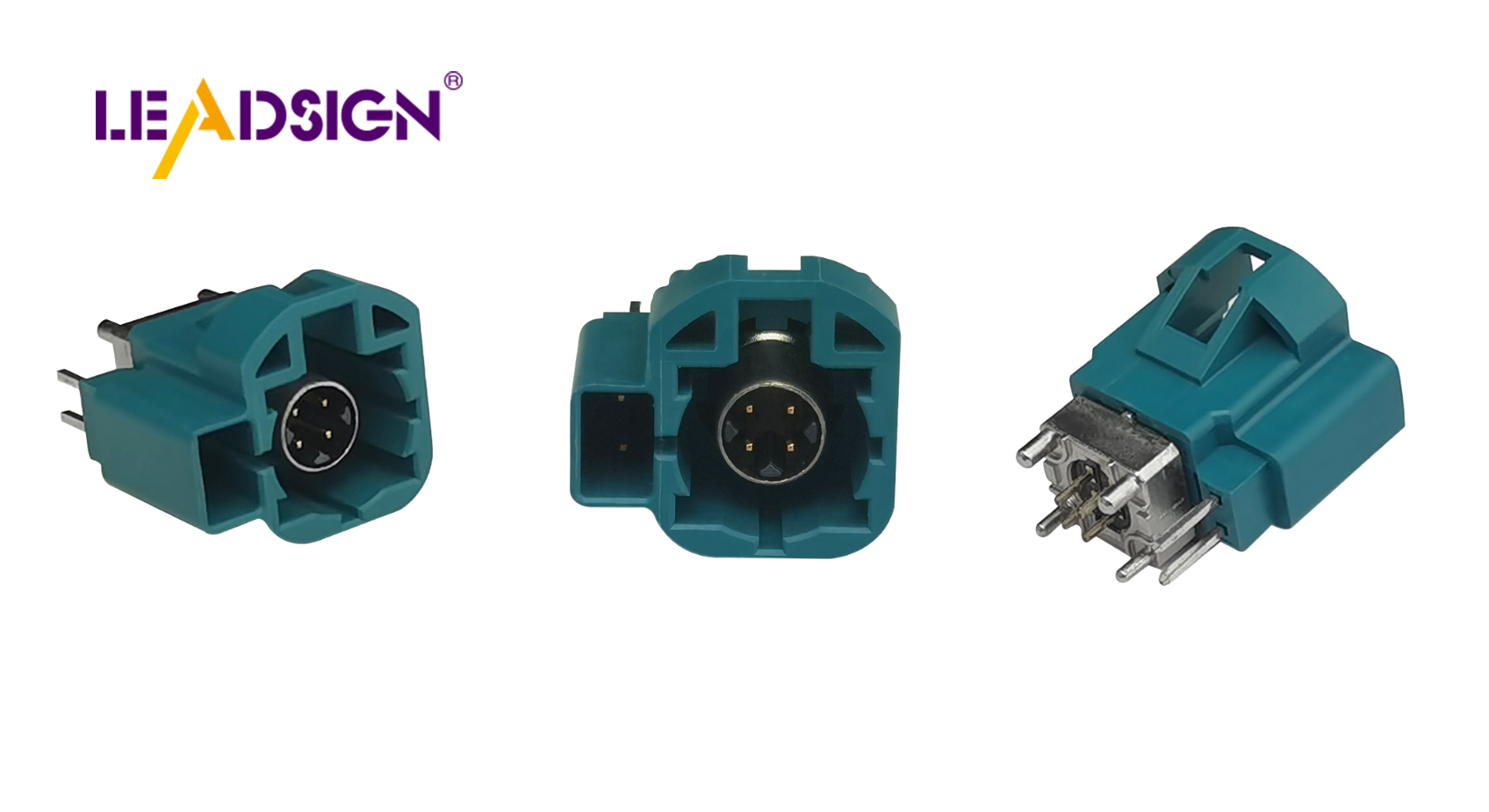

Fast Data Connectors

Important Parts and Rules

Fast data connectors are key in car electronics. They make sure data moves well, which is needed for today's cars. These systems must follow certain rules to work right.

Rules and Guidelines

Car connectors need to follow different rules to work well. Low-voltage connectors focus on sending signals safely. They are used for low power and have special designs. High-voltage connectors carry big currents and fit certain car parts. They must meet industry rules for safety.

Proofs and Maker Details

Makers give proofs that their connectors meet standards. These proofs show the product is good and works well. When picking connectors, check the maker's name and their proofs. This helps choose the best ones.

Where They're Used

Fast data connectors are used in many car and factory places. They help put together electronic systems in cars.

Factory Electronics and Fun Systems

In factories, connectors help parts talk to each other. They keep data moving smoothly, making things work better. In fun systems, they connect sound, video, and data signals for a great experience.

Car Needs and Connections

Car connectors need to meet certain needs for good connections. Different types like pin connectors or pigtail connectors do different jobs. Pin ones are good for strong power like headlights, while others send signals or carry high power. Each car part needs special connectors to work best.

Important Things to Think About: Fast PCB design for cars needs careful planning. You must focus on keeping signals strong, picking the right materials, and using good connector systems. These help data move well and keep everything working great.

Last Thoughts: To pick the best car wire, know its material and if it works with fast needs. This choice affects how long car electronics last and how well they work.

Looking Ahead: As tech gets better, PCBs will make new things possible in cars. Knowing about new tech helps choose parts that fit future needs.

See Also

Improving Automotive Data Transfer with FAKRA PCB Connectors

Benefits of FAKRA PCB Connectors for Automotive Uses

Boosting Data Transfer: The Significance of High-Speed Auto Connectors

Advantages of Employing FAKRA PCB Connectors for Auto Uses

The Vital Role of FAKRA PCB Connectors in Auto Communication