Best Automotive Harness Connectors for Durability and Performance

Durable automotive harness connectors are important for safety and efficiency. They handle tough conditions to work reliably. These connectors resist shaking, temperature changes, water, and harmful chemicals. Picking the right connector helps it last longer and keeps your car’s electrical parts from breaking.

Key Takeaways

Pick strong connectors to keep your car's electrical system safe.

Find connectors that resist water and heat for tough conditions.

Clean and check connectors often to stop overheating and last longer.

Top-Rated Automotive Harness Connectors

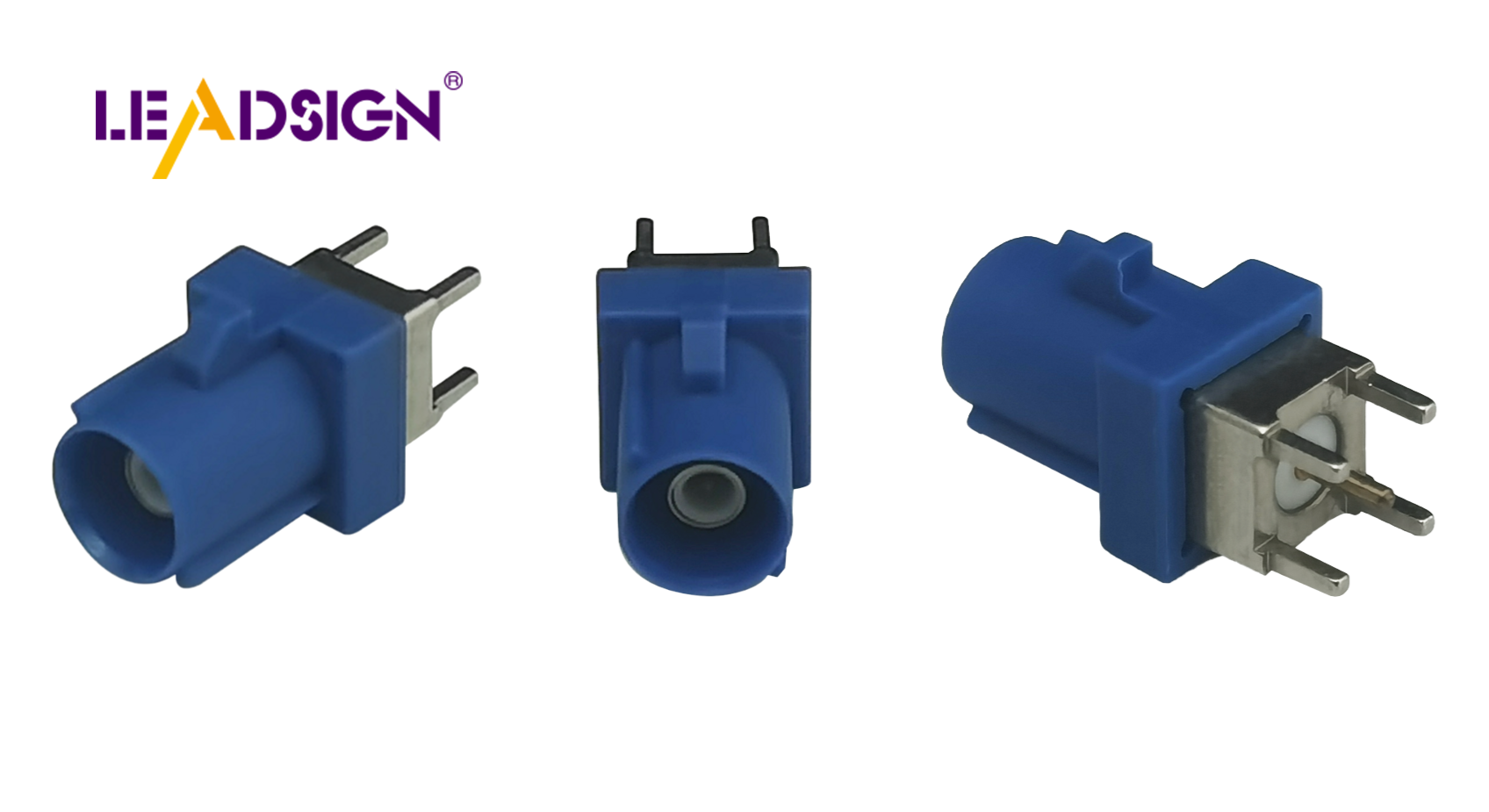

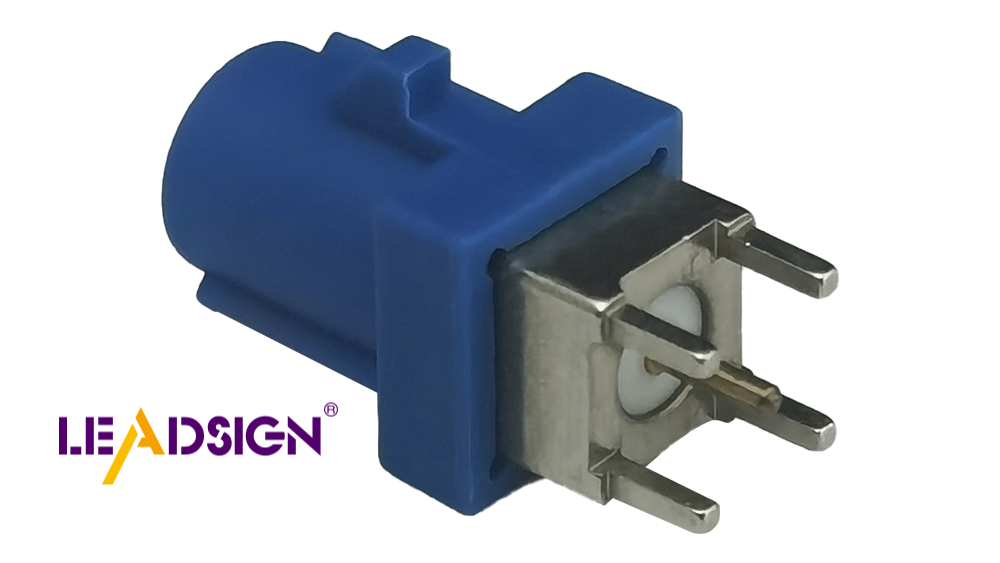

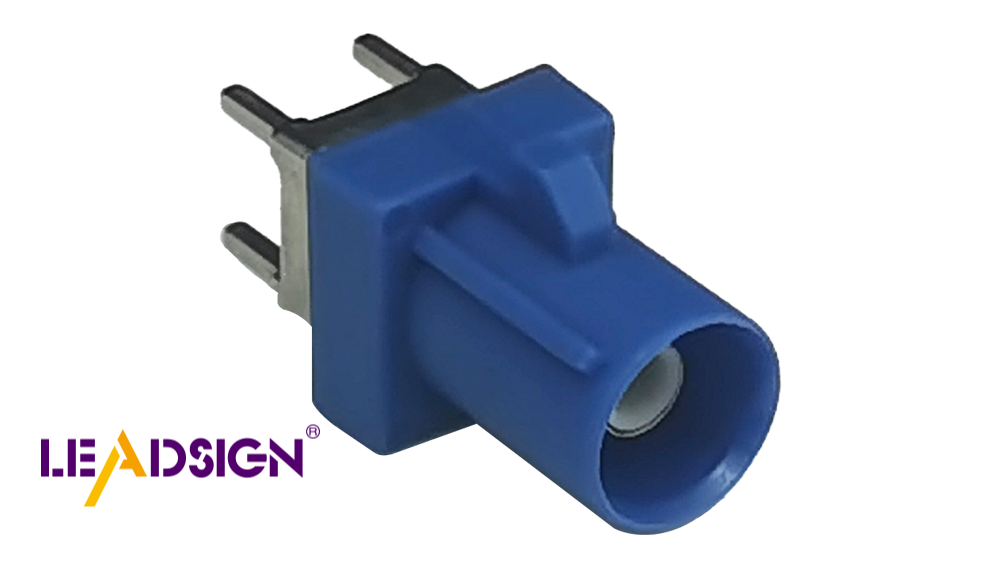

LEADSIGN FAKRA Connector

The LEADSIGN FAKRA Connector is great for cars needing high-frequency links. It works well for GPS antennas, radios, and infotainment systems. Its strong build handles the tough demands of car use. A secure coding system stops mistakes and keeps connections firm. It works in temperatures from -40°C to +105°C, perfect for extreme weather. Waterproof options give extra safety, lasting long even in bad conditions.

Deutsch DTM and DTP Connectors

Deutsch DTM and DTP connectors are trusted for heavy-duty vehicles. They handle high power and resist tough environments. These connectors are great for waterproof and vibration-proof needs. Push-in wire connectors make setup quick and easy. They meet industry rules, ensuring steady and reliable performance.

TICONN Solder Seal Wire Connector

TICONN Solder Seal Wire Connectors make strong, waterproof connections. They use heat shrink tubes and solder rings for a tight bond. These are perfect for car wiring, especially in wet areas. They are easy to use and made with quality materials. Both DIY users and experts like them for their reliability.

Weatherpack Connectors

Weatherpack connectors are built for rough conditions. They are waterproof and block dirt, ideal for outdoor use. These connectors work well for headlights and fog lights. Their locking system keeps them secure, and they last a long time. They are a dependable choice for your car.

TE Superseal Connectors

TE Superseal connectors are small, waterproof, and made with strong materials. They follow the USCAR 2 Standard, so they work well in tough conditions. They keep signals clear and fit different wire sizes. Push-in wire connectors make them easy to install, even for beginners.

Pro Tip: Pick connectors that meet standards like the USCAR 2 Standard. This ensures they last long and work safely in your car.

Features to Look for in Durable Automotive Harness Connectors

Material Quality and Durability

The materials in automotive harness connectors affect how long they last. Good materials make connectors strong, even in tough conditions. Common materials include:

Plastic: Light, sturdy, and great for most car uses.

Metal: Strong and perfect for heavy-duty vehicles like trucks.

Here’s a simple comparison of material features:

Material | Features |

|---|---|

PTFE/Teflon | Smooth, handles heat, resists water, oil, and chemicals |

Nylon | Strong and durable but soaks up moisture |

Polyurethane | Flexible and UV-safe but not great with extreme heat |

For lasting use, pick connectors with coatings like gold or stainless steel to stop rust.

Environmental Resistance (e.g., waterproof, heat-resistant)

Connectors must survive harsh conditions. Waterproof ones block water, brake fluid, and antifreeze. This keeps connections safe. Heat resistance is key for connectors near engines. Choose ones with rubber seals and heatproof materials to avoid cracks or leaks.

Electrical Performance and Compatibility

Good electrical performance keeps car connections working well. Check these factors:

Factor | What It Does |

|---|---|

Current Rating | Handles high current without getting too hot. |

Voltage Rating | Works with high voltage safely. |

Contact Resistance | Keeps power loss low and signals clear. |

Insulation Resistance | Stops electricity from leaking out. |

Make sure connectors match your car’s needs and pin layouts to avoid problems.

Certifications and Standards (e.g., ISO, SAE)

Certifications prove the quality of connectors. Look for ISO and SAE standards for safety and performance. Other certifications like UL or CSA show they resist things like salt and shaking.

Ease of Installation and Maintenance

Push-in connectors are easy to install and save time. Modular harnesses reduce wire mess, making assembly simple. For repairs, pick connectors with common designs for easy swaps.

Note: Installing connectors properly and checking them often prevents problems like overheating or bad fits. This helps them last longer.

How to Pick the Best Connector for Your Vehicle

Understanding Your Vehicle’s Needs

Start by knowing what your vehicle requires. Think about these points:

Environmental Conditions: Will the connectors face heat, water, or dirt?

Mechanical Factors: Pick ones that resist shaking and lock tightly.

Type of Termination: Choose soldering, crimping, or screw-on based on your wires.

Material: Use plastic for light jobs or metal for tough tasks.

Signal Integrity: Make sure they use good materials for clear signals.

Also, check the current and voltage ratings. This ensures they handle power safely without breaking.

Choosing Connectors for Specific Jobs

Different tasks need different connectors. Use this chart to decide:

Job | What It Does |

|---|---|

Keeps wires neat and secure. | |

Power Distribution | Sends power to lights and motors. |

Engine and Transmission Systems | Links sensors, injectors, and ignition parts. |

Lighting Systems | Connects headlights and taillights. |

Audio and Infotainment Systems | Joins speakers, radios, and screens. |

For example, waterproof connectors work well for outdoor lights. Push-in connectors are easy for audio setups.

Thinking About Costs

It’s important to balance price and quality. Metal connectors last longer and resist rust but cost more. Plastic ones are cheaper and lighter, good for simple uses. Always check they meet power needs to avoid problems. Test them to ensure they work well in your car’s conditions.

Tips for Keeping Connectors Working Well

Follow these steps to make connectors last longer:

Clean them often to remove dirt and grime.

Install them carefully to avoid damage.

Use covers to protect them in bad weather.

Pick strong materials like copper alloys or advanced plastics.

Taking care of connectors stops issues like overheating or loose fits. This helps them stay reliable for a long time.

Picking the right harness connector keeps your car working well. The best connectors are strong, weatherproof, and useful for many tasks.

Feature | What It Means |

|---|---|

Handles Tough Conditions | Built to survive heat, water, and dirt for safe use. |

Strong Locking Systems | Different locks (snap, twist, screw) stop wires from coming loose. |

Works for Many Uses | Fits different car gadgets and systems for smooth power and data flow. |

Strong connectors last in rough car conditions. They also fit well with different systems. Weatherproof ones block water and rust, keeping them working longer. Spend more on good connectors to avoid replacing them often. Whether you need waterproof plugs or twist-on caps, choosing quality ensures safety and good performance.

FAQ

What are push-in wire connectors, and why are they popular?

Push-in wire connectors join wires fast without needing tools. They are easy to use and save time. Both experts and beginners like them for quick setups.

Are all automotive harness connectors waterproof?

No, not every connector is waterproof. Check for rubber seals or waterproof ratings. These features help them handle water and tough conditions safely.

How do I maintain my automotive harness connectors?

Clean your connectors often to remove dirt and grime. Look for any damage or loose wires during checks. Use covers to protect them in bad weather and make them last longer.

See Also

Benefits of HFM Connectors for Today's Automotive Sector

Significance of Fakra Connectors in Contemporary Automotive Design

Crucial Role of HSD Connectors in Auto Manufacturing

Enhancing Vehicle Data Transfer with Modern Connectors and Cables