Best Practices for Picking Automotive Harness Connectors in 2025

Automotive harness connectors are important for safety and smooth driving. As cars get smarter with self-driving and electric features, these connectors do more jobs. They help sensors, entertainment systems, and electric parts work together. Bad connectors can rust, get water damage, or stop working. Choosing high-quality automotive harness connectors saves money on repairs and keeps your car functioning well.

Key Takeaways

Pick connectors that fit your car's voltage and current needs. This keeps it safe and working well.

Use connectors with high IP ratings to block dust and water. This is important in harsh conditions.

Choose connectors made of strong materials like stainless steel or plastic. This helps them last longer.

Electrical Specifications for Automotive Harness Connectors

Current and Voltage Ratings

When picking harness connectors, check current and voltage ratings. Most cars use 12V systems, but hybrids and EVs may use 24V or 48V. Make sure the connector can handle the voltage safely. Current rating is just as important. The connector must carry the current without overheating. Ampacity and derating factors help ensure safety under heavy loads. Always match the connector's specs to your car's electrical needs.

Overcurrent Protection

Overcurrent protection is very important for harness connectors. Without it, power surges can harm your car or cause fires. Many connectors now have built-in safety features to stop overcurrent problems. These features protect parts like sensors, GPS, and entertainment systems. Choose connectors with good overcurrent protection to keep your car safe.

Matching Connectors to Vehicle Electrical Systems

Matching connectors to your car's system makes them work better. Makers think about:

Temperature and moisture resistance for tough conditions.

Strength to handle bumps and shakes.

Good wire connections to keep signals clear.

Connectors often have seals to block dust and water, lasting longer. Terminal Position Assurance systems help ensure proper assembly. Picking the right connectors avoids problems and keeps your car running smoothly.

Environmental and Mechanical Considerations for Automotive Electrical Connectors

IP Ratings for Water and Dust Resistance

When picking connectors, think about water and dust protection. IP ratings show how well a connector blocks solids and liquids. For example, an IP6x rating means no dust can get inside. An IPx7 rating means it can handle being in water briefly. Here's a simple guide to common IP ratings:

IP Rating (first digit: solids) | Protection Level |

|---|---|

IP5x | Keeps out most dust |

IP6x | Fully blocks all dust |

IP Rating (second digit: liquids) | Protection Level |

|---|---|

IPx5 | Handles water sprays |

IPx7 | Handles short dips in water |

If your car is used in tough places, like off-road or near the sea, pick connectors with higher IP ratings. These will protect wires from dust and water damage.

Vibration and Shock Resistance

Cars deal with shaking and bumps, especially on rough roads. These movements can loosen or break connectors. To avoid this, makers test connectors for vibrations and shocks. For example, the MIL-STD-810 test checks how connectors handle real-world bumps. Choose connectors made to resist shaking and impacts. This helps your car's wires last longer and work better.

Strain Relief and Cable Management

Strain relief protects cables from pulling or bending damage. It stops connectors from breaking under pressure. This is very useful in cars where cables move often. Strain relief also keeps cables neat and reduces wear. It protects connection points, making cables and connectors last longer. To keep your system working well, pick connectors with good strain relief.

Connector Design and Material in Automotive Wire Harness Connectors

Number of Contacts and Pin Configuration

The number of contacts affects how well a connector works. Pick a connector that fits your car's electrical system. Modern cars often need multi-pin connectors for advanced features. These include sensors, entertainment systems, and self-driving tech. A good pin setup keeps connections secure and avoids bad contact. Bad contact can cause electrical problems. Always check the maker's details to ensure it fits your system.

Housing Materials and Durability

The material of a connector's housing affects its strength and use. Different materials work better in different conditions. Here's a simple guide to common materials:

Material | Properties |

|---|---|

Stainless Steel | Strong, rust-proof, great for tough environments. |

Polycarbonate (PC) | Tough, heat-resistant, and insulates electricity well. |

Nylon | Flexible, stable, and resists wear and chemicals. |

Polypropylene | Affordable and resists chemicals. |

For rough places like off-road or near the sea, use stainless steel or polycarbonate. Nylon and polypropylene are good for normal use. They balance cost and durability.

Termination Types (Crimp, Solder, or Screw)

The way wires connect to the harness is important. Each method has good and bad points. Choose based on what you need:

Crimping:

Quick and strong.

Blocks dirt and water.

Needs special tools, which cost more.

Soldering:

Cheap and needs few tools.

Can be damaged by heat or weather.

Takes time and skill to do well.

Screw Terminals:

Easy to use without special tools.

Not great for big production jobs.

Crimping is the best for car connectors because it lasts long. It also handles tough conditions well. Soldering and screw terminals work for smaller, simpler jobs. Think about these points to pick connectors that last and work well in modern cars.

Signal Integrity and Compatibility in Automotive Harness Connectors

Low Resistance and Reliable Signal Transmission

Signal quality is very important for car connectors. Good connectors send signals smoothly and reliably. Low resistance helps stop signal loss and keeps systems working well. Materials like gold or silver coatings are often used. These materials lower resistance and make connectors last longer.

For fast data transfer, special connectors keep low capacitance and inductance. This helps advanced systems like GPS and sensors work without problems. Always pick connectors that focus on low resistance and steady signal flow.

Interchangeability with Existing Systems

Your new connectors must fit your car’s current systems. Finding original connectors can be hard due to supply issues. But many companies now make good replacement options.

Check your car’s electronic setup to ensure compatibility. Different brands use different designs and rules. Also, think about how easy it will be to upgrade later. This way, you solve today’s needs and plan for future tech.

Compliance with Industry Standards (ISO, SAE)

Standards like ISO and SAE help you pick the right connectors. ISO sets rules for wire sizes and connector types. SAE focuses on how well connectors perform. Following these standards ensures connectors work well with your car.

Manufacturers test products carefully to meet these rules. This catches problems early, so only good products are sold. Choosing connectors that meet ISO and SAE standards means better safety and reliability for your car.

Picking the right car harness connectors keeps your car safe. Look at electrical needs, tough environments, and design fit. Always pick quality over saving money. For good choices, check:

Connectors that match your car’s voltage and current.

Strong materials for harsh conditions.

Products that meet ISO and SAE standards.

Check connectors often and care for them to last longer.

FAQ

What does an automotive wire harness connector do?

It links car parts to share power and signals. It keeps wires safe and your car's system neat.

How can I find a connector's current and voltage ratings?

Check the product details for these ratings. Match them to your car's system to avoid problems.

Why is picking the right wire harness important for cars?

The right harness helps your car work well and stay safe. It stops electrical problems and supports cool features like sensors and screens. It also lowers repair costs.

See Also

Enhancing Automotive Performance Using HFM Connectors Effectively

Why HSD Connectors Are Crucial for Automotive Applications

Key Benefits of Utilizing HFM Connectors in Automotive

Understanding HSD Connectors: A Guide for Automotive Professionals

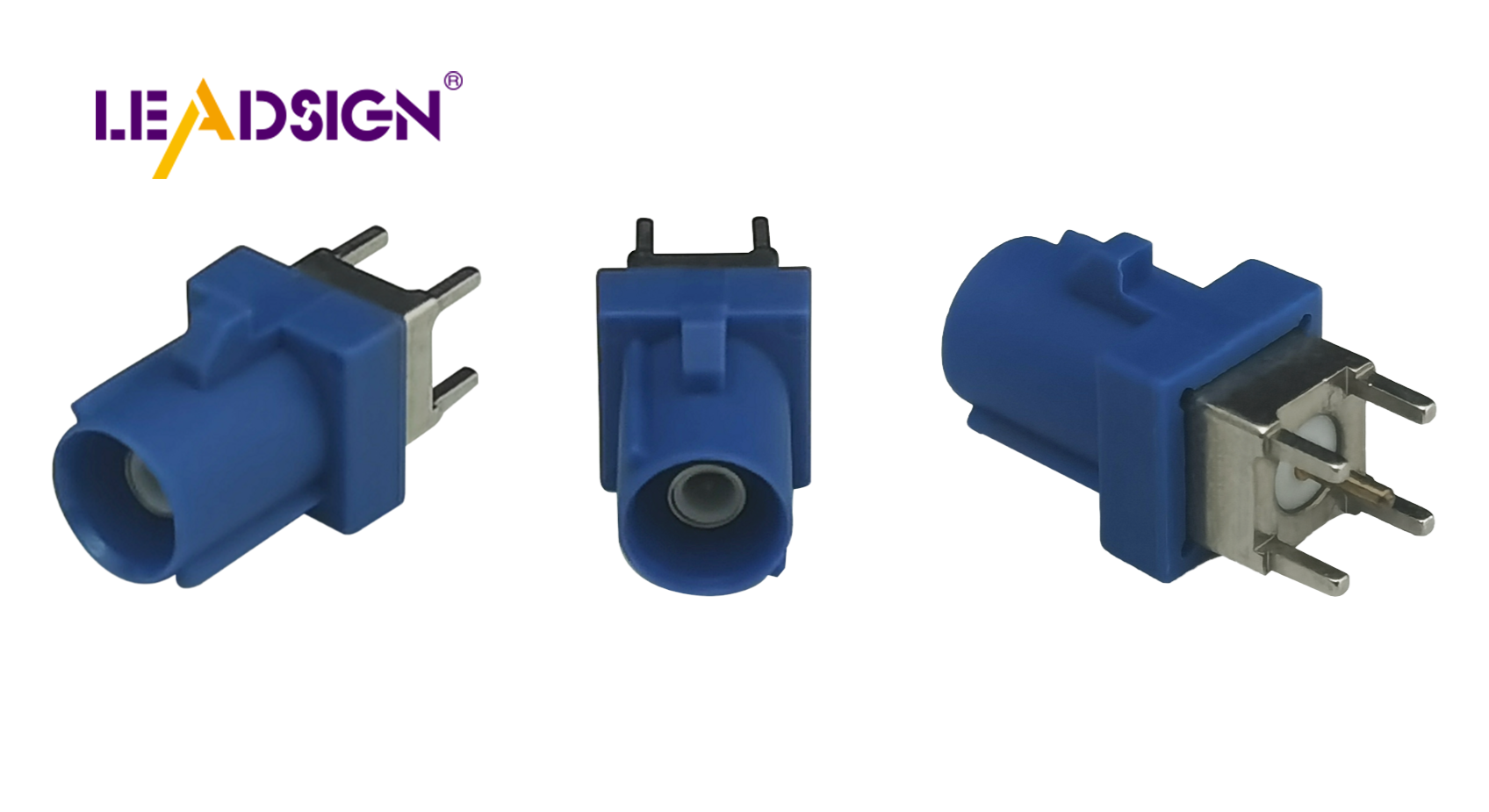

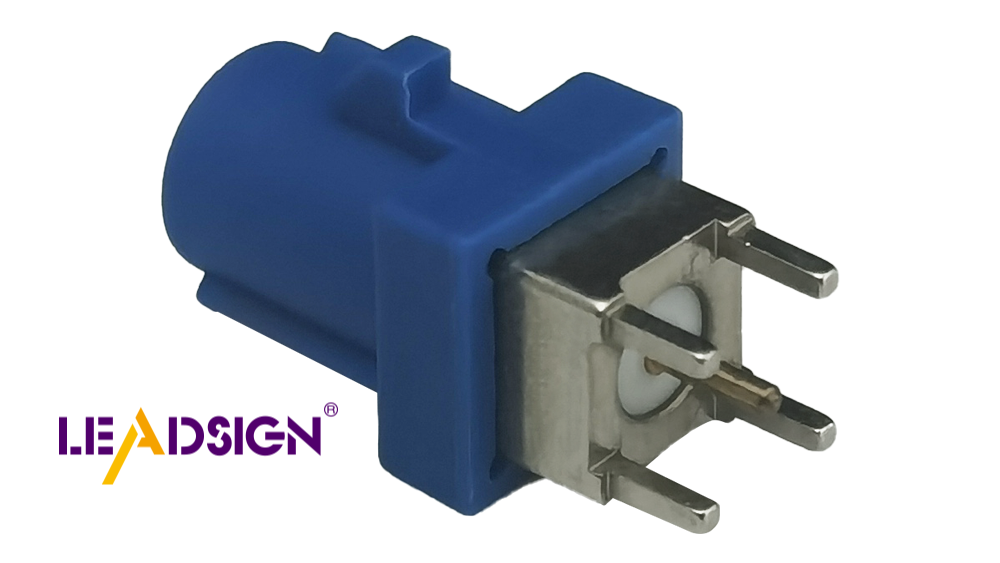

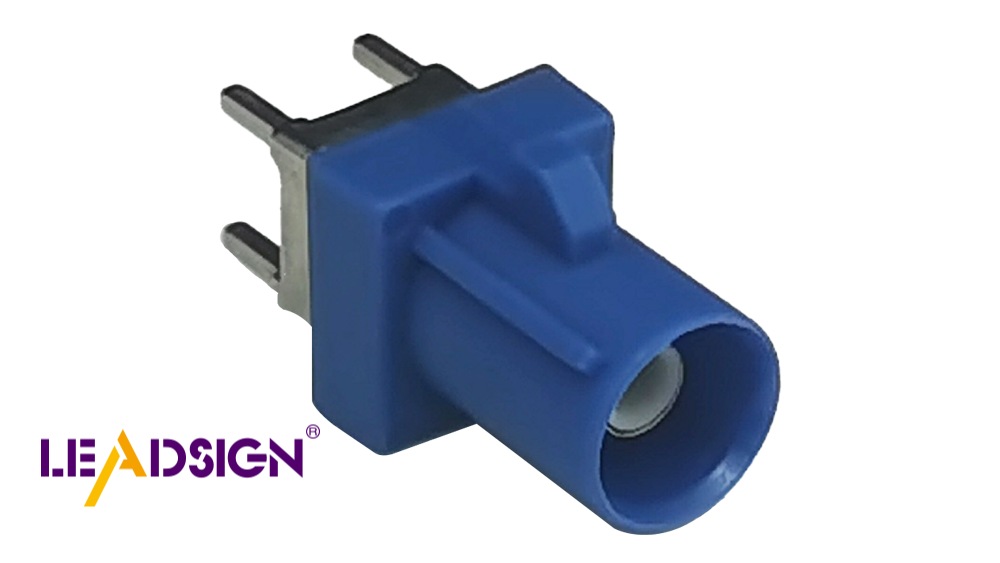

Significance of Fakra Connectors in Modern Automotive Systems