Discover the Best Auto Wire Connector Types Today

Automotive electrical connectors play a crucial role in automotive electronics. They facilitate effective communication between various components, ensuring seamless operation. These connectors are essential for enhancing the performance and safety of vehicles by establishing connections between multiple electrical circuits. Reliable automotive electrical connectors are vital for preventing issues that could impact car performance, making them indispensable in modern vehicles. The automotive electrical connectors types market is experiencing rapid growth, with a projected annual increase of 5.8% until 2026, underscoring their significance in the automotive industry.

Understanding Types of Automotive Electrical Connectors

Importance in Car Electronics

Auto electrical connectors are key to car electronics. They help systems talk to each other, which keeps cars running well. These connectors move signals and power so parts like fuel injectors and brakes work smoothly. Strong connections stop problems that might cause car breakdowns.

Role in Car Systems

In cars, these connectors do important jobs. They join circuits for good power flow and signal sharing. Metri-Pack Connectors are flexible and work well in tough spots. They handle shaking, heat changes, and wetness, making sure they work even in rough places.

Effect on Safety and Performance

Connectors greatly affect car safety and how well they work. Good ones stop rust and big problems that can make cars unsafe. OEM Automotive Electrical Wiring Connectors are made from strong stuff to last in bad conditions, cutting down failures. By keeping connections steady, they boost safety and efficiency.

Types of Auto Electrical Connectors

These connectors come in many shapes and sizes for different car needs. Knowing them helps pick the right one for the job.

Shape and Size Categories

Connectors are sorted by shape and size for various uses. Circular ones fit engine spaces because they're small and easy to put in. Rectangular ones have more contact points for complex systems needing many links. Hybrid types mix features of both shapes for design flexibility.

Uses and Advantages

Different connector types suit specific tasks with special perks. High amperage contacts charge batteries best, while crimping systems fit various wires. These connectors guard against heat, wetness, and rust for lasting use. Features like self-cleaning contacts add reliability, making them crucial today.

Important Things to Think About

Size and Power Handling

Automotive electrical connectors types come in different sizes. They handle power differently too. Picking the right one helps cars work well. It stops problems from happening.

Matching with Car Systems

Every car part needs a certain connector type. Big power parts need strong connectors for lots of electricity. OEM Automotive Electrical Wiring Connectors are good and not too pricey. They keep water out and stop rust, so they last long. They're great for many car jobs, even big trucks.

Power Needs and Limits

Knowing what power a car part needs is key. Connectors should meet these needs but not go over their limits. Big power contacts are great for charging batteries. Crimping systems fit many wires well. These connectors fight heat, water, and rust to work well everywhere.

How Well They Work and Stand Up to Weather

How well connectors work in bad weather matters a lot when picking automotive electrical connectors types. They must stay strong in tough spots to keep working right.

Toughness in Bad Places

Connectors in big vehicles deal with shaking and hot or cold places. Deutsch connectors fit tight and resist weather problems. They give special protection, so they're good for hard jobs. These connectors keep links steady, cutting down on failures in rough areas.

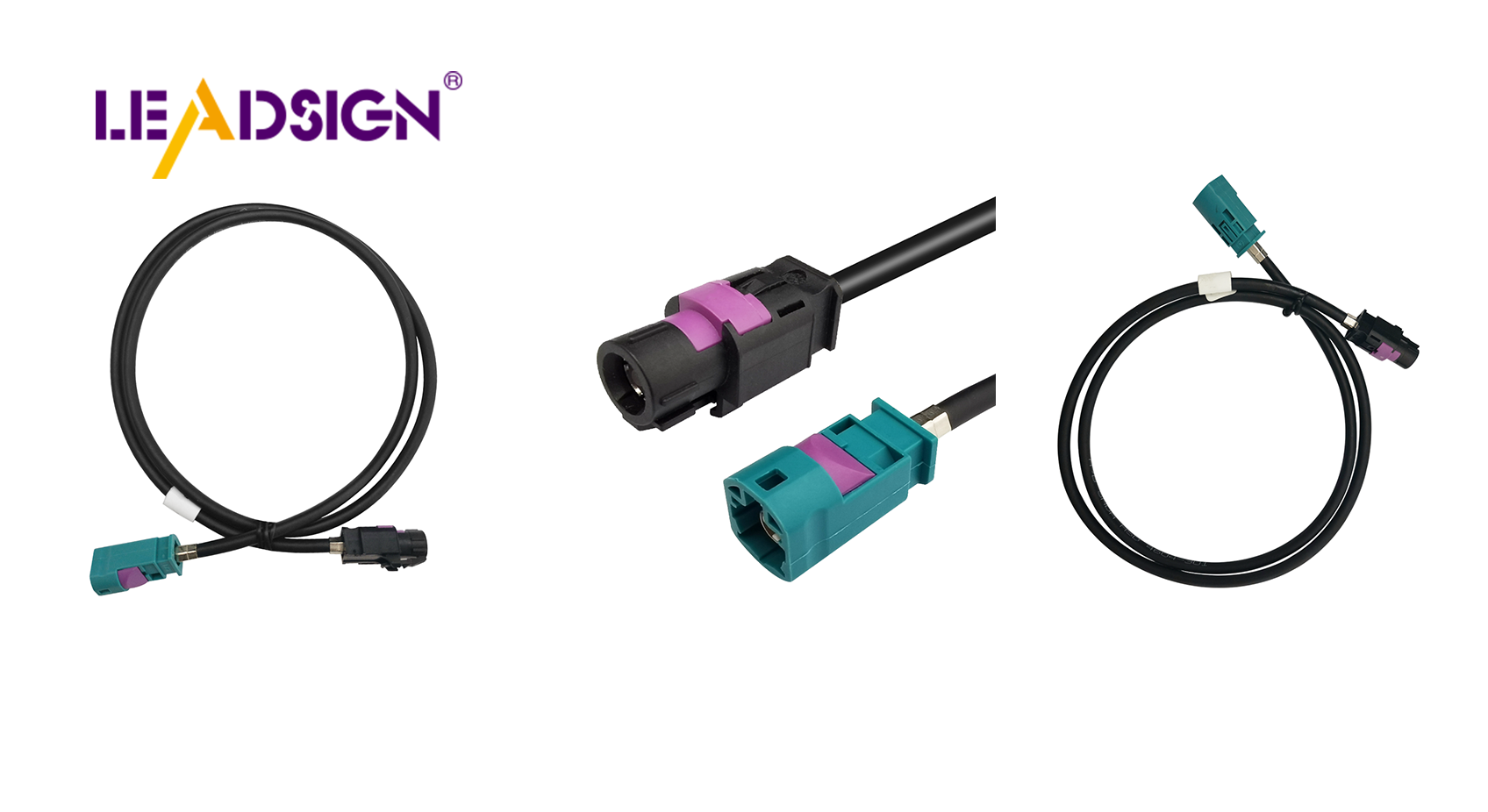

Fighting Heat and Water

Automotive electrical connectors types need to beat heat and water to stop rusting and last long. FAKRA connectors, using SMB tech, have strong plastic covers with guides to avoid mistakes when putting them on. They're good for high-frequency use and fight off bad weather well. This makes them perfect for new cars needing solid data links.

Materials Used in Connectors

Plastic Connectors

Plastic connectors are light and cheap. They are used in cars a lot. They use materials like nylon and polypropylene. These materials stop rust and can bend easily.

Advantages and Disadvantages

Plastic connectors have many good points. They don't rust, so they last long. Being light helps cars save fuel by weighing less. They can be made into different shapes and sizes.

But, plastic connectors have some downsides too. They can't handle high heat like metal ones can. In tough spots, they might break faster. Still, they are cheap and useful for many uses.

Common Applications

Plastic connectors are used in car electronics a lot. They're great for parts that don't need much power but need to be light. You find them in things like car lights and radios.

Metal Connectors

Metal connectors are strong and last long. They're important in car electronics. Made from copper or brass, they conduct electricity well and don't rust easily.

Benefits of Metal Construction

Metal connectors work better than plastic ones in hot places. They stay strong under pressure and send power well, which is key for important car systems.

Use Cases in Automotive Electronics

Metal connectors are needed where strength is crucial. They're used near engines where it's hot and shaky. They're also vital for safety parts like airbags because they can't fail.

New Improvements in Connector Technology

What are HSD Connectors?

High-Speed Data (HSD) connectors are a big step forward in car connector technology. They help with the fast data needs of today's cars. HSD connectors Rosenberger is a top company for these connectors. Their RosenbergerHSD® connectors work with both shielded and unshielded cables, making them useful for many things.

How High-Speed Data Works

HSD connectors send lots of data quickly and well. They have two locks to keep connections safe, even in tough places. The crimp connection makes cables stay put, so data moves reliably. These connectors also have smart coding to stop wrong connections.

Two Locks: Keep connections safe.

Crimp Connection: Holds cables tight.

Smart Coding: Stops wrong hookups.

"Rosenberger’s sales person taught me about HSD connections and gave me a connector kit." - Rosenberger Sales Person

Use in Today's Cars

HSD connectors are used a lot in new cars, especially where fast data is needed. Trucks use them to send camera pictures to screens, helping drivers see better and stay safe. Companies like Volkswagen and Daimler use these connectors in their cars too. As self-driving cars grow, HSD connectors become more important because they move lots of sensor info to the car's main computer.

Camera Picture Sending: Helps drivers see better.

Used by Big Car Makers: Volkswagen and Daimler lead here.

Self-Driving Cars: Needed for moving sensor info.

"Trucks mainly use HSD connections to send camera pictures to screens. Car makers like Volkswagen and Daimler push this tech in cars." - TE Connectivity Sales Person

In short, HSD connectors are key for improving car tech today. They support the need for fast data movement in modern vehicles. Their strong features and many uses make them very important now.

Picking the right car wire connector is very important for how well a vehicle works and stays safe. These connectors help electronic parts talk to each other, powering things like the engine control unit and the radio. OEM Automotive Electric Wiring Connectors are known for being strong and dependable. They protect against heat, wetness, and rust. Keeping up with new tech is key. New connector types, like High-Speed Data connectors, make data move faster in today's cars. Looking into these new ideas can make cars work better and driving smoother.

See Also

Unveiling the Significance of Fakra Auto Connectors in Vehicles Today

Discovering the Advantages of Fakra Auto Connectors

The Significance of Fakra Connectors in Automotive Sector

Transforming Auto Connectivity: The Benefits of HFM Connectors