Discover the Best Types of Wire Connectors for Automotive Use

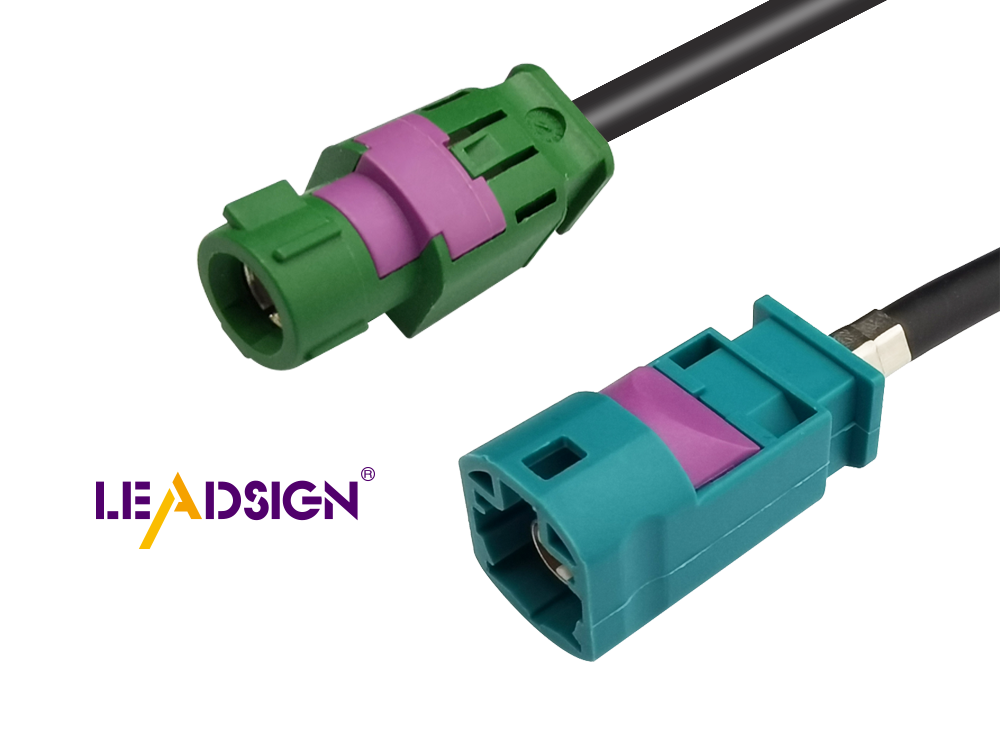

Image Source: LEADSIGN

Auto wire connector types are crucial in cars. They facilitate communication between various components. Modern vehicles are equipped with a multitude of connectors, with some having as many as 700 connectors and over 3,000 wires, highlighting the intricate nature of car systems. These connectors vary in shapes and sizes to cater to different purposes. Understanding the various auto wire connector types is essential for maintaining the efficiency of your car's electrical system. Familiarizing yourself with these connectors ensures they are compatible with other components, ultimately enhancing the performance of your vehicle.

Understanding Wire Connectors

What are Wire Connectors?

Definition and Purpose

Wire connectors are important in car electrical systems. They connect wires safely and help signals move smoothly in the car. These connectors come in many shapes and sizes for different uses. You can join wires easily with them without needing to strip or solder, which is great for quick fixes.

Importance in Automotive Systems

In cars, wire connectors keep the electrical system working well. They help parts talk to each other so your car runs smoothly. As cars get more complex, good wire connectors are needed more than ever. They make sure signals go right, lowering problems and making your car work better.

Common Materials Used

Copper

Copper is often used because it carries electricity well. It helps signals move fast, which is good for cars. Copper connectors last long and don’t rust easily.

Aluminum

Aluminum is also used a lot in wire connectors. It's light and cheap, which helps when you want to make cars lighter. Even though it doesn’t carry electricity as well as copper, it still works fine in many car systems.

Plastic Insulation

Plastic covers are used on wire connectors to keep out water and dirt. This makes them strong even when conditions are tough. Using plastic-insulated connectors helps your car’s electrical system last longer.

Auto Wire Connector Types

Image Source: LEADSIGN

Knowing different wire connectors helps your car's electric system. Each type has a special job for strong connections.

Butt Connectors

Features and Benefits

Butt connectors are easy to use. They connect two wires end-to-end safely. You can get them in many sizes for different wires. Their design keeps signals clear and strong. The cover stops water and rust, perfect for cars.

Common Applications

Use butt connectors to fix or extend wires. They're great in small spaces like under the dashboard or engine area. Both mechanics and DIY people like them because they work well.

Crimp Connectors

Types of Crimp Connectors

Crimp connectors have ring, spade, and bullet types. Each one does something special. Ring ones hold grounding wires tight. Spade ones are easy to take off, good for parts needing care often. Bullet ones make quick wire links.

Pros and Cons

Crimp connectors last long and are simple to use. You don’t need soldering, saving time but need a tool to crimp right. If done wrong, it might fail causing electric problems. Still, they’re handy in cars because they're reliable.

Solder Connectors

Advantages of Soldering

Solder connectors make strong permanent links. Soldering gives good electricity flow with less signal loss risk. It holds up against shakes and heat changes in cars well. They look neat and professional too.

Situations for Use

Use solder connectors when you need very reliable links like sensors or control parts connecting them is key even if it takes more skill and time it's worth it for solid connections.

Quick Disconnects

Quick disconnects make it easy to join and unjoin wires fast. You don't need tools, so they're great when you often unplug wires.

How They Work

Quick disconnects use a plug-and-socket system. The male part fits into the female part for a tight hold. This keeps them steady but lets you pull them apart easily. Many have locks to stop them from coming loose by accident, which is important in cars.

Best Use Cases

Use quick disconnects when parts need frequent changes. They're handy in cars where you swap or fix things a lot. For example, they work well with headlights and taillights. Because they're simple and dependable, many people pick them for car wire jobs, especially where fast fixes are needed.

Tip: Pick quick disconnects that can handle tough weather if they'll be outside. This helps them last longer and work better.

Things to Think About When Picking Wire Connectors

When picking wire connectors for your car, think about a few things. Knowing these helps you pick connectors that make your car's electric system work well.

Electrical Load Needs

Knowing Load Capacity

First, know how much electricity your car uses. Each connector can handle a certain amount. Pick one that fits your car's needs to stop it from getting too hot or breaking. Bullet connectors are good for simple circuits because they handle medium loads well.

Matching Connectors to Needs

Match the connector to what your car needs. Check how much power and voltage it uses. Make sure the connectors can take the most load safely. This keeps your car's electric system strong and stops extra fixes.

Weather Conditions

Heat Resistance

Cars face tough weather with big temperature changes. You need connectors that don't break in heat or cold. Good ones work even when it's really hot or freezing, keeping electricity steady.

Water and Rust Resistance

Water and rust are common problems in cars. Choose connectors with strong covers and rust-proof materials. Plastic-covered ones keep water out, making your car's electric parts last longer.

Easy to Install

Needed Tools

Think about tools needed for putting in connectors. Some need special tools like crimpers for crimp connectors. Right tools make sure connections are safe and stop electric problems.

Skill Level Needed

Check how hard it is to install them. Some need more skill like solder ones needing care and practice. If you like DIY, choose easy ones like quick disconnects that don’t need tools and are fast to use.

Expert Tip: Experts say bullet connectors are handy in cars because they're easy to unplug during fixes.

By thinking about these things, you can pick the best wire connectors for your car. This makes sure your car’s electric system works well now and stays reliable later.

Common Problems and Fixes

Wire connectors are important for your car's electric system. But they can have problems that mess things up. Knowing these problems and how to fix them keeps your car working well.

Bad Connections

Why They Happen

Bad connections can happen for many reasons. Loose parts make weak electric links. Dirt or rust on connectors stops electricity from flowing right. Also, using the wrong connector type can cause bad links.

How to Fix Them

To fix bad connections, make sure all parts fit tight. Clean dirt or rust off with a good cleaner. Pick the right connector for each job to keep links strong. Check often to find and fix problems early.

Connector Breaks

Spotting Breaks

Connector breaks show in different ways. You might see lights flicker or power go on and off in spots. These signs mean there's a break in the connectors' flow. Things like water and shaking make it worse, causing more breaks.

Stopping Breaks

Stopping connector breaks needs some careful steps. Use connectors that handle heat, wetness, and shaking well. Look at connectors often for wear or damage signs. Change any broken ones fast to stop more trouble. Doing this makes your car's electric system work better and stay safe.

Note: Water and shaking hurt electric links a lot. Using tough connectors helps stop breaks that could be dangerous.

Picking the right wire connectors for your car is important. You learned about types like butt, crimp, solder, and quick disconnects. Each type has special uses and benefits. Think about things like power needs, weather conditions, and how easy they are to put in. This keeps your car's electric system working well.

Remember: Using good methods like crimping, soldering, and heat shrinking gives you useful car skills. This makes things safer and helps you feel sure when fixing car electrical stuff.

See Also

The Significance of FAKRA Connectors in Auto Industry Uses

The Vital Role of FAKRA Connectors in Contemporary Cars

The Benefits of HFM Connectors in Auto Sector