Best Auto Wire Connector Types for Dependable Performance

In automotive engineering, the types of automotive electrical connectors play a crucial role. They ensure that your car's electrical systems function efficiently and safely. Poor-quality connectors can frequently lead to electrical issues, often caused by exposed wires or rigid connector covers. Selecting the appropriate automotive electrical connectors types significantly reduces these risks. High-quality connectors enhance both the performance and safety of vehicles. Understanding their importance aids in making informed choices for your automotive needs.

Understanding Automotive Wire Connectors

Definition and Features

What are automotive wire connectors?

Automotive wire connectors are key parts of your car's electrical system. They keep connections strong, helping different systems work well. These connectors join wires and cables so electricity can flow easily. You see them in places like engine control, audio systems, and lights. Knowing their job helps you see how they help cars run every day.

Key features of reliable connectors

Good automotive wire connectors have important features. They give secure connections to lower the chance of electrical problems. Quality connectors use tough materials that stand up to weather. This toughness means they last a long time. Also, they come in many shapes and sizes for different wiring needs. Picking these kinds of connectors makes your car's electrical systems safer and better.

Applications in the Automotive Industry

Common uses in vehicles

In cars, wire connectors do many jobs. They link single wires to big multi-wire systems for smooth electric flow. You find them in important spots like lights, sensors, and control devices. These connectors help your car work right by making sure parts connect well.

Wire connectors matter for car safety and how it runs. They make sure electric links are correct and steady, which keeps car systems safe. A good connection stops problems like short circuits that can be dangerous. By working well, these connectors keep your car healthy overall. Knowing their importance in vehicle safety helps you pick the right ones for fixes or upgrades.

Wire connectors matter for car safety and how it runs. They make sure electric links are correct and steady, which keeps car systems safe. A good connection stops problems like short circuits that can be dangerous. By working well, these connectors keep your car healthy overall. Knowing their importance helps you pick the right ones for fixes or upgrades.

Types of Automotive Wire Connectors

Picking the right car wire connectors is important. It helps your car work well. Let's look at some common types and what makes them special.

Crimp Connectors

Features and benefits

Crimp connectors make strong connections. You press them onto wires to hold tight. This keeps out water, dirt, and dust. Crimping is easier than soldering, so many people use it in cars. It gives a steady connection, stopping problems from happening later.

Common applications

Crimp connectors are used where strength matters most. You see them in engines, lights, and other key car parts. They handle tough conditions well, making them perfect for these spots.

Solder Connectors

Features and benefits

Solder connectors join wires by melting solder on them. This makes a lasting link that’s very strong at ends. Soldering has low resistance and good electricity flow, great for high-power uses. But it takes more skill and time than crimping.

Common applications

Solder connectors are used where a lasting link is needed. They’re found in sound systems, sensors, and parts needing exactness and steadiness. Their strong hold suits these delicate uses.

Quick Disconnect Connectors

Features and benefits

Quick disconnect connectors let you easily unplug parts fast. You can connect or disconnect wires quickly without tools, which is handy. They're made for places needing frequent unhooking.

Common applications

Quick disconnects are used where parts need regular checks or swaps. They’re often in lights, batteries, and areas needing easy access often. Their simple design makes them useful here.

Knowing about these wire connector types helps you choose wisely to boost your car's performance and safety. Each type has its own perks, so think about what you need when picking for your car projects.

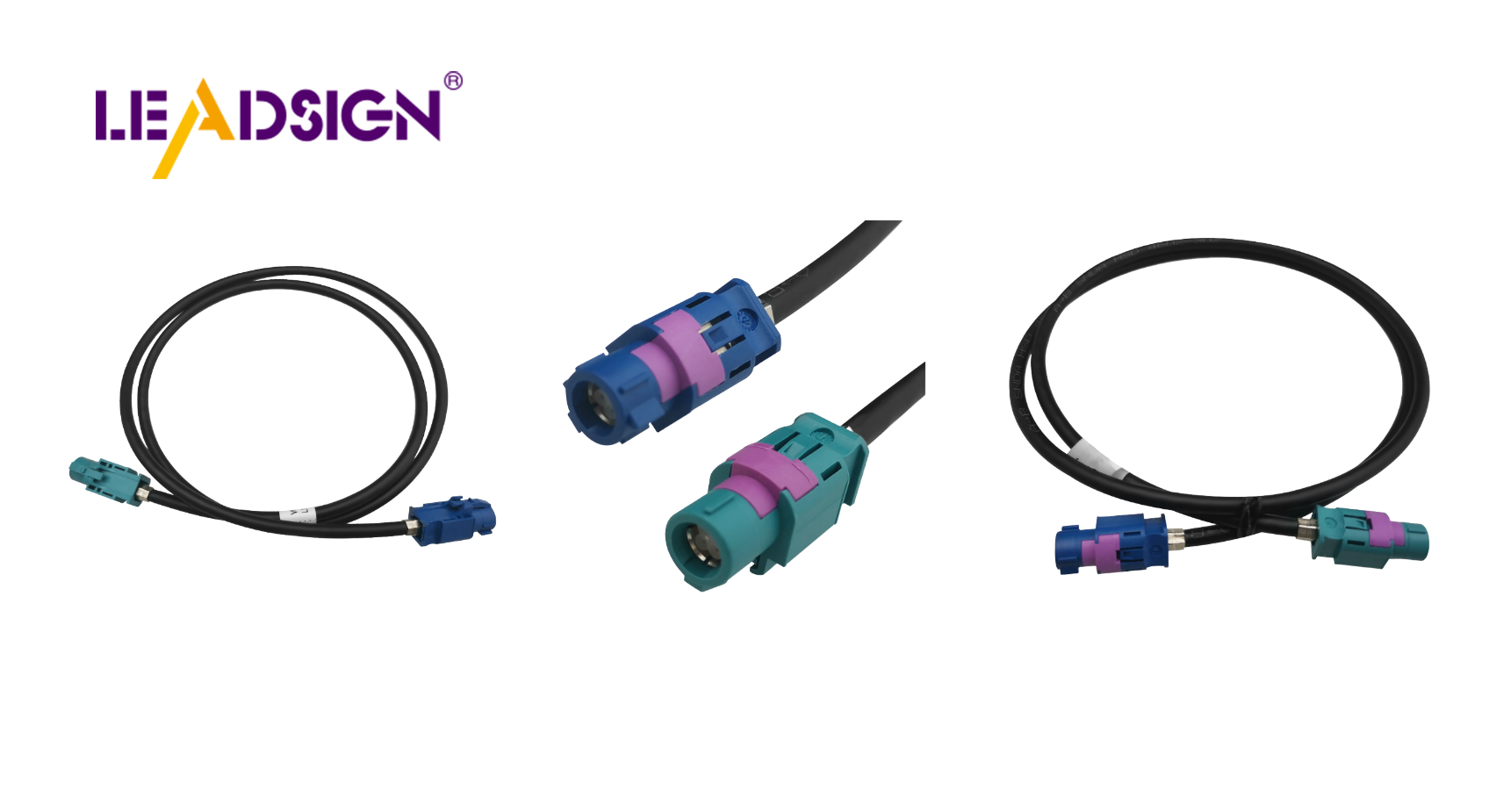

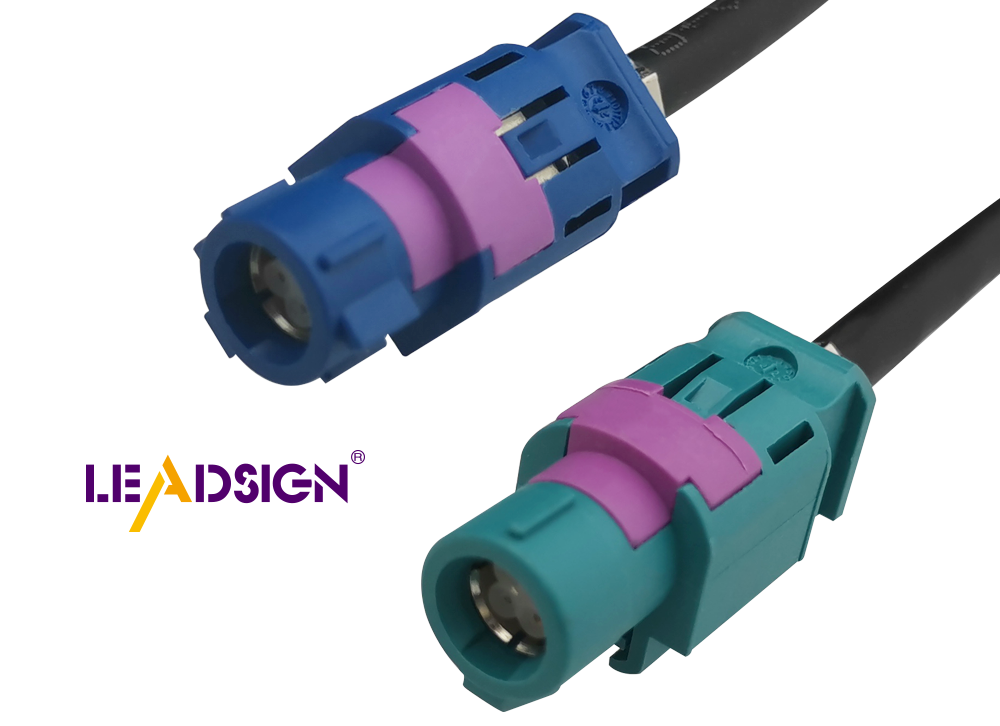

High-Speed Data (HSD) Connectors

Features and benefits

High-Speed Data (HSD) connectors are special among car wire connectors. They send fast data, perfect for new car tech. HSD connectors have key features:

Primary and Secondary Lock: These keep connections tight, stopping wires from coming loose.

Crimp Connection: This makes strong links that block water and dirt. Crimping is tougher than soldering for cables.

High Cable Retention Force: Cables stay put even when shaken or pulled.

High Coding Efficiency: Different codes stop wrong connections, keeping systems safe.

These features make HSD connectors a smart pick for your car's electric parts.

Common applications

HSD connectors work in many car areas. You find them in:

Automotive Electronics: Needed for fast data like cameras and music systems.

Telecom Industries: Used in radio stations to keep data flowing well.

Digital Infotainment Electronics: Help connect entertainment gear smoothly.

USB and Ethernet Connections: Fit with USB 1.0, 2.0, 3.0, and Ethernet for device links.

IEEE 1394 (Firewire) and LVDS: Support these types for clear data moves.

Knowing about HSD connectors helps you choose the right ones. This boosts how your car runs and keeps it safe too.

Picking the Right Connector

Choosing the right automotive electrical connectors is key for your car's best performance and safety. Think about a few things and follow some tips to decide well.

Things to Think About

Electrical needs

First, check your car's electrical needs when picking connectors. Different parts need different power levels. For example, big systems like the engine control unit need connectors that handle lots of electricity. Make sure your connectors can meet each part's power needs.

Environment conditions

Where the connectors will be used matters a lot too. Automotive electrical connectors must handle tough places like hot or wet spots and shaking. For instance, in the engine area, they should resist heat and oil. Choose strong materials for long-lasting use.

Tips for Choosing

To get good results, match connectors to their jobs. Each connector type has its own use. For example, HSD Connectors are great for fast data jobs like music systems and screens. Knowing what each system needs helps you pick better.

To get good results, match connectors to their jobs. Each connector type has its own use. For example, HSD Connectors are great for fast data jobs like music systems and screens. Knowing what each system needs helps you pick better.

Checking compatibility and safety

Compatibility and safety are very important when choosing automotive electrical connectors. Make sure they fit with your car’s wires and parts to avoid problems like bad connections or electric issues. Also, pick safe ones with strong locks and good coding to stop accidents.

By thinking about these things and using these tips, you can choose the right automotive electrical connectors for your car easily. This makes your car work better and keeps it safe too.

Picking the right wire connectors is key for your car's safety. Good connectors, like those from the factory, use strong materials. They can handle heat, wetness, and shaking. This keeps connections steady and lowers failure chances. When choosing connectors, think about where they'll be used. For high power, make sure they fit well and are designed right. Weatherproof ones are important in tough places. By knowing these things, you can choose wisely to make your car last longer and work better.

See Also

Enhancing Automotive Connectivity with HSD Connectors

Benefits of HFM Connectors for Automotive Applications

Significance of FAKRA Connectors in Automotive Uses