A Beginner's Guide to Installing Car Wire Connectors

Proper wire connections in automotive applications are crucial for safety. They play a key role in functions such as headlights and radios. Understanding the various automotive wire connectors types available can assist in selecting the most suitable one for the job. Prioritize safety by familiarizing yourself with the different connector options. Remember to disconnect the battery to prevent any electrical shocks. Wear protective gloves and goggles to safeguard yourself during the installation process. Maintain a clean and organized workspace free of clutter to ensure a safe and efficient installation experience.

Understanding Automotive Wire Connectors Types

Overview of Automotive Wire Connectors Types

Car wire connectors come in different shapes. Each type is made for a special job. Knowing these helps pick the right one for your car.

Common Types and Their Applications

Pin Connectors: These are flexible and used in many car parts. They can have one pin or many pins. You see them in lights and radios.

Crimp Connectors: These hold tight by squeezing onto the wire. They're great where things shake a lot, like near engines.

Solder Connectors: These make a strong link that stays put. Use them where you need it to be very reliable.

Push-In Connectors: These are easy to use and fast to set up. They're good where you often unplug things.

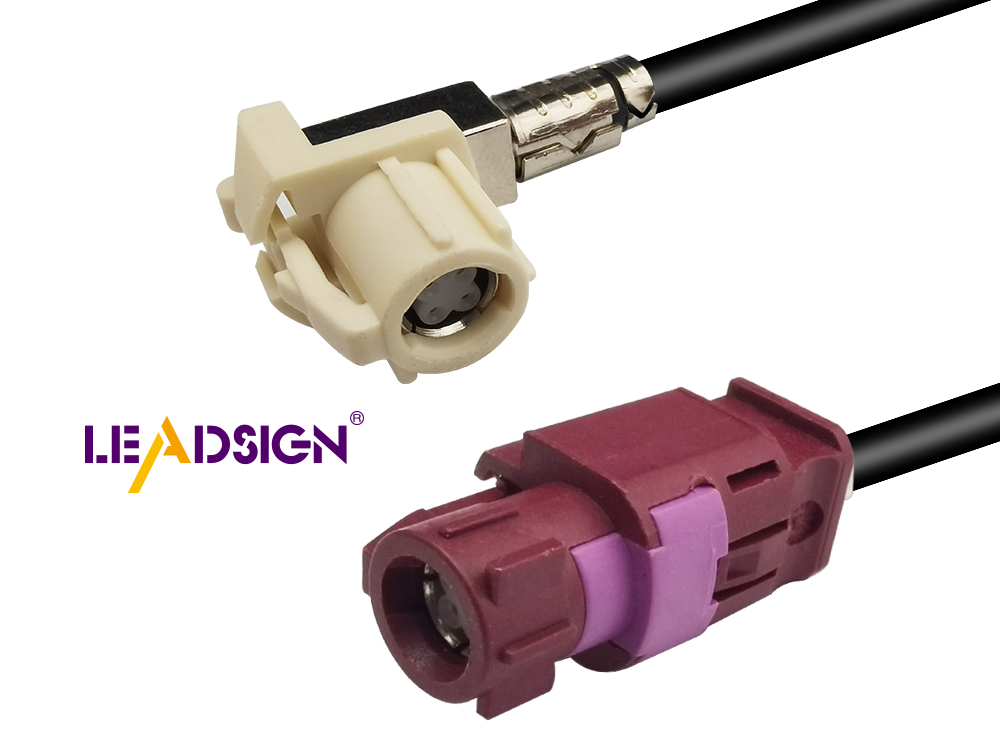

HSD Connectors: HSD Connectors are key for new cars. They work with USBs and digital systems.

Advantages and Disadvantages of Each Type

Pin Connectors:

Advantages: Simple to put in and swap.

Disadvantages: Not best for high power use.

Crimp Connectors:

Advantages: Tough and steady in rough spots.

Disadvantages: Needs exact tools to fit right.

Solder Connectors:

Advantages: Makes a strong, lasting link.

Disadvantages: Takes time and skill with soldering.

Push-In Connectors:

Advantages: Fast and simple to handle.

Disadvantages: Might not last long if shaken hard.

HSD Connectors:

Advantages: Handles fast data well.

Disadvantages: More tricky, might need expert help.

Picking the right car wire connector types makes sure your car's electric parts work well. By knowing what each type does, you can choose smartly and fix things confidently.

Tools and Materials Needed

To install car wire connectors, you need the right tools. Having them ready makes the job easier.

Essential Tools

Wire Strippers

Wire strippers are important for wires. They help take off the cover without cutting the wire. This lets you connect wires safely. Pick a stripper that matches your wire size.

Crimping Tool

A crimping tool connects wires to connectors. It squeezes the connector onto the wire tightly. This keeps it secure even if things shake, like near engines. Choose one that fits your connectors.

Multimeter

A multimeter checks electricity like voltage and current. It helps test if connections work well. Knowing its symbols helps find problems fast. Use its leads for correct readings.

Necessary Materials

Different Types of Wire Connectors

Having many types of connectors is key. Each type does something special, like pin or data connectors. Pick based on what your project needs.

Electrical Tape

Electrical tape covers and protects connections from water and dirt. Wrap it tight so it stays in place.

Heat Shrink Tubing

Heat shrink tubing adds more protection to wires. When heated, it shrinks around them tightly, keeping out moisture or dust. Use a heat gun for best results.

By getting these tools and materials, you're ready to install car wire connectors well.

Getting the Wires Ready

Finding the Right Wires

Before connecting, find the right wires. This stops mistakes.

Knowing Wire Colors and Jobs

Wire colors mean different things. Wire colors mean different things. Red is power; black is ground. Check your car's manual for exact colors.

Testing Wires with a Multimeter

A multimeter checks wires. Set it to the right voltage. Use red lead on positive, black on negative. This shows if wires work.

Stripping the Wires

After finding wires, strip them carefully.

How to Strip Insulation Right

Use a wire stripper. Match wire size in the tool. Squeeze and pull off insulation gently.

Keeping Wires Safe

Don’t cut metal core when stripping. Use correct notch size. If damaged, cut and strip again.

Follow these steps to get wires ready for connectors.

Installing the Connectors

Picking the Right Connector

Choosing the right connector is very important. Match it to your car's needs.

Types of Connectors and Their Uses

Different connectors have different jobs:

Pin Connectors: Good for lights and radios. Check shape and pins.

Crimp Connectors: Great near engines where things shake. They hold tight.

Solder Connectors: Best for strong, lasting links.

Push-In Connectors: Easy for quick setups with many unplugs.

HSD Connectors: Needed for fast data like USBs. HSD Connectors

Things to Think About When Picking Connectors

Think about these when choosing:

Compatibility: Make sure it fits your car's needs.

Environment: Pick ones that handle heat or wet places well.

Ease of Use: Choose what you can use easily with your tools.

Experts say check shape and pins to stop problems.

Attaching the Connectors

Attach them right for a strong link.

Crimping Steps

Crimping means squeezing onto the wire. Do this:

Strip wire to show metal.

Put wire in connector.

Press with tool hard for a tight grip.

Making Sure It's Secure

Pull wire gently to test it. It should stay put. A firm link stops electric issues.

Covering the Connection

Cover keeps it safe from outside stuff.

Using Electrical Tape

Wrap tape around connection tightly. This keeps out water and dirt.

Using Heat Shrink Tubing

Slide tubing over connection. Heat it so it shrinks snugly on wires. This adds more protection.

By doing these steps, your connectors will work well, keeping your car's electric system safe and good.

Try different automotive wire connectors to see what fits your needs best. automotive wire connectors

Eric Palazzolo: Finding your car electrical connectors can be tough. But for many happy customers, it’s been very easy.

See Also

An Extensive Overview of HSD Connectors

Navigating Ford Fakra Connectors

Essential HSD Connectors in Automotive Sector

In-Depth Look at Fakra Connectors: Benefits, Uses, and Setup Advice

Thorough Examination of Fakra Connectors: Fundamentals, Varieties, and Uses