A Beginner's Journey into Car Wiring with Two Pin Connectors

Starting to learn car wiring can be scary. But, knowing two-pin connectors is important in cars today. These connectors link electronic parts together, including car wiring wire. They help systems work well. You can see them in things like car lights. They are useful and dependable. Learning wiring basics is not too hard. With good help, you can learn car wiring. You will gain new skills.

Key Takeaways

Understanding the basics of car wiring, including the types of wires and their properties, is essential for successful projects.

Two-pin connectors are crucial for linking car components, ensuring reliable power and signal transmission.

Using the right tools, such as wire strippers and crimping tools, is vital for making safe and effective connections.

Regularly checking and maintaining car wiring can prevent issues like loose connections and rust, saving time and money.

Learning color coding in wiring helps identify wire functions quickly, making the wiring process safer and more efficient.

Testing connections with a multimeter ensures that your wiring is functioning correctly and securely.

Practicing car wiring skills can boost your confidence and enable you to assist others with their car projects.

Understanding Car Wiring

When you look at car wiring, you'll see different wires. Each wire has a special job in the car. Knowing these wires is important if you want to learn about car wiring.

Types of Car Wire Used in Cars

Primary Wire: This is the most used car wire. It's for general electric connections in cars. It's bendy and easy to use, so it's good for tight spots.

Battery Cable: This wire links the battery to the car's electric system. It's thicker than primary wire because it carries more power. The cover on battery cables is strong to handle tough conditions under the hood.

Speaker Wire: In car wiring, speaker wire connects audio parts. It can handle heat, wetness, and shakes, so your car's sound system works well. This wire is made to last in a car's tough environment.

Wire Properties and Why They Matter

Knowing about car wire properties helps you pick the right wire.

Gauge: Gauge means how thick a wire is. A smaller gauge number means a thicker wire, which carries more power. You need the right gauge so the wire doesn't get too hot.

Insulation: Insulation keeps the wire safe from outside stuff and stops electric shorts. Different insulation types resist heat, chemicals, and scratches. For example, cross-linked car wire, or XLPE wire, is made to resist heat and chemicals better.

Color Coding: Color coding helps you know wires fast. Each color usually means a job, like power or ground. Learning these colors makes wiring easier and less risky.

By knowing these wires and their properties, you can do car wiring projects with confidence. This knowledge helps you make smart choices and keeps your car's electric system safe and working well.

Important Tools for Car Wiring

To start car wiring, you need good tools. These tools help make safe connections. Let's look at the tools you need.

Basic Tools

Wire Strippers: Wire strippers take off wire covers without harm. They help get wires ready for connecting. Using them makes a neat cut, which is key for good wiring.

Crimping Tools: Crimping tools attach ends to wires. They make a strong hold that keeps wires in place. Good crimpers are important for a strong link. Don't use pliers; they make weak links.

Multimeter: A multimeter checks electric circuits. It shows voltage, current, and resistance. This helps find problems in car wiring. With it, you know if connections work right.

Advanced Tools

Soldering Iron: A soldering iron joins wires by melting solder. This makes a lasting connection. Soldering is better where shaking might loosen wires.

Heat Gun: A heat gun shrinks tubing over connections. This tubing keeps wires safe from water and wear. Using it keeps wiring safe and strong.

These tools make car wiring easier and better. Each tool helps your car's electric system work well. As you learn more, you'll see why good tools matter for wiring jobs.

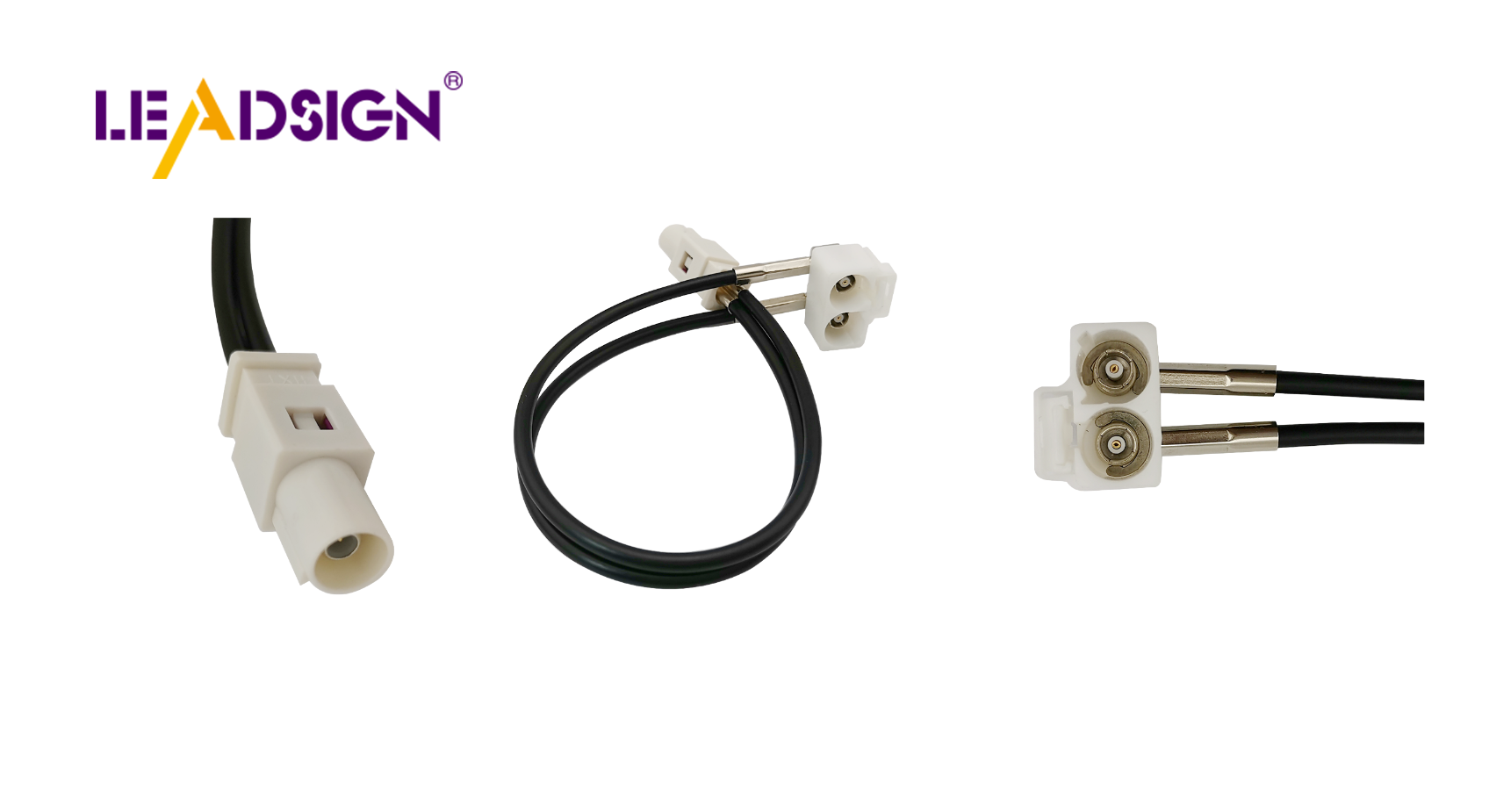

Easy Steps to Use Two Pin Connectors in Car Wiring

Two-pin connectors are important in car wiring systems. They help send signals and power to car parts. This guide will show you how to use them well.

Getting Wires Ready

Before starting, get the car wires ready. This makes sure they connect well.

Taking Off Wire Covers

Get Your Tools: Use wire strippers to take off the wire cover. This tool helps you do it without hurting the wire.

Remove the Cover: Take off about half an inch of cover from each wire end. This shows the bare wire for connecting.

Check the Wire: Look at the bare wire for any damage. Bad wires can mess up signals and power.

Picking the Right Connector

Choose the Connector: Pick a two-pin connector that fits your wire size and job. The right one fits well and connects right.

Think About Conditions: If wires face tough conditions, pick connectors with strong covers and seals.

Joining the Wires

After getting wires ready, connect them with the two-pin connector.

Putting Wires in the Connector

Line Up the Wires: Put the bare wire ends into the right slots of the connector. Make sure wire colors match the diagram for right connections.

Check the Fit: Ensure wires are fully in and seated right in the connector. This keeps signals working well.

Making the Connection Secure

Crimp the Connector: Use a crimping tool to hold wires in the connector. A good crimp makes a strong link.

Check the Connection: Make sure wires are held tight. Loose wires can cause signal and power problems.

Testing the Connection

After making the connection, test it to see if it works.

Using a Multimeter

Set Up the Multimeter: Set your multimeter to check continuity or resistance. This tool checks if the connection is good.

Test the Connection: Put the multimeter probes on the connector ends. A beep or low number means a good connection.

Making Sure It Fits Well

Do a Tug Test: Gently pull the wires to see if they stay in the connector. This checks if the connection is strong.

Check for Safety: Make sure the connection is safe. Good setup stops dangers.

By following these steps, you can use two-pin connectors in car wiring easily. Knowing wire harness design and parts helps in wiring a car. Pre-made and custom wire harnesses make it easier, but knowing how to work with parts improves your skills.

Fixing Problems and Good Habits for Car Wiring

When you work on car wiring, problems can happen. Knowing these problems and fixing them saves time and stress.

Common Wiring Problems

Loose Wires

Loose wires can cause electrical issues. If your car's lights or radio act weird, check the wires. Move the wires gently to see if the problem comes back. Loose wires stop electricity, making parts not work. Tighten any loose wires for a good connection.

Rust

Rust is bad for car wires. It can be on battery ends, connectors, and metal parts. Rust stops electricity, causing things to fail. Check these spots for rust often. Clean rusty parts with a wire brush or change them if needed. Clean connections work better.

Care Tips

Taking care of car wires means checking them often and caring for your tools.

Regular Checks

Look at your car's wires often. See if there are cracks or bare wires. Change bad wires fast to stop problems. Regular checks find issues early, saving money later.

Storing Tools Right

Put your wiring tools away right to keep them nice. Clean them after using and store them dry. Good storage makes tools last longer and ready to use. Good tools make wiring jobs easier.

By using these tips, you keep car wires working well. Paying attention stops problems and keeps your car's electric parts working right.

Learning basic car wiring skills makes you feel confident. As you keep learning and practicing, wiring jobs become fun and satisfying. Think about how hard tasks can turn into exciting challenges. You might even want to help friends with their cars. Doing wiring tasks by yourself feels great. Remember, there are many guides to help you. Enjoy the journey, and soon, you'll handle car wiring easily and skillfully.

FAQ

What do 2-pin connectors do in car wiring?

2-pin connectors help send power or signals between car parts. They link sensors, switches, and lights. They work well even in tough conditions. They are simple and very important for cars.

How do I pick the right 2-pin connector for my car?

Before buying a 2-pin connector, check it fits your car's wires. Make sure your car uses a 2-pin connector. Look at the part closely to see its shape and size. This helps you find the right connector.

What tools do I need to put in 2-pin connectors?

To put in 2-pin connectors, you need wire strippers, crimping tools, and a multimeter. Wire strippers take off wire covers safely. Crimping tools hold wire ends tight. A multimeter checks if circuits work right.

How can I make sure 2-pin connectors are secure?

To make sure they are secure, put wire ends in the right slots. Use a crimping tool to hold wires tight. After connecting, gently pull wires to see if they stay. This checks if the connection is strong.

What should I do if wires are loose in my car?

Loose wires can cause problems. If car lights or radio act up, check wires. Move them gently to see if the problem stays. Tighten loose wires to fix the connection.

How do I keep my car's wiring system good?

Check your car's wires often for cracks or bare spots. Change bad wires fast to stop problems. Store your tools right after use. Clean them and keep them dry so they last long.

Why is color coding important in car wiring?

Color coding helps you know wires fast. Each color shows a job, like power or ground. Learning these colors makes wiring easy and safe. It helps connect wires right.

Can I use a soldering iron for 2-pin connectors?

Yes, a soldering iron can join wires by melting solder. This makes a strong connection. Soldering is good where shaking might loosen wires. Be sure you know how to use it safely.

What are the benefits of using 2-pin connectors in cars?

2-pin connectors are key in car systems. They help cars work smoothly. They are reliable and flexible. As car tech grows, these connectors will stay important.

See Also

Everything You Need to Know About HSD Connectors

Understanding HSD Connectors for Automotive Applications

Exploring Mini Fakra Connectors: An In-Depth Overview