Automotive Wiring Connector Types: What You Need to Know

Knowing the different automotive wiring connector types is crucial for repairing cars. These connectors play a vital role in ensuring the proper functioning of electrical components in various automotive systems. People are increasingly seeking improved connectors due to safety concerns and evolving regulations. Connectors are typically equipped with locks to prevent accidental disconnection, particularly in critical components such as airbags and sensors. In 2019, automotive wiring connectors accounted for 23.7% of global sales, underscoring their significance in the automotive industry. Reliable connectors not only enhance the performance of vehicles but also contribute to their overall safety, making them indispensable in modern automobiles.

Basics of Automotive Wiring Connectors

Definition and Function

What are wiring connectors?

Wiring connectors are important parts in cars. They help different electronic parts talk to each other. These connectors come in many shapes and sizes to fit different needs. By holding wires tightly, they make sure signals move well from one part to another.

How do they function in automotive systems?

In cars, wiring connectors are very important. They connect electronic parts so they can work together easily. For example, they send signals from sensors to the car's control units. This makes sure things like airbags work right. It's important for these parts to be very reliable, especially for safety reasons. Makers add features like waterproofing and locks to stop them from coming apart by accident.

Importance in Automotive Systems

Ensuring electrical connectivity

Wiring connectors keep electrical connections steady in cars. They hold wires together so signals don't get cut off. This steadiness is key for electronics to work well. Without good connectors, parts might not talk, causing problems.

Impact on vehicle performance and safety

A car's performance and safety rely a lot on its wiring connectors. Good connectors help the car run smoothly by making sure all systems work well together. They also keep people safe by ensuring critical systems like airbags stay working right. Bad connectors can cause failures that are dangerous for the car and people inside it. So, picking the right connector is crucial for a safe and good-running car.

Types of Automotive Wiring Connectors

Knowing different automotive wiring connector types is important for fixing cars. Each type has a special job and features for car needs. Let's look at some common connectors used in cars.

Blade Connectors

Features and uses

Blade connectors, also called spade connectors, are simple and reliable. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect, perfect for frequent maintenance. You can find them in car audio systems, lights, and low-voltage areas.

Good and bad points

Good points:

Easy to use without tools.

Stay connected even with shaking.

Come in different sizes for various wires.

Bad points:

Not good for high power.

Can rust if not sealed well.

Pin Connectors

Features and uses

Pin connectors are also popular in cars. They have pins that fit into sockets, making strong connections. They're great for important systems like engines and safety parts. Pin connectors are used in sensors and control units.

Good and bad points

Good points:

Strong connection.

Work with both low and high power.

Resist weather when sealed right.

Bad points:

Harder to install than blade ones.

Need exact alignment to work.

Butt Connectors

Features and uses

Butt connectors join two wires end-to-end. They're used in car wiring fixes or changes. These give a safe connection so signals pass well between wires. They're found in wire bundles where permanent links are needed.

Good and bad points

Good points:

Strong, lasting connection.

Insulated to stop short circuits.

Simple with crimping tools.

Bad points:

Hard to take apart once set up.

Need the right crimping tools to install.

Special Connectors

Special connectors do special jobs in cars. They help where regular connectors can't. These have unique designs to work well in tough places. They are important for keeping car wiring safe, especially where normal ones might not work.

Pigtail Connectors

Pigtail connectors are flexible and easy to use. They have a short wire with a connector on the end. This makes them easy to add to car wires that need changing often.

Features of Pigtail Connectors:

Flexibility: The extra wire helps connect in tight spots.

Reliability: They hold strong, even if the car shakes or moves.

Ease of Installation: You can attach them quickly without many tools.

Pigtail connectors are great when space is small and direct links aren't possible. Their design lets them handle tough car conditions, making them a good choice for many uses.

Uses in Certain Systems

Special connectors like pigtails are used in certain car systems where they must work well and last long.

Common Uses:

Lighting Systems: Pigtails make it easy to change headlights and taillights.

Sensor Connections: In things like ABS and airbags, they keep connections safe for protection.

Infotainment Systems: They give steady links for music and video parts, so entertainment doesn't stop.

The material of these connectors matters too, like copper or aluminum. Copper is great because it conducts electricity well and doesn’t rust easily, which is why it's often used in car wiring types. Aluminum is lighter, which helps make cars weigh less overall.

Common Problems and Fixes

Knowing issues with automotive wiring connector types helps keep cars safe. This part looks at problems and how to fix them.

Connector Problems

Why they fail

Connectors can break for many reasons:

Weather Effects: Heat, water, and shaking can harm connectors. Near engines, they face heat and oil.

Material Damage: Over time, plastic and metal wear out, causing bad links.

Wrong Setup: Bad installation can misalign or break parts, hurting connections.

How to stop failures

Stopping failures needs good choices and care:

Pick the Right Kind: Use connectors made for certain places. Waterproof ones are best where there's water or dust.

Check Often: Regular checks find damage early so you can fix it fast.

Install Right: Put connectors in properly using correct tools to avoid mistakes.

Fixing Methods

Finding bad connectors

Finding connector issues needs careful looking:

Look Closely: Spot rust, wear, or breaks. Check for loose or broken pieces.

Use Tools: Multimeters help test if signals pass correctly.

Tips for fixing or changing

Fixing or swapping connectors needs care:

Fixing: Clean rusty spots and tighten loose parts. Use sealants to keep out water.

Changing: Pick strong connectors that fit the car's needs. Think about size, shape, and weather safety.

By knowing these problems and fixes, people make sure automotive wiring connector types work well, keeping cars reliable and safe.

Industry Insights and Trends

How Connectors Changed Over Time

Early Beginnings

Long ago, car connectors were very simple. Engineers used copper and brass to make them. These early connectors weren't fancy like today’s ones. They just helped electric signals move between parts. As cars got more complicated, better connectors were needed.

Modern Changes

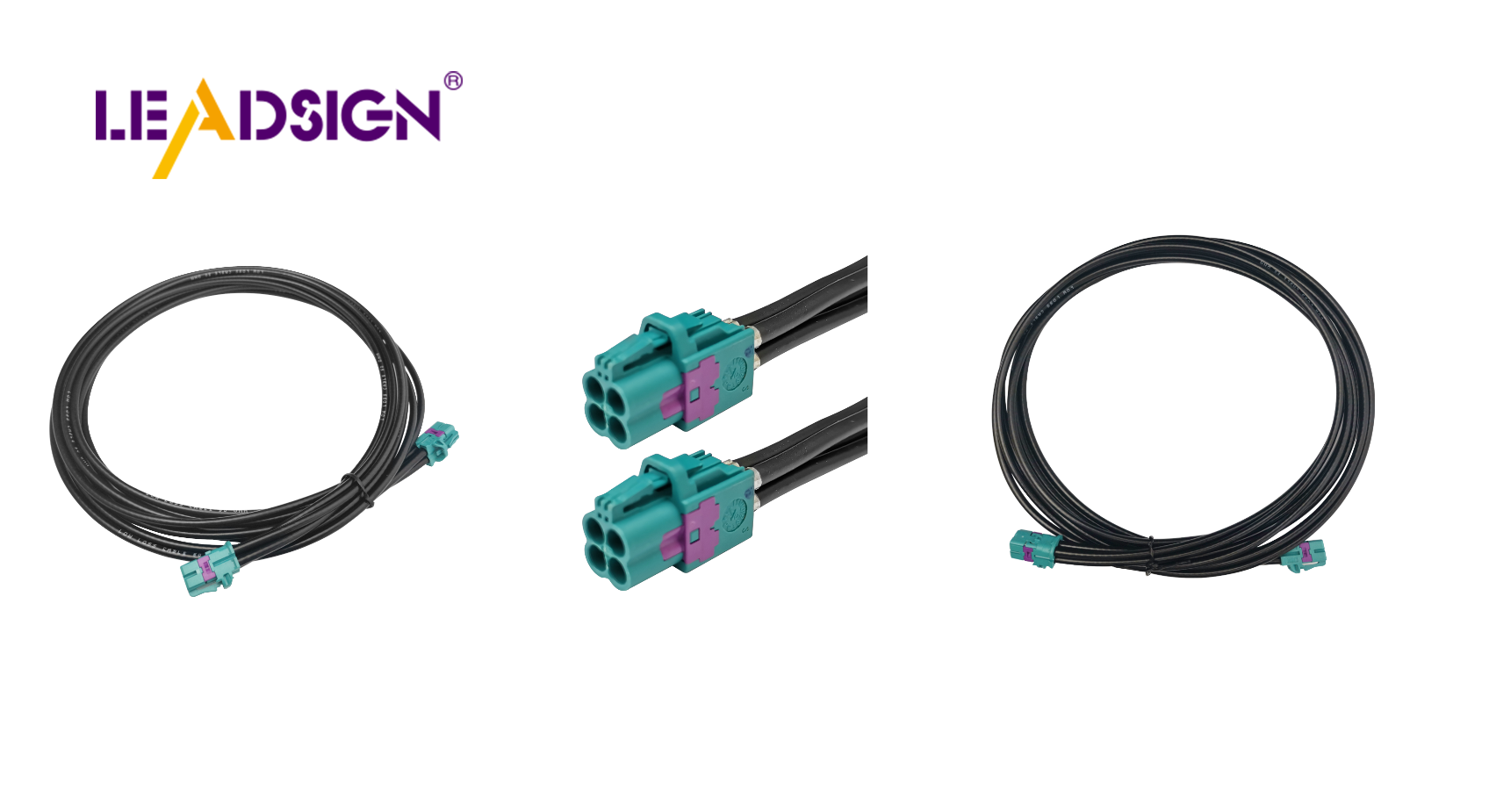

Today’s connectors are much better. Makers use strong materials like special plastics and metals. These materials last long and resist heat and water. Modern connectors often have waterproofing and locks to stay secure. New data connectors, like FAKRA-Mini, help with smart car tech like self-driving and entertainment systems.

Top Connector Companies

TE Connectivity

TE Connectivity is a big name in making connectors. They have many products for cars that work well and are trusted. TE Connectivity keeps inventing new things to fit modern cars' needs. Their products help with safety features and fun stuff in cars.

Delphi Technologies

Delphi Technologies is also important in the connector world. They make strong connectors for tough conditions while working great. Delphi focuses on being green and efficient in their designs. By using new tech, they help improve car wiring systems.

"The automotive connector market will grow a lot because of the need for advanced vehicle technologies." - Industry Report

Both TE Connectivity and Delphi Technologies keep improving car wiring connectors. Their focus on quality helps cars stay safe and work well as technology changes.

Automotive wiring connectors are key for car performance and safety. Picking the right connector ensures good electrical links. Companies like TE Connectivity and Amphenol create new solutions for different car needs. Knowing industry trends helps people choose wisely. As tech grows, knowing about these connectors is vital for keeping cars efficient and safe.

See Also

Exploring the Fundamentals of HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Contemporary Automobiles

The Significance of FAKRA Connectors in Vehicle Uses