Automotive Wire vs Industrial HSD Connectors: Key Differences

Automotive wires and HSD PCB connectors play a crucial role in today's technology. Automotive wires provide power and signals within vehicles, while HSD PCB connectors excel in high-speed data transmission, such as in-car entertainment systems and Ethernet cable connectors. Understanding the differences between various wire connectors types is essential for selecting the right technology to meet specific needs. For instance, both HSD PCB connectors and Ethernet cable connectors are indispensable, each serving unique functions in automotive and industrial applications.

Design and Construction

Automotive Wire Design

Automotive wires are key for a car's electrical system. They help move power and signals smoothly to different parts.

Material Composition

Car wires are often made from copper or aluminum because they conduct electricity well. Copper is better at carrying electricity, so it's used more. Aluminum is lighter and used when weight matters. These materials help power and signals flow well in cars.

Insulation and Protection

Car wires need strong covers to handle tough conditions. PVC and XLPE are common covers that protect against heat, water, and scratches. This keeps the wires working well for a long time, even in hard places.

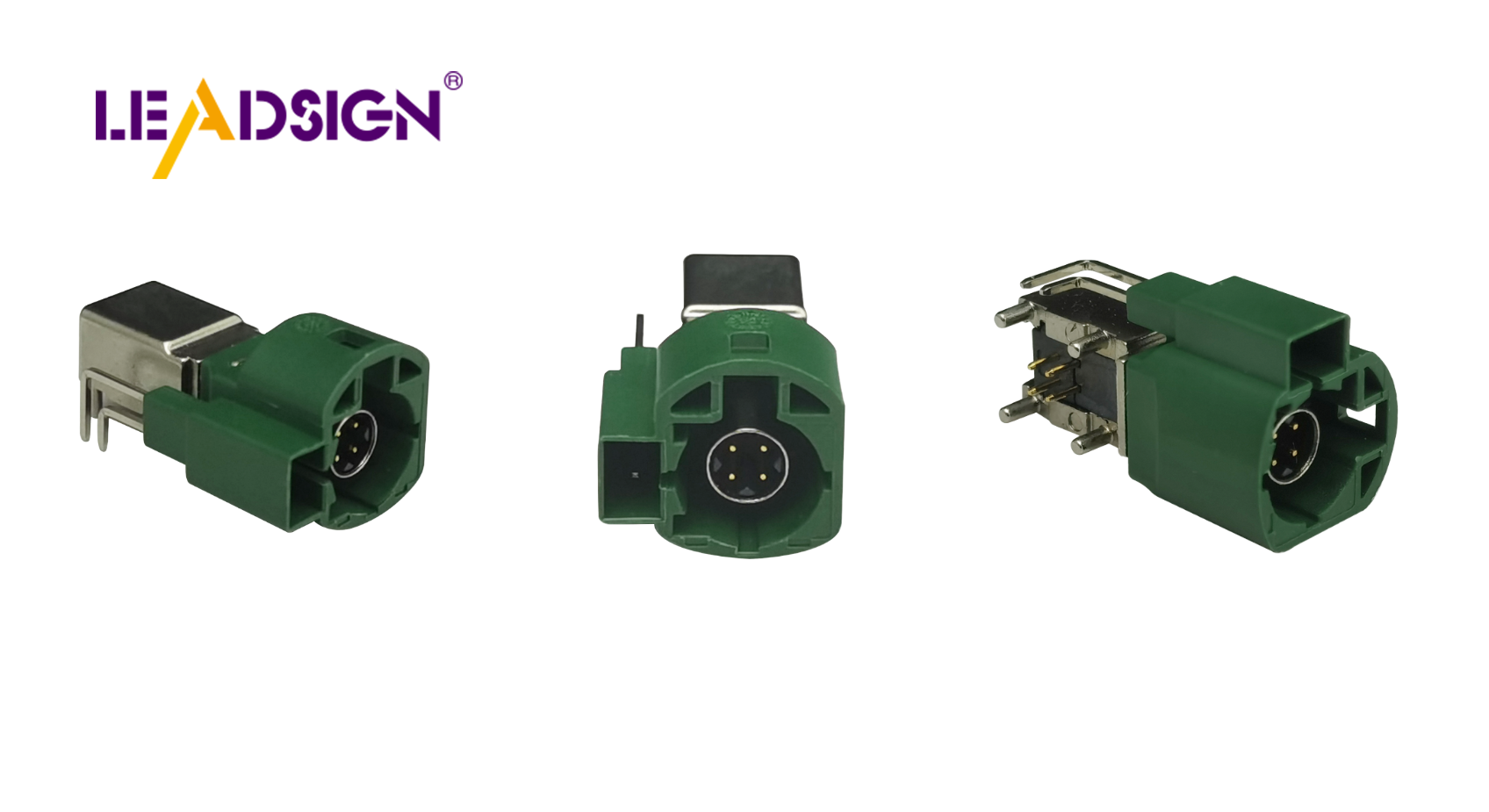

Industrial HSD Connector Design

HSD PCB Connectors are important for fast data transfer. They work in both cars and factories, helping systems talk to each other.

Connector Types

HSD connectors have different kinds for special uses. Fakra and Mini Fakra connectors send data in car systems. They support things like USB 2.0/3.0 and Ethernet, making them useful in many places.

Shielding and Durability

HSD connectors have great shielding to stop noise from outside sources, keeping signals clear. Their full shield design works well where there's lots of electronic noise around. Also, these connectors last long even in tough spots.

Compatibility and Applications

Automotive Wire Uses

Car Systems

Car wires are the main part of a car's electric system. Car wires are the main part of a car's electric system. They link different parts, making sure power and signals flow well. These wires help important systems like lights, engine control, and music players. By giving strong links, they make cars work better and safer.

Weather Challenges

Car wires need to handle tough weather. They face things like hot or cold temperatures, wetness, and shaking. Makers use strong materials and covers to keep them lasting long. This toughness is key for cars to work in all kinds of places.

Industrial HSD Connector Uses

Fast Data Sharing

HSD connectors are great for fast data sharing. They help devices talk in big systems. These connectors are used in factory machines, robots, and phone networks. They can move lots of data quickly and correctly.

Rules to Follow

HSD connectors follow strict rules set by industries. Meeting rules like USB, Ethernet, and LVDS makes sure they work well together. These rules make sure connectors do their job right with good data quality. By sticking to these rules, makers give products that fit today's industry needs.

Performance and Reliability

How Car Wires Work

Car wires are very important for a car's electric system. Car wires are very important They help the car work well and stay safe.

Carrying Electricity

Car wires need to carry electricity really well. Copper is often used because it lets electricity flow easily. This helps all parts of the car get the power they need to work right. Aluminum is lighter but not as good at carrying electricity. It's used when making the car lighter is more important.

Handling Heat and Cold

Car wires must handle hot and cold weather. They work in places where temperatures change a lot. Covers like PVC and XLPE keep them safe from heat and cold. These covers stop wires from melting or breaking, so they keep working no matter the weather outside.

How HSD Connectors Work

HSD connectors move data fast. HSD connectors move data fast They are key for keeping data clear in many uses.

Moving Data Fast

HSD connectors are great at moving data quickly. They help with things like USB 3.0 and Ethernet that need fast data moves. Their design lets them handle lots of data well, which is perfect for big systems needing quick, steady data sharing.

Keeping Signals Clear

It's important for HSD connectors to keep signals clear. They have strong shields to block outside noise that can mess up signals. This keeps the data correct and reliable even in noisy places like factories or cars.

Cost and Money Matters

Costs for Car Wires

Material Prices

Car wires depend a lot on material prices. Copper is key because it carries electricity well. It's often more expensive. Aluminum costs less but isn't as good at carrying power. Makers must pick materials that fit their budget and work well.

Making the Wires

How wires are made affects their cost. Processes like shaping and covering need to be exact. Good methods cut waste and make better wires, affecting price. Companies use smart machines and skilled workers to keep costs low while keeping quality high.

Costs for HSD Connectors

Design Details

HSD connectors have different designs, which change their cost. Fast data needs special designs with strong parts. This makes them more complex and costly. Makers think about these when setting prices, making sure they meet rules but stay affordable.

Setup and Care

Setting up and caring for HSD connectors costs money too. Skilled workers are needed for setup, raising starting costs. But good connectors need less fixing later, saving money over time. Companies try to make easy-to-use designs that lower long-term costs.

Automotive wires and HSD connectors do different jobs. Car wires move power and signals inside vehicles. HSD connectors are best for fast data transfer.

Think about what you need when picking parts. Cars need strong covers and to handle heat well. Factories care more about keeping data safe and moving it quickly.

Picking the right tools makes things work better and last longer. Knowing these differences helps choose wisely, improving both car and factory systems.

See Also

Exploring the Significance of HSD Connectors in Automotive Sector

Understanding the Fundamentals of HSD Connectors in Auto Sector

Benefits of HSD Connectors in Auto Applications