Exploring Automotive Wire Connectors Types for Modern Vehicles

Automotive wire connectors types play a crucial role in modern vehicles. They ensure reliable electrical connections, which are essential for both safety and performance. As technology advances, automotive wire connectors types have evolved significantly. These advancements enhance the functionality of automotive systems. New connectors are designed to withstand harsh conditions and facilitate rapid data transmission. They enable seamless integration of various electronic components, contributing to smarter and more efficient vehicles.

Understanding Automotive Wire Connectors Types

Basic Ideas

What They Are and Do

Automotive wire connectors are important for car electrical systems. They join wires to keep electricity flowing well. These connectors stop problems by holding connections tight. Each type is made for different car needs. Some can handle tough weather, others are easy to unplug.

Main Parts

Automotive wire connectors have key parts. The outside case keeps the inside safe and covered. Inside parts help electricity move through the connector. Seals keep out water and dust, making them last longer. Locks hold connections in place so they don't come apart by accident. Every part helps the connector work well.

Why They're Important in Cars Today

Keeping Cars Safe

Wire connectors are crucial for car safety. They make sure systems like airbags and brakes work right. Good connectors stop shorts that could cause fires. By keeping connections steady, they help keep cars and people safe.

Helping Cars Work Better

Cars today need good wire connectors to work well. Connectors help with things like GPS and music systems in cars. Top-notch connectors send data fast, boosting tech features in cars. By connecting electronic parts smoothly, they make cars run better and more efficiently.

Historical Context and Evolution

Early Developments

First Designs

At first, car wire connectors were basic and useful. Engineers made them for simple electric tasks. These early types were often just metal clips or twist-ons. They connected wires but weren't strong or reliable. As cars got more complex, better connectors were needed.

Changes Over Time

Over time, wire connectors changed a lot. Makers improved materials and designs. They used plastic covers to protect metal parts from rust and harm. This made connectors last longer. Locks kept connections tight even if they shook. As tech grew, connectors became special for different car needs.

Modern Innovations

New Technology

Today’s car wire connectors have advanced a lot with technology. Engineers make them handle fast data and hot temperatures. They help with the need for high-tech systems in cars. For example, they send data quickly for music and maps in cars. Better materials make them tough and dependable.

Smart System Links

Smart systems in cars changed wire connectors more. Connectors now link sensors and control units well. They let electronic parts talk to each other easily. This helps with self-driving features and smart driver aids (ADAS). By keeping connections good, new connectors help cars be safe and work well.

Types of Automotive Wire Connectors

Common Automotive Wire Connectors Types

Blade Connectors

Blade connectors are popular in cars. They have a flat metal piece that fits into a slot. This makes connections strong and safe. They are used in many car parts because they are simple and work well. You can connect and disconnect them quickly, which helps with regular maintenance.

Ring Connectors

Ring connectors go around bolts or screws to stay secure. They hold tight even if things shake or move. These connectors are important for grounding and battery links. Their strong design makes them reliable in car systems.

Specialized Connectors

Weatherproof Connectors

Weatherproof connectors keep out water, dust, and dirt. They have seals to protect against bad weather. These are used in places like engines and outside lights. By staying connected, they help car systems last longer.

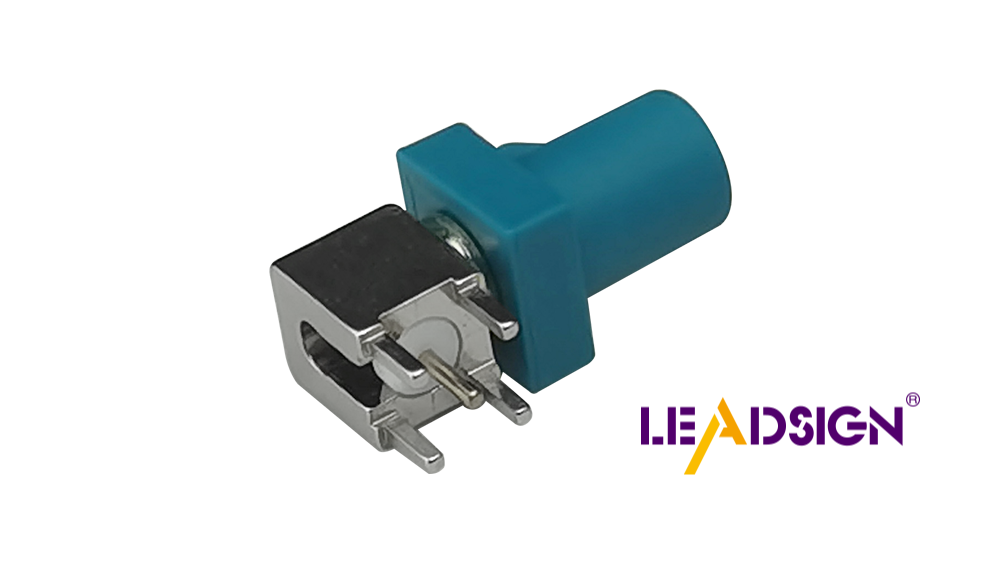

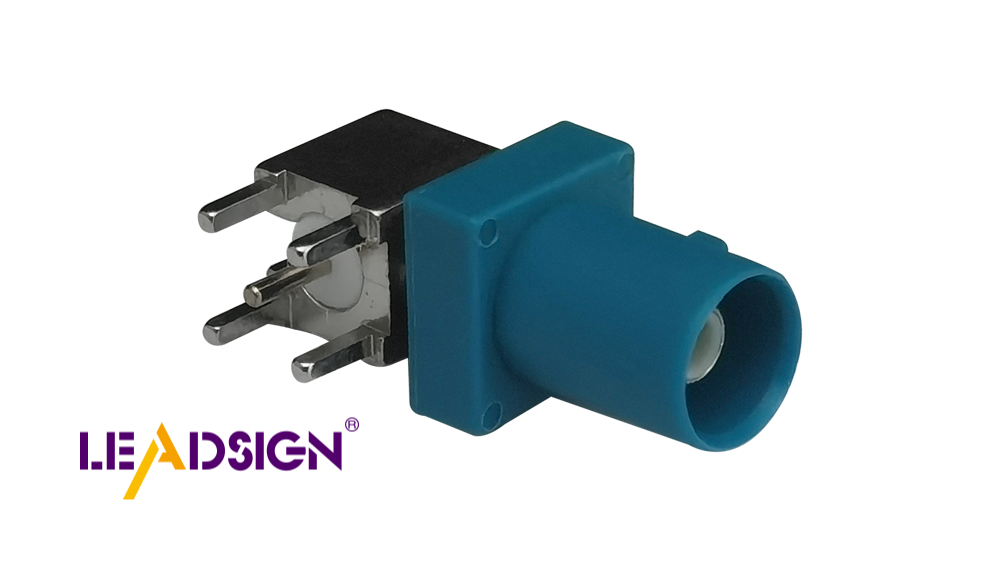

High-Performance Connectors

High-performance connectors handle fast data and hot temperatures. They are key for new car tech like music systems and driver aids (ADAS). These connectors let electronic parts talk well, helping cars be safe and work better.

Practical Aspects and Installation

How to Install

Tools You Need

To put in automotive wire connectors, you need certain tools. These tools help make sure the connection is strong:

Wire Strippers: They take off the plastic cover from wires without hurting them.

Crimping Tool: This tool helps attach connectors tightly to wire ends.

Screwdriver Set: Different connectors might need different screwdrivers.

Multimeter: It checks if the electrical connections work right.

Heat Gun: For heat-shrink tubes, this gun seals the connection.

Easy Steps

Get Wires Ready: Strip about half an inch of cover from wire ends.

Pick a Connector: Choose a connector that fits the wire size.

Connect Them: Put the bare wire into the connector and crimp it tight.

Check It Works: Use a multimeter to see if electricity flows well.

Seal It Up: If there's heat-shrink tubing, use a heat gun to seal it tight.

Test Everything: After installing, test all parts to make sure they work.

Fixing Problems

Common Troubles

Sometimes, issues happen with car wire connectors like:

Loose Connections: Car vibrations can loosen them up.

Rusty Parts: Water can cause rust, making connections bad.

Broken Wires: Wires might snap from wear or rough handling.

How to Fix Them

Here are some ways to fix these problems:

Check Often: Look at all connections for damage often and tighten loose ones.

Use Rust-Proof Connectors: Pick ones with coatings or seals against rust.

Handle Gently: Be careful with wires during setup and fixes to avoid breaks.

Swap Bad Parts Out: Change any damaged wires or connectors quickly for safety.

Write Down Repairs: Keep notes on what you fix or check regularly.

By using these tips for installation and care, your car's wire connectors will stay reliable and work well in modern cars.

To sum up, automotive wire connectors are key for today's cars. They keep cars safe and working well. As tech grows, these connectors get tougher and more efficient. In the future, look for smarter systems and eco-friendly materials.

"The future of automotive connectors is about new ideas and being green," experts say.

For common questions, remember:

Why are connectors important? They make sure electricity flows well.

How to maintain them? Check often and use rust-proof ones.

What trends to watch? Smart links and green choices are important.

See Also

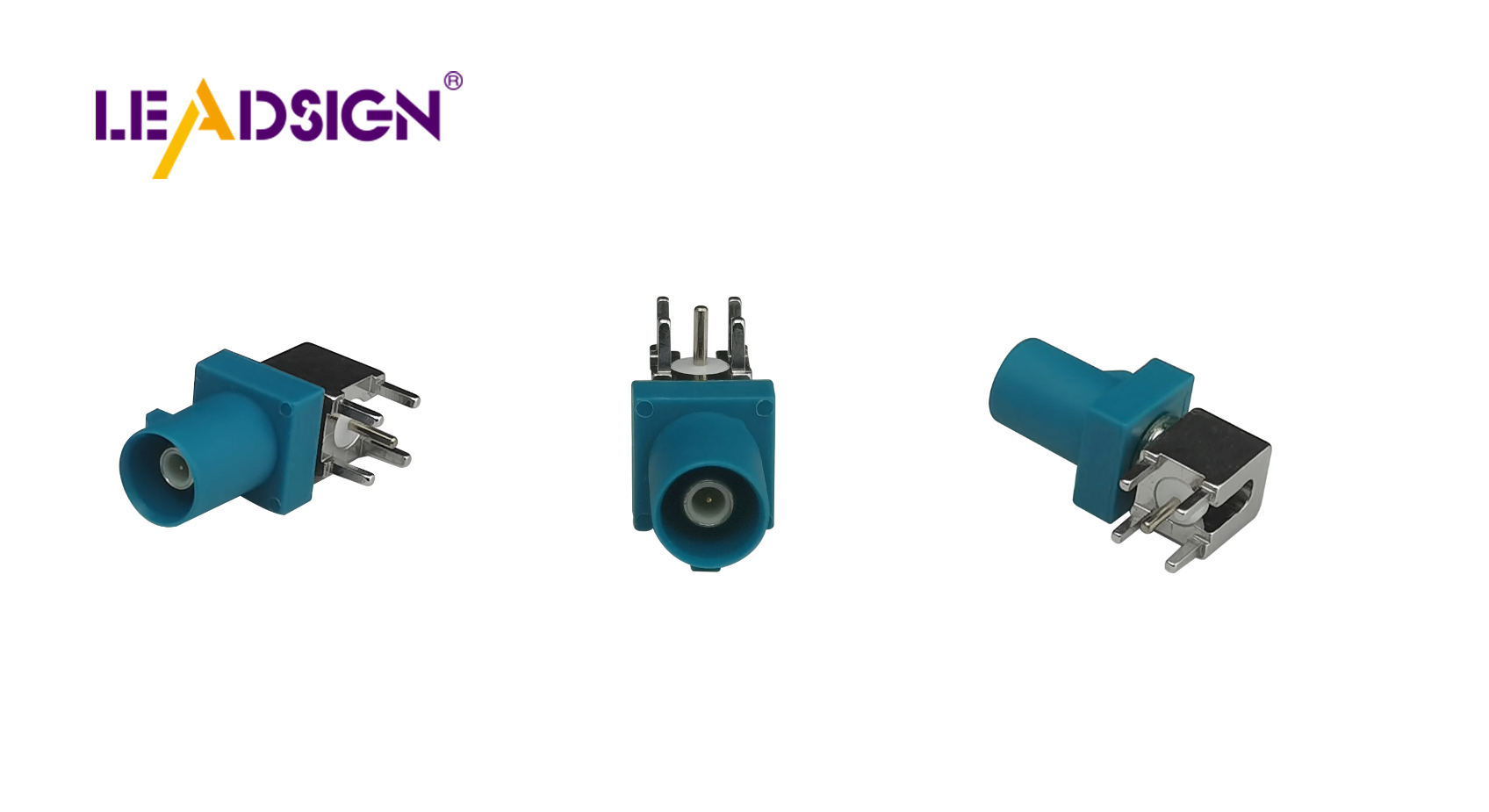

Exploring the Significance of Fakra Connectors in Modern Cars

Discovering the Advantages of Fakra Connectors in Vehicles

Understanding the Fundamentals of HSD Connectors in Autos

Enhancing Auto Data Transmission: Cutting-Edge Connectors and Cables