Automotive Wire Connectors Types: What You Need to Know

Automotive wire connectors are crucial for safety and functionality. They ensure robust electrical connections, preventing issues that could lead to accidents. Over the years, advancements in automotive wire connectors types have significantly improved their durability and efficiency. Older designs struggled with longevity and performance, but modern innovations have enhanced these connectors. They are essential for the complex components in vehicles. Understanding automotive wire connectors types highlights their role in enhancing safety and performance.

Basics of Automotive Wire Connectors

Definition and Purpose

Automotive wire connectors are important in cars. They link parts to keep electricity flowing. This stops problems that might cause safety issues.

Ensuring Electrical Connectivity

Wire connectors help electricity move smoothly. They join wires so power and signals don't stop. This is key for cars to work well.

Preventing Electrical Failures

Electrical problems can be big trouble. Connectors keep connections tight, stopping failures. They handle shakes and weather, lowering disconnection risks.

Importance in Modern Vehicles

Connectors are crucial in today's cars. They support systems that boost safety and performance.

Role in Vehicle Safety Systems

Modern cars need good safety systems. Connectors make sure these work right. They link sensors to features like airbags and brakes.

Impact on Vehicle Performance

Good connections mean better performance. Connectors help with engine control and entertainment systems, making driving better.

New materials have made connectors stronger. Heat-resistant stuff keeps them working in tough spots like engines, boosting durability.

New materials have made connectors stronger. Heat-resistant stuff keeps them working in tough spots like engines, boosting durability.

Connection Technology

New tech makes connectors easy to put together and strong. Standards have made harnesses tougher against weather changes.

How Wire Connectors Changed Over Time

First Steps

Early Designs and Materials

At first, car wire connectors were simple. Engineers used metal and rubber to make them. They wanted good electrical links in cars. But these early ones had problems. The materials weren't strong and didn't last in tough car conditions.

Problems They Faced

Early wire connectors had many issues. They wore out easily from heat, water, and shaking. This caused frequent electrical problems, hurting car safety and performance. Also, without standards, making parts that fit together was hard for makers.

New Improvements

Better Materials and Technologies

Wire connectors got better with new materials and tech. In the 1930s, plastic replaced cloth wires, a big change. Plastic resisted wear and water better, making cars more reliable. It also made making and using connectors easier.

In the 1960s, standardizing connectors helped parts fit together well. This led to modular designs for easier building and fixing.

Working with Smart Systems

Electric cars brought new wiring needs for safety and efficiency. Modern connectors now work with smart systems like GPS and safety sensors. This makes cars perform better and gives drivers more features.

Overall, how wire connectors changed shows how cars aim to be safer and work better over time. As tech grows, these connectors will be key in smarter cars.

Types of Automotive Wire Connectors

Knowing different automotive wire connectors helps in fixing cars. Each type has special uses and benefits.

Crimp Connectors

Crimp connectors are very common. They connect by squeezing the connector onto the wire.

Features and Applications

Features: Use a metal piece crimped on the wire for strength.

Applications: Used a lot because they are reliable and easy to install. Great for tight spots where soldering is hard.

Pros and Cons

Pros:

Fast to set up.

Strong, reliable link.

Resist shaking and rust.

Cons:

Need a crimping tool.

Bad crimping makes weak links.

Solder Connectors

Solder connectors join wires with melted solder for a lasting hold.

Features and Applications

Features: Melt solder around wires for a solid bond.

Applications: Used where strong, lasting connections are needed, like engines.

Pros and Cons

Pros:

Great electrical flow.

Strong, long-lasting link.

Cons:

Takes time and skill to set up.

Not good in shaky areas.

Push-On Connectors

Push-on connectors let you easily connect or disconnect wires.

Features and Applications

Features: Simple design lets you push wires in without tools.

Applications: Used in car lights and audio systems needing quick disconnection.

Pros and Cons

Pros:

Easy to use.

No special tools needed.

Cons:

Not as strong as crimp or solder types.

Can loosen if not secured well.

Special Connectors

Special connectors are important in cars. They have unique uses. FAKRA, pigtail, and bullet connectors are special types.

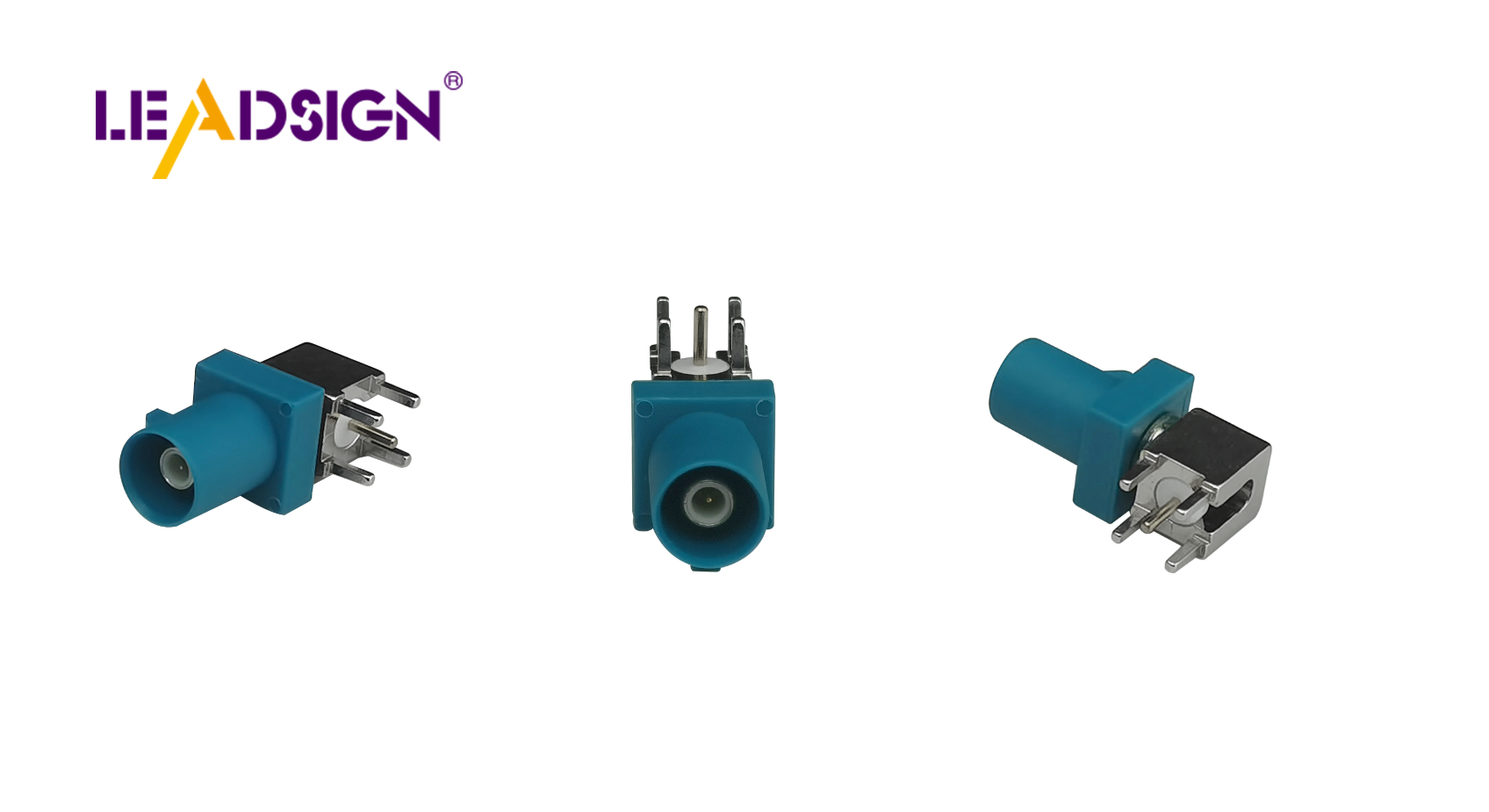

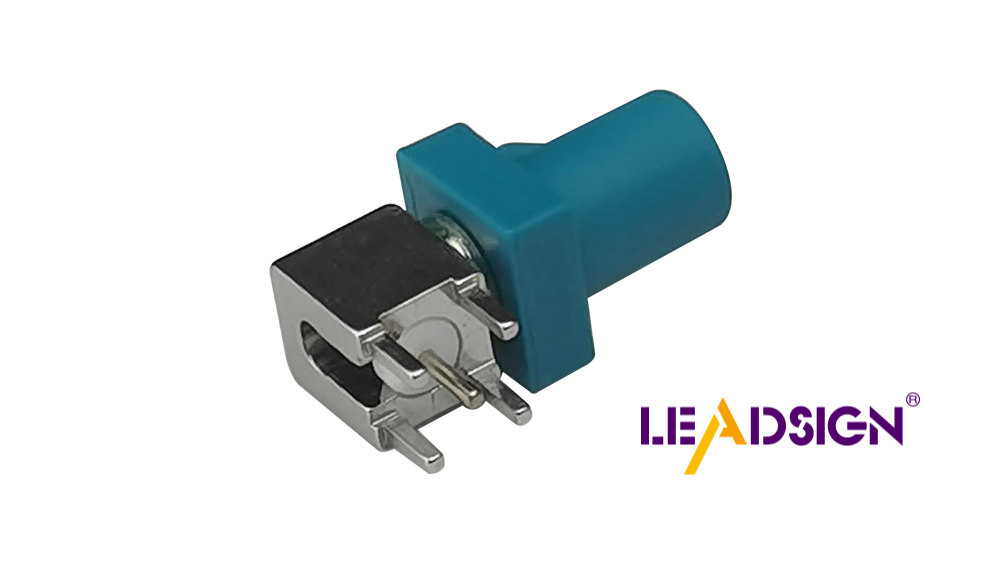

FAKRA Connectors: Features and Uses

FAKRA connectors work with high-frequency stuff in cars. They link radio antennas and GPS systems. These connectors meet strict car standards for strong connections. FAKRA connectors

Features:

Work with 50 Ω impedance and up to 6 GHz.

Handle data rates up to 8 Gbps.

Can take temperatures from -40 °C to +105 °C.

Have different colors to avoid mistakes.

Locking systems make them secure.

Uses:

Used in radios and GPS systems.

Important for TV, mobile communication, and infotainment.

Support Bluetooth RF and WLAN uses.

Key for remote keyless entry and extra car heating.

FAKRA connectors show how car wire connections have improved. They help make cars safer with new tech.

Pigtail and Bullet Connectors: Features and Uses

Pigtail and bullet connectors are easy to use in car wiring. They make quick connections possible in many car parts.

Pigtail Connectors:

Features: Short wire with a connector at one end for easy linking.

Uses: Great for lights and sensors. Make wiring easier by providing ready points.

Bullet Connectors:

Features: Quick connect design with male/female ends that snap together.

Uses: Commonly used in car lights/audio systems. Easy to disconnect/reconnect for fixes.

Both pigtail and bullet connectors show the variety of car wire connections. They help save time/costs by making reliable links quickly.

Installation Tips and Best Ways

Installing automotive wire connectors right makes sure they work well. Using the correct tools and methods helps avoid problems.

Needed Tools

Important tools for installing

To put in automotive wire connectors, you need certain tools. A wire stripper takes off the plastic cover from wires. Crimping tools are used for crimp connectors. Soldering irons are needed for solder connectors. A multimeter checks if connections work and have power. These tools make sure everything is set up safely and correctly.

Staying Safe

Being safe is key when working with electricity in cars. Always unplug the car's battery first. Wear safety glasses to keep eyes safe from sparks or bits flying around. Use tools with covers to stop electric shocks. Make sure your workspace is dry and bright. Doing these things keeps you safer while working.

Easy Steps to Install

Getting wires ready

Cut the wire: Use a cutter to make the wire the right size.

Strip the cover: Take off about half an inch of cover from each end using a stripper.

Twist strands: Twist bare wire ends together so they don't come apart.

Connecting securely

Pick a connector: Choose the right type of connector for what you need.

Attach it:

For crimp, put the wire in and squeeze it tight with a tool.

For solder, heat up iron, then melt solder to join parts.

Check it works: Use a multimeter to see if power flows through well.

Make it safe: Wrap with tape or use tubing to protect it.

Doing these steps makes sure connections last long and work well. Good installation helps automotive wire connectors do their job better over time.

Q&A: Common Problems and Care

Frequently Asked Questions

Fixing Usual Issues

Automotive wire connectors can have problems that affect cars. Here are some common issues and fixes:

Loose Connections: Loose connections make electrical parts fail. They happen from bad setup or shaking. To fix, make sure connectors are tight. Use a multimeter to test if power flows.

Corrosion: Corrosion happens when metal gets wet. It makes connectors work poorly. Clean rust with a wire brush and use grease to stop more rust.

Overheating: Overheating occurs if connectors can't handle the power they carry. This harms the connector and wires nearby. Always pick connectors that fit the electric needs.

Wire Breakage: Wires break from bending or pulling too much. Check wires often and change any broken ones. Use supports to lessen stress on wires.

Tips for Longer Life

Taking care of automotive wire connectors helps them last longer. Here are tips for keeping them in good shape:

Regular Checks: Look at connectors now and then for wear, rust, or damage. Finding problems early stops big trouble.

Keep Clean: Keep connectors free of dirt and junk. Use a soft brush or air to clear away things that might mess up connections.

Store Right: Put extra connectors in a dry, cool place away from heat or wetness, which can ruin them.

Use Good Stuff: Buy strong, high-quality connectors that last through tough conditions better.

Follow Rules: Stick to what makers say for setting up and caring for them so they work well and safely.

By fixing usual problems and following care tips, automotive wire connectors can work well, helping cars stay safe and run smoothly.

Automotive wire connectors are important for car safety and work well. Knowing about crimp, solder, and special connectors helps you choose wisely. Using good methods to install and care for them makes sure they last long. People should learn more, ask questions, and share what they know to help everyone understand better.

See Also

Exploring HSD Connectors in Automotive Sector

Significance of FAKRA Connectors in Auto Uses

Vital Role of Fakra Auto Connectors in Modern Cars