Automotive Wire Connectors Types: What You Need to Know

Automotive wire connectors are crucial for your car's electrical system, facilitating communication between components like the engine and radio. High-quality connectors ensure your vehicle operates efficiently and safely. Using robust connectors prevents issues and extends your car's lifespan. These connectors seal tightly to protect against water and rust, especially in external environments. Understanding automotive wire connectors types helps you make informed choices, ensuring your car runs smoothly and remains protected.

Types of Automotive Wire Connectors

Knowing about different wire connectors helps you pick the right ones for your car. Each kind has special features and uses.

Crimp Connectors

Features and Benefits

Crimp connectors make a strong connection. You attach them by squeezing the connector onto the wire. This makes a tight bond. They resist shaking and are easy to put on without needing soldering. They conduct electricity well and don't cost much.

Common Applications

You often see crimp connectors in engines and lights. They work well where there is shaking, so they are great for cars.

Solder Connectors

Features and Benefits

Solder connectors make a lasting connection by melting solder around the wire. This gives a strong bond that lasts long. Soldering keeps resistance low and conducts electricity very well.

Common Applications

Use solder connectors in important systems like engine controls and sensors. They are perfect where you need a steady, long-lasting link.

Push-On Connectors

Features and Benefits

Push-on connectors let you connect things quickly. Just push them onto the terminal. They are handy and can be used again. These are good for setups that change often or need quick disconnections.

Common Applications

You usually use push-on connectors in dashboards and speakers. They fit places where you often connect or disconnect parts.

Specialty Connectors

Knowing about different automotive wire connectors helps you pick the right ones. Specialty connectors have special features for certain uses.

Waterproof Connectors

Waterproof connectors keep your car's wires safe from water. They close tightly to stop water from getting in and causing harm. You find them where rain or splashes happen, like under the hood or by the wheels. They are made to last and work well even in tough weather.

Features:

Block water and dust

Made with strong materials

Easy to put on with secure locks

Common Applications:

Engine areas

Outside lights

Off-road cars

Using good waterproof connectors keeps your car's electric parts safe.

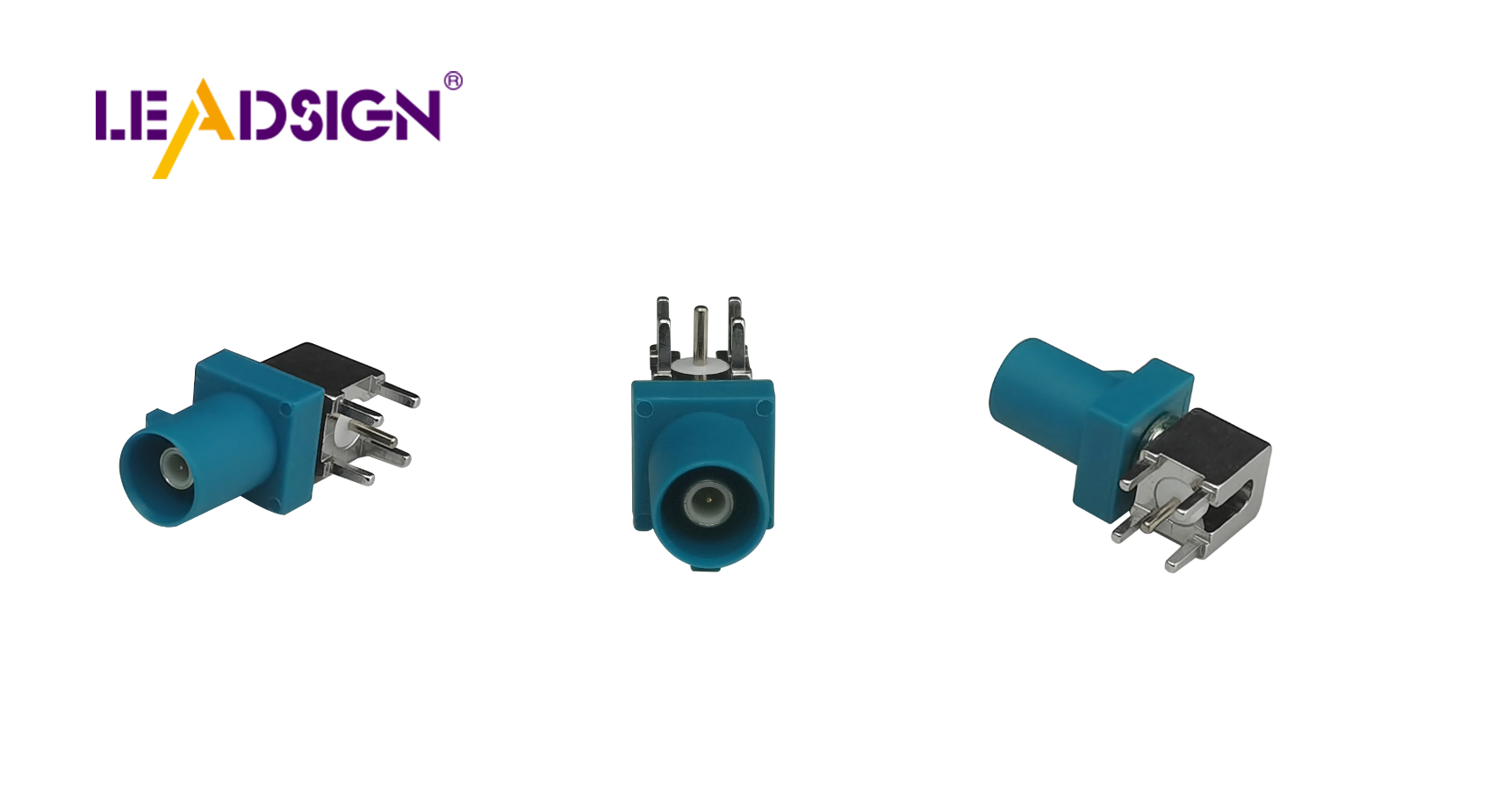

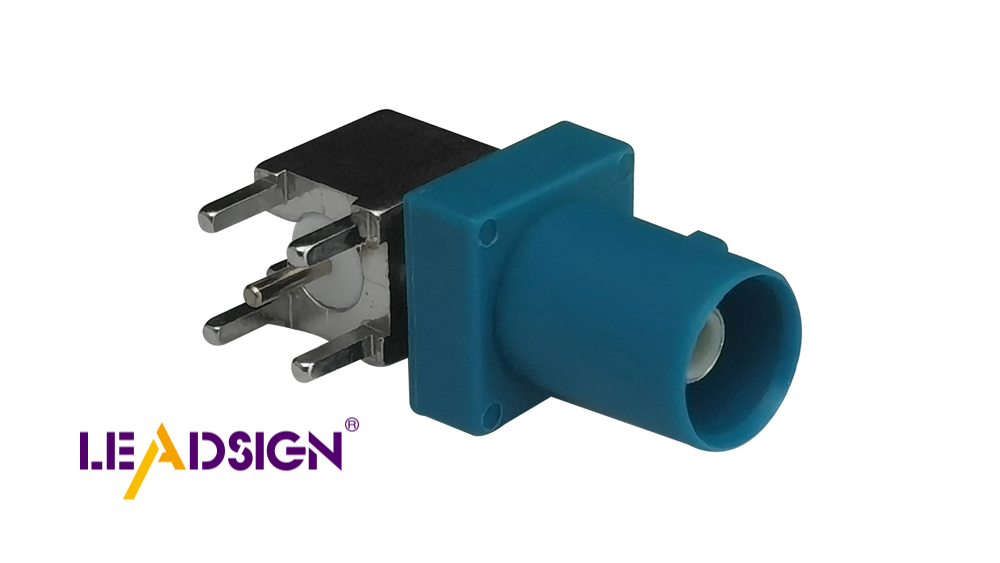

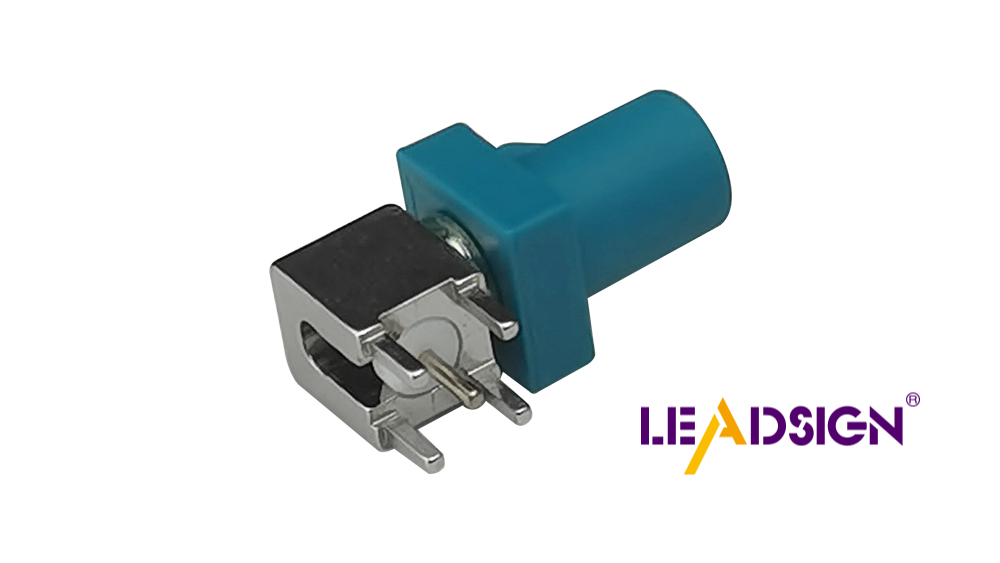

High-Frequency Connectors

High-frequency connectors handle fast signals, great for new car tech. They help systems like GPS, radio, and Bluetooth work without stopping. High-frequency connectors handle fast

Features:

Handle fast data speeds

Strong links with little signal loss

Work with many car systems

Common Applications:

Music and video systems

Map devices

Wireless gadgets

High-frequency connectors make your car's tech better. They help different systems talk to each other while driving.

Product Information:

OEM Automotive Electrical Wiring Connectors are very strong and connect well. They send power smoothly between parts.

By knowing these types of automotive wire connectors, you can choose wisely to make your car safer and better.

Factors to Consider When Choosing Connectors

When picking automotive wire connectors, think about a few things. This helps your car work well and stay safe.

Electrical Needs

Current and Voltage Ratings

Check the current and voltage ratings. These show how much electricity the connector can handle. Wrong ratings can cause overheating or failure. Match the connector's ratings with your car's needs for safety.

Environmental Conditions

Think about where you'll use the connectors. Some, like OEM Automotive Electrical Wiring Connectors, have great seals with grommets and O-rings. These keep water and dust out, perfect for tough weather. If your car faces extreme conditions, pick strong connectors.

Mechanical Needs

Durability and Material

Connectors should be durable. Look for ones made from strong materials that last in harsh places. OEM connectors use special methods to hold wires tight. They have crimp barrels and gold plating to keep connections good over time.

Ease of Installation

Installation should be easy too. Choose connectors that are simple to put on or take off if you do it yourself. Those with secure locks, like in OEM structures, are stable and user-friendly.

By thinking about these things, you can choose the best automotive wire connectors for safety and performance.

Practical Tips for Installation and Maintenance

How to Install Connectors

Installing automotive wire connectors right is important. Follow these steps to do it well.

Tools You Need

To put on wire connectors, you need these tools:

Wire stripper

Crimping tool

Soldering iron (for solder connectors)

Heat shrink tubing

Multimeter for checking connections

Having the right tools makes things easier and faster.

Easy Steps to Follow

Get Wires Ready: Use a wire stripper to remove the cover from the wire ends. Make sure enough wire shows for a good connection.

Pick the Right Connector: Choose the connector that fits your job. Use crimp connectors where there is shaking.

Put on the Connector:

For crimp connectors, push the wire in and use a crimping tool to hold it tight.

For solder connectors, twist wires together, add solder, and heat with a soldering iron until smooth.

Make it Secure: Slide heat shrink tubing over and heat it up to seal. This keeps out water and dirt.

Check Your Work: Use a multimeter to make sure everything connects well.

Doing these steps gives you a strong connection.

Keeping Connectors Working Well

Look after your automotive wire connectors regularly. Fix problems fast so they don't get worse.

Check Regularly

Look Closely: Check for wear or damage on connectors. See if any wires are loose or showing.

Keep Tight: Make sure all parts stay tight. Loose parts can cause bad performance or breakage.

Stay Clean: Keep them clean from dirt or dust. Use a soft brush or air spray to clean them up.

Regular checks help find problems early.

Common Problems and Fixes

Rusty Parts: If you see rust, clean with contact cleaner. Add grease to stop more rust later.

Loose Parts: Tighten loose parts or replace them if needed.

Weak Signals: Look for broken wires or parts and change them if needed to fix signals.

Fixing these problems helps your car's electric system work well. Good installation and care of your connectors keep your car safe and running great.

Knowing about automotive wire connectors is important for your car's safety. Here's a simple summary:

Types of Connectors: Crimp, solder, push-on, and special ones have different uses.

Picking the Right Connector: Think about electrical needs to make sure it works well.

Putting Them On and Checking Them: Use good methods and check often to keep things working.

Choosing the right connector makes your car work better and last longer. Focus on quality to avoid problems and stay safe while driving.

See Also

Exploring HSD Connectors Impact on Auto Sector

Significance of FAKRA Connectors in Auto Implementations

Vital Role of Fakra Auto Connectors in Modern Cars