Automotive Wire Connectors Types: What You Need to Know

Automotive wire connectors are crucial in car design and functionality, ensuring that electrical connections remain safe and reliable. These connectors are essential for critical components such as airbags and engines. High-quality automotive wire connectors types prevent failures that could pose significant dangers. The demand for these connectors is increasing, with the market valued at $17.047 billion in 2021. Understanding the different types of connectors enhances vehicle safety and performance.

Basics of Automotive Wire Connectors

Definition and Function

Purpose in automotive systems

Automotive wire connectors are like the car's nervous system. They let electricity move smoothly between parts. These connectors join things like the engine to the lights. They keep the car working well and safely.

Key features and benefits

These connectors have special features that make them work better. They can handle tough weather, like heat and shaking. This makes them last a long time. They are easy to put in and fix, saving time and money. Their small size helps save space in cars, making them look neat.

Historical Evolution

Early developments

At first, car wire connectors were simple for basic use. They needed to be put together by hand and weren't all the same. As cars got more complex, better connectors were needed. Makers created ones that could carry more electricity and had better covering.

Modern advancements

Now, car wire connectors are much improved. New materials help them meet today's car needs. Waterproof and heatproof designs are common now. Makers aim to work faster and cheaper while keeping up with new car demands. A report says this market will grow big by 2032, showing how it keeps getting better.

Types of Automotive Wire Connectors

Knowing different automotive wire connectors types is important. It helps cars work well and stay safe. Each connector type has a special job and benefits.

Crimp Connectors

Crimp connectors are popular in cars. They are easy to use and very reliable.

Kinds of crimp connectors

Butt Connectors: These link two wires together, making them secure.

Ring Terminals: They attach wires to screws or studs for a strong hold.

Spade Terminals: These make it easy to connect and disconnect wires, good for frequent checks.

Good and bad sides

Crimp connectors have many good points:

Easy to Install: Few tools needed, quick setup.

Strong: Once done, they hold tight.

But there are some downsides too:

Needs Skill: Must be done right for a good hold.

Tool Needed: Special tools required, not always on hand.

Solder Connectors

Solder connectors give a lasting connection that conducts electricity well. They are used where reliability is key.

Kinds of solder connectors

Solder Sleeves: Mix solder with heat shrink wrap for protection and connection.

Solder Lugs: Attach wires to fixed spots like terminal blocks.

Pros and cons

Solder connectors have clear advantages:

Great Conductivity: Metal-to-metal contact makes them conduct well.

Durable: Once joined, they last long even if shaken.

But there are drawbacks:

Takes Time: More time needed than crimp ones.

Needs Skill: Requires knowing how to solder with the right gear.

Push-On Connectors

Push-on connectors, also called quick disconnects, make fast connections easy.

Types and uses

Male and Female Disconnects: Come in pairs for quick linking or unlinking.

Insulated/Non-Insulated: Insulated ones stop short circuits better.

Benefits and limits

Push-on connectors offer these perks:

Handy Use: Quick links without tools needed.

Flexible Use: Fit many uses because they're simple.

Yet they also have limits:

Less Secure Hold: Not as tight as crimp or solder ones.

Low Current Limitations: Can't handle high power needs.

How to Install Connectors

Tools You Need

Important tools for the job

To put in automotive wire connectors, you need special tools. These help make sure the connection is strong and works well. Common tools are:

Wire Strippers: Take off the plastic cover from wires without breaking them.

Crimping Tool: Needed for crimp connectors, it squeezes the connector onto the wire.

Soldering Iron: Melts solder to stick wires together for solder connectors.

Heat Gun: Shrinks tubing around connections for heat shrink connectors.

Multimeter: Checks if electricity flows right through the connection.

Staying safe

Safety is very important when working with these connectors. Follow these rules:

Wear Safety Gear: Put on gloves and goggles to keep safe from sharp wires and hot tools.

Turn Off Power: Always unplug the car battery before starting work to avoid shocks.

Ventilate Area: Soldering makes smoke, so work where air moves well.

Check Your Tools: Make sure all your tools work properly to prevent accidents.

Steps to Follow

Getting wires ready

Cut Wire Lengths: Use cutters to make wires the right size.

Strip Insulation Off: Remove about 1/4 inch of covering with strippers from wire ends.

Twist Wires Together: Twist bare strands so they don't come apart.

Connecting and making secure

Pick a Connector Type: Choose based on what you need it for.

Attach Connector Properly:

For crimp ones, put wire in and squeeze with tool until tight.

For solder ones, place wire inside, melt solder over it, then let cool down.

For push-on ones, just push wire in until it clicks shut.

Make Sure It's Secure:

Use heat gun on any tubing over connections for extra safety.

Test with multimeter to see if it's holding tight and electricity flows well.

As cars get better tech, we need good connections more than ever. The cable-to-wire part is big in car connector markets, helping new cars improve. Good installation helps these parts work best, making driving better everywhere.

Q&A: Common Issues and Solutions

Fixing Connection Problems

Finding bad connections

Sometimes, automotive wire connectors break and cause car problems. It's important to find these bad connections to keep cars running well. Mechanics look for things like flickering lights or parts not working. They use tools like multimeters to check electricity flow. By spotting loose or rusty connectors, they find where the problem is.

Fixes and good habits

After finding a bad connection, mechanics fix it using best methods. They clean rust with a brush or cleaner first. For loose ones, they make sure it's tight and secure. If broken, replacing it is often best. Regular checks can stop many problems before they start.

Expert Insight: "I've worked on many car designs and seen how choosing the right cables and connectors affects a car's electrical system."

Common Questions

How long do connectors last?

The life of automotive wire connectors depends on use and weather. Good ones made for tough conditions last longer. Regular checks help them last more years. Mechanics suggest using strong connectors that meet standards.

Fit with different systems

Picking the right connectors for a car's system is key. Right fit ensures they work well with other parts. Mechanics study the car's setup to choose matching connectors. This careful choice boosts safety and performance.

Consideration: "Have you thought about how important picking the right cables and connectors is for safety? How often do you check if your chosen parts fit your car's system?"

Car wire connectors are important for keeping cars safe and working well. They make sure parts stay connected in key systems. Picking the right connector is very important. Different types, like crimp or solder, have their own good and bad points. Choosing the right one depends on what you need it for. Think about things like how well it seals, keeps out dust and water, and locks tightly. These things make sure it's reliable. Using what you know helps cars work better. By learning these details, people can choose wisely to keep their cars safe and running smoothly.

See Also

Exploring HSD Connectors Impact on Auto Sector

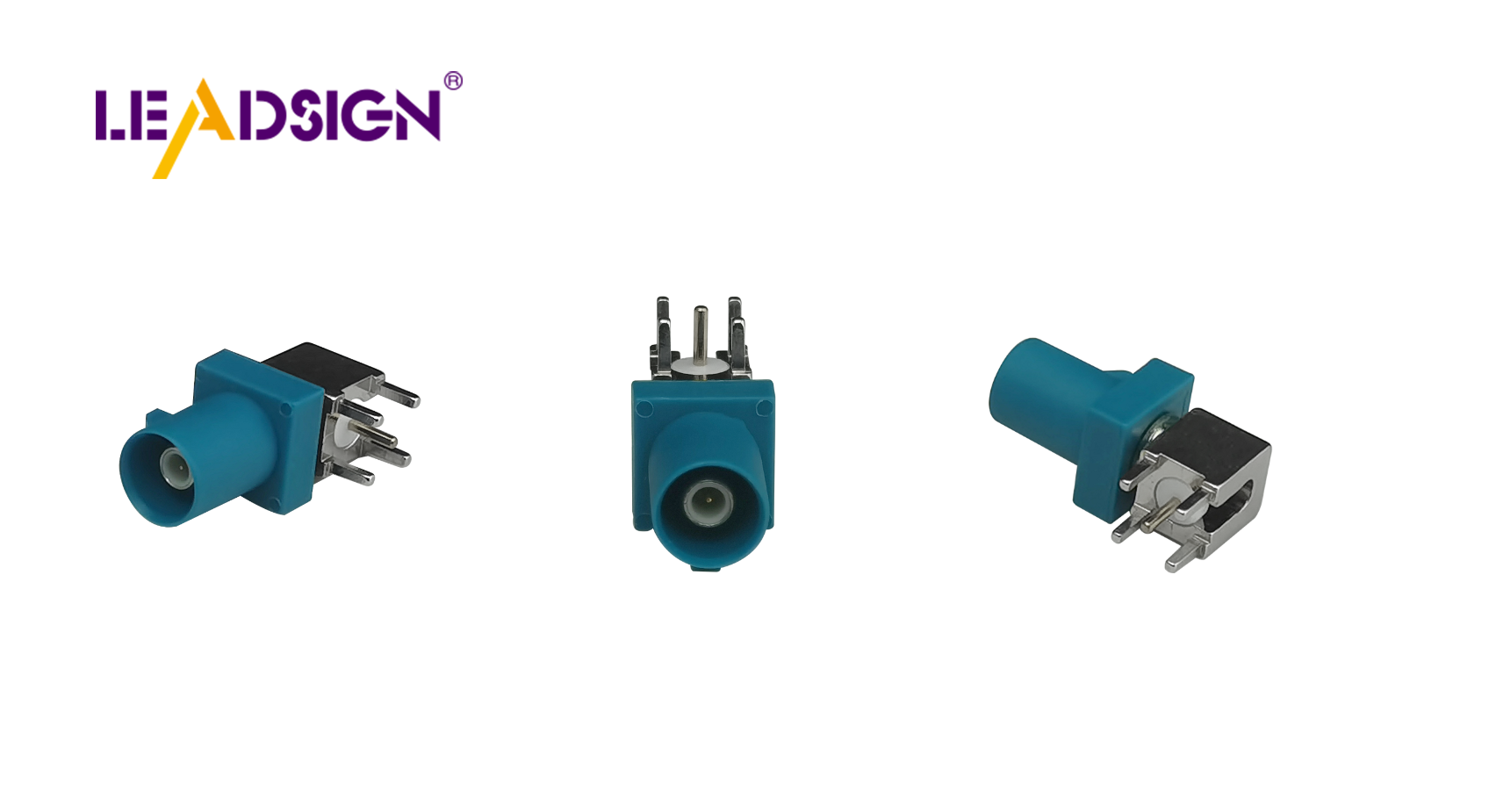

Significance of FAKRA Connectors in Auto Implementations

Vital Role of Fakra Connectors in Contemporary Cars