Understanding Automotive Wire Connectors Types and Their Classifications

Car wire connectors are key parts of vehicle electrical systems, and understanding the various automotive wire connectors types is essential. They help send power, signals, and data smoothly to parts. These connectors are important for safety, efficiency, and performance. As cars use more electronics, the need for them grows. Choosing the right wire connectors from the different automotive wire connectors types makes them work better and fit well. Good connectors improve how cars work and make driving better.

Key Takeaways

Automotive wire connectors are essential for ensuring reliable power, signal, and data transmission in modern vehicles, enhancing safety and performance.

Understanding the different types of connectors—power, signal, and data—helps in selecting the right one for specific automotive applications.

Key features of automotive connectors include secure locking mechanisms, environmental resistance, and high data transmission rates, which contribute to their durability and reliability.

Connectors are classified by function and structure, with wire-to-wire, wire-to-board, and board-to-board connectors each serving unique roles in vehicle systems.

As automotive technology evolves, connectors are becoming smaller, lighter, and smarter, supporting the growing demand for electric and self-driving vehicles.

Choosing the right automotive connector not only improves system performance but also ensures longevity and efficiency in vehicle electrical systems.

Overview of Automotive Electrical Connectors

Automotive electrical connectors are very important in today’s cars. They help different electronic parts work together smoothly. These connectors are made to handle tough conditions like heat, shaking, and wetness. By keeping connections strong, they improve car safety and performance.

Purpose and Importance of Automotive Connectors

Automotive connectors are the main part of car electrical systems. They connect parts securely to keep power and signals flowing. For example, OEM Car Twin Connectors give strong connections in advanced engines, making systems work better.

In racing or high-power uses, connectors like Deutsch DRC Series Connectors are crucial. They handle many pins and work well under stress. Also, automotive connectors must meet strict rules like ISO or SAE for reliability and compatibility.

These connectors do more than just connect. They last longer with features like strain relief, which stops wires from bending or breaking. Special connectors, like water-resistant ones, are made for specific jobs, showing their importance in cars.

Key Features of Automotive Wire Connectors Types

Automotive connectors have features to meet different needs. They resist shaking and heat, especially in electric cars. These cars need connectors for batteries and power systems. Connectors must carry power and be small for easy use.

Important features include:

Secure Locking Mechanisms: Stop accidental unplugging during use.

Environmental Resistance: Handle heat, oil, and wet conditions.

High Data Transmission Rates: Work with systems needing fast communication.

Durability: Built to last in tough situations.

Products like Three-Cavity Connectors and 3-Pin Automotive Connectors show these features. They are strong and secure for fixes or new setups. Connectors like Cable Connectors reduce signal problems, keeping systems working well.

Modern connectors are also easy to use. Quick plug-in designs save time and space. For example, Reliable Automotive Connectors are simple yet strong, making them a must-have in today’s cars.

Classification of Automotive Connectors by Function

Classifying automotive connectors by function shows their specific jobs in cars. Each type has a unique role, helping systems work well and reliably.

Power Connectors

Power connectors move electrical energy between car parts. They handle high currents and voltages, making them important for batteries, alternators, and motors. Their strong design helps them last in heat and shaking.

Modern power connectors have locks to stop unplugging by accident. For example, three-cavity connectors keep multiple parts connected in one place. This saves space and keeps connections strong, which is important in small car systems. They also use insulation to stay safe and avoid electrical problems.

Signal Connectors

Signal connectors send low-power signals between sensors and control units. They help systems like engine controls and safety features work correctly. Their accuracy and dependability are key for these systems to perform well.

Signal connectors resist tough conditions like wetness and dust. They also send data quickly. For instance, cable connectors stop signal problems, keeping communication smooth between parts.

Data Connectors

Data connectors move digital information between systems like GPS and Bluetooth. As cars get smarter, fast data transfer is more needed. These connectors support features like navigation and wireless tools.

Good data connectors reduce data loss and interference. For example, connectors for infotainment systems handle fast data speeds, making multimedia work smoothly. Their small size also saves space, which is useful in modern cars.

Classifying automotive connectors by function shows how they help cars run. Knowing their types and uses ensures systems work well and stay reliable.

Classification of Automotive Connectors by Structure

Wire-to-Wire Connectors

Wire-to-wire connectors link two wires for smooth electricity flow. They are common in cars to connect wires with special ends. These connectors are strong and reliable, perfect for tough conditions.

They have features like secure locks and vibration resistance. These stop wires from disconnecting, keeping power or signals steady. For example, three-cavity connectors hold parts firmly together, improving system performance.

Wire-to-wire connectors are easy to install and fix. Their small size saves space, helpful in tight car areas. With their strong build, they make car systems more dependable.

Wire-to-Board Connectors

Wire-to-board connectors join a wire to a circuit board. They help connect wiring to electronic parts in cars. Their design ensures wires fit tightly and stay in place.

These connectors can handle heat and tough conditions. This makes them great for engines and infotainment systems. For instance, cable connectors stop signal issues, keeping communication clear between parts.

Wire-to-board connectors work with different wire sizes and setups. They carry both power and data, making them key in modern car designs.

Board-to-Board Connectors

Board-to-board connectors link two circuit boards without extra wires. They are useful in small spaces, common in advanced car systems.

These connectors are made for accuracy and strength. Some snap onto boards, making setup quick and easy. They stay reliable even with lots of movement.

Board-to-board connectors use different mounting methods for flexibility. By directly linking boards, they simplify systems and save space. They are vital as cars move toward electric and self-driving technology.

"Knowing about connector changes helps improve electric and self-driving cars." This shows how important board-to-board connectors are for future car designs.

Classification of Automotive Connectors by Application

Engine and Powertrain Systems

Connectors are vital for engine and powertrain systems. These systems need connectors that handle heat, shaking, and fluids. OEM Automotive Connectors are made for these tough conditions. Their strong build ensures they last and work well.

These connectors send power and signals between parts like the ECU, sensors, and actuators. Secure locks stop them from unplugging due to shaking. This keeps the engine and powertrain running smoothly. Strain relief features protect wires from bending or breaking, making them reliable for a long time.

Safety and Control Systems

Safety systems depend on reliable connectors to work properly. These include airbags, ABS, and ESC systems. Connectors here must meet strict rules like ISO or SAE for safety.

Automotive Electrical Connectors in safety systems give stable and secure links. They help sensors, control units, and actuators communicate well. For example, connectors with vibration resistance and seals work in harsh conditions. They handle moisture and dust, making safety systems more dependable.

Infotainment and Communication Systems

Modern cars have advanced infotainment and communication systems. These need connectors for fast data transfer. Systems like GPS, Bluetooth, and multimedia use Automotive Wiring Connectors for smooth data flow.

These connectors are small to save space inside cars. They support fast data speeds for wireless tools and navigation. Some have multiple housing options for quick plug-ins, making setup easy. Their ability to connect different devices improves the driving experience, making them essential in today’s cars.

"Automotive connectors are key parts of car electrical systems." This shows their importance in everything from engines to infotainment.

Material and Performance Needs for Automotive Connectors

Car connectors must meet strict rules to work well. These rules focus on strength, safety, and efficiency, making them key in today’s cars.

Strength and Weather Protection

Strength is very important for car connectors to work properly. They must handle tough conditions like heat, shaking, and wetness. For example, engine connectors face constant heat and stress. Makers use strong materials and tight locks to stop problems.

Weather protection is also crucial. Many connectors have waterproof seals and coatings to fight rust. High-power connectors use shields to block electrical noise. This keeps them working even in hard situations.

"Car connectors are made to handle tough conditions and keep connections safe." - Kinkong Wire Harness

Insulation and Safety Rules

Good insulation keeps car connectors safe. It stops short circuits and leaks, lowering the chance of problems or fires. Connectors must follow global safety rules like ISO and SAE to work well in all cars.

Safety locks make connections more secure. These locks stop wires from coming loose, especially in systems like airbags or brakes. By following these rules, connectors help cars stay safe and work better.

Special Materials for Car Connectors

The materials used in connectors affect how well they work. Strong plastics and metals are common because they are light and resist heat. Electric car connectors need materials that handle high power without getting too hot.

Better materials also make connectors last longer. Heat-proof plastics and rust-free metals keep them working for years. These materials help connectors send data fast and deliver power, meeting modern car needs.

"High-power car connectors need to resist heat, seal well, and block electrical noise." - Tiandian Connector

By being strong, safe, and made with advanced materials, car connectors meet the changing needs of the auto world. Their smart design makes cars more reliable and efficient.

Future Trends in Types of Automotive Connectors

The car industry is changing fast, and automotive connectors are keeping up. As cars get smarter, new designs and tech improve how they work. These changes show why knowing automotive wire connectors types is so important for the future.

Smaller and Lighter Designs

Modern cars need small, light parts to save fuel and fit new systems. Automotive connectors are now smaller and lighter but still work well. Their tiny size makes them perfect for tight spaces in electric and self-driving cars.

Makers use new materials to cut weight but keep strength. For example, light plastics and alloys replace heavy metals in traditional automotive connectors. This change lowers car weight and helps the environment by using less energy to make them.

Mini connectors can do more than one job. They send power, signals, and data all at once. This makes car systems simpler and easier to manage.

Fast Data and Smart Connectors

Connected and self-driving cars need automotive connectors that send data quickly. These connectors help sensors and systems talk to each other without problems. Better designs stop data loss, making systems work smoothly.

Smart connectors are another big step forward. They check their own performance in real-time. For example, high-voltage automotive connectors in electric cars track heat and power flow to stay safe and efficient.

Fast connectors also work with new tech like 5G and V2X communication. These features allow updates and advanced driving tools, improving car connectivity.

Wireless and Advanced Connectors

Wireless tech is changing how automotive connectors are made. Wireless connectors don’t need wires, making cars lighter and easier to build. They’re great for moving parts or far-away sensors where wires won’t work.

Strong high-voltage and high-current connectors are key for electric cars. They handle big power needs for batteries and chargers. High-voltage and low-current connectors are used for lights and smaller systems, focusing on accuracy and efficiency.

Waterproof and rust-proof connectors are also improving. They work well in tough conditions, like off-road vehicles or bad weather.

As cars move toward electric and self-driving tech, automotive wire connectors types become even more important. New designs and ideas will keep making connectors better for future cars.

Car wire connectors are key parts of modern vehicle systems. They help send power, signals, and data smoothly, improving safety and performance. Knowing how they are grouped by function, structure, and use helps people pick the right ones for their needs. This makes systems work better and last longer.

"Car connectors are very important in today’s vehicles," showing their value.

As car technology grows, new connectors will improve electric and self-driving cars. These changes will make cars smarter, safer, and more efficient in the future.

FAQ

How strong are automotive connectors?

Automotive connectors are made to handle tough car conditions. They last long and keep connections reliable in vehicle wiring. Strong materials and designs help them resist heat, shaking, and wetness. This makes them important for automotive electrical systems.

What do automotive connectors do?

Automotive connectors link parts in automobile electrical systems. They let power, signals, and data move smoothly. By keeping connections secure, they help systems like safety controls and engines work well.

What is a terminal in wiring?

A terminal is where a wire connects to a system. It helps send power or signals easily. Terminals are key in high-voltage wiring harnesses, making energy flow safe and effective.

Why is shielding important for high-voltage connectors?

Shielding stops electromagnetic interference from harming sensitive parts. It keeps high-voltage wiring harnesses working without affecting nearby systems. This is vital in electric and hybrid cars with high-voltage currents.

How do connectors help with charging stations?

Connectors are key for linking cars to chargers. They ensure safe and fast energy transfer. These connectors handle high power, supporting charging infrastructure.

Why can automotive connectors handle harsh conditions?

Automotive connectors use materials that resist heat, water, and stress. Waterproof seals and rust-proof coatings make them strong. These features are crucial for automotive electrical systems.

Can automotive connectors send data quickly?

Yes, modern connectors send data fast and reliably. They connect systems like GPS and Bluetooth. This is important for connected and self-driving cars.

Why use special automotive connectors?

Special connectors are made for specific jobs. For example, high-voltage shielding keeps electric cars safe. Small designs save space in tight areas, improving automotive connector products.

How do connectors improve car safety?

Connectors keep safety systems like airbags and ABS working well. Their strong designs follow safety rules, lowering the chance of failure.

Can connectors be customized?

Yes, many connectors can be made to fit special needs. Custom options include size, shape, and material changes. This helps them work in different systems, like engines or charging infrastructure.

See Also

Understanding HSD Connectors Essential for Automotive Applications

Enhancing Data Transfer in Vehicles with Advanced Connectors

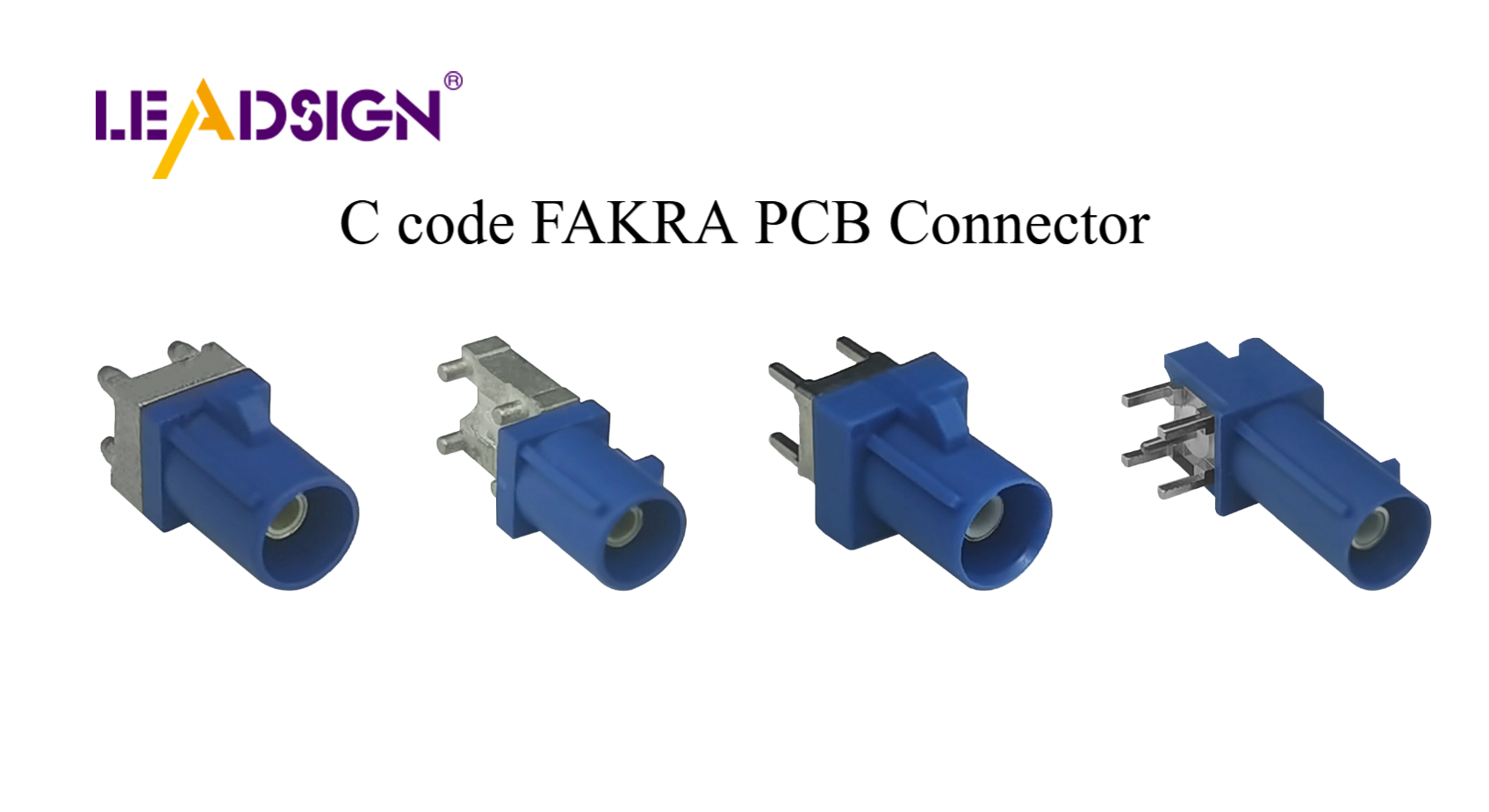

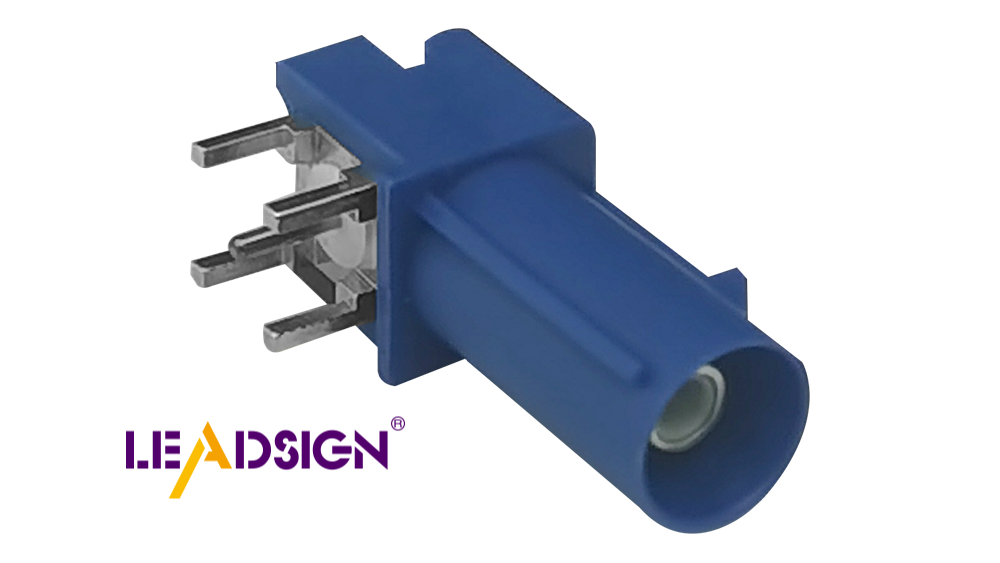

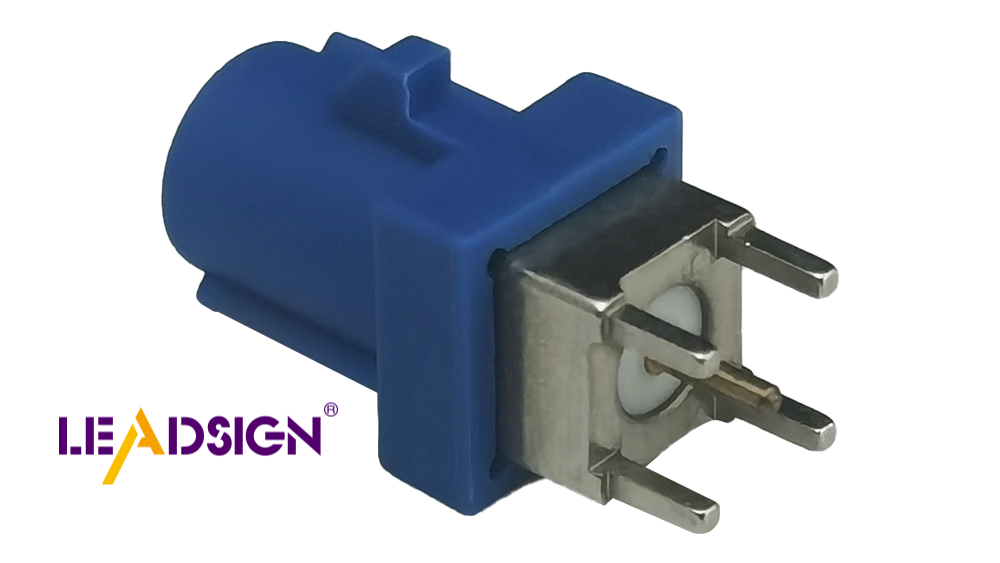

Significance of FAKRA Connectors for Automotive Systems