Understanding the Basics of Automotive Wire Connectors Types

Car wire connectors are key to your car's electrical system. They help send power and signals between parts of the car, ensuring that important functions like steering and braking operate effectively. Choosing the right connector, such as pcb board to wire connectors, significantly impacts how your car performs. New technology has made connectors stronger for tough conditions, and modern cars require these improved connectors to function properly. The main types include board-to-board, wire-to-board, and wire-to-wire connectors. Each type plays a crucial role in maintaining safe and efficient electrical connections.

Key Takeaways

Car wire connectors are essential for the electrical system, ensuring safe and efficient power and signal transmission.

Choose the right connector type—board-to-board, wire-to-board, or wire-to-wire—based on your specific needs and environment.

Board-to-board connectors are ideal for compact designs and high-speed data transfer, commonly used in infotainment systems.

Wire-to-board connectors provide reliable connections for sensors and power distribution, enhancing overall system performance.

Wire-to-wire connectors are built for durability and flexibility, perfect for lighting systems and engine wiring harnesses.

Consider features like locking mechanisms, waterproofing, and heat resistance when selecting connectors to ensure reliability in harsh conditions.

Understanding connector types and their applications helps you make informed choices, improving your car's electrical system performance and longevity.

Board-to-Board Connectors

Features of Board-to-Board Connectors

Board-to-board connectors link two PCBs directly. They do not need cables, which is great for small designs. There are three main ways they connect:

Parallel Connections: These place PCBs side by side to save space.

Perpendicular Connections: These join PCBs at a 90-degree angle for stacked layouts.

Co-Planar Connections: These keep the PCBs flat on the same level.

When picking board-to-board connectors, think about these factors:

Pitch Size: Smaller pitches fit more connections in tight spaces.

Durability: Strong materials help them last longer without breaking.

Current Capacity: They must handle electricity safely without overheating.

These features make them useful and dependable for many purposes.

Applications of Board-to-Board Connectors

Board-to-board connectors are common in cars because they save space and send data fast. Some examples include:

Infotainment Systems: They connect parts like screens, speakers, and GPS units easily.

Control Modules: They provide steady links for systems like engines and brakes.

Their small size and high capacity reduce wiring problems in tight car spaces. They also support advanced car tech like driver aids and electric engines with quick data transfer abilities.

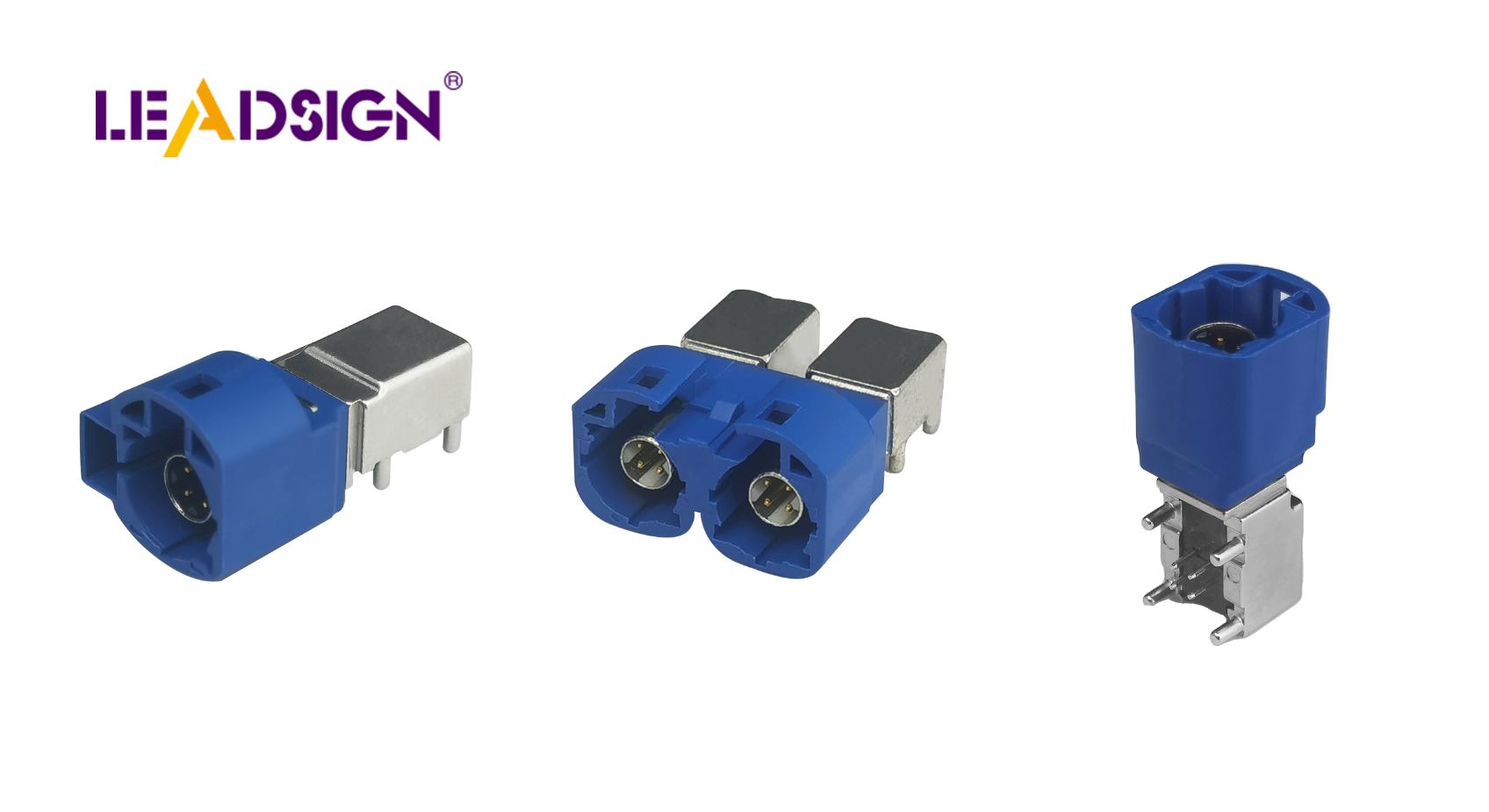

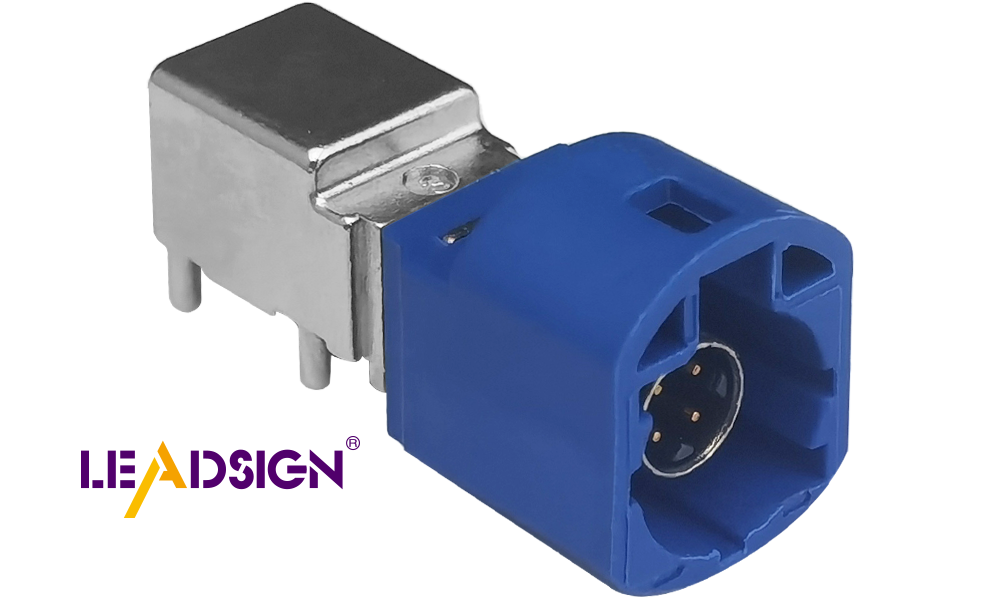

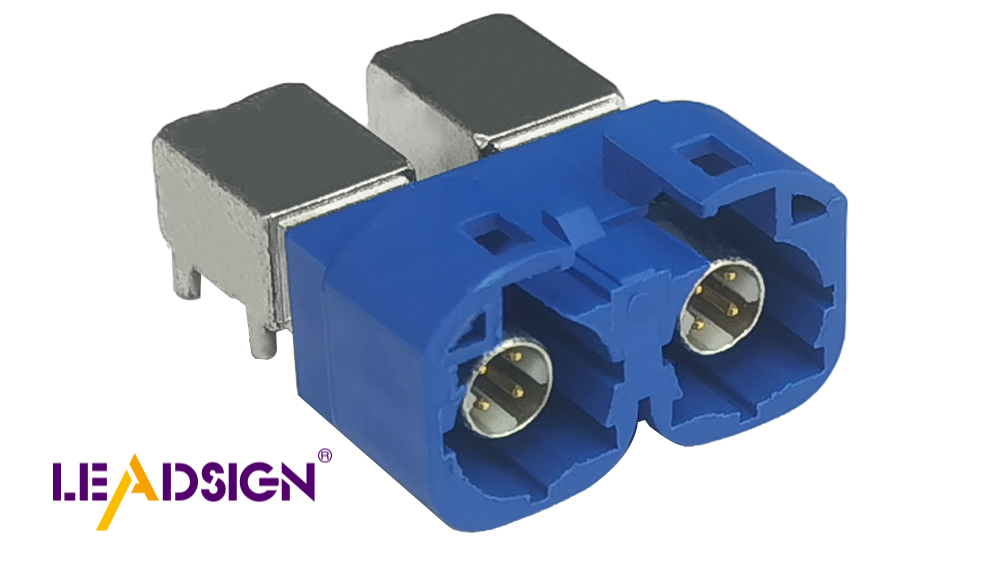

Wire-to-Board Connectors and PCB Board to Wire Connectors

Features of Wire-to-Board Connectors

Wire-to-board connectors link wires to a PCB. They help move power and signals between parts easily. These connectors use different methods for strong and safe connections:

Crimping: A metal sleeve is pressed onto the wire tightly.

Soldering: Melted solder joins the wire and connector firmly.

Insulation Displacement: The insulation is cut to connect without stripping.

When choosing these connectors, look for features that improve their use:

Locking Mechanisms: These stop wires from disconnecting by accident.

Vibration Resistance: This keeps connections steady in moving vehicles.

These qualities make wire-to-board connectors reliable for car systems.

Applications of Wire-to-Board Connectors

Wire-to-board connectors are important in cars, connecting wires to PCBs. Common uses include:

Sensors: They help sensors send data to control systems accurately.

Power Distribution: They move power from the battery to other parts safely.

Using pcb board to wire connectors saves time during setup and improves reliability. They also fit well in small spaces, perfect for modern cars. Picking the right type can boost your car's electrical system performance and lifespan.

Wire-to-Wire Connectors

Features of Wire-to-Wire Connectors

Wire-to-wire connectors join two or more wires directly. They help move power and signals smoothly in car systems. There are different types for various needs:

Inline Connections: These join wires in a straight line. They work well for simple setups.

Multi-Pin Connections: These connect many wires in one unit. They are great for compact, complex systems.

When choosing wire-to-wire connectors, focus on important features:

Waterproofing: This keeps connections safe from water damage in wet areas.

Heat Resistance: Engine heat requires connectors that handle high temperatures safely.

These features make them strong and reliable for tough conditions.

Applications of Wire-to-Wire Connectors

Wire-to-wire connectors are important in many car systems. They add flexibility and make modern cars easier to maintain. Common uses include:

Lighting Systems: These connectors link lights like headlights and taillights to the car's power system. This ensures steady light performance.

Engine Wiring Harnesses: They organize and connect engine wires neatly, making repairs easier.

"Car connectors must handle heat, vibrations, and moisture while working well." Wire-to-wire connectors meet these needs with sturdy designs for harsh conditions.

Their design allows you to adjust or expand your car's wiring easily. This flexibility keeps your car’s electrical parts connected and working properly even in tough environments.

Key Differences Between Connector Types

How they connect and their shapes

Each type of connector works differently and looks unique. Board-to-board connectors join two PCBs directly without wires. This makes wiring simpler and saves space. Wire-to-board connectors link single wires to a PCB, moving power or signals securely. Wire-to-wire connectors connect two or more wires for smooth communication between parts.

Their shapes are also different. Board-to-board connectors can be parallel, perpendicular, or co-planar in design. Wire-to-board connectors have male and female parts; one attaches to the PCB, the other to a wire harness. Wire-to-wire connectors come in straight-line or multi-pin styles for various setups.

Where they are used and materials

Where these connectors are used depends on their design. Board-to-board connectors work well in small systems like infotainment units or control modules. They handle high-speed data transmission, making them great for advanced car tech. Wire-to-board connectors are found in sensors or power systems where external wires meet a PCB. Wire-to-wire connectors are used in lights or engine wiring, built tough for harsh conditions.

Materials matter too. Some use plastic for light jobs, while others use metal for strength. For example, wire-to-wire connectors with strong builds work well in hot or wet places.

Picking the Right Connector

Things to think about (like electricity needs and environment)

Choosing the right connector means thinking about your needs first. Check electrical needs like current capacity, voltage levels, and if high-speed data transmission is required. Board-to-board connectors fit systems needing fast data transfer.

Next, think about the environment it will face. If there’s water or heat involved, pick waterproof and heat-resistant options like rugged wire-to-wire types. For areas with lots of movement, go with wire-to-board ones that lock tightly.

Examples of when to use each type

Board-to-board connectors: Great for infotainment systems needing fast data transfer in small spaces.

Wire-to-board connectors: Best for linking sensors to controls or sending battery power around.

Wire-to-wire connectors: Useful for connecting headlights to power or organizing engine wires neatly.

Knowing these details helps you choose better options for your car’s electrical system!

Knowing about board-to-board, wire-to-board, and wire-to-wire connectors helps you choose wisely for your car. Each type has a special job, like joining circuit boards or connecting wires for power and signals. Picking the right connector keeps your car running smoothly and reliably. Think about what your system needs, like weather conditions or electricity levels. For tricky setups, ask experts or makers for advice. This way, your car stays efficient and works well.

FAQ

What do wire harnesses and connectors do in cars?

Wire harnesses and connectors are key to a car's electrical system. They connect parts, allowing power and signals to flow smoothly. Without them, systems like lights, sensors, or screens wouldn’t work right. These connectors also improve safety by keeping connections steady.

What are auto connectors used for?

Auto connectors join wires and parts in your car. They move power and data between systems. Different types exist for tasks like linking sensors, powering devices, or connecting lights.

How can I pick the best connector for my car?

Think about your car’s needs and where it will be used. For fast data transfer, use board-to-board connectors. To link wires to a PCB, choose wire-to-board ones. In wet or hot areas, go with waterproof wire-to-wire connectors.

Why are locking features important in connectors?

Locking features stop wires from coming loose by accident. This is helpful in moving cars with vibrations or bumps. It keeps electrical connections secure and reliable.

Can auto connectors handle tough conditions?

Yes, many are built for harsh environments like heat or water exposure. Features like waterproofing protect them from damage in engines or outdoor areas.

How are board-to-board and wire-to-board connectors different?

Board-to-board ones join two PCBs without wires, saving space. Wire-to-board ones connect single wires to a PCB for sending power or signals.

Where do we use wire-to-wire connectors most often?

Wire-to-wire ones are common in lighting systems and engine wiring setups. They connect headlights or organize engine wires neatly for easy repairs.

What’s the difference between crimping and soldering methods?

Crimping presses a metal piece onto the wire tightly. Soldering melts metal to attach the wire firmly to the connector.

Are auto connectors easy to replace or upgrade?

Yes, they’re designed for simple swapping or upgrades when needed. Standard sizes make it easy to improve your car’s electrical system over time.

Why should you learn about connector types?

Knowing about connector types helps you choose better options for your car’s needs. The right choice ensures good performance, safety, and long-lasting reliability.

See Also

Understanding HSD Connectors Within Automotive Applications

An In-Depth Overview of Fakra Connectors and Their Uses

Why Fakra Connectors Matter in Today's Vehicles