The Ultimate Guide to Automotive Harness Connectors Selection

Choosing the right automotive harness connectors is very important. They help electrical systems communicate with each other and function effectively. Selecting the appropriate ones provides you with stronger, better, and more reliable components. This enhances your car's safety and ensures it operates optimally for an extended period.

Key Takeaways

Picking the right car harness connectors improves safety and performance. Choose connectors that match your car type and weather conditions.

Use strong materials like stainless steel or PEEK for connectors. These materials fight rust, chemicals, and heat, lasting longer in tough places.

Installing connectors the right way is very important. Do steps like crimping properly and adding heat shrink tubing to keep water and damage away.

Understanding Automotive Harness Connectors

What are automotive harness connectors?

Automotive harness connectors are small but very important parts. They link wires and cables in your car's electrical system. These connectors help different car parts communicate and work together. Think of them as the "glue" for your car's electrical network. Without them, systems like lights, sensors, and radios wouldn't work.

Connectors come in many shapes, sizes, and designs for different jobs. Some are used inside the car, like for the stereo or sensors. Others are for outside tasks, like helping with repairs. Here's a simple table showing their main uses:

Function | Description |

|---|---|

Internal connectivity | Links parts inside the car, like stereos and sensors. |

External connectivity | Helps mechanics connect tools for repairs and checks. |

Replacement | Allows temporary swaps of devices to keep the car working. |

Knowing their purpose shows why picking the right connectors matters for your car.

The role of wiring connectors in vehicle systems

Wiring connectors are key to keeping your car running well. They help send power and messages between car parts. For example, they make sure your radio plays music and videos smoothly. They also power safety features like airbags and brakes when needed.

Here’s how wiring connectors help your car work better:

They keep comfort features like AC and power seats working.

They send power from the battery to important car parts.

They allow fast data sharing for smart safety systems (ADAS).

They help mechanics check your car’s health with diagnostic tools.

In short, wiring connectors are like the backbone of your car. They keep everything connected, safe, and working properly.

Key Things to Think About When Picking Wiring Connectors

Type of Vehicle (e.g., regular car, race car, off-road)

The kind of vehicle matters when picking connectors. Race cars need special ones like Deutsch DT or DTM. These are sealed tight and use epoxy for extra safety. Off-road vehicles need strong connectors for bumpy rides but not as complex. Here's a simple comparison:

Feature | Race Cars | Off-Road Vehicles |

|---|---|---|

Connector Type | Special ones like Deutsch DT, DTM, and DTP Sealed connectors | Strong but simpler ones |

Sealing | Fully sealed with epoxy and Raychem boots | Basic sealing for dust/water |

Build Complexity | Needs careful planning, takes more time | Medium-level complexity |

Toughness and Strength in Hard Conditions

Connectors should survive tough places. Look for stainless steel or strong plastics like PEEK. These materials fight rust, chemicals, and heat. High IP ratings (like IP67 or IP68) keep out water, dust, and dirt. This makes sure your connectors stay strong even in bad conditions.

Feature | What It Does |

|---|---|

Materials | Stainless steel and PEEK resist damage and last long. |

Sealing | High IP ratings block water, dust, and dirt. |

Resistance | Handles chemicals, heat, and physical hits. |

Durability | Stays strong in tough environments. |

Matching Your Vehicle's Wiring System

Not all connectors work with every car. Check if they fit your car’s wiring. Problems can happen with wrong wire sizes or insulation issues. Heat and moisture can also cause trouble. Always make sure connectors match your car to avoid problems.

Electrical needs: Check wire size and current limits.

Environment: Think about heat, moisture, and fluids.

Common problems: Rust, wear, and bad wiring.

Environmental Challenges (e.g., heat, water, shaking)

Connectors face many challenges from the environment. Heat can make materials expand and weaken them. Water can cause rust and damage insulation. Shaking from the engine or road can loosen them. Use sealed connectors to protect against these problems.

Heat: Weakens connections by expanding materials.

Water: Causes rust and damages insulation.

Shaking: Loosens connectors over time.

Current and Voltage for Safety

Safety is very important for car wiring. Make sure connectors handle the right current and voltage. Voltage ratings should include things like altitude effects. Current ratings should cover both single wires and the whole connector. Test connectors to ensure they work well.

Voltage: Think about altitude and partial discharge.

Current: Check single wires and full connector limits.

Testing: Ensures connectors work in real situations.

Types of Automotive Harness Connectors

Deutsch connectors

Deutsch connectors are strong and dependable for cars. They work well in tough conditions like heat, shaking, and water. These connectors are built to last and perform reliably. Here’s a simple breakdown of their key features:

Feature | Details |

|---|---|

Temperature Range | |

Durability | Stays good after 100 plug-in and pull-out cycles. |

Vibration Strength | Handles 20 G’s at 10 to 2000 Hz without breaking or losing power. |

Shock Resistance | Survives 50 G’s with no power loss longer than 1 microsecond. |

Fluid Protection | Safe when exposed to most industrial liquids. |

Water Resistance | Works underwater up to three feet without losing function. |

These features make Deutsch connectors a great pick for regular and high-performance cars.

Milspec connectors

Milspec connectors are made for very tough jobs. They are strong and built for military use, so they last long. Here’s why they’re great for high-performance vehicles:

They don’t rust and are very strong.

Their design locks in place to avoid accidental unplugging.

They handle shaking and extreme heat or cold easily.

They can be used in many industries, not just cars.

Milspec connectors are perfect for vehicles needing top strength and reliability.

TE Connectivity connectors

TE Connectivity connectors are known for being safe and reliable. They handle high power even in hard conditions. While they cost more, their long life and low failure rate make them worth it. Many car makers trust these connectors for their quality and durability.

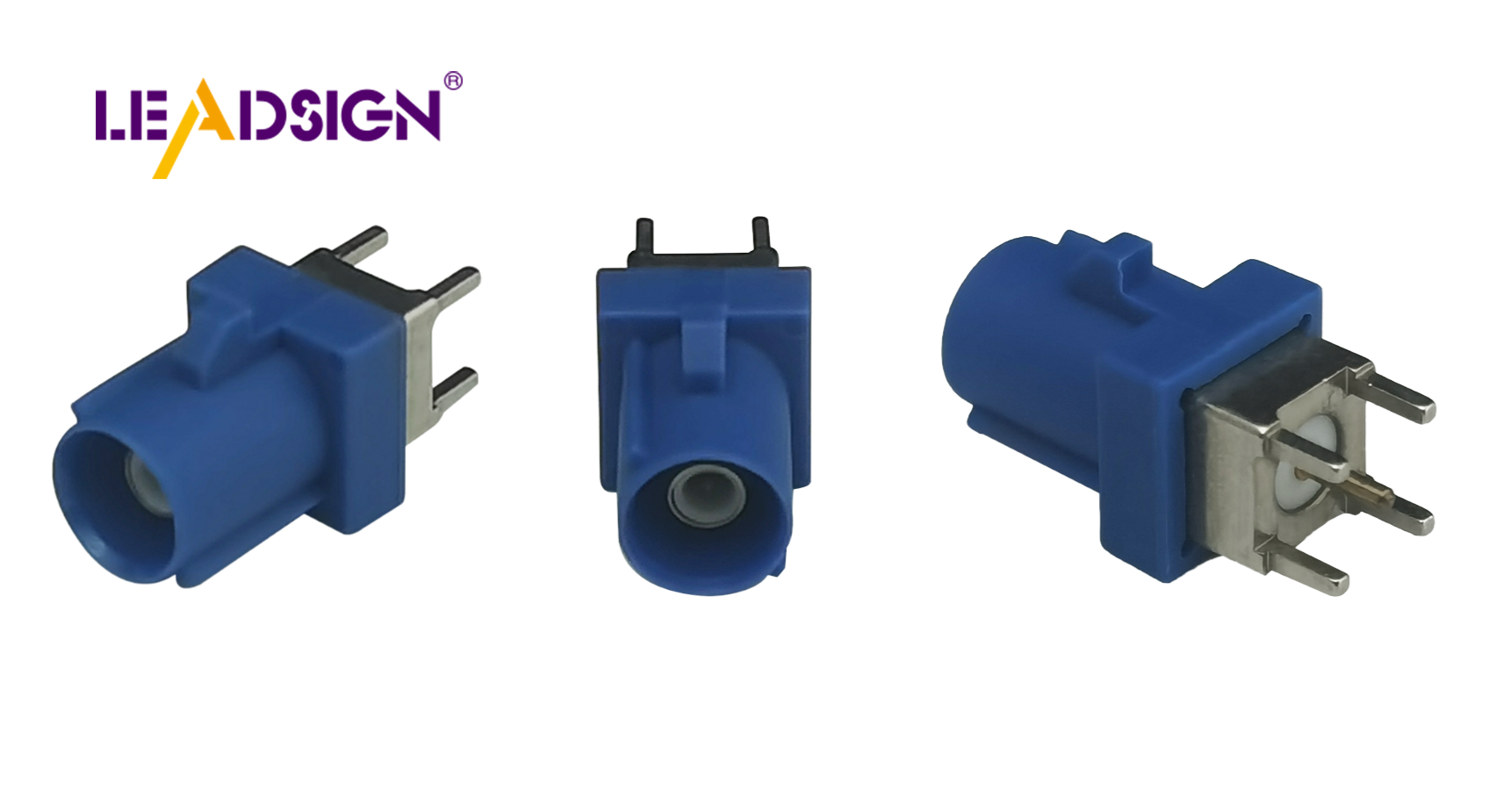

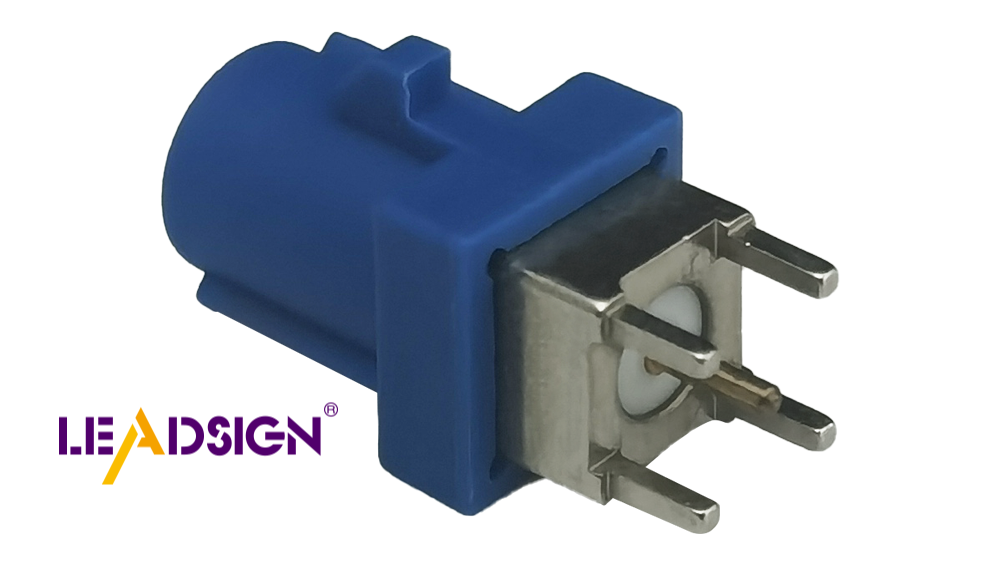

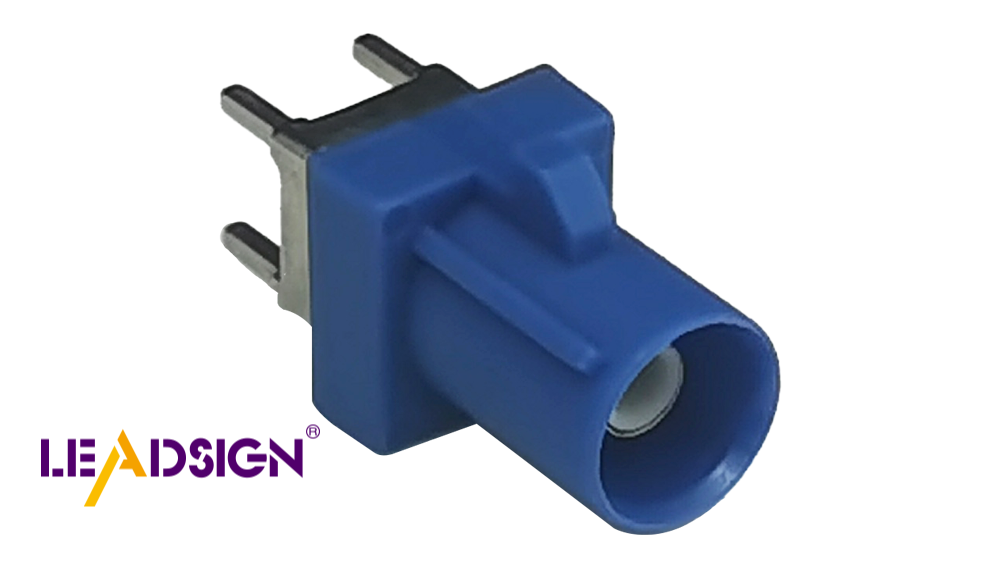

FAKRA connectors for high-frequency applications

FAKRA connectors are best for systems needing high-frequency signals. They are used for GPS, satellite radio, and Bluetooth. These connectors resist water and shaking, keeping connections stable. You’ll see them in Wi-Fi and entertainment systems inside cars.

Pros and cons of each type

Each connector has good and bad points. Here’s a quick comparison:

Connector Type | Pros | Cons |

|---|---|---|

Deutsch | Strong, water-resistant, handles tough jobs | Needs special tools |

Milspec | Rust-proof, very strong, versatile | Costs more |

TE Connectivity | Reliable, lasts long, handles high power | Expensive upfront |

FAKRA | Great for high-frequency, waterproof | Limited to certain uses |

Pick the right connector based on your car’s needs and conditions.

Common Problems with Factory Wiring Connectors

Issues with factory connectors

Factory connectors often don’t last very long. You might see power loss in some car parts or flickering lights. Sometimes, there’s a burning smell or visible damage on the connectors. These problems can be annoying and confusing.

Here are some common factory connector problems:

Rust from water or road salt exposure.

Damage from wear and tear over time.

Unstable connections that work sometimes but fail other times.

Bad wiring during setup causing things to break.

Problem | What Happens |

|---|---|

Rust | Moisture or salt causes damage and poor connections. |

Wear and Tear | Connectors weaken and stop working properly. |

Unstable Connections | Power comes and goes, causing systems to fail randomly. |

Bad Wiring | Mistakes during setup lead to broken systems. |

These problems make fixing wiring harder. Factory connectors aren’t tough enough for harsh conditions, so they might fail when you need them most.

Why aftermarket connectors are better

Aftermarket connectors can fix these issues. They are made to be stronger and more reliable than factory ones. Many use better materials that resist rust and damage, making them great for tough conditions.

Their design is also improved. Aftermarket connectors often seal out water and dirt better. They lock more securely, so they don’t come loose easily. If you’re fixing or upgrading your car, these connectors can save you time and trouble.

In short, aftermarket connectors are a smart choice. They last longer and work better, making your car’s electrical system more dependable.

Recommended Suppliers and Brands for Automotive Harness Connectors

Trusted brands for high-quality connectors

Picking a trusted brand for automotive harness connectors is very important. Good connectors last long, work well, and keep cars safe. Here are some of the best brands you can trust:

Brand | Strengths | Market Presence |

|---|---|---|

Amphenol | Fast systems, great for smart driving features. | Second largest connector company. |

TE Connectivity | Durable, high-quality, handles strong power safely. | Top leader in car connectors. |

Molex | Creative designs, strong in tough conditions. | Nearly 100 years in electronics. |

Delphi Packard | Tough connectors for hard environments. | Trusted by many car brands. |

Yazaki | Reliable connectors for good car performance. | Big name in car connectors. |

Hirose | Smart tech, resists water and temperature changes. | Known for innovation. |

Sumitomo | Strong connectors for harsh conditions. | Popular with car makers. |

These brands are known for making dependable connectors. Whether fixing wires or upgrading, they are great choices.

Where to buy reliable connectors

Finding the right place to buy connectors is also key. Look for sellers offering real products and good service. Start with authorized dealers of the brands above. Many have online stores for easy shopping and comparing.

You can also check specialty car stores or trusted sites like Digi-Key, Mouser Electronics, or Newark. These sites sell many connectors from top brands. If you like shopping in person, visit local car parts shops. They can help you pick the best connectors for your car.

💡 Tip: Always check if the connector fits your car before buying. This helps avoid mistakes and ensures it works perfectly.

Choosing a good supplier saves time and avoids bad products.

Installation Tips for Automotive Harness Connectors

How to install connectors the right way

Installing automotive harness connectors properly helps them last longer. Follow these simple steps:

Get the wires ready: Cut wires to the right size. Carefully remove the insulation without harming the wire inside.

Crimp terminals correctly: Use proper crimping tools to attach terminals tightly. Don’t crush or bend the wire or terminal.

Protect with insulation: Cover the connection with heat shrink tubing. This keeps out water and prevents wear, making it stronger.

Secure the connector housing: Line up the terminals with the housing. Push them in until you hear a click.

These steps make sure your connectors stay strong and work well.

Staggering wires for better strength

Staggering wires makes the harness more reliable. Don’t line up all splices in one spot. Spread them out along the harness. This reduces weak spots and makes the harness bend easier in tight areas.

Potting for extra protection

Potting adds extra safety to your connections. Fill the connector housing with epoxy or silicone. This keeps out water, dirt, and shaking. If your car faces tough conditions, potting is a smart choice.

Checking locks for safety

Always check that connectors lock tightly. Loose connections can cause problems or stop working. Choose connectors with double-lock systems. These keep terminals secure even during heavy vibrations.

💡 Tip: After locking, gently pull the connector to ensure it’s tight.

Mistakes to avoid when installing

Avoiding errors makes installation easier. Watch out for these common mistakes:

Using the wrong tools to cut or crimp wires.

Forgetting to slide on heat shrink tubing before crimping.

Misplacing terminals in the connector housing.

Tightening connections too much or too little.

By avoiding these mistakes, you’ll have a smooth and successful installation.

Picking the right car harness connectors is very important. Good quality and proper fit keep your car safe and working well. Strong, reliable connectors last longer and won’t fail when needed. Choosing wisely helps protect your car and gives you peace of mind.

FAQ

How can I pick the right connector for my car?

Check your car’s wiring and environment needs first. Match the connector’s features, like voltage and sealing, to your car.

💡 Tip: Read your car’s manual to ensure it fits properly.

How do I check if a connector is waterproof?

Look for IP ratings such as IP67 or IP68. These show how well the connector blocks water and dust in tough places.

Can I install connectors on my own?

Yes, you can do it yourself! Use tools like crimpers and heat shrink tubing. Follow the steps in this guide for a strong and safe connection.

⚠️ Note: If you’re unsure, ask a professional to avoid mistakes.

See Also

Understanding Ford Fakra Connectors: A Comprehensive Overview

Essential Insights Into HSD Connectors for Automotive Applications

Why FAKRA Connectors Matter for Automotive Systems

Key Reasons HSD Connectors Are Vital in Automotive Technology