Explaining Automotive Harness Connectors and Their Role in Cars

Automotive harness connectors are important for your car's electrical system. They connect and hold wires together for smooth communication in the car. Without them, you could have flickering lights or power problems. Their design makes sure your car works safely and well.

Key Takeaways

Car harness connectors link wires, helping car parts work together.

There are many connector types, like blade and pin ones. Each type has a job in the car's electrical system. They make fixing and maintaining cars simpler.

Good-quality connectors make cars safer and more reliable. They stop electrical problems and keep important systems working well.

Types of Automotive Harness Connectors

Automotive harness connectors come in different shapes and sizes. Each type has a job to help your car’s electrical system work well. Here are some common types of wire harness connectors.

Blade Connectors

Blade connectors are small and dependable. They have a flat, blade-shaped end that fits into a matching slot. These connectors are great for tight spaces because they are very small, often under 10mm. Screws in blade connectors hold wires tightly, making them a favorite for car wiring. You’ll see them used to connect wires to small gadgets or circuits.

Pin Connectors

Pin connectors have round pins to make connections. They are flexible and often used in car wiring systems. Their design makes them easy to plug in and take out. This makes them good for connecting wires to sensors or control parts. Pin connectors are strong and stay connected even when the car shakes a lot.

Circular Connectors

Circular connectors are made for tough conditions. Their round shape keeps out water, dust, and dirt. These connectors are used for things like headlights, taillights, and other outside car parts. Their strong design makes them reliable in rough environments.

Rectangular Connectors

Rectangular connectors are neat and can hold many pins. They are used in car wiring to link control systems, entertainment systems, and other complex parts. These connectors save space while allowing many connections, which is important for modern cars.

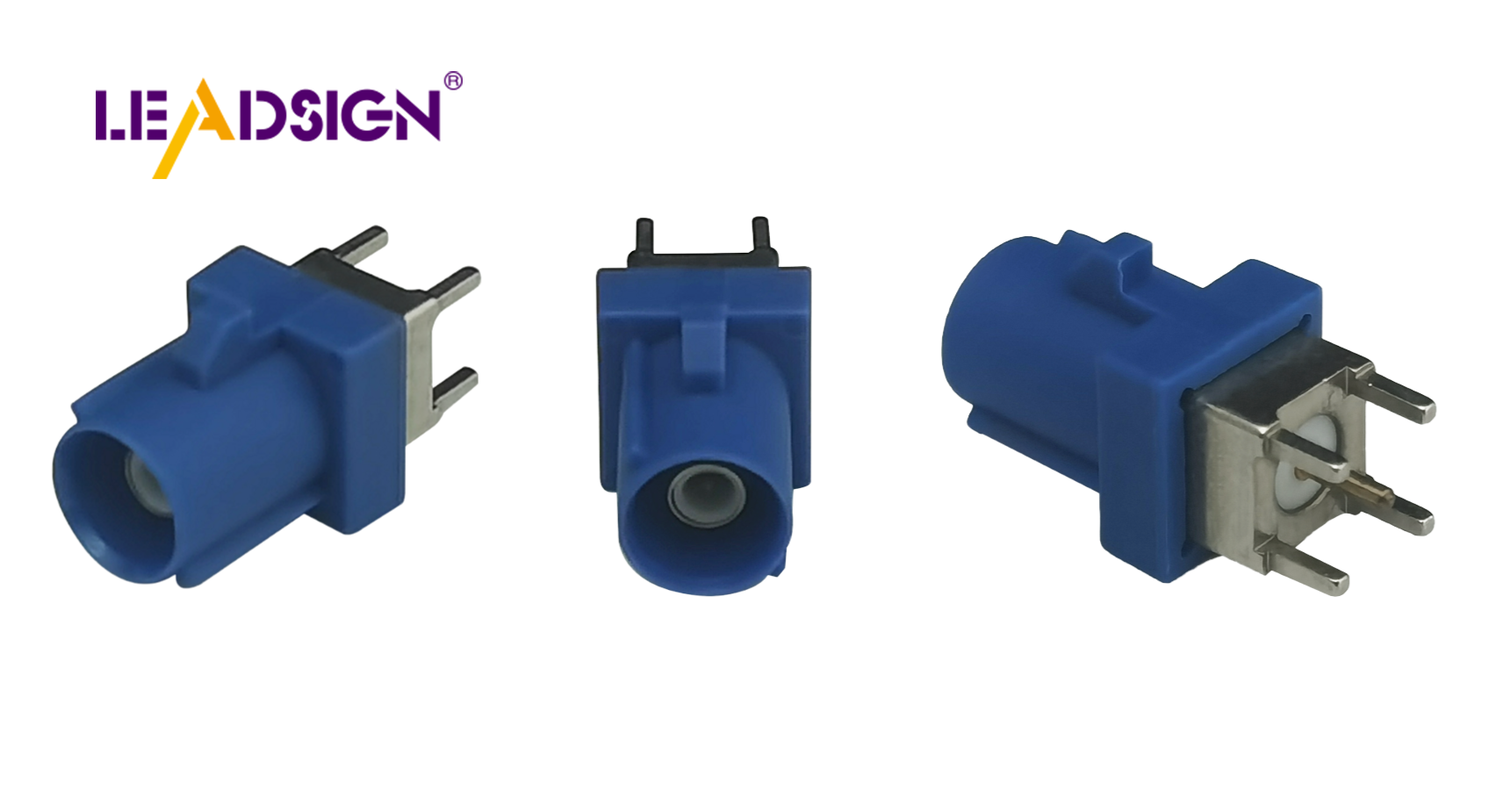

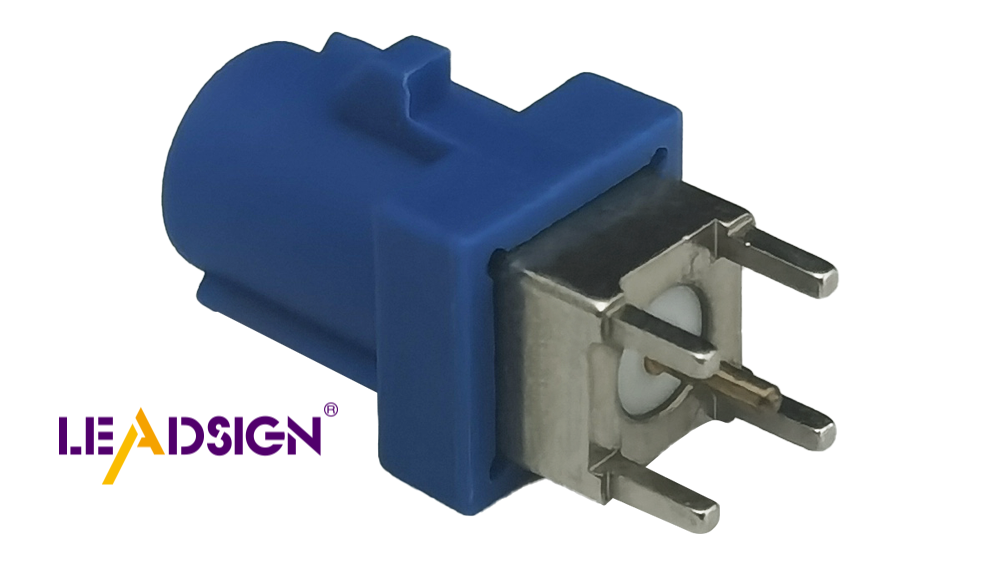

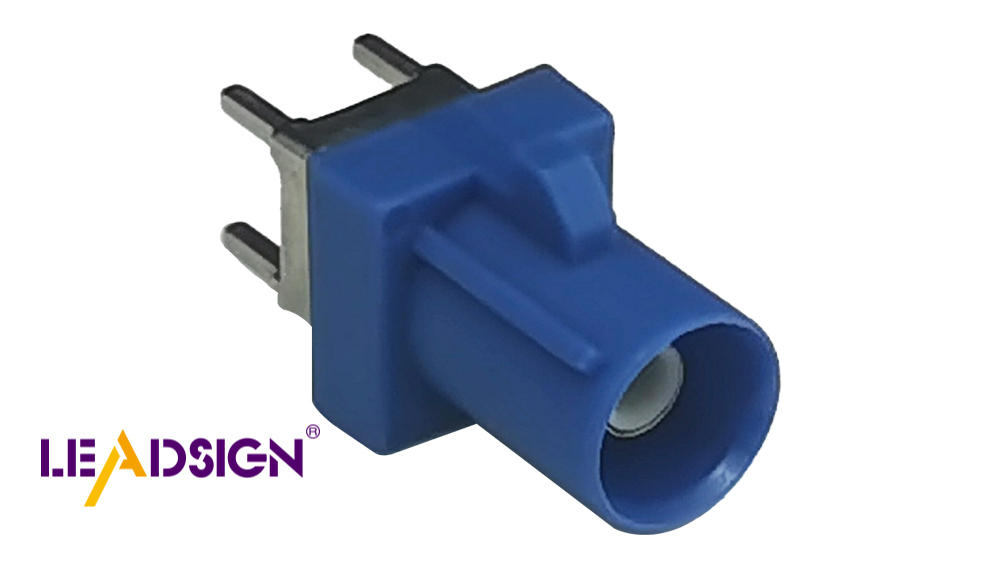

FAKRA Connectors

FAKRA connectors are special connectors for high-tech uses. They are found in car wiring for GPS, radios, and Bluetooth. These connectors have a locking system to avoid mistakes and work well. They can handle fast data and extreme heat, making them perfect for advanced car systems.

Uses of Automotive Harness Connectors in Cars

Connecting Headlights and Taillights

Car connectors help power headlights and taillights. Pigtail connectors send steady power from the battery to lights. They also link lights to the car's wiring system. This setup keeps lights working, even in tough conditions.

Linking Sensors and Control Modules

Connectors join sensors and control modules in cars. They allow communication between ECUs, sensors, and actuators. This is important for engine control, lighting, and navigation. Without them, these parts wouldn't work together well.

Powering Infotainment and Navigation Systems

Connectors support infotainment and navigation systems in cars. They improve safety by helping advanced driver-assistance systems (ADAS). They also make driving easier with automated features. These connectors keep systems running smoothly and efficiently.

Supporting Engine and Transmission Systems

Connectors are key for engine and transmission systems to work. They connect electrical parts for power and communication. This helps ECUs, sensors, and actuators work together. It’s important for engine control and other main functions.

Enabling Radio and GPS Antennas

Radio and GPS antennas need special connectors like FAKRA. These connectors send data quickly and stay secure. They handle heat and vibrations well. This ensures your car's radio and GPS work reliably.

Benefits of Automotive Harness Connectors

Strong and Long-Lasting

Automotive harness connectors are made to last a long time. They use materials like copper, which conducts electricity well and resists rust. For covering, materials like PVC, XLPE, and TPE are used. PVC is cheap, XLPE handles heat, and TPE is flexible and tough. These materials keep connectors strong and dependable for your car's life.

Protection from Harsh Conditions

Car connectors are built to survive tough environments. Sealed connectors stop water, dust, and heat from causing damage.

Special seals, like radial seals, block dirt and water. This keeps connectors working even in bad conditions.

Many connectors meet IP ratings, which stop liquids and particles from getting in. This makes them great for cars exposed to fluids like brake oil or antifreeze.

Better Safety and Dependability

Car wiring connectors give safe and steady connections. They follow strict rules like ISO 26262 for safety and SAE J2030 for testing.

Standard | Purpose |

|---|---|

ISO 6722 | Protects wires from heat and rust. |

ISO 26262 | Ensures safety in car electronic systems. |

SAE J2030 | Tests how well connectors perform. |

These rules make sure connectors work well in important systems, keeping your car safe. |

Easier Fixes and Maintenance

Wire connectors make fixing cars simpler. Their design helps you find and solve problems fast.

Strong connections make repairs easier.

Easy-to-reach wires help both mechanics and car owners.

Neat wiring layouts make repairs more effective.

This saves time and effort when taking care of your car.

Fast Data and Secure Links

Modern car connectors send data very quickly. Some can handle speeds up to 10 gigabits per second. Small designs save space and improve car performance. Sealed connectors protect from damage, keeping connections safe and steady. These features make car wiring systems better and more reliable.

Automotive harness connectors are very important in today’s cars. They help car parts talk to each other and power features like touchscreens, airbags, and safety systems. These connectors manage the complex wiring in cars, making sure power and data move smoothly. As more cars become electric, these systems handle more signals, boosting safety and performance.

To keep your car working well, learn about wiring harnesses and connectors. Ask experts to explain how these parts make your car safer and more reliable.

FAQ

What do automotive harness connectors do?

They link and hold wires in cars. These connectors help parts like sensors, lights, and screens work together smoothly.

How do these connectors make cars safer?

They create strong and steady connections. This stops electrical problems and keeps important systems like airbags and lights working.

Can you change these connectors on your own?

Yes, but it depends on how complex the system is. For tricky systems, it’s best to ask an expert for help.

See Also

Understanding HSD Connectors' Role in Automotive Applications

Why Fakra Connectors Are Essential for Today's Vehicles

Significance of HSD Connectors in Automotive Technology