The Ultimate Guide to Custom Automotive Wiring Harness Repair

The car's wiring harness is like its nervous system. It sends power and signals to important parts. Fixing it quickly keeps you safe and avoids big costs. Automotive harness connectors in the harness help keep electrical connections working well. Knowing why quick repairs matter helps your car stay reliable.

Key Takeaways

Check your car's wiring often to find small problems early. Watch for things like cut wires or rust spots.

Use proper tools like wire cutters and crimpers for repairs. This helps make strong and durable connections.

Pick good-quality connectors with covers to protect wires from water and harm.

Understanding Automotive Wiring Harnesses and Common Issues

What is an automotive wiring harness?

A car's wiring harness is its electrical lifeline. It links and powers key parts like airbags, brakes, lights, and the engine. Think of it as your car's nervous system. It helps sensors, switches, and control units work together. Without it, your car’s systems wouldn’t work right. This complex setup is crucial for smooth driving.

Common problems with automotive harness connectors

Harness connectors in cars face many problems. Moisture and dirt can cause rust and damage metal parts. Rough handling or tough conditions can crack covers or tear wires. Wrong wiring, like crossed wires, can cause short circuits. Worn-out terminals from bad materials or assembly also create issues. These problems can make your car less reliable.

Signs of a damaged wiring harness

Spotting wiring harness problems early can prevent bigger issues. If your car stalls or won’t start easily, the harness might be the problem. Rusty battery terminals, flickering lights, or broken electronics are warning signs. A battery that dies fast could also mean trouble. Your car may jerk or stop while driving. Loose connections or damaged parts often cause these problems, so fix them quickly.

Tools and Components for Wiring Harness Repair

Tools you need for fixing engine wiring harnesses

Fixing an engine wiring harness needs the right tools. These tools help you work on wires and connectors easily. Here’s a list of must-have tools:

Wire strippers to safely remove wire coverings.

Crimpers to attach terminals and connectors tightly.

A soldering iron to make strong, lasting connections.

Good-quality parts like wires, connectors, terminals, and sleeves.

Using these tools helps you fix problems correctly. Keep them neat and ready for use when needed.

Important parts like wire harness connectors

Wire harness connectors are key for keeping electrical connections working. They protect wires and keep signals flowing properly. When picking connectors, check for these features:

Covers that protect pins and terminals.

A click feature to ensure terminals are locked in place.

Protection against damage from weather or dirt.

Seals to block moisture and dirt from getting inside.

Plugs to close off unused openings.

These features make connectors strong and dependable. Knowing about different connectors helps you pick the right ones for repairs.

How to pick good tools and materials

Choosing good tools and materials is important for proper repairs. Pick tools made from strong materials that last a long time. For connectors, choose ones with tough covers and good seals. Look for connectors that can handle heat, water, and shaking. High-quality materials prevent problems from happening again. Always buy from trusted brands for the best results.

Step-by-Step Wiring Harness Repair Process

Diagnosing issues in the automotive wiring harness

Finding problems in the wiring harness is the first step. Look for damaged wires, like frayed or burnt sections. Use a continuity tester to see if the circuit works. A short circuit test can find wrong connections causing failures. Advanced tools use software and hardware to check data and locate issues. The table below shows helpful diagnostic methods:

Description | |

|---|---|

Continuity Tester | Finds breaks or miswiring by sending a small current through wires. |

Proprietary Modular Testing Systems | Uses advanced tools with software for automatic testing and analysis. |

Short Circuit Test | Detects wrong connections that may cause short circuits. |

High Voltage Test | Checks insulation strength to stop leaks or defects. |

Resistance Measurement with Milliohm Tests | Tests wire quality and connection strength to find problems. |

Preparing for wiring harness repair

Getting ready makes repairs easier. Follow these steps:

Find the damage, like rusted parts or broken wires.

Gather tools like wire strippers, crimpers, and a soldering iron. Get good replacement parts like connectors and sleeves.

Use a multimeter to test the damaged area before fixing it.

Check wires often to avoid future problems. Look for loose parts, worn covers, or rust. Store wires in a dry, cool place to keep them safe.

Repairing damaged automotive harness connectors

Fixing connectors needs care. First, check for dirt or cracks. Clean the connector well before fixing it. If repairable, tighten loose parts or replace bad terminals. For major damage, replace the connector and terminals. Use matching pigtail connectors or terminals. Secure repairs with crimping tools and cover them with heat shrink tubing.

Testing the repaired wiring harness

Testing makes sure the repair works. Use a multimeter to check voltage, resistance, and continuity. A continuity tester ensures the circuit is complete. Advanced systems can run automatic checks for specific setups. Always confirm the fixed section meets standards before putting it back.

Tool | Description |

|---|---|

Continuity Tester | Finds breaks or miswiring by sending a small current. |

Proprietary Modular Systems | Offers advanced tools for automatic and custom testing. |

Multimeter | Checks voltage, resistance, and continuity for electrical safety. |

Milliohm Meter | Measures resistance to check wire quality and connections. |

Reinstalling the wiring harness

Putting the harness back needs careful work. Place it along its original path, avoiding hot or moving areas. Use cable ties and clips to keep it secure. Make sure all connections are tight and lined up correctly. This step finishes the repair and gets your car working again.

Tips for Maintenance and Preventing Future Problems

Regular inspection and cleaning of automotive wiring harness

Check your car's wiring harness often to keep it working well. Regular checks help you find small problems before they get worse. Look for broken covers, loose wires, or bent areas. Cleaning removes dirt and water that can cause rust.

Why regular care is important:

It makes your wiring harness last longer.

It keeps electrical parts working properly.

It stops sudden car problems.

A simple care plan saves money and keeps your car safe.

Protecting wiring harnesses from environmental damage

Things like water, heat, and chemicals can harm wires. Rust from water or salt makes wires weak and less effective. Too much heat can melt covers, and chemicals can ruin protective layers.

How to protect your wiring harness:

Keep it dry to stop rust.

Use materials that resist rust and damage.

Don’t overload circuits to avoid overheating.

The table below shows common dangers and how to avoid them:

Environmental Factor | Problem it Causes | How to Prevent It |

|---|---|---|

Heat and Temperature | Melts covers or causes fires. | Use good insulation and manage heat. |

Chemical Damage | Ruins protective layers and weakens wires. | Use materials that resist chemicals. |

Overloading Circuits | Wears out covers faster and causes breakdowns. | Avoid overloading and check circuits. |

Moisture | Water gets into joints and damages wires. | Seal joints well to keep water out. |

Using protective measures like conduit tubing

Conduit tubing helps protect wires from damage. It keeps wires safe from water, chemicals, and physical harm. Different types of tubing have special benefits. For example, HDPE is strong and resists chemicals, while nylon stops scratches and impacts.

The table below explains the benefits of different tubing materials:

Material Type | Benefits |

|---|---|

HDPE | Strong, flexible, and resists chemicals. |

Polypropylene | Very flexible and handles pressure well. |

Nylon | Stops scratches and protects from impacts. |

PVC coated metal | Resists rust and keeps water out. |

Using conduit tubing is an easy way to keep wires safe in tough conditions. It helps prevent future problems and keeps your car running smoothly.

DIY vs. Professional Wiring Harness Repair

Pros and cons of fixing wiring harness yourself

Fixing a wiring harness yourself can save money. It also helps you learn new skills. You get to pick the tools and parts you use. This works well for small problems like fixing loose wires. You can also learn about different wire connectors. This knowledge helps you make better repair choices.

But, fixing it yourself has downsides. Without the right tools, you might mess up. A mistake could cause safety problems or more damage. Hard repairs, like fixing complex connectors, need special skills. If you’re not experienced, your fix might not last.

When to choose professional repair services

Professional help is best for big or tricky problems. Experts have the tools and know-how to fix tough issues. They can quickly repair things like a broken wiring harness. They also use strong, high-quality parts that last longer. If problems keep coming back or you’re unsure, hire a pro.

Comparing costs of DIY and professional repair

DIY repairs cost less since you only buy tools and parts. But mistakes can make you spend more to fix them again. Professional repairs cost more at first but save time and ensure good results. Think about the repair difficulty and costs to choose the best option.

Taking care of your car's wiring harness has many benefits:

Your car works better with regular maintenance.

You save money by avoiding costly repairs later.

Always use good-quality materials for repairs. Test wires with tools like continuity testers to check safety. Strong materials help prevent future damage.

FAQ

How should you clean a wiring harness?

Use a soft brush and special cleaner for electrical parts. Carefully wipe away dirt and water. Don’t use strong chemicals that might harm wires or connectors.

How often do you need to check your car’s wiring harness?

Check it twice a year. Look for broken wires, rust, or torn covers. Regular checks help find small issues early and save money on big repairs.

Can any connector work for wiring harness repairs?

No, only use connectors made for cars. Pick ones with weatherproofing, strong locks, and durability for tough conditions.

💡 Tip: Always use a multimeter to test repairs. This ensures safety and proper function before putting the harness back.

See Also

Understanding Ford Fakra Connectors: A Comprehensive Overview

Fundamentals of HSD Connectors for Automotive Applications

Improving Data Transmission in Vehicles with Advanced Connectors

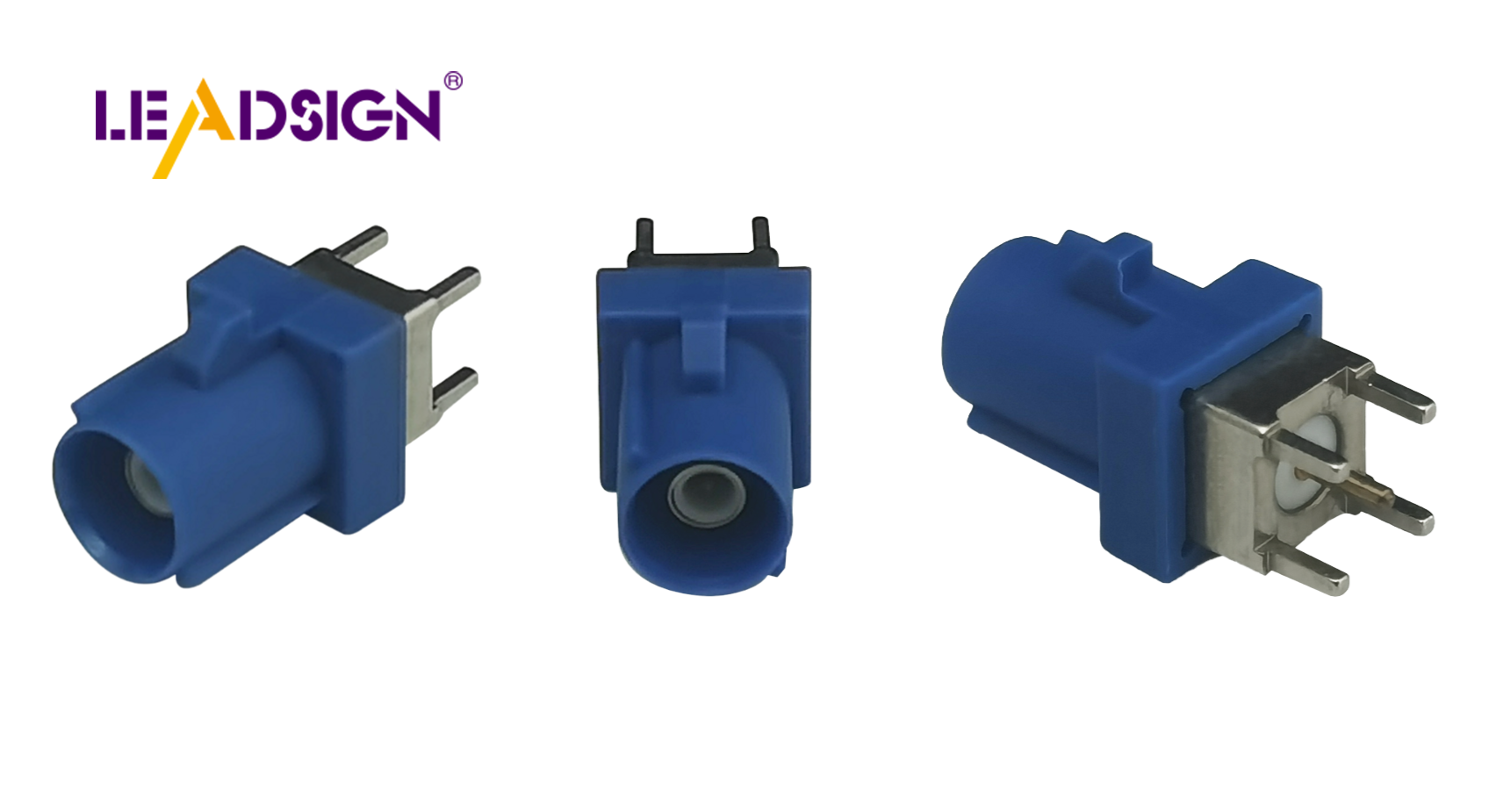

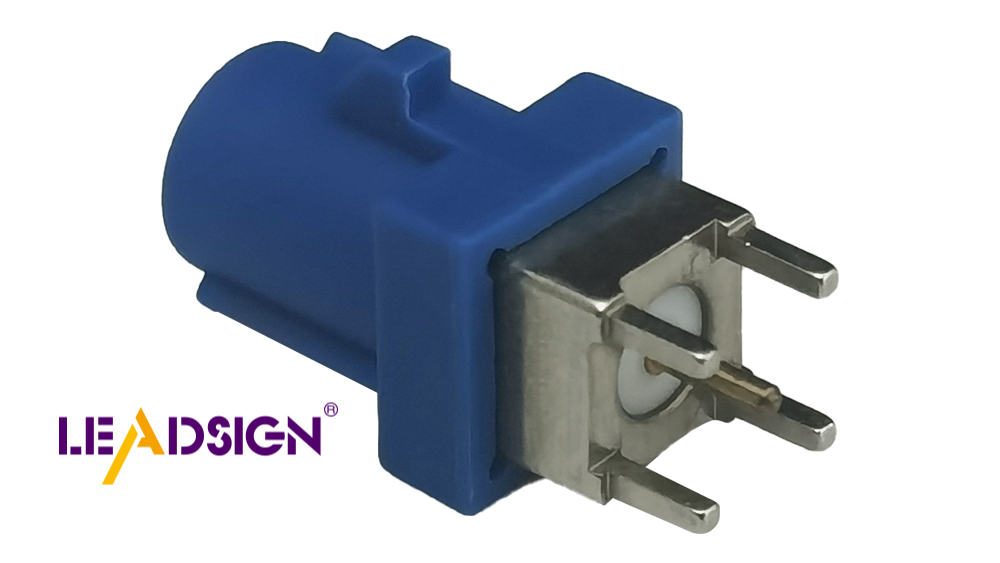

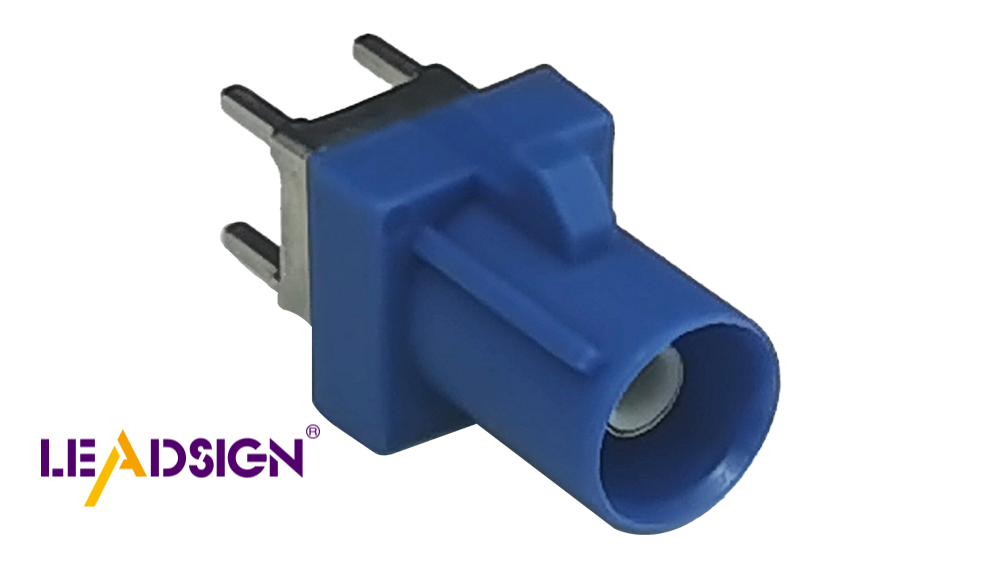

Boosting Vehicle Data Transfer Using FAKRA PCB Connectors

Improving Automotive Communication Through FAKRA PCB Connectors