The Ultimate Guide to Automotive Electrical Connectors Types

Choosing the right automotive electrical connectors types is crucial for your vehicle's performance and safety. These connectors directly affect the reliability and efficiency of automotive systems. A poor choice can lead to frequent failures, as connectors have a failure rate estimated to be 1-2 orders of magnitude greater than general aircraft wiring. By selecting the appropriate connectors, you ensure that your vehicle operates smoothly and safely, minimizing the risk of electrical issues. Understanding the importance of these components helps you make informed decisions that enhance your vehicle's overall functionality.

Understanding Automotive Electrical Connectors

Definition and Purpose

Automotive electrical connectors play a vital role in your vehicle's electrical system. These connectors are specifically designed to link various components within the automobile, ensuring seamless communication and power distribution. You will find them in different forms, such as multi-pin sealed connectors, terminal connectors, and wire-to-board connectors. Each type serves a unique purpose, catering to specific needs within the vehicle's complex electrical network. By understanding their definition and purpose, you can appreciate how these connectors contribute to the overall functionality and safety of your car.

Common Applications in Vehicles

In your vehicle, automotive electrical connectors are indispensable. They connect essential systems, ensuring everything operates smoothly. Here are some common applications:

Engine Management Systems: Connectors facilitate communication between sensors and the engine control unit (ECU), optimizing performance.

Lighting Systems: They ensure reliable connections for headlights, taillights, and interior lighting, enhancing visibility and safety.

Infotainment Systems: Connectors link audio, video, and navigation components, providing entertainment and information.

Safety Features: Airbags, anti-lock braking systems (ABS), and other safety mechanisms rely on connectors for proper function.

Climate Control Systems: They connect components like fans and temperature sensors, maintaining a comfortable cabin environment.

By recognizing these applications, you can better understand the critical role connectors play in your vehicle's operation.

Types of Automotive Electrical Connectors

Understanding the various automotive electrical connectors types helps you make informed decisions for your vehicle's electrical system. Each type serves a specific purpose, ensuring optimal performance and safety.

Wire Terminals

Wire terminals are essential components in your vehicle's electrical system. They provide secure connections between wires and other components.

Ring Terminals

Ring terminals feature a circular end that fits over a stud or bolt. You use them to create a reliable connection that withstands vibrations and harsh conditions. These terminals are ideal for grounding applications and connecting battery cables.

Spade Terminals

Spade terminals, also known as fork terminals, have a forked shape that allows easy installation and removal. You find them useful in situations where you need to frequently disconnect and reconnect wires. Their design ensures a secure connection while allowing quick access.

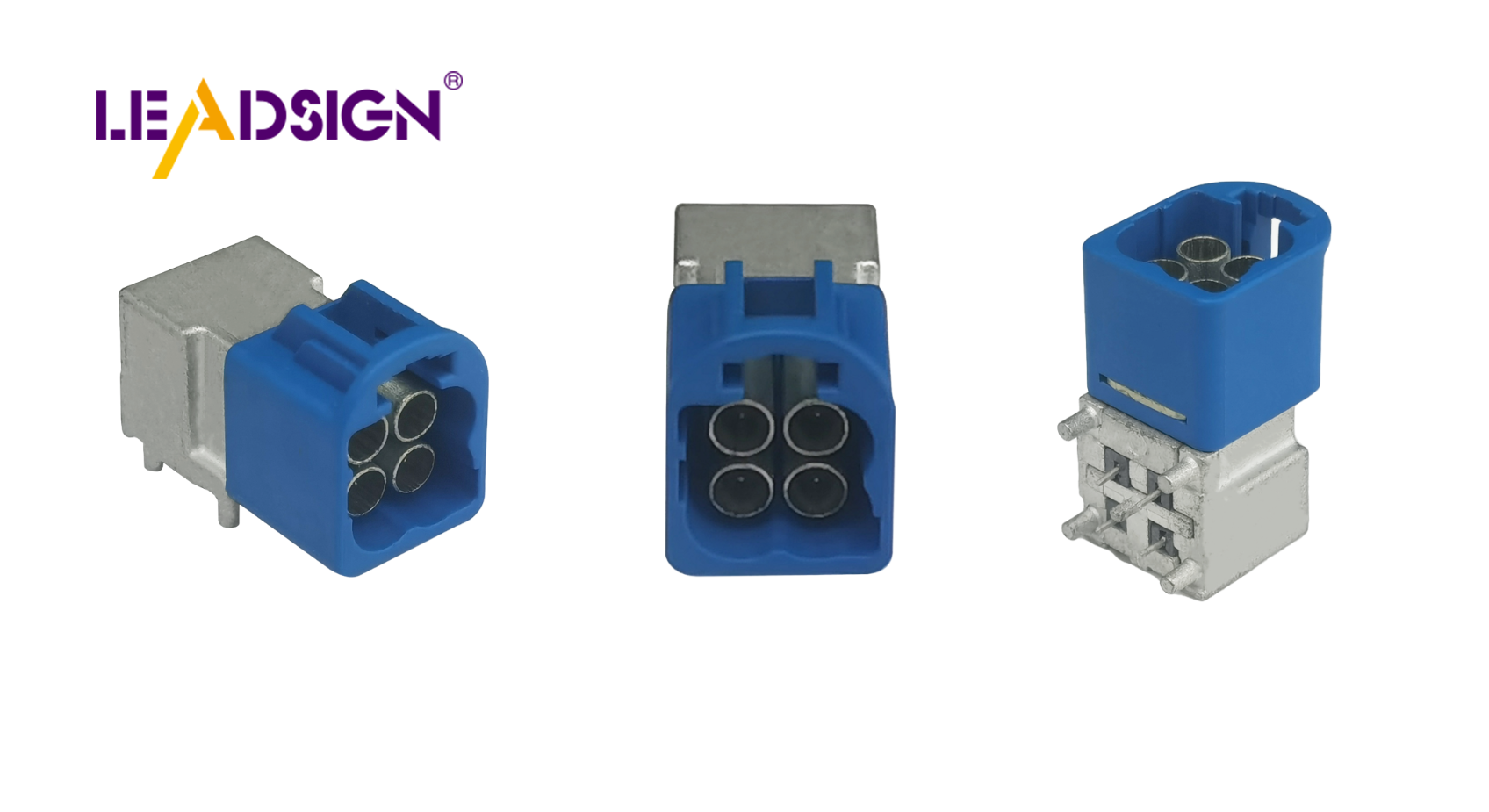

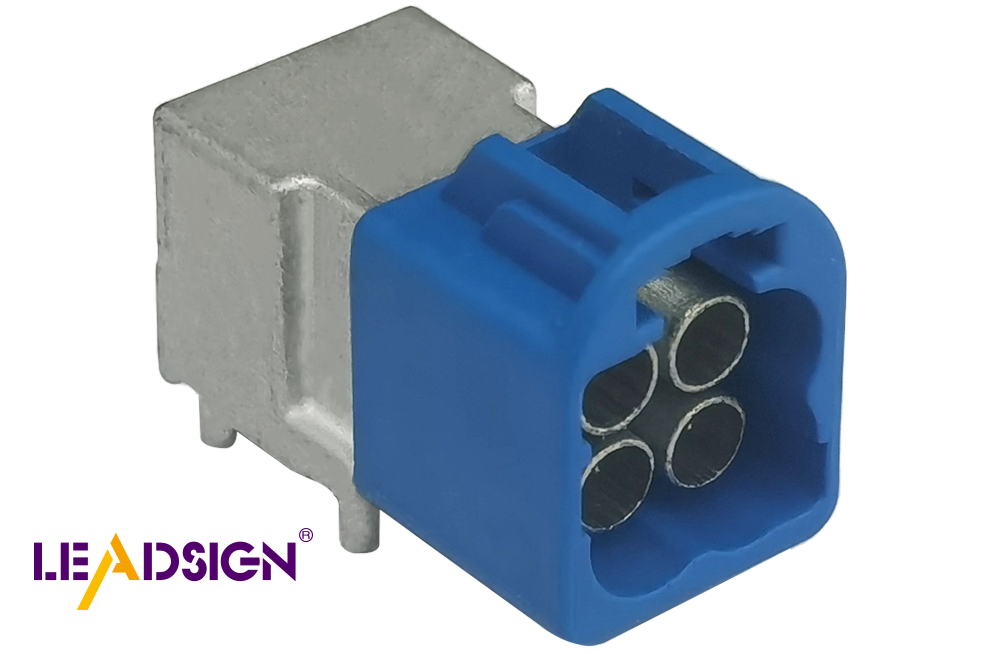

Multi-Pin Connectors

Multi-pin connectors play a crucial role in complex automotive systems. They allow multiple wires to connect through a single interface, streamlining the assembly process.

Uses in Complex Systems

You often encounter multi-pin connectors in systems that require numerous connections, such as engine management and infotainment systems. These connectors simplify the wiring process, reducing the risk of errors during installation.

Variations and Configurations

Multi-pin connectors come in various configurations to suit different applications. Some feature locking mechanisms for added security, while others offer color-coded pins for easy identification. By choosing the right configuration, you ensure compatibility with your vehicle's specific requirements.

Weatherproof Connectors

Weatherproof connectors protect your vehicle's electrical system from environmental factors. They are designed to withstand moisture, dust, and temperature fluctuations.

Importance in Harsh Environments

In harsh environments, weatherproof connectors prevent corrosion and electrical failures. You rely on them to maintain the integrity of connections in areas exposed to the elements, such as under the hood or near the wheels.

Examples and Benefits

Examples of weatherproof connectors include sealed multi-pin connectors and waterproof wire terminals. These connectors offer several benefits, including enhanced durability and reduced maintenance needs. By using weatherproof connectors, you extend the lifespan of your vehicle's electrical system and ensure reliable performance.

Quick Disconnects

Quick disconnects offer a convenient solution for connecting and disconnecting wires in your vehicle's electrical system. These connectors are designed to simplify the process, making them an excellent choice for applications where frequent disconnection is necessary.

Ease of Use

You will find quick disconnects incredibly user-friendly. Their design allows you to connect and disconnect wires without the need for specialized tools. This ease of use makes them ideal for situations where you need to perform maintenance or repairs quickly. The connectors typically feature a simple push-and-pull mechanism, ensuring a secure connection while allowing for rapid disassembly. This functionality is particularly beneficial in automotive settings, where time and efficiency are crucial.

Common Applications

Quick disconnects are versatile and find applications in various automotive systems. Here are some common uses:

Battery Connections: You can use quick disconnects to easily connect and disconnect battery terminals, facilitating battery replacement or maintenance.

Lighting Systems: These connectors allow for quick changes in lighting components, such as headlights or taillights, without the hassle of complex wiring.

Audio Systems: Quick disconnects enable you to swap out speakers or other audio components swiftly, enhancing your vehicle's sound system with minimal effort.

Engine Components: In engine management systems, quick disconnects provide a reliable way to connect sensors and other components, ensuring optimal performance.

By incorporating quick disconnects into your vehicle's electrical system, you enhance both the efficiency and flexibility of maintenance tasks. These connectors exemplify the importance of selecting the right automotive electrical connectors types, as they streamline operations and reduce downtime.

Key Considerations for Selecting Connectors

When choosing automotive electrical connectors types, you must consider several key factors to ensure optimal performance and safety. These considerations help you select connectors that meet your vehicle's specific needs.

Current and Voltage Ratings

Understanding the current and voltage ratings of connectors is crucial. You need to ensure that the connectors can handle the electrical load of your vehicle's systems. If a connector's rating is too low, it may overheat or fail, leading to potential hazards. Always check the specifications to match the connector with your vehicle's requirements.

Environmental Suitability

Automotive environments can be harsh, so selecting connectors that withstand these conditions is essential.

Temperature Resistance

Temperature fluctuations can affect connector performance. You should choose connectors designed to operate within the temperature range of your vehicle's environment. This ensures reliability and prevents failures due to thermal stress.

Moisture and Dust Protection

Moisture and dust can cause corrosion and electrical shorts. Opt for connectors with protective features like seals or coatings. These features help maintain the integrity of connections in challenging conditions, such as under the hood or near the wheels.

Material Composition

The materials used in connectors impact their performance and longevity.

Conductivity and Durability

Connectors must provide excellent electrical conductivity. Materials like copper or gold-plated contacts offer superior conductivity. Durability is also vital, as connectors endure vibrations and mechanical stress. Choose materials that balance conductivity with strength.

Corrosion Resistance

Corrosion can degrade connectors over time. Select connectors with corrosion-resistant materials to ensure long-term reliability. This is especially important in environments exposed to moisture or chemicals.

Expert Testimony: Wiring Harness News highlights the importance of assessing failure modes in connectors due to their higher likelihood of failure. By understanding these considerations, you can reduce the risk of connector-related issues.

By focusing on these key considerations, you ensure that the automotive electrical connectors types you choose will enhance your vehicle's performance and safety. Making informed decisions about connectors helps you avoid potential problems and maintain the efficiency of your vehicle's electrical systems.

The Importance of Quality and Standards

When selecting automotive electrical connectors types, you must prioritize quality and standards. These factors significantly influence your vehicle's performance and safety.

Impact on Vehicle Performance

High-quality connectors ensure optimal vehicle performance. They provide reliable connections, reducing the risk of electrical failures. Poor-quality connectors can lead to frequent malfunctions. For instance, physical damage from mishandling or electrical arcing inside connectors can disrupt performance. By choosing connectors designed for durability and efficiency, you enhance your vehicle's reliability.

Safety Considerations

Safety is paramount in automotive applications. Connectors play a crucial role in maintaining safe operations. Faulty connectors can cause electrical shorts or fires, posing serious risks. You should select connectors that meet stringent safety standards. This ensures they can withstand harsh conditions and prevent potential hazards. Proper wire termination and connector design, such as shorter pins, also contribute to safety by minimizing failure modes.

Industry Standards and Certifications

When choosing connectors, look for certifications from recognized organizations. This assures you that the connectors comply with industry requirements.

By focusing on quality and standards, you ensure that the automotive electrical connectors types you choose will support your vehicle's performance and safety. Making informed decisions about connectors helps you avoid potential problems and maintain the efficiency of your vehicle's electrical systems.

High-quality connectors reduce the risk of electrical failures and enhance vehicle reliability.

See Also

Understanding Ford Fakra Connectors: A Comprehensive Guide

Fundamentals of HSD Connectors for Automotive Applications

Why Fakra Connectors Matter in Today's Vehicles